Checking injector flow capacity (B235R, B205L/R)

|

|

Checking injector flow capacity (B235R, B205L/R)

|

Warning

Warning

|

|

This check involves partial dismantling of the car's fuel system. The following points must therefore be observed in connection with the work:

|

|

•

|

Work only in a well-ventilated area! If approved equipment for the extraction of fuel vapours is available, be sure to use it.

|

|

•

|

Wear suitable gloves! Prolonged contact with fuel can cause skin irritation or dermatitis.

|

|

•

|

Keep a class BE fire extinguisher close at hand! Beware of sparks caused by short circuits and when connecting and disconnecting leads in electrical circuits.

|

|

•

|

No smoking anywhere in the vicinity.

|

|

|

|

|

|

|

Important

|

|

The utmost cleanliness must be observed when handling the fuel rails and injectors. Wash around the injectors, fuel rail and intake manifold and dry with compressed air.

|

|

|

|

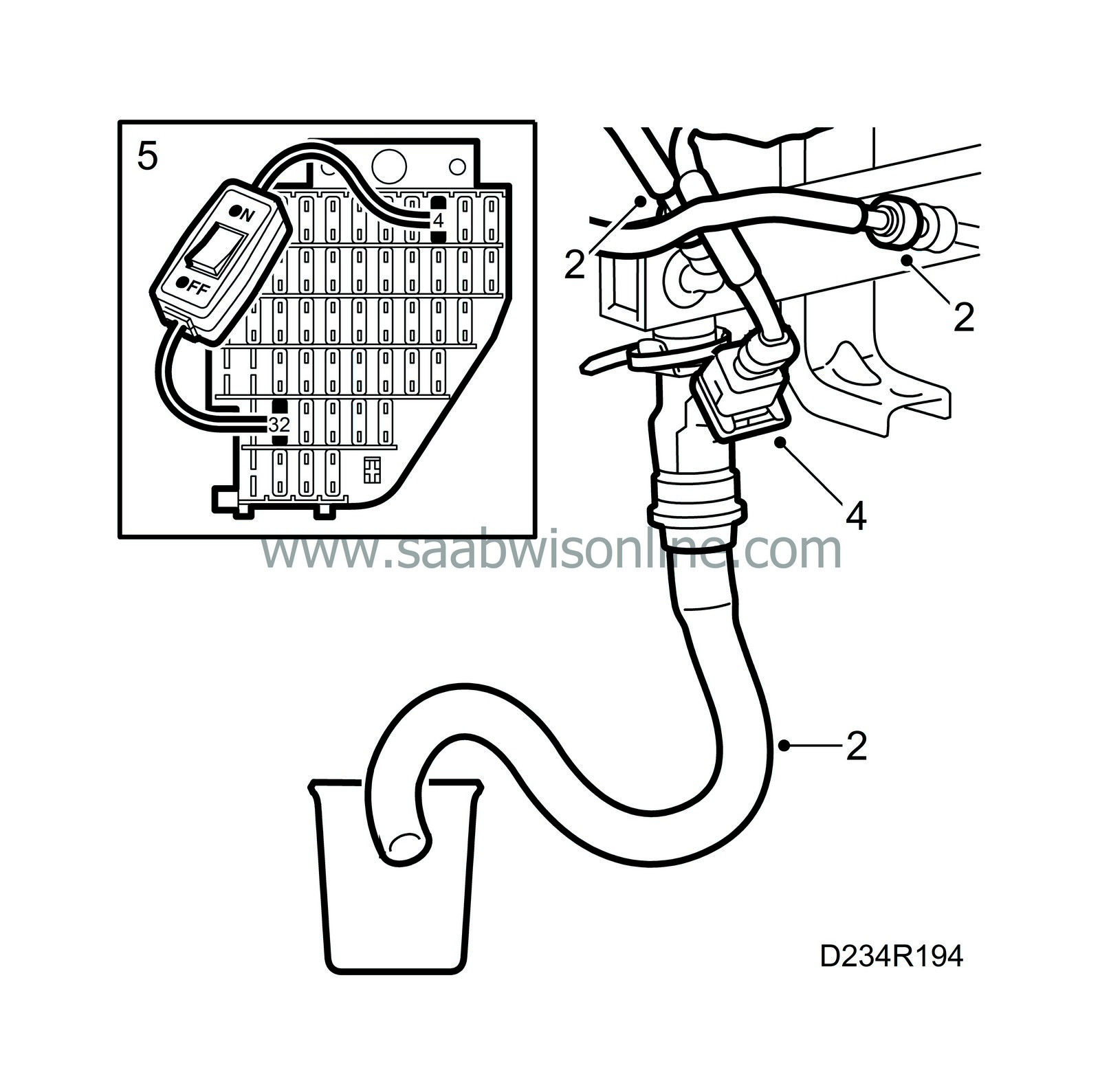

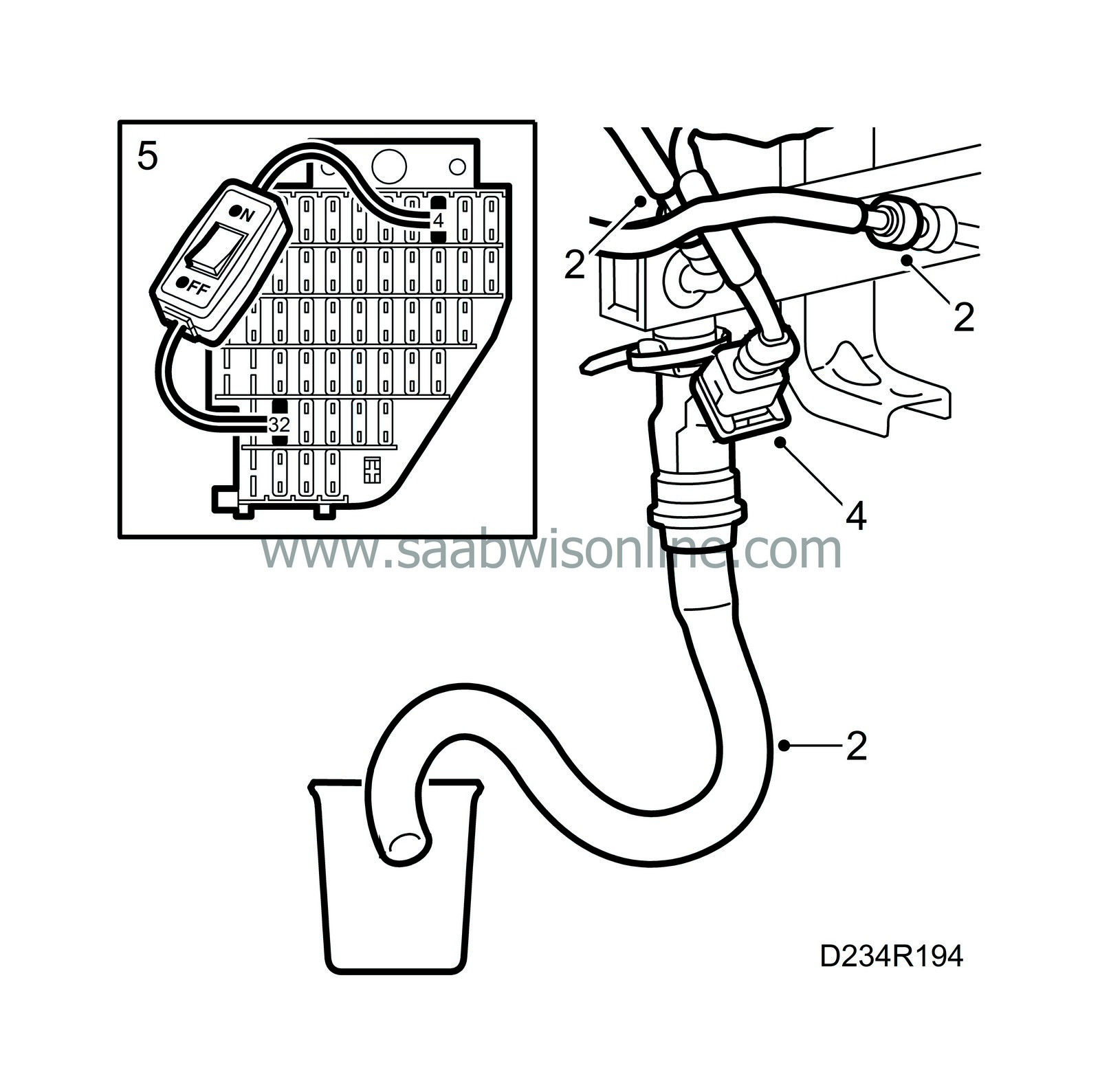

2.

|

Attach the fuel connections to the fuel rail.

Fit a transparent hose to the nozzle. The hose should be approx. 40 cm long with an inner diameter of 15 mm.

|

|

3.

|

Direct the hose into a receptacle/measuring glass.

|

|

4.

|

Plug in the connectors to their respective injectors.

|

|

5.

|

Start the fuel pump by connecting jumper lead,

83 93 886 Diagnostics cable, LH system

, between the

lower pin

of fuse 32 for the fuel pump and the

upper pin

of fuse 4 for the luggage compartment lighting.

|

|

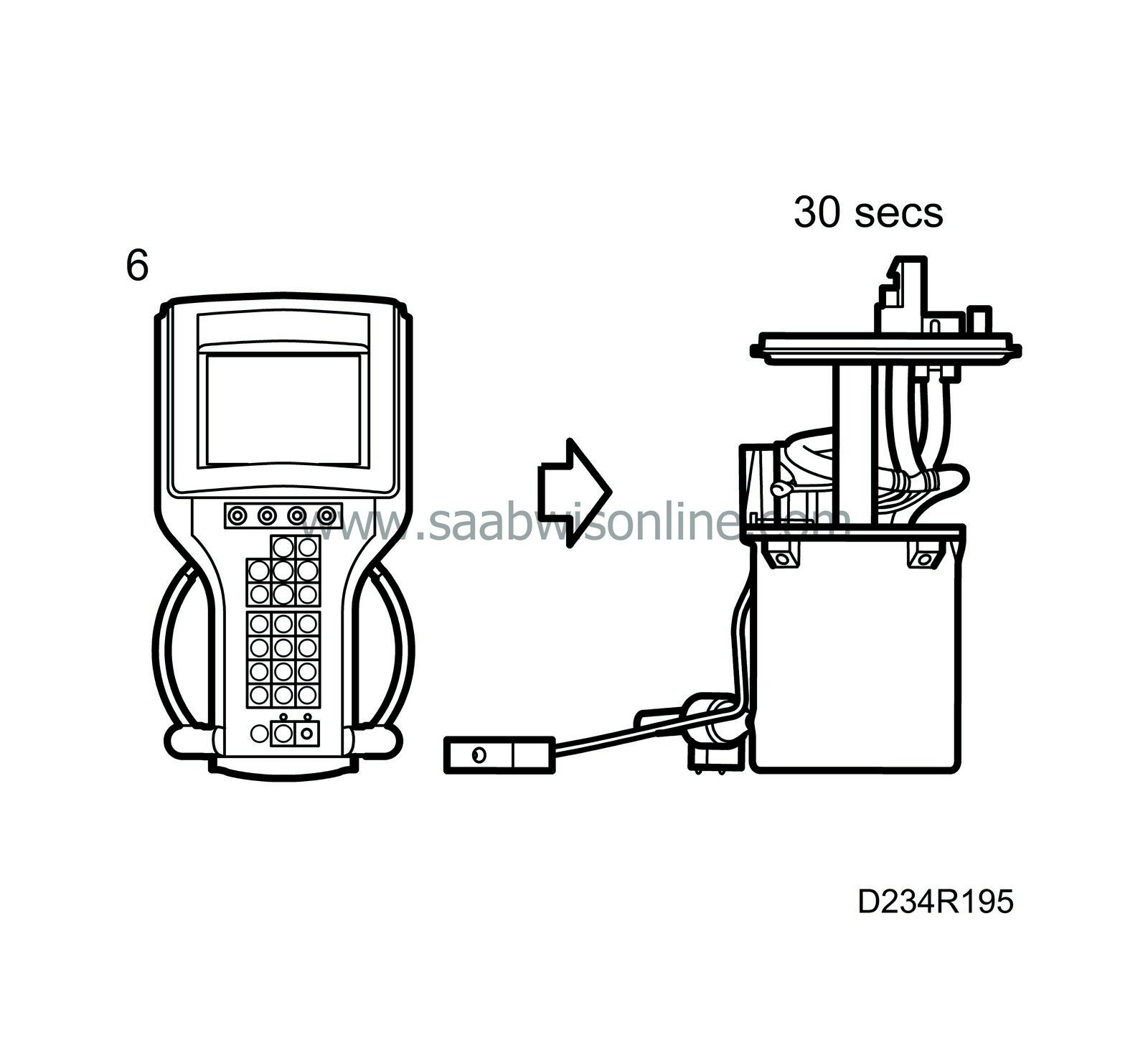

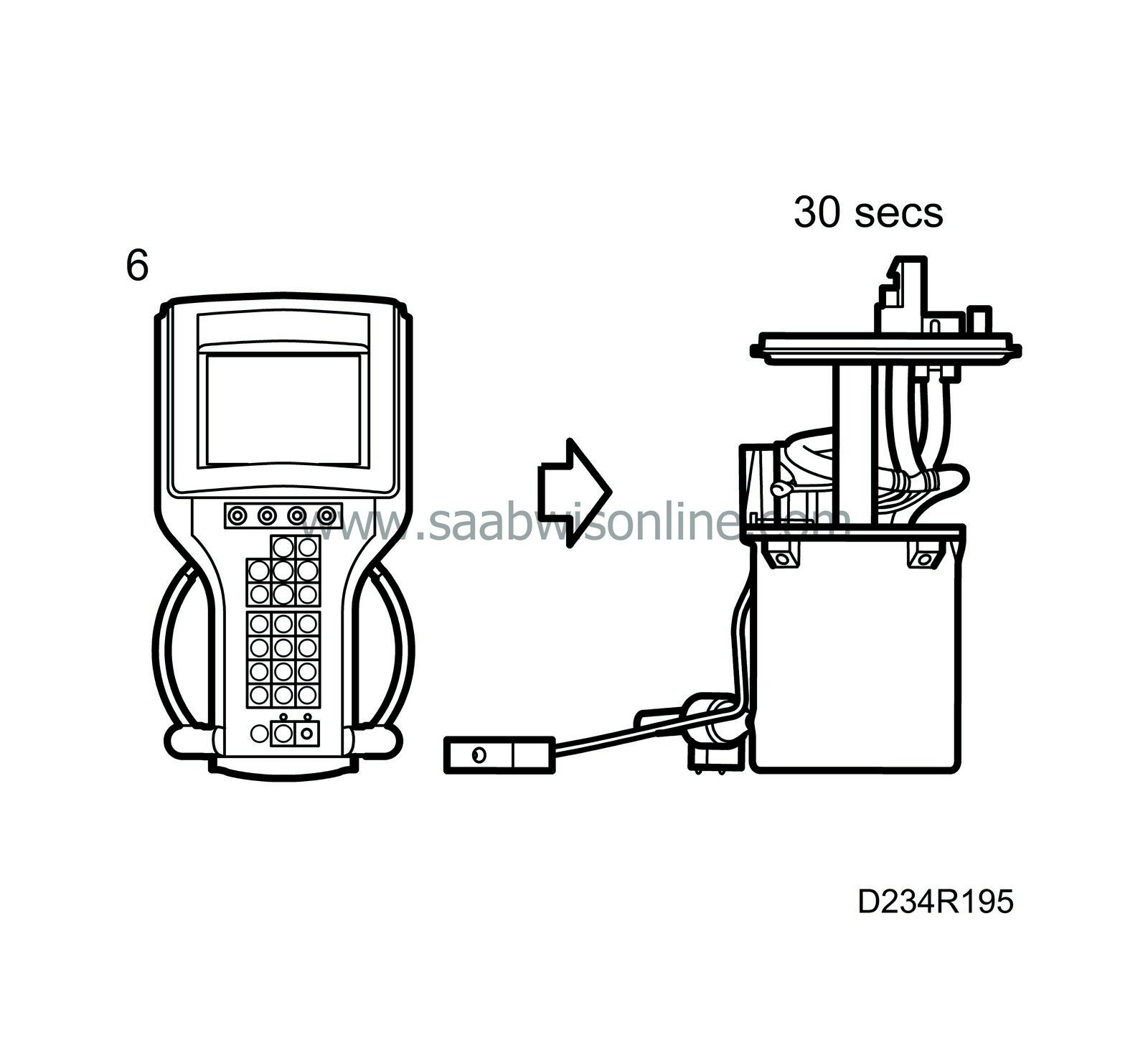

6.

|

Conduct the flow capacity test using the diagnostic tool. The diagnostic tool will then activate the injector in question with battery voltage for exactly 30 s.

|

|

7.

|

After

30

seconds, the amount of fuel should be

176 +/- 7 ml

.

The difference between injectors must not exceed

14 ml

.

|

|

8.

|

Change any defective injectors.

|

Warning

Warning