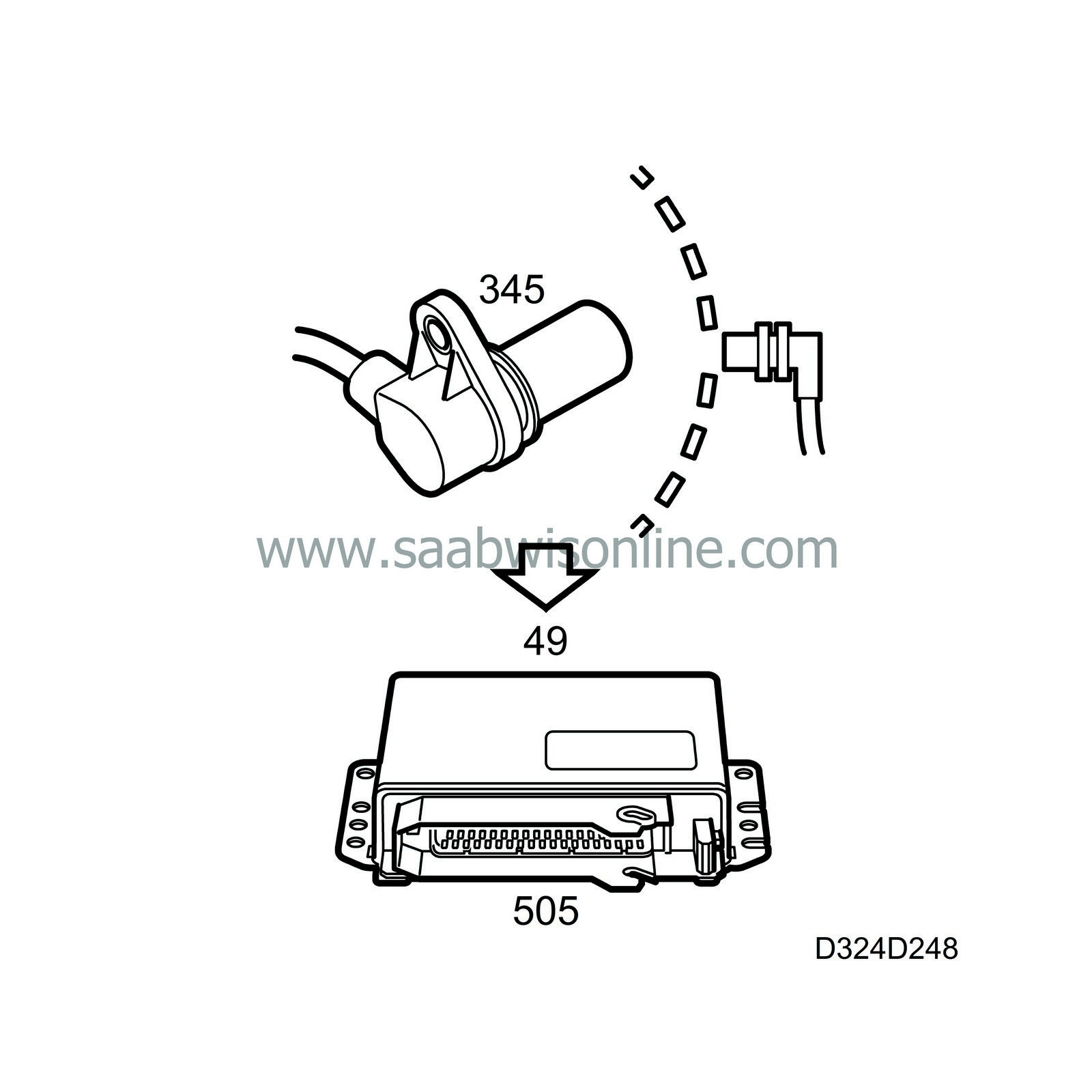

Crankshaft position sensor, engine speed

| Crankshaft position sensor, engine speed |

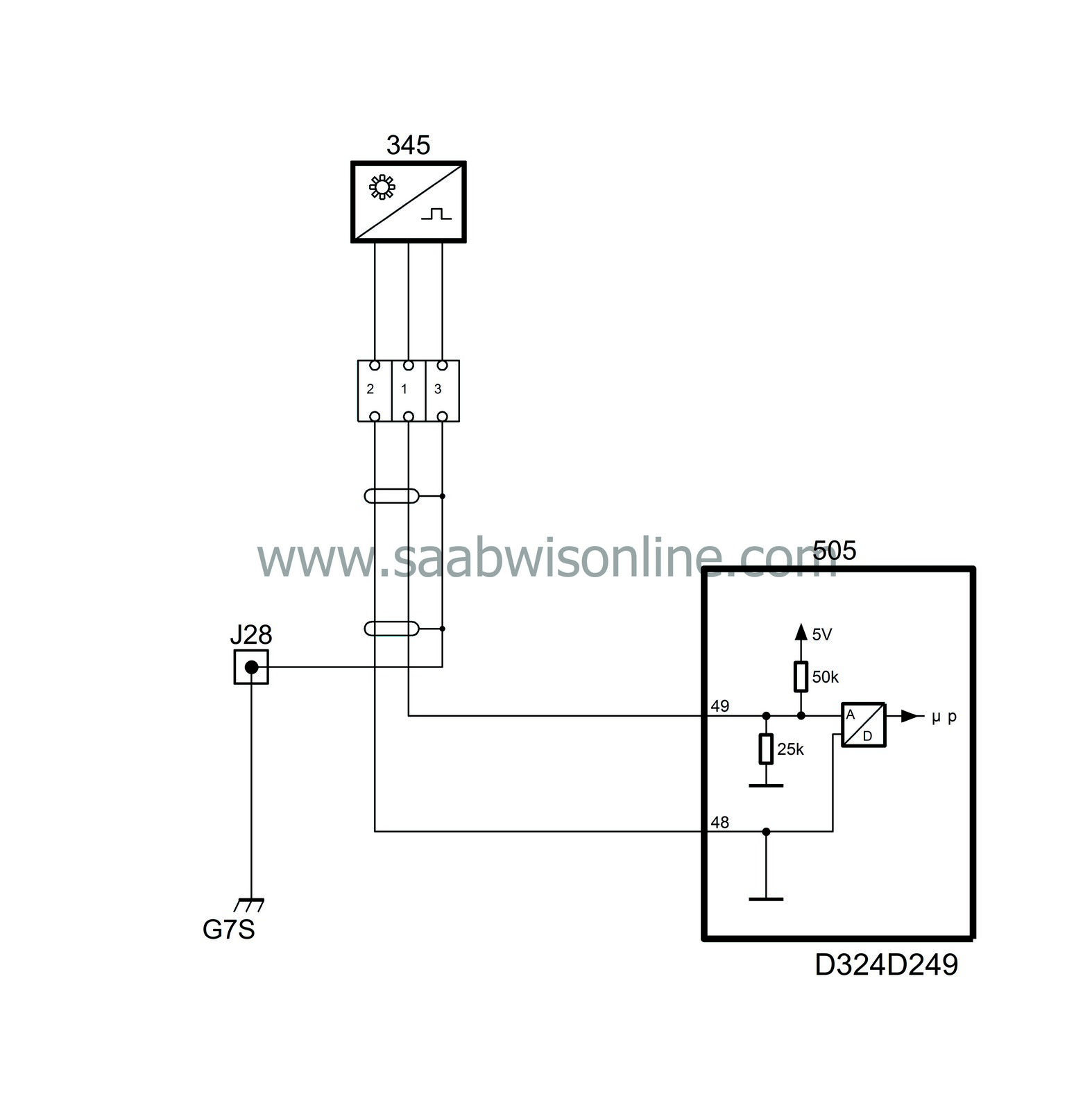

From the crankshaft position sensor the control module receives signals on pin 48 and 49 as regards to the crankshaft position and speed.

The sensor consists partly of a slotted ring on the crankshaft in the flywheel end, and partly of an inductive sensor mounted in the engine block.

The distance between the slotted ring and the sensor is 0.4-1.3 mm. The inductive sensor has a function similar to a generator, whereby the sine voltage increases with increasing speed.

Sine voltage changes between positive and negative polarity, which is achieved by alternating holes and "ribs" on the aperture disc. The control module utilizes the polarity change as a pulse sensor to determine the crankshaft speed. The slotted ring has 60 minus 2, in other words 58, "ribs" and a larger hole where 2 "ribs" have been removed. The larger hole is used to determine the position of the crankshaft.

Each "rib" and adjoining hole correspond to 3 °, altogether 6°. Total for a complete crankshaft rotation 6x60=360°.

The large hole in the slotted ring is displaced 84° in relation to TDC., Which gives the control module the possibility to quickly work out when cylinder 1 and 4 are at the top. To be able to identify which of these two to fire, the control module must also be informed of the information that is provided by the camshaft position sensor.

The voltage from the crankshaft position sensor increases with speed, when idling approx. 7-10 Volts (AC) and at 2500 rpm approx. 20 Volts (AC).

With a multimeter set on alternating voltage, one should be able to measure between the sensor pin 1 and 2 a voltage when cranking the starter motor of approx. 2-5 volts AC and when idling 7-10 volts AC. At 2500 rpm the alternating voltage is approx. 20 volts.

If the sensor does not work or if there is a break in the circuit, the engine will not start.

The sensor resistance is 540 ohms (±10%).

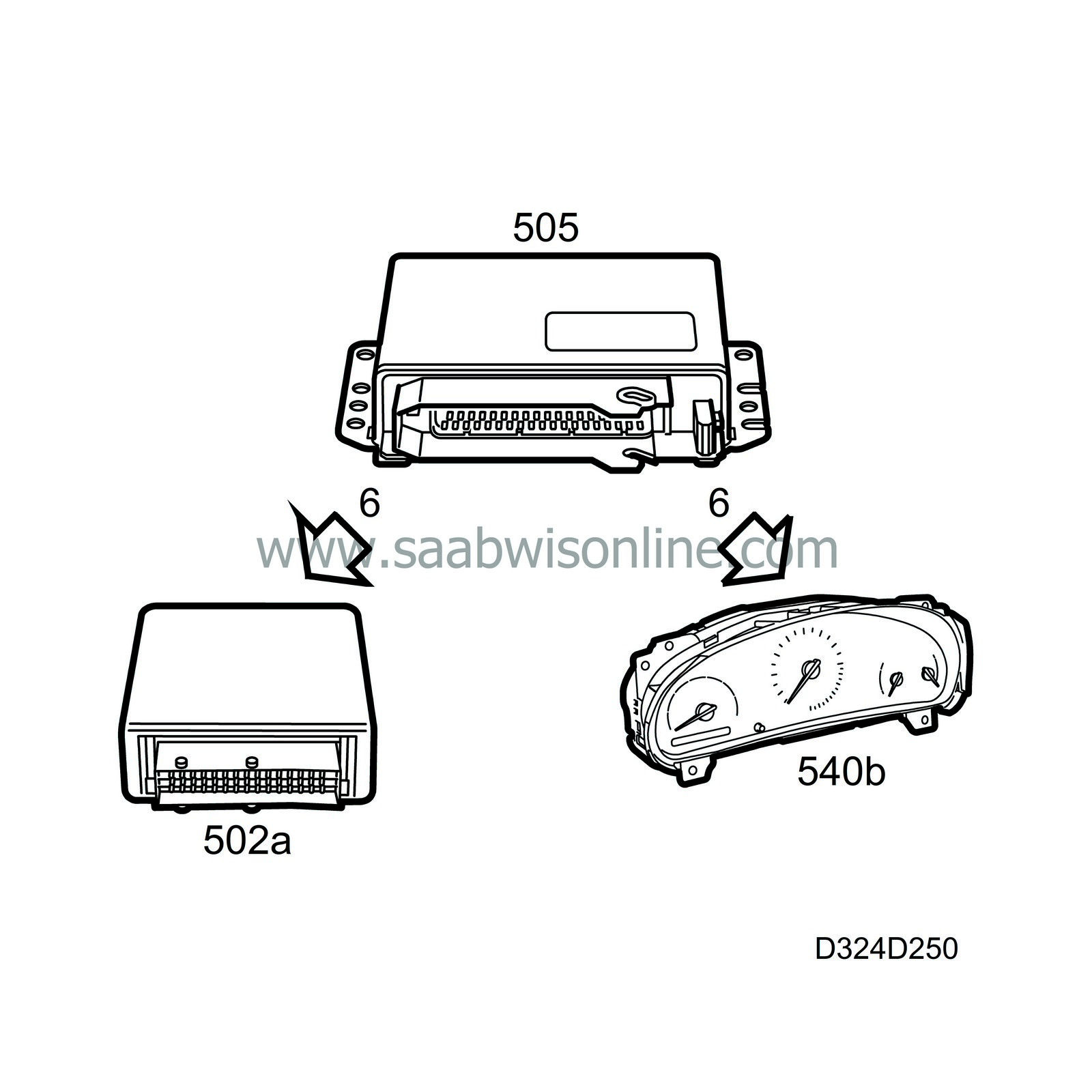

| Engine speed (Td) |

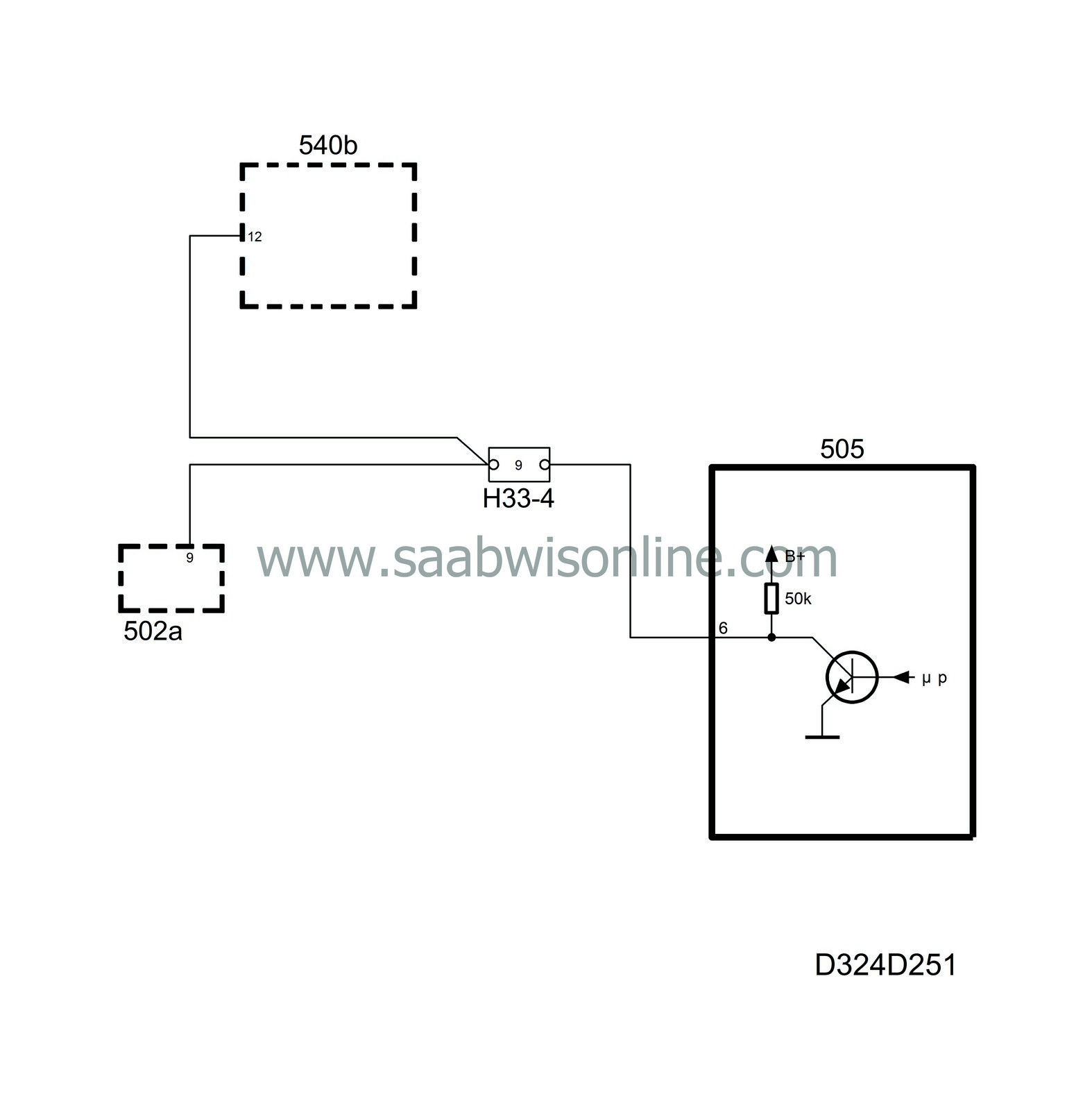

The control module sends out signals with information about engine speed on pin 6.

The signal is a square wave that measures approx. 30-32 Hz when idling and approx. 85 Hz at 2500 rpm. Measured with the voltmeter the voltage is approx. 2.5 volts when idling.

The signal is used by the tachometer and the automatic transmission control module.