Fuel injection

| Fuel injection |

| Injectors |

The injection valves are of the solenoid type with a needle and seat, which open when the current passes through the coil and close with the help of a powerful spring when the voltage is turned off.

To achieve optimum combustion and by that cleaner exhaust gas, the nozzles are equipped with 4 holes that give a good distribution of the petrol.

The jets of petrol are set to very exact limits, each jet in itself as well as between the two main jets (one jet for each inlet valve). This puts demands on the positioning of the injectors. To help guarantee exact positioning of the valves they are secured in pairs in special mounting brackets between 1-2 and 3-4.

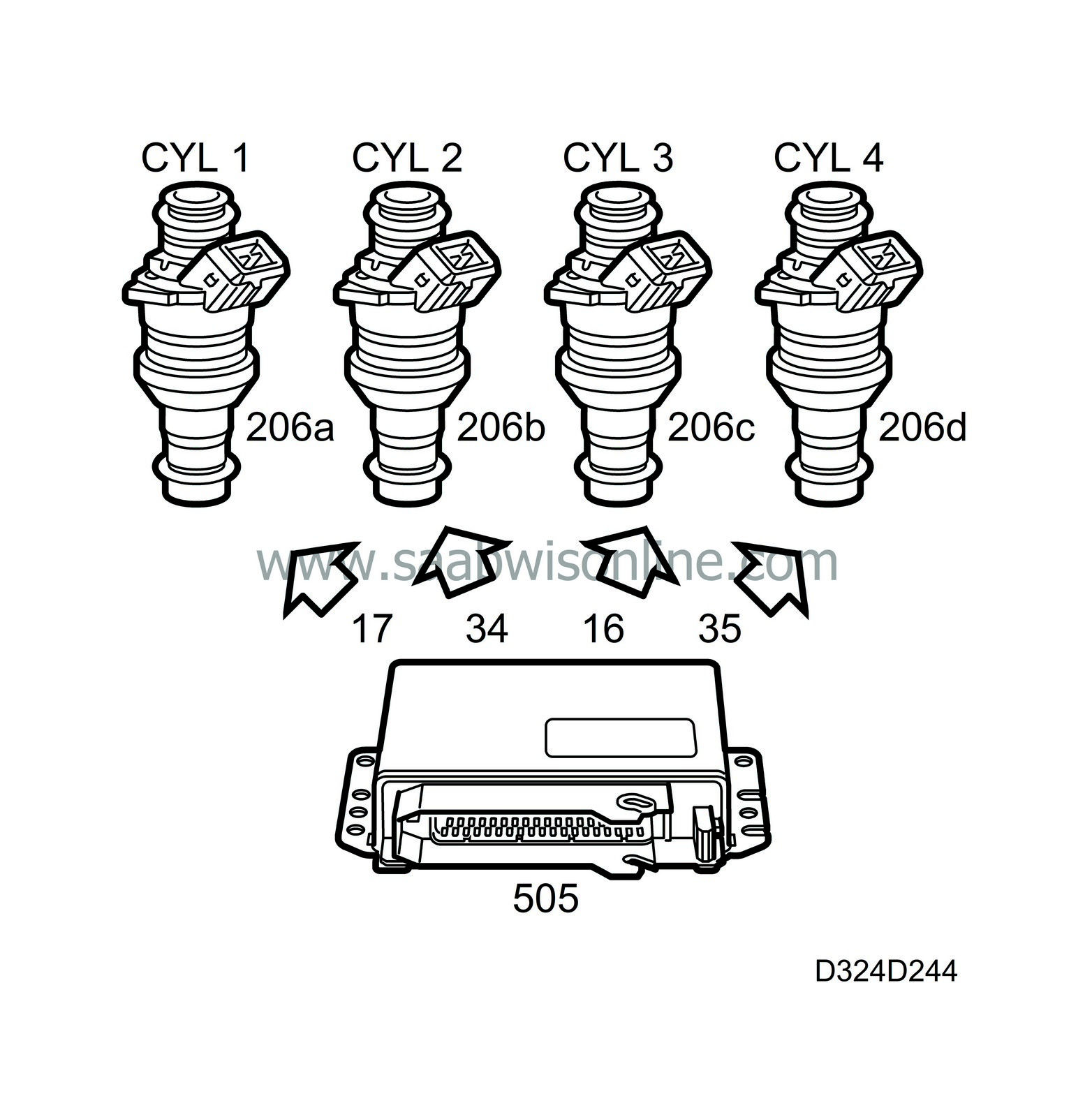

The injectors receive all their voltage from the main relay, whereas the control module grounds the valves individually according to the following:

| • |

Injector 1 is grounded from pin 17

|

|

| • |

Injector 2 is grounded from pin 34

|

|

| • |

Injector 3 is grounded from pin 16

|

|

| • |

Injector 4 is grounded from pin 35

|

|

From the control module's input signals from for instance the oxygen sensor, mass air flow sensor and crankshaft position sensor the exact amount of fuel is calculated that should be supplied to the cylinders. This is done by varying the length of the grounding signals between 3 and 15 ms. In extreme temperatures, i.e. under -30°C (-22°F), the signals can amount to 220 ms. The system does not have a cold start valve.

When cranking the starter motor and when the temperature is under 20°C (68°F), the control module sends out signals to all the valves at the same time to help make starting easier (only in the first injection).

On deceleration, all valves are closed to reduce the amount of HC (fuel cut).

| Fuel consumption |

The signal to the instrument for information of fuel consumption is not a separate output signal from the control module. The signal is taken instead from control module pin 16, the signal that also goes to injector 3.