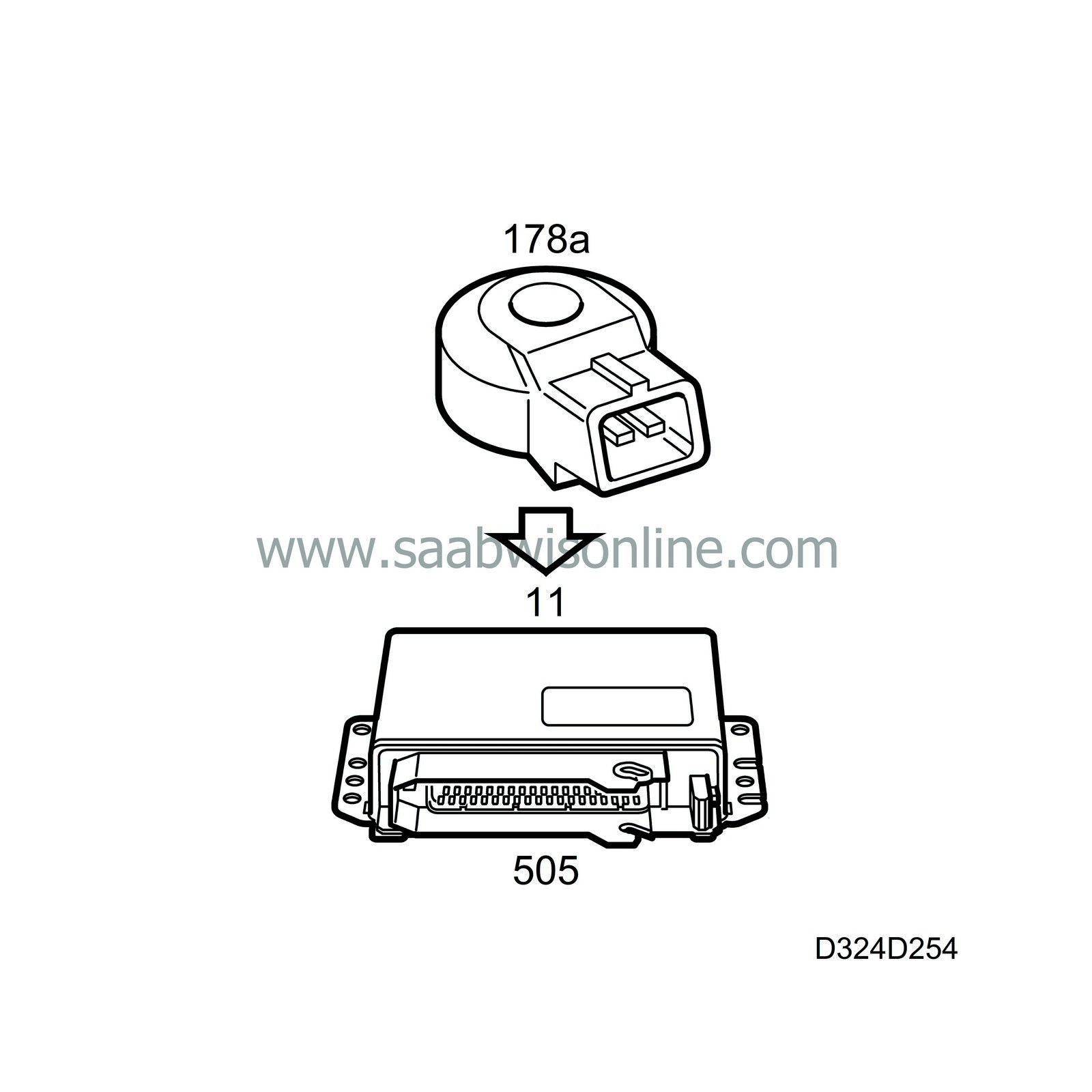

Knock Sensor

| Knock Sensor |

The knock sensor contains a piezo-electric element, which is known for its ability to emit voltage when it is exposed to pressure.

When knocking occurs in one of the cylinders, this brings about powerful vibrations and movement in the material that exerts the sensor to pressure. If powerful knocking occurs the sensor can give off up to approx. 500 mV

The knock sensor is mounted to the engine block with a through screw. The tightening torques are of great importance for the function and should therefore be followed carefully.

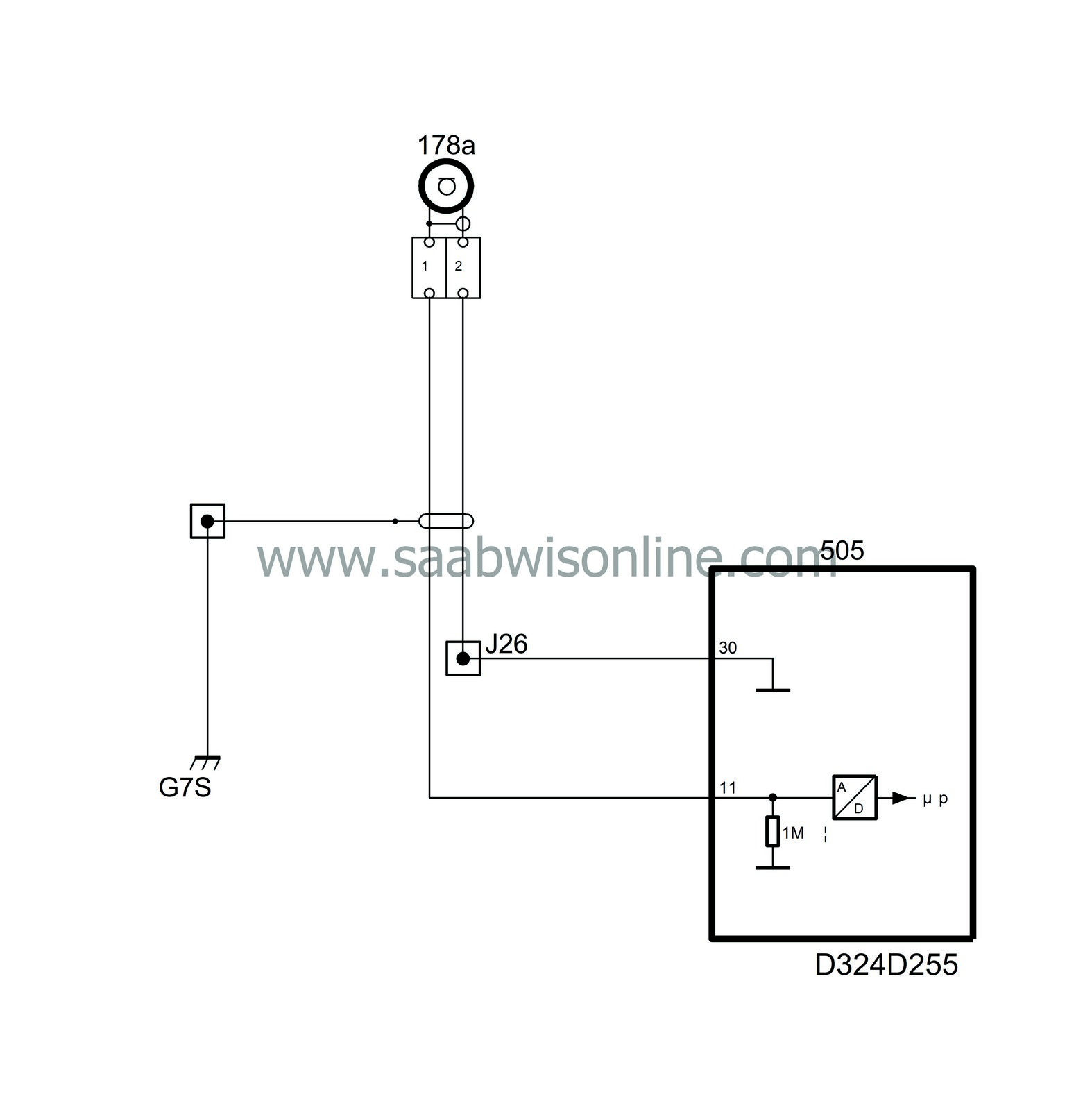

The knock sensor gives information to the control module via pin 11 if knocking occurs in the cylinder block. It is grounded from the control module pin 30 together with other sensors.

Because the knock sensor signal voltage is very low, the signal lead is shielded. Due to this the risk that unwanted signal sources induce voltage in the lead and give the control module faulty information is reduced.

If the voltage in the signal lead exceeds 250 mV, the control module interprets this as a serious knocking and then retards the ignition on the knocking cylinder.

If an open circuit occurs the CHECK ENGINE lamp (MIL) comes on at the same time as the control module retrieves its information from a pre-programmed Limp-home-program, by which the ignition is retarded by 13° on all cylinders (at >2000 rpm).