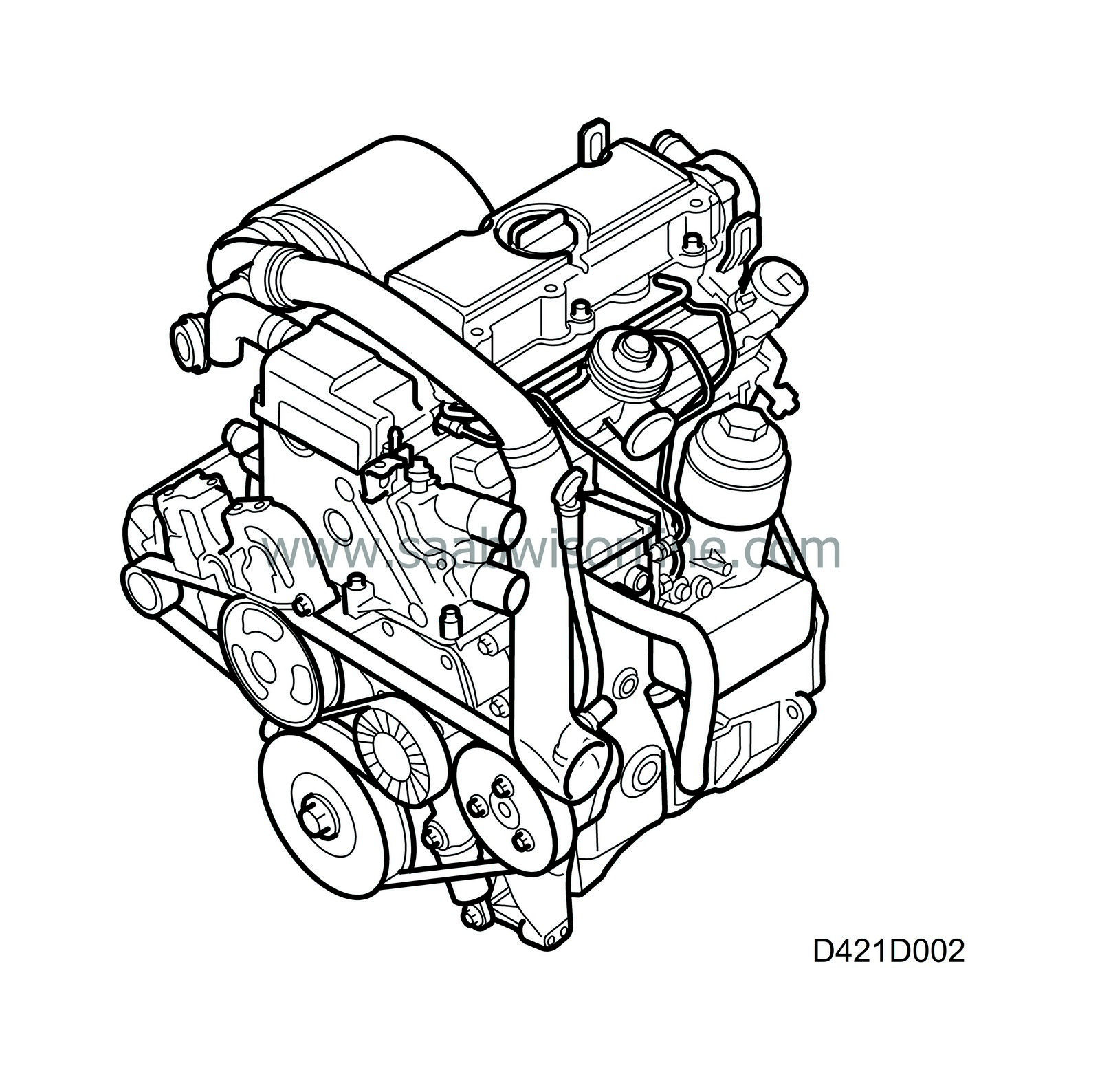

Engine block

| Engine block |

The total swept volume of 2.2 litres delivers a high torque even at low engine speeds, which is advantageous when driving in normal traffic conditions.

The balancer shafts suppress vibration and the forces from moving parts in the engine while lowering the level of engine noise.

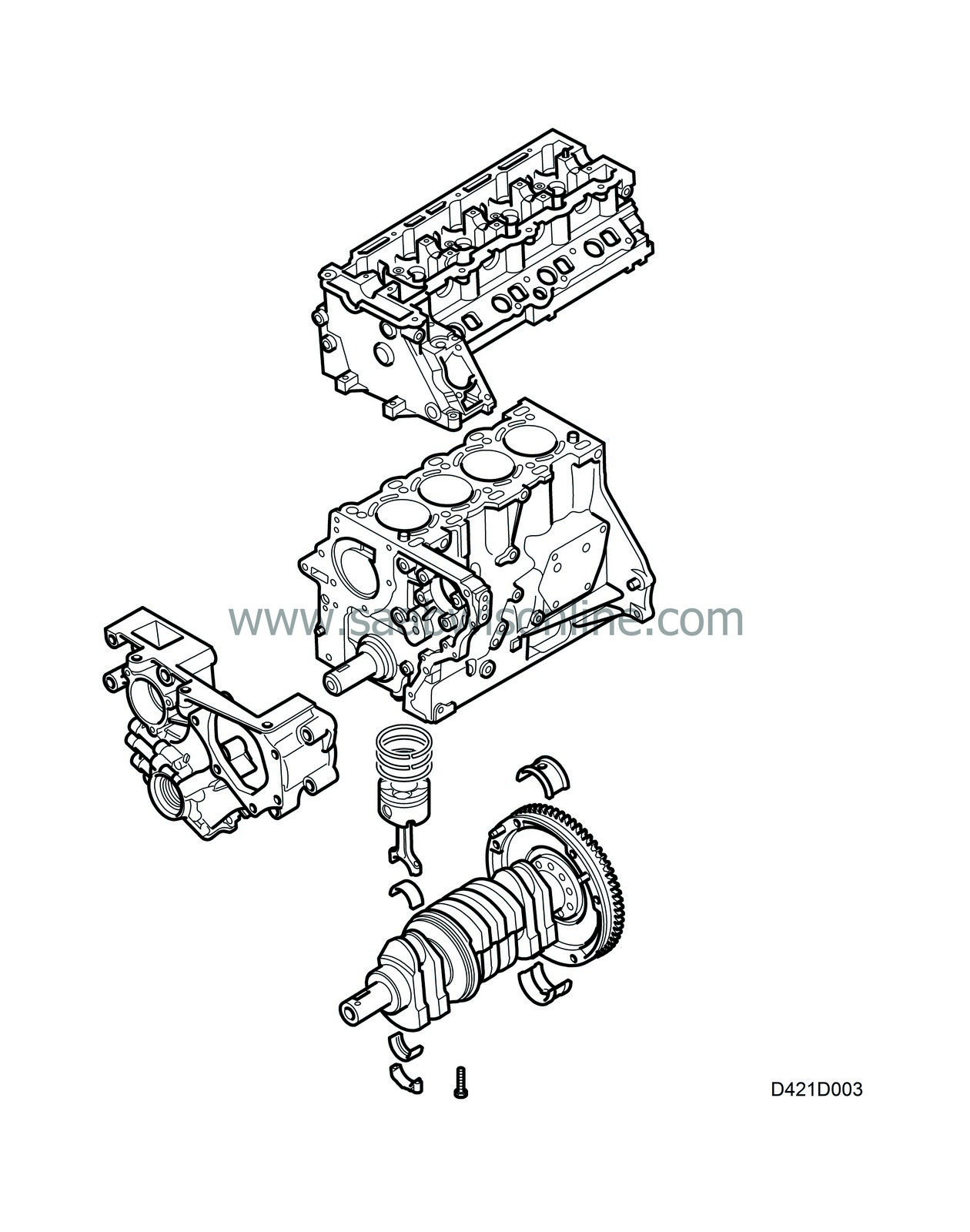

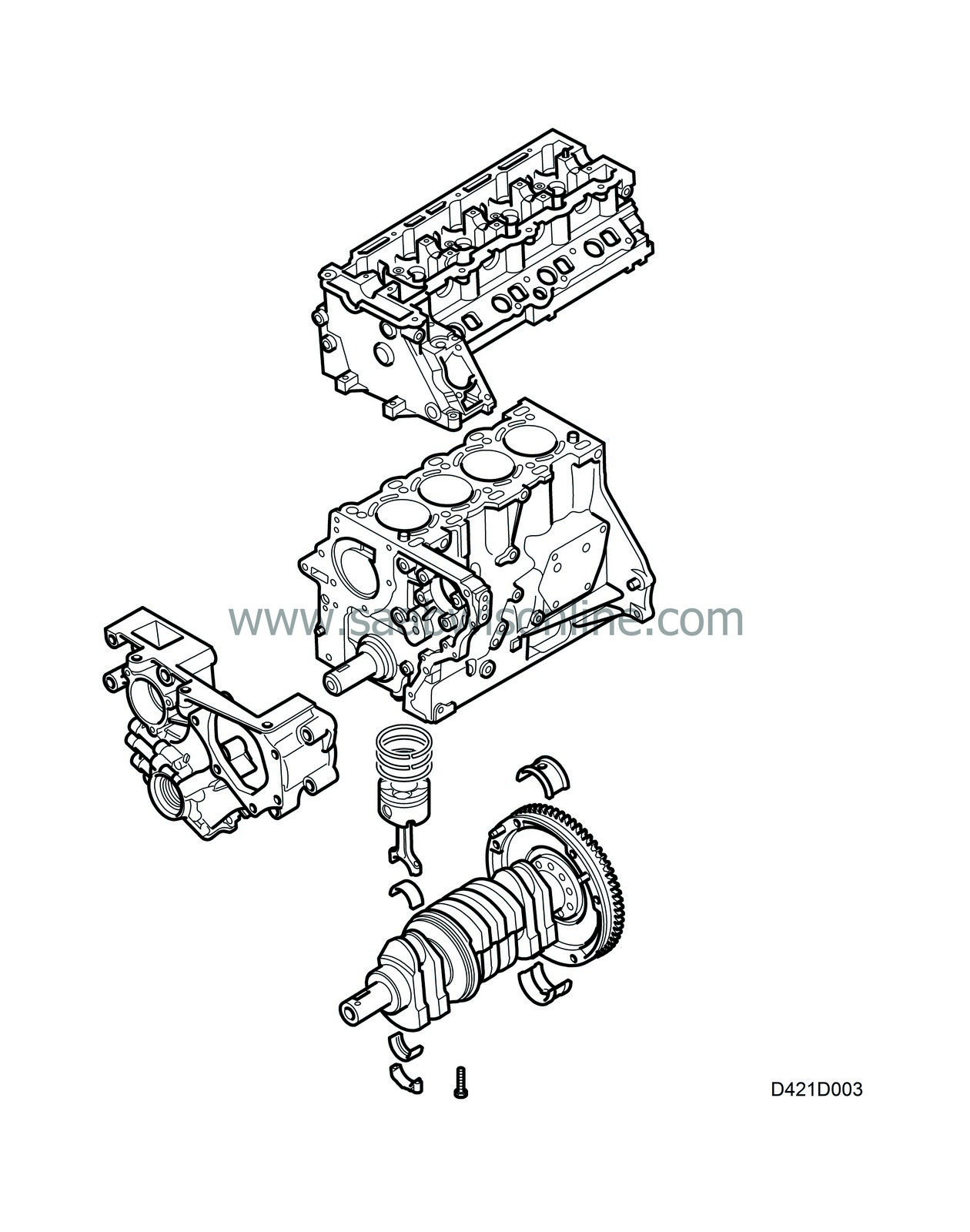

| Cylinder block |

The cylinder block is a special one-piece casting with the cylinder bores drilled directly into the block. Special oilways for the lubricating system are also drilled into the block.

The balancer shafts are fitted in a separate unit under the crankshaft. They are driven by the crankshaft via a chain.

| Cylinder head |

The cylinder head is precision-cast in light alloy and bolted to the cylinder block. There are 4 valves per cylinder with centrally placed injectors. There are twin intake passages but the engine management system controls only one throttle, which opens and closes the intake passage to the respective cylinder. In this way, the swirl in the cylinders is improved, giving more efficient combustion of the fuel, i.e. the engine reaches a high degree of efficiency. The cylinder head is sealed with a metal gasket, which is available in a number of thicknesses.

| Timing cover |

The timing cover is designed to fit the shape of the cylinder block. Inside the timing cover are the oil pump and coolant pump. The cover is sealed with a metal gasket with vulcanized rubber elements.

| Crankshaft assembly |

The crankshaft is forged and has ground bearing journals, the surfaces of which are induction hardened. This gives a hard surface to protect against wear. The crankshaft is mounted in 5 main bearings, of which the one in the centre also acts as an axial guide bearing. There are oilways drilled in the shaft for lubrication. All the main bearing shells are replaceable.

| Connecting rods |

The connecting rods are forged and fitted with bearing bushes for the gudgeon pins.

The gudgeon pins are of fully-floating type, being free to turn in both piston and connecting rod. Axial movement of the gudgeon pin is limited by circlips in the gudgeon pin holes.

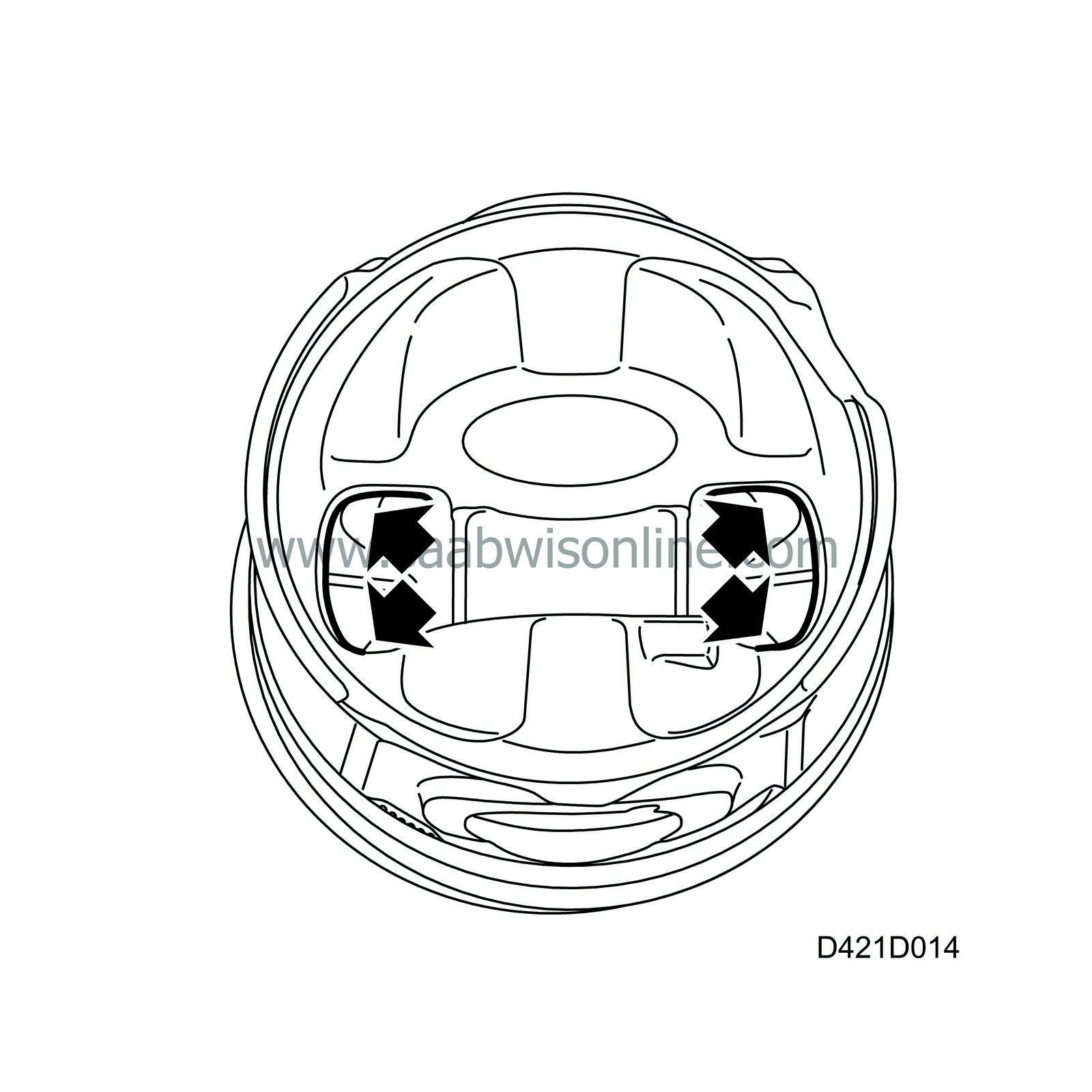

| Pistons |

The pistons are manufactured in light alloy and have grooves for two compression rings and one oil/scraper ring. The combustion chamber is located in the top of the piston.

The upper compression ring is flat, the lower one has oil-scraper characteristics and is slightly wider than the upper one. The actual oil-scraper ring is in three pieces.