Main and big-end bearing clearances

|

|

Main and big-end bearing clearances

|

|

Important

|

|

When using the Plastigauge to measure play, be careful not to get any in the oil holes.

|

|

|

|

Note

|

|

The crankshaft must remain absolutely still while measurement is in progress.

|

Before measuring bearing clearance when fitting new bearings, the ovality and taper of the crankshaft journals must be checked. Use Plastigauge, part no. (45) 30 06 558, which is available in three thicknesses, to measure the clearance. Use type PG-1 (green).

Measure ovality with a micrometer at two positions 90° from each other. Use Plastigauge to measure clearance as follows:

|

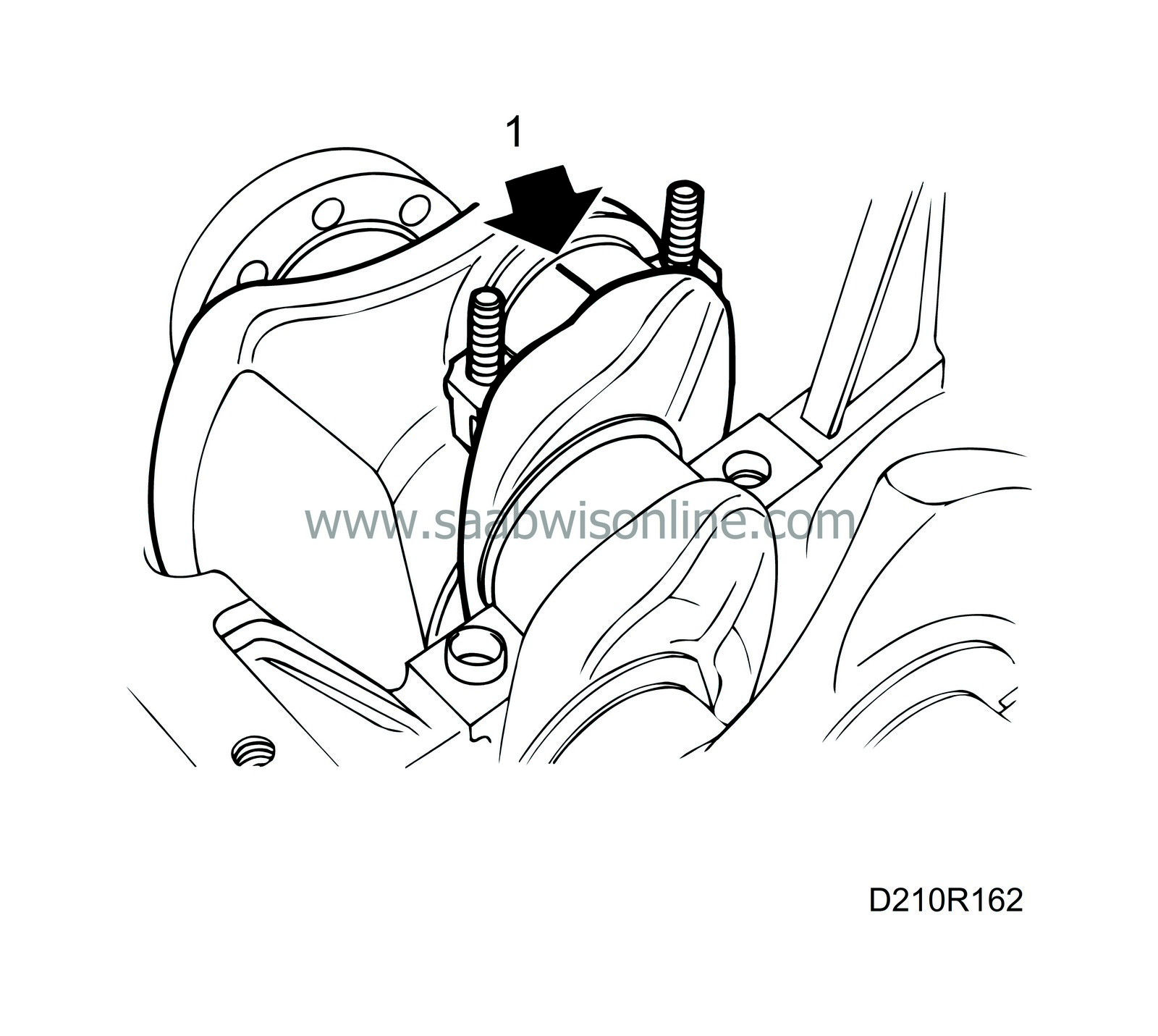

1.

|

Turn the engine upside down on the stand so that the weight of the crankshaft will not affect the measurements.

|

|

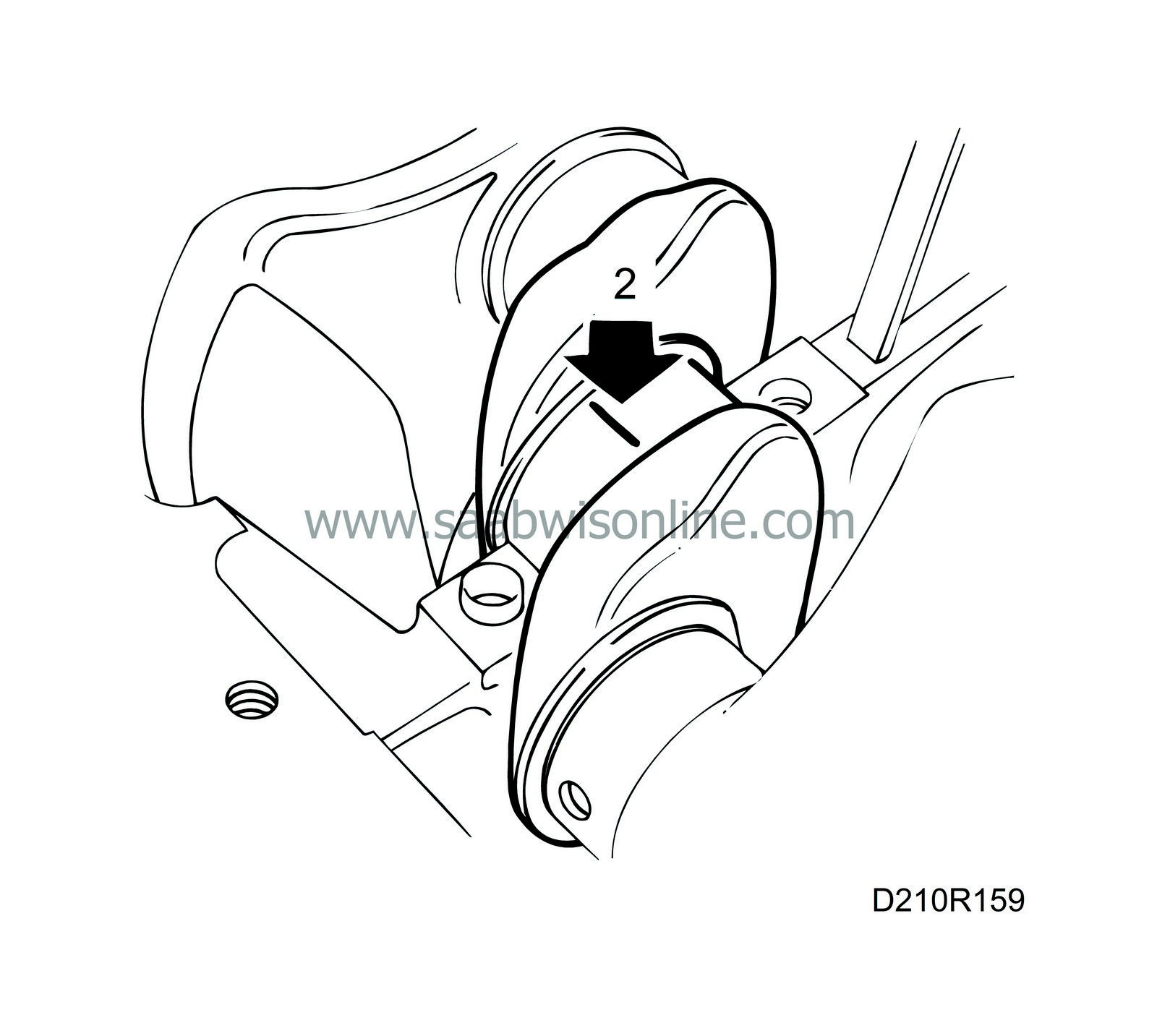

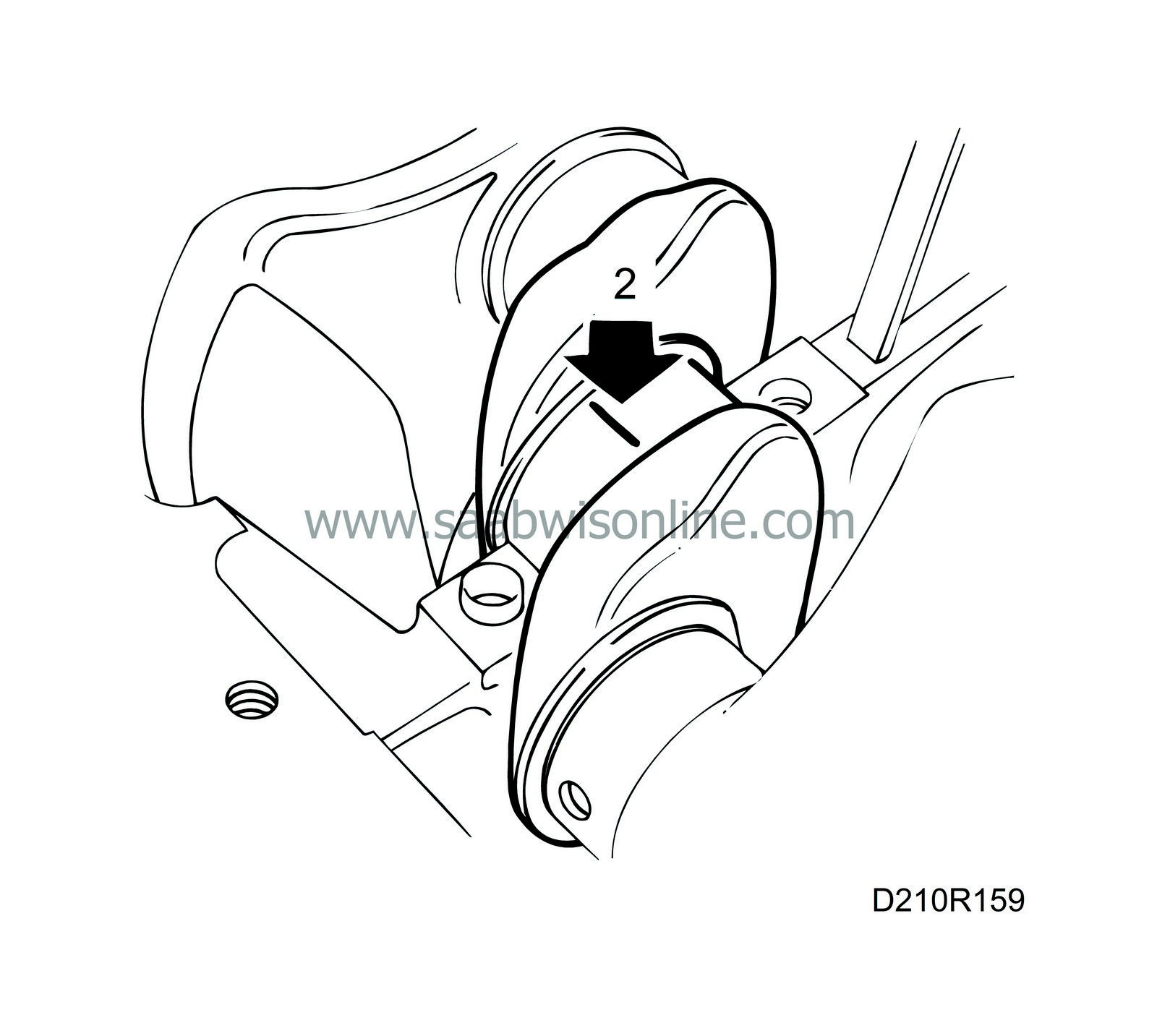

2.

|

Clean the parts to be measured so that they are dry and free from oil and dirt. Place a strip of Plastigauge along the shaft.

|

|

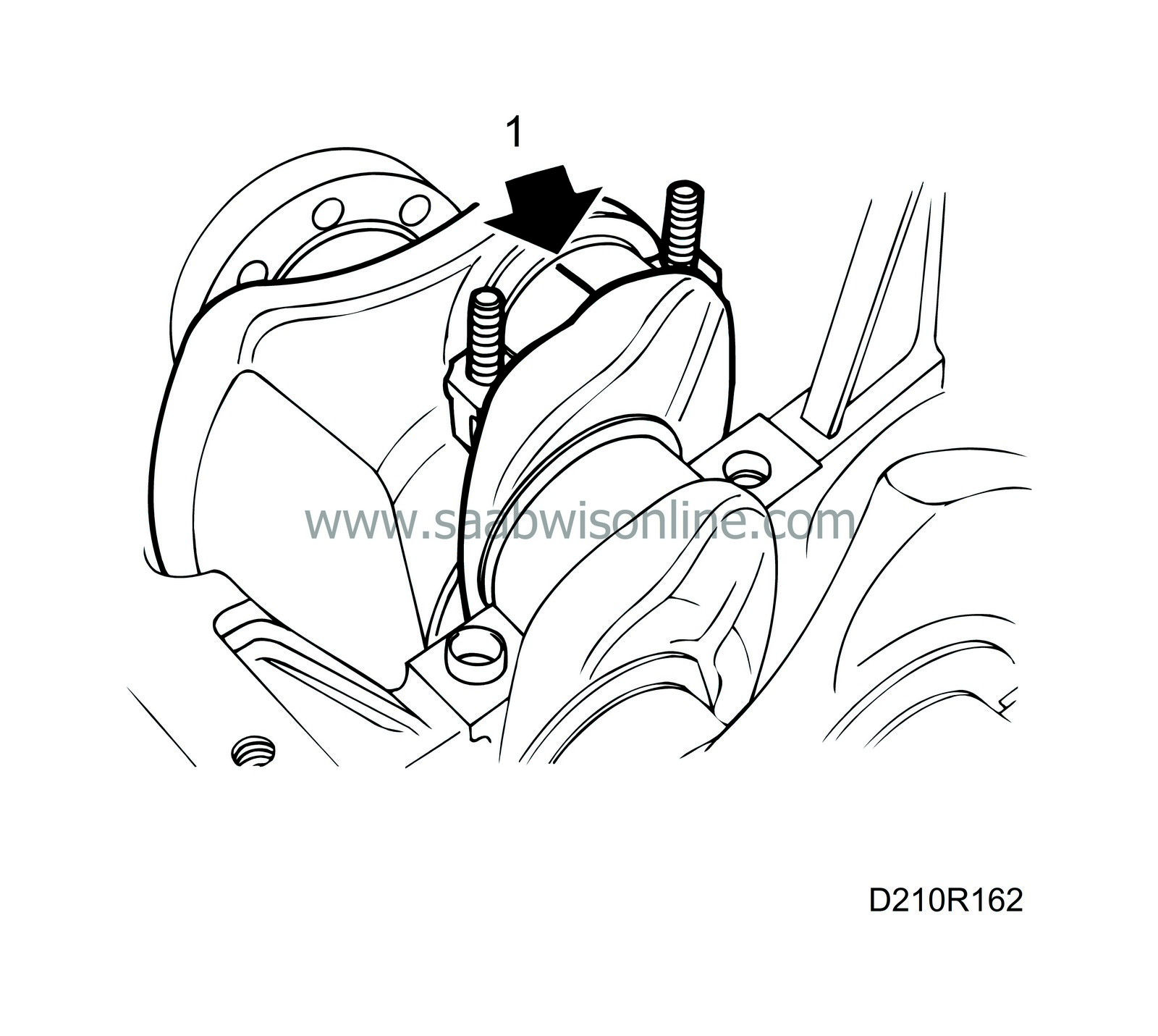

3.

|

Fit the bearing cap.

Tightening torques:

20 Nm + 70° (15 lbf ft + 70°)

|

|

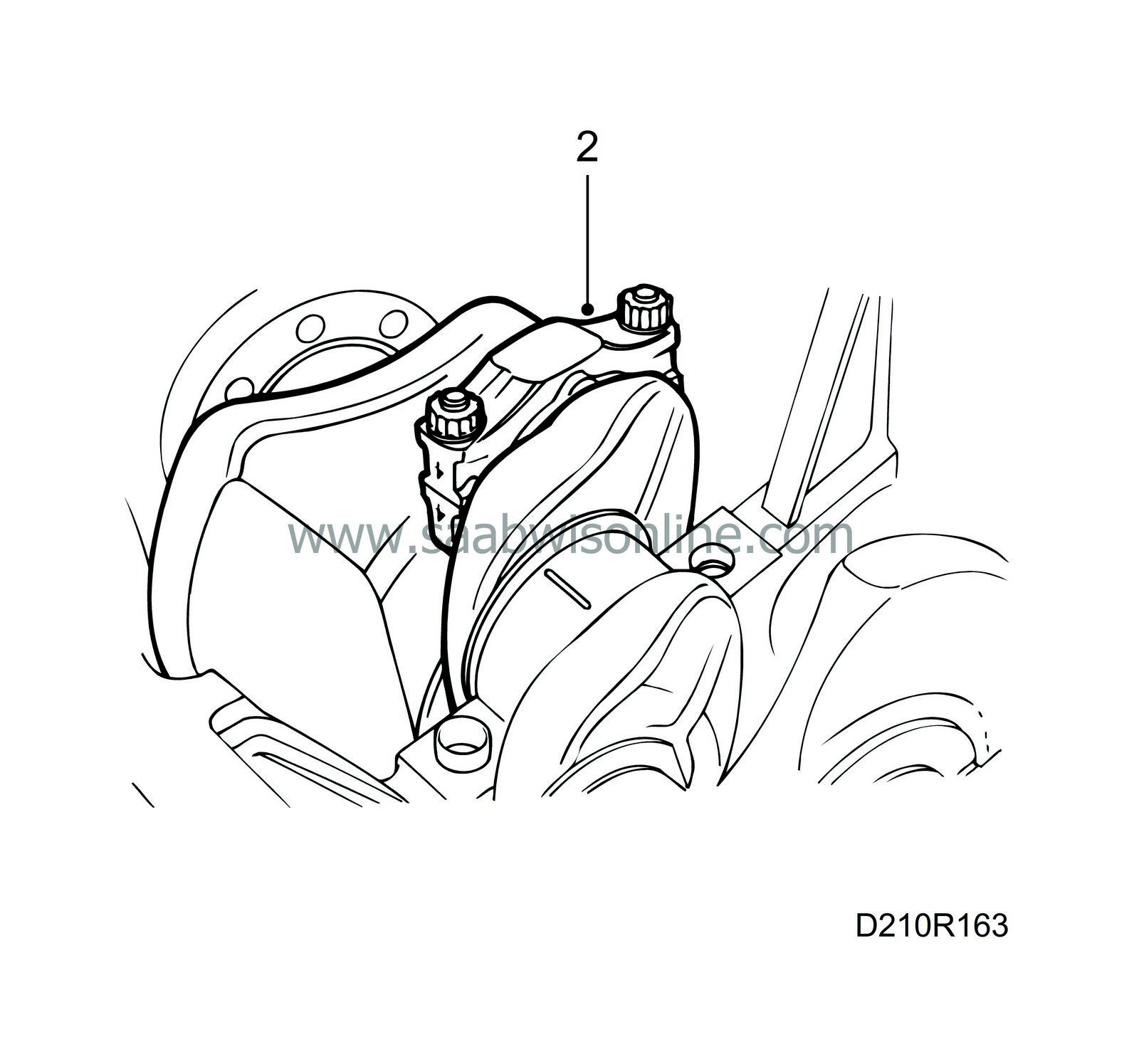

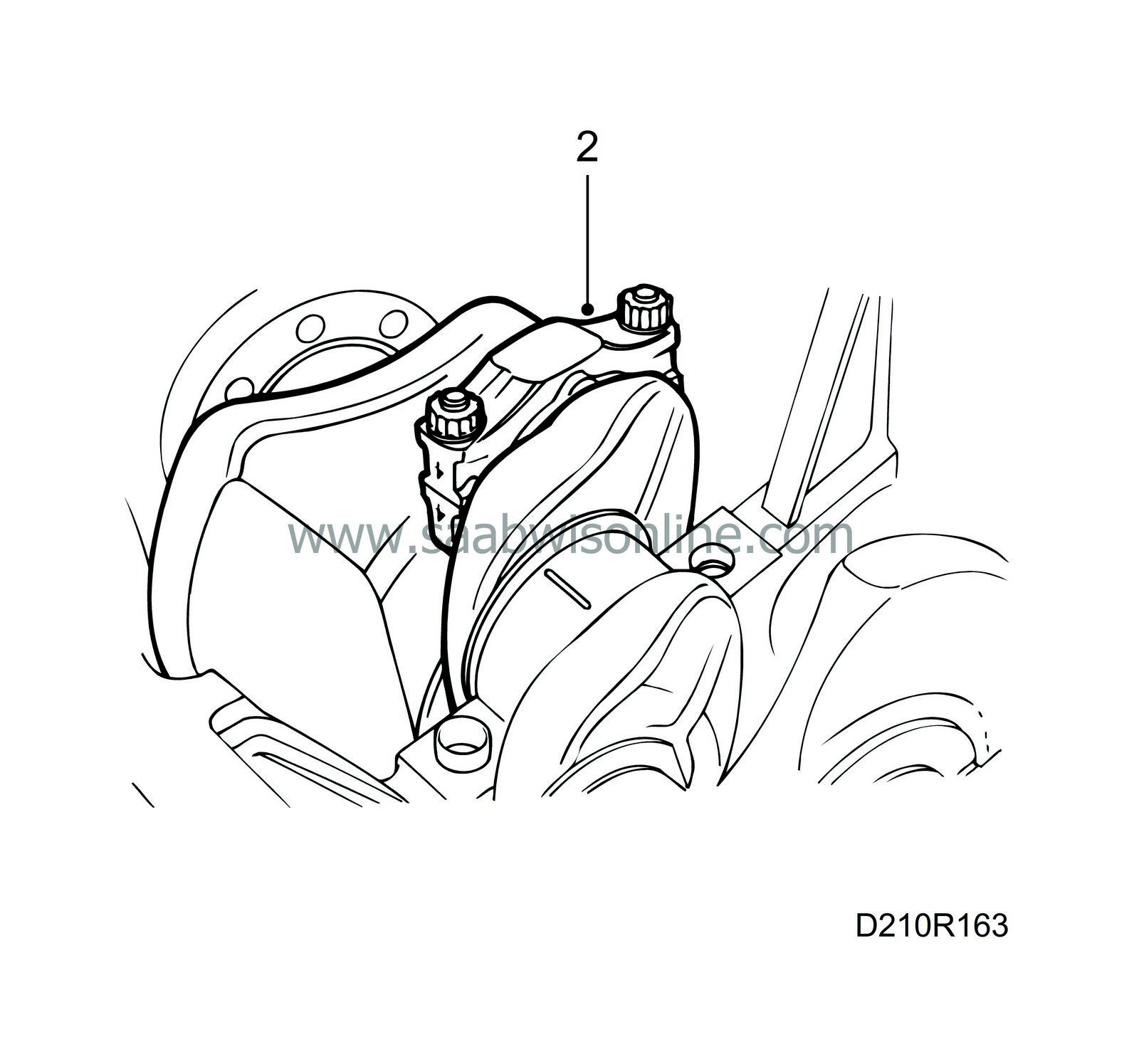

4.

|

Remove the bearing cap. The strip of Plastigauge should now have adhered to either the bearing cap or the main journal.

|

|

5.

|

Measure the width of the Plastigauge strip with the scale printed on the packet and read off the clearance. One side of the packet is measured in mm, the other in 1/1000 inch. Measure the strip at its widest point but do not touch it with your fingers.

For measurements, see

|

|

Important

|

|

When using the Plastigauge to measure play, be careful not to get any in the oil holes.

|

|

|

|

Note

|

|

The crankshaft must remain absolutely still while measurement is in progress.

|

Before measuring bearing clearance when fitting new bearings, the ovality and taper of the crankshaft journals must be checked. Use Plastigauge, part no. (45) 30 06 558, which is available in three thicknesses, to measure the clearance. Use type PG-1 (green).

Measure ovality with a micrometer at two positions 90° from each other. Use Plastigauge to measure clearance as follows:

|

1.

|

Clean the parts to be measured so that they are dry and free from oil and dirt. Place a strip of Plastigauge along the shaft.

|

|

2.

|

Fit the bearing cap.

Tightening torques:

20 Nm + 70° (15 lbf ft + 70°)

|

|

3.

|

Remove the bearing cap. The strip of Plastigauge should now have adhered to either the bearing cap or the main journal.

|

|

4.

|

Measure the width of the Plastigauge strip with the scale printed on the packet and read off the clearance. One side of the packet is measured in mm, the other in 1/1000 inch. Measure the strip at its widest point but do not touch it with your fingers.

For measurements, see

|