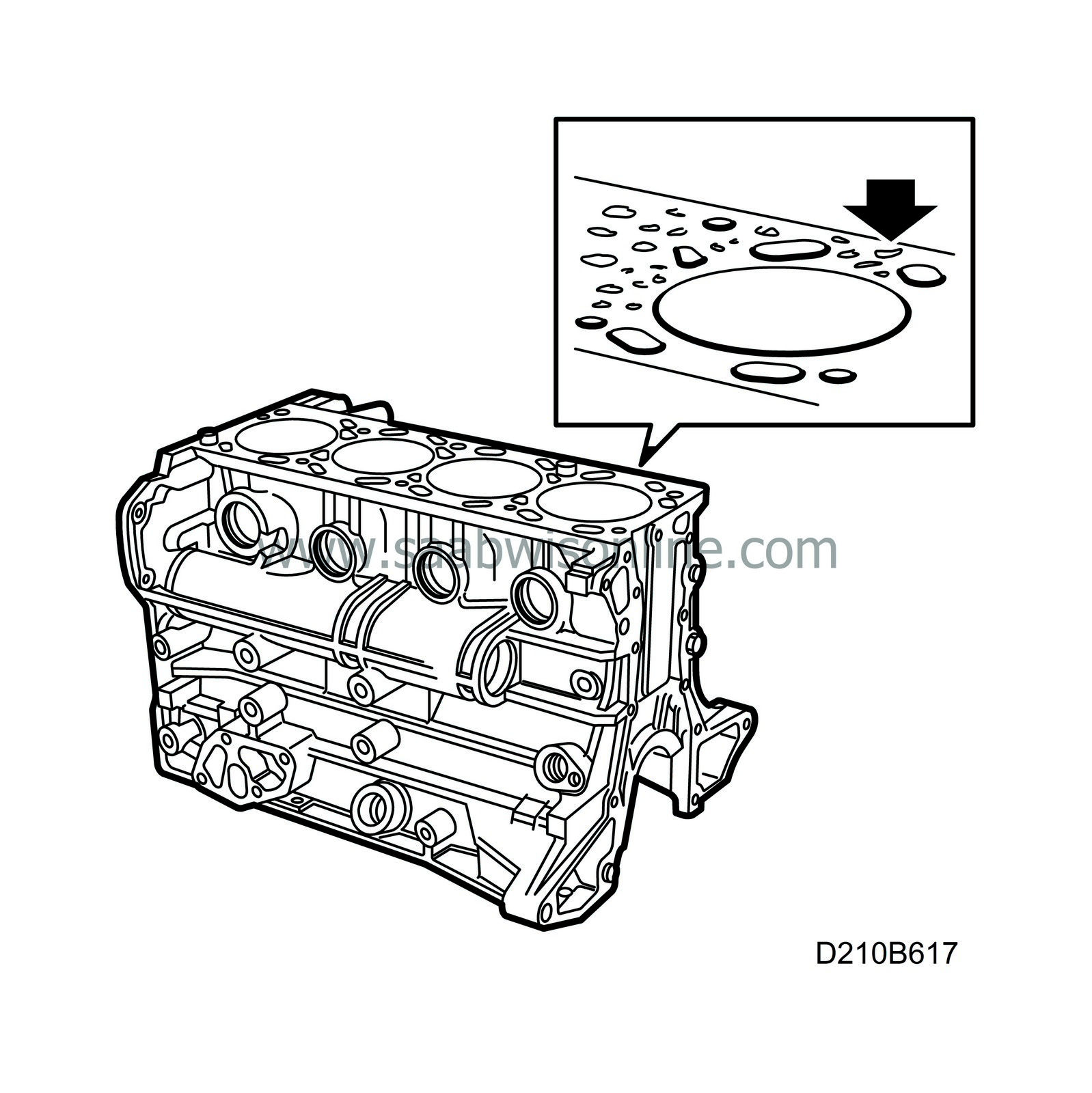

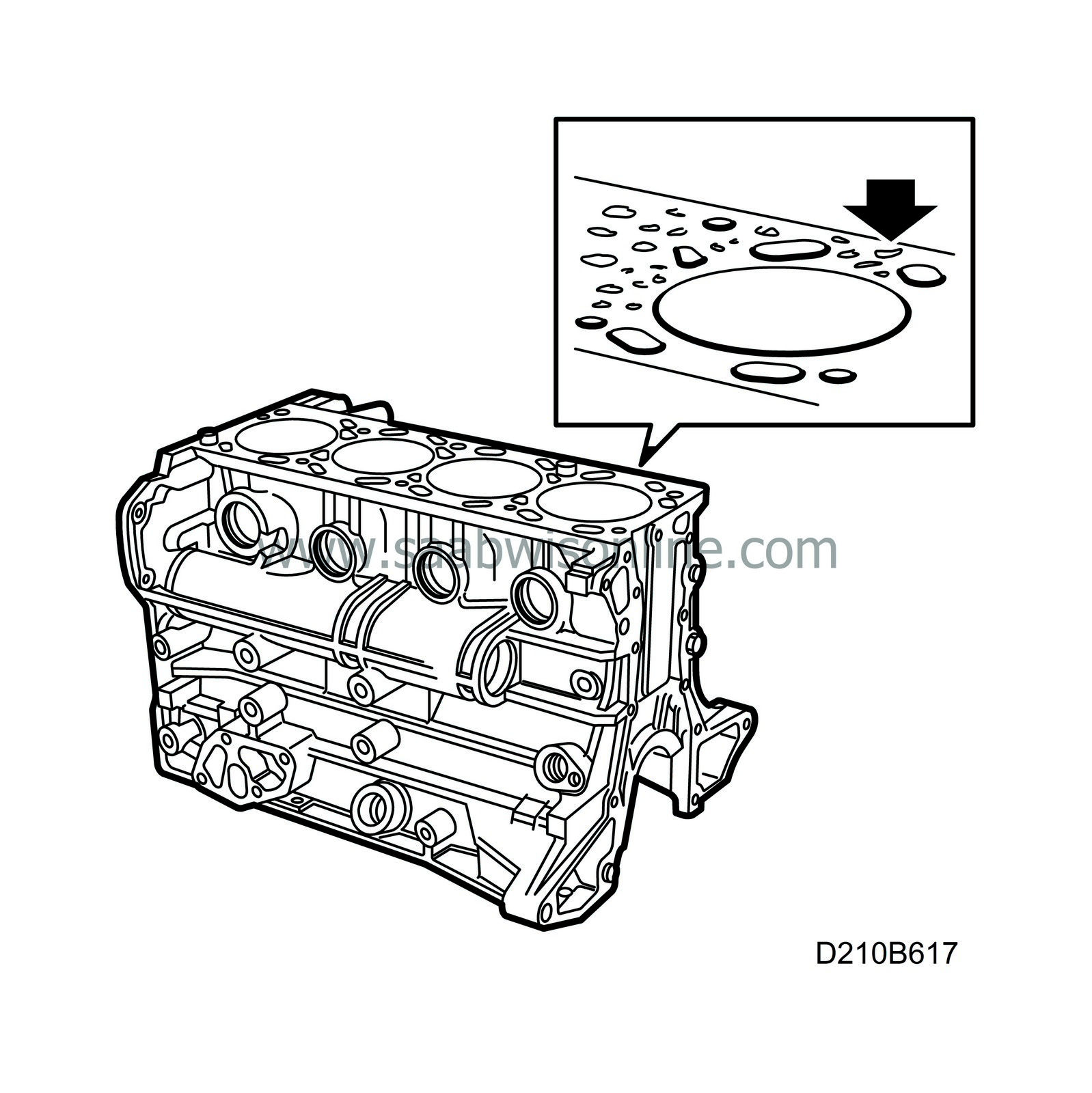

Pits on the cylinder block

|

|

Pits on the cylinder block

|

|

Pits on the sealing surface with the cylinder head

|

Under certain conditions, the surface sealing the cylinder block to the cylinder head can become pitted due to prolonged leaks in the cylinder head gasket. The pitting arises in the area around the engine coolant passageways.

|

1.

|

Remove the cylinder head and cylinder head gasket, refer to

Removing the cylinder head (in situ)

. Seal the oilways, coolant ducts and cylinders.

|

Important

|

|

Make sure no repair compound or grindings enter the cylinders, coolant ducts or oil ways.

|

|

|

|

|

2.

|

Clean the surface thoroughly. For maximum adhesion the surface should be roughened slightly with course abrasive paper.

|

|

3.

|

Put on protective rubber gloves. Cut off the desired quantity of repair compound,

30 31 259 Alustick

and remove the plastic sheath from the compound.

Warning

Warning

|

|

Always use protective gloves when working with chemicals.

|

|

|

|

|

|

|

|

4.

|

Knead the repair compound with your fingers until it has acquired an even colour.

|

|

5.

|

Within 2 minutes, press the repair compound onto the area requiring repair. Make sure you apply the compound in an even layer, and make sure that the surface is raised in relation to the sealing surface of the cylinder block. To make the surface as even as possible, wipe off any excess repair compound with a damp cloth immediately.

|

|

6.

|

Let the compound harden through (1-2 hours) and then smooth off the area with a grinding block so that the surface of the cylinder block is level and smooth. Make sure that no metal is removed from the surface of the cylinder block.

|

Warning

Warning