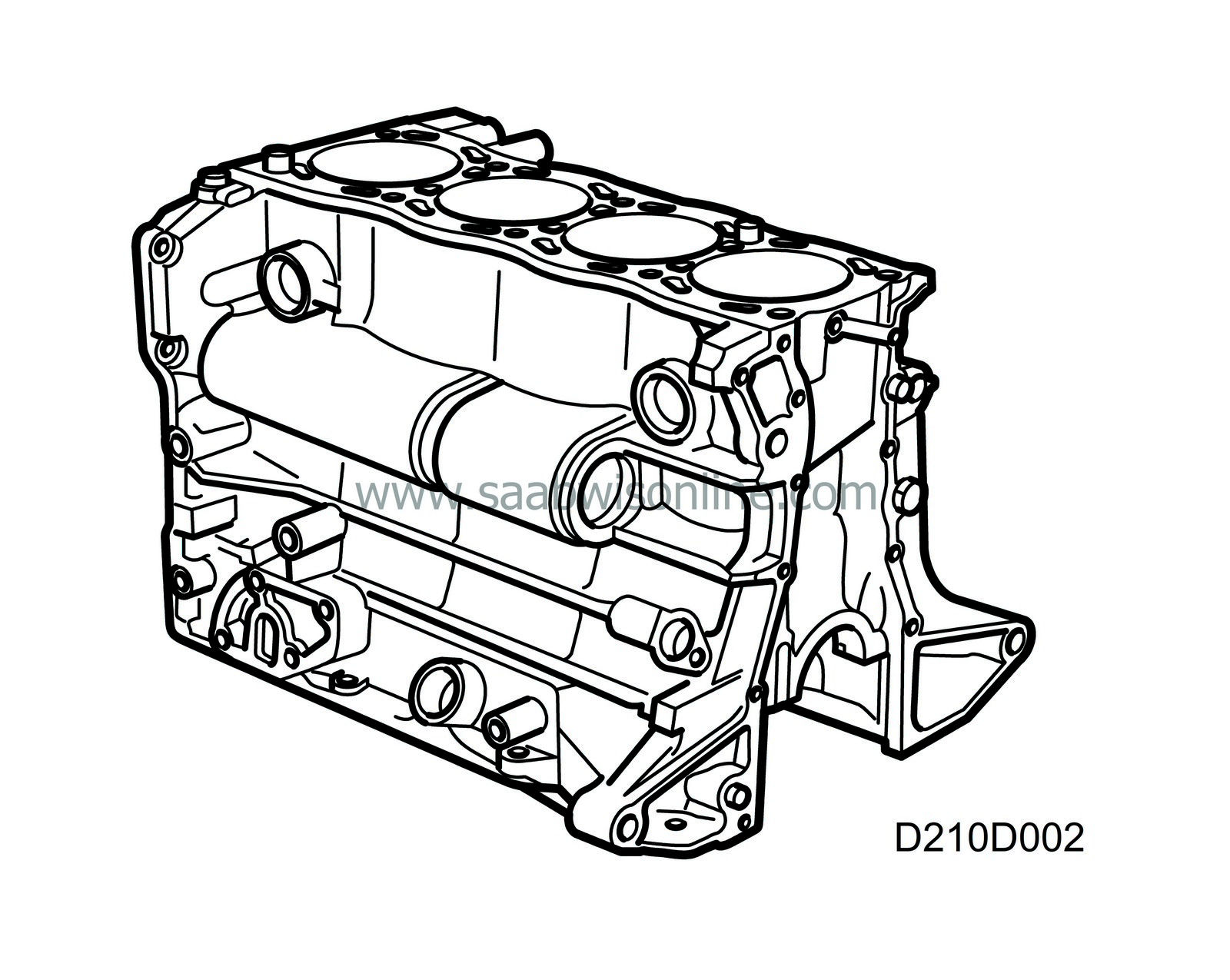

Engine block

| Engine block |

The engine is mounted transversely and is tilted forwards 8°.

The 2.0 litre (B205L/R/E) and 2.3 litre (B235R) cylinder capacity provides a high torque even at low engine speeds, which is an advantage when driving in normal traffic conditions.

The balancer shafts neutralize vibrations and forces from the moving parts in the engine while reducing unwanted engine noise.

| Cylinder block |

The cylinder block is a special one-piece casting with the cylinder bores drilled directly into the block. Special oilways for the lubricating system are also drilled into the block.

There are two tunnels for the balancer shafts in the block. The tunnels have aluminium bearing bushings pressed into them. The bushings are replaceable without requiring machining.

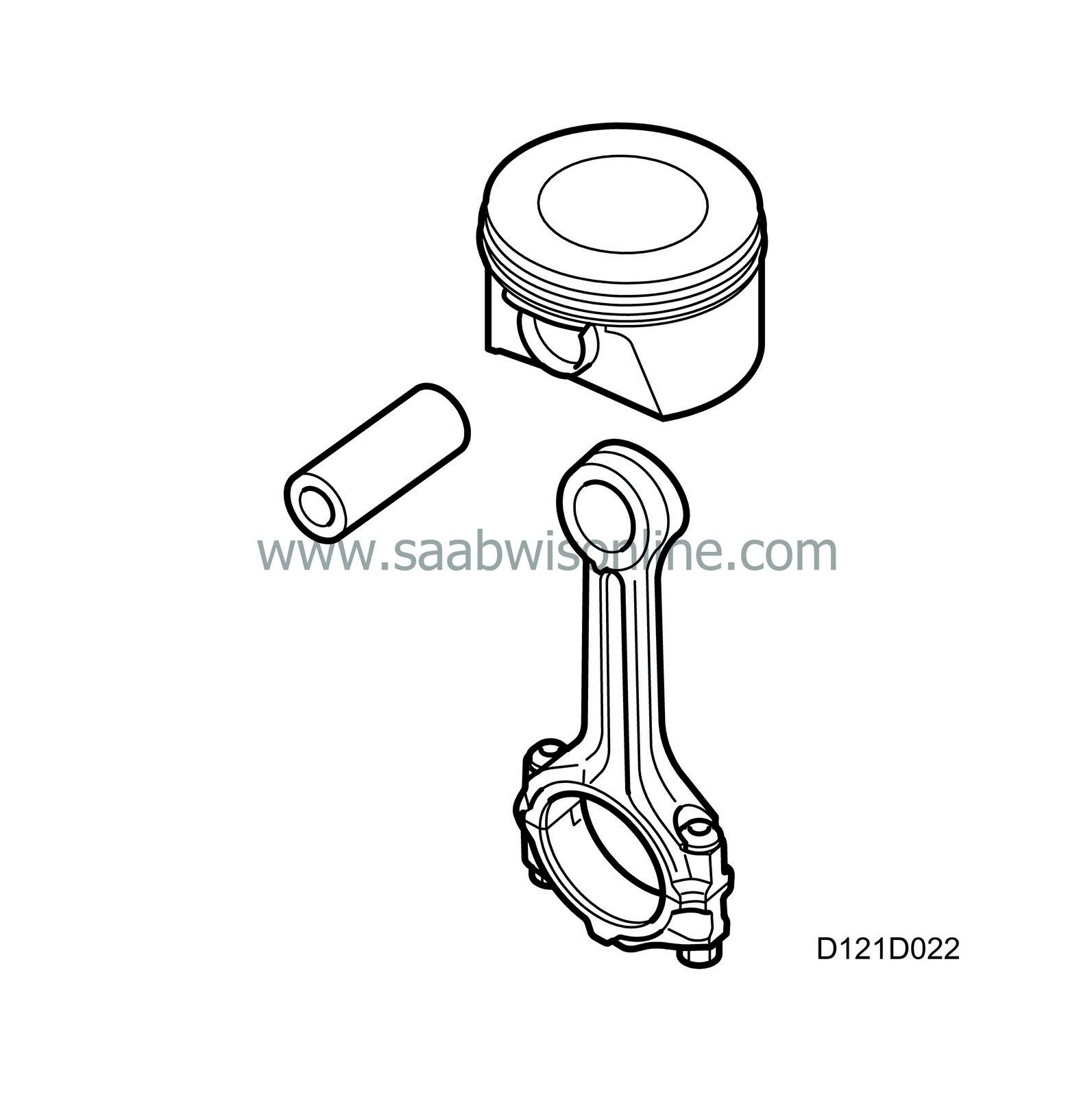

| Pistons |

The pistons are made of light alloy and have grooves for two compression rings and one oil scraper ring.

The plain top compression ring is chromium- or molybdenum-coated and the bottom compression ring has oil scraping characteristics. The actual oil scraper ring is in three parts. The pistons are tin-coated.

The engines are fitted with reinforced pistons, the tops of which are hard-anodized, of slightly lower dimensions that previous models to give lower compression. The pistons have been adapted to take connecting rods with trapezoid little ends. They are also fitted with nitrogen case-hardened gudgeon pins. All 2.0 litre engines have a compression ratio of 8.8:1 and 2.3 litres engines 9.3:1.

| Connecting rods |

The connecting rods are forgings and incorporate bushings for the gudgeon pins. The gudgeon pin bushings and big-end bearing shells are replaceable.

The gudgeon pin has a floating fit in the piston and connecting rod. The axial movement of the gudgeon pin is limited by circlips in the gudgeon pin hole. The little end is trapezoid.

| Crankshaft assembly |

The crankshaft is forged and has induction-hardened ground journals. This produces a hard surface finish, which is resistant to wear. The crankshaft has five main bearings, of which the middle one also functions as a locating bearing axially. Oilways are drilled in the crankshaft for lubrication. All main bearing shells are replaceable.

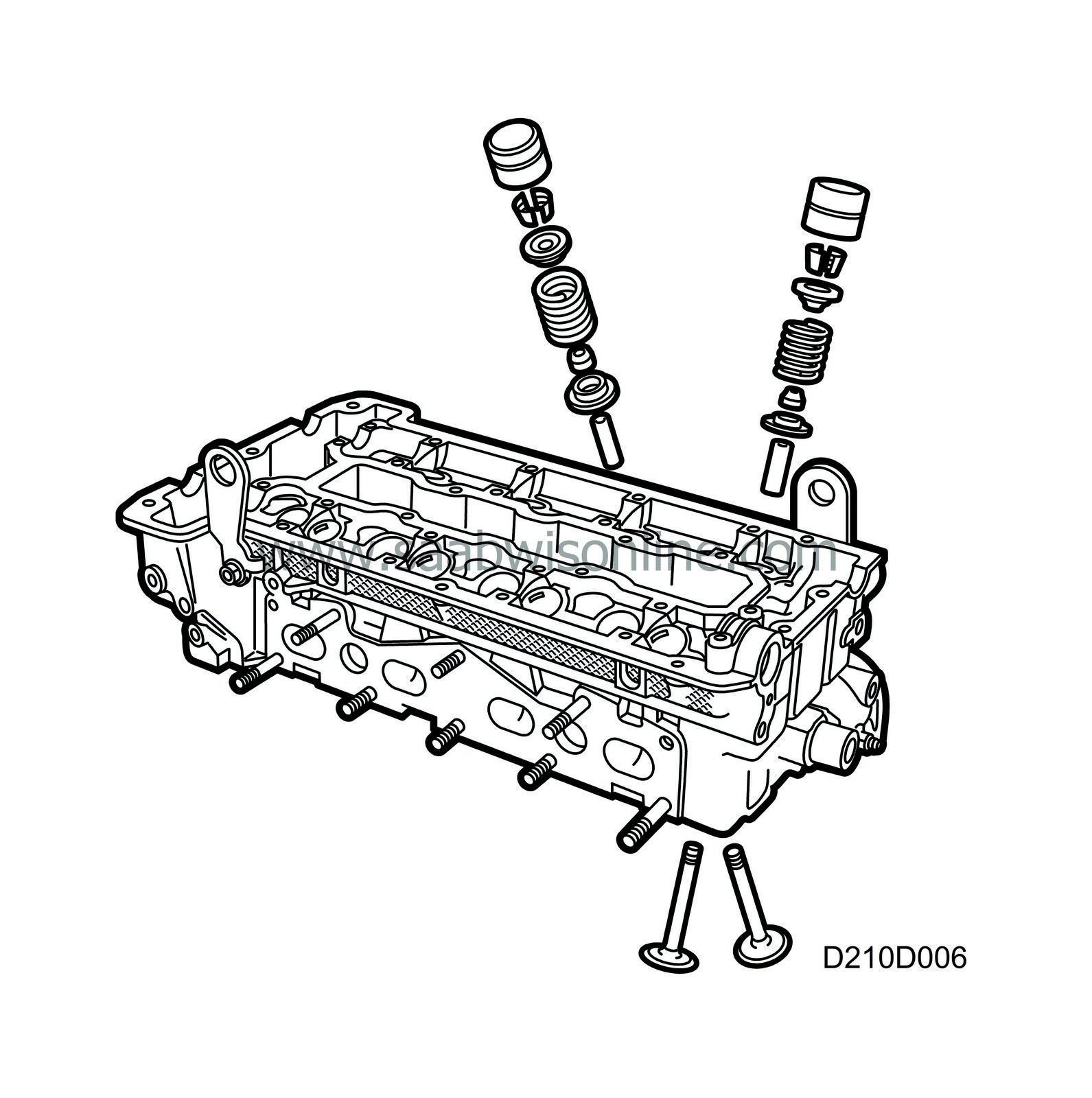

| Cylinder head |

The cylinder head is precision-manufactured in light alloy and bolted to the cylinder block. The combustion chambers are hemispherical with 4 valves per cylinder and centrally located spark plug. This improves the flow of gases in the cylinders, providing efficient combustion and increased engine power.

| Timing cover and end plate |

The timing cover and the end plate are both designed to fit the form of the cylinder block. The oil pump is mounted inside the timing cover. The timing cover and the end plate are both sealed against the block with flange sealant, part no. 93 21 795.