Refueling system function

|

|

Refueling system function

|

|

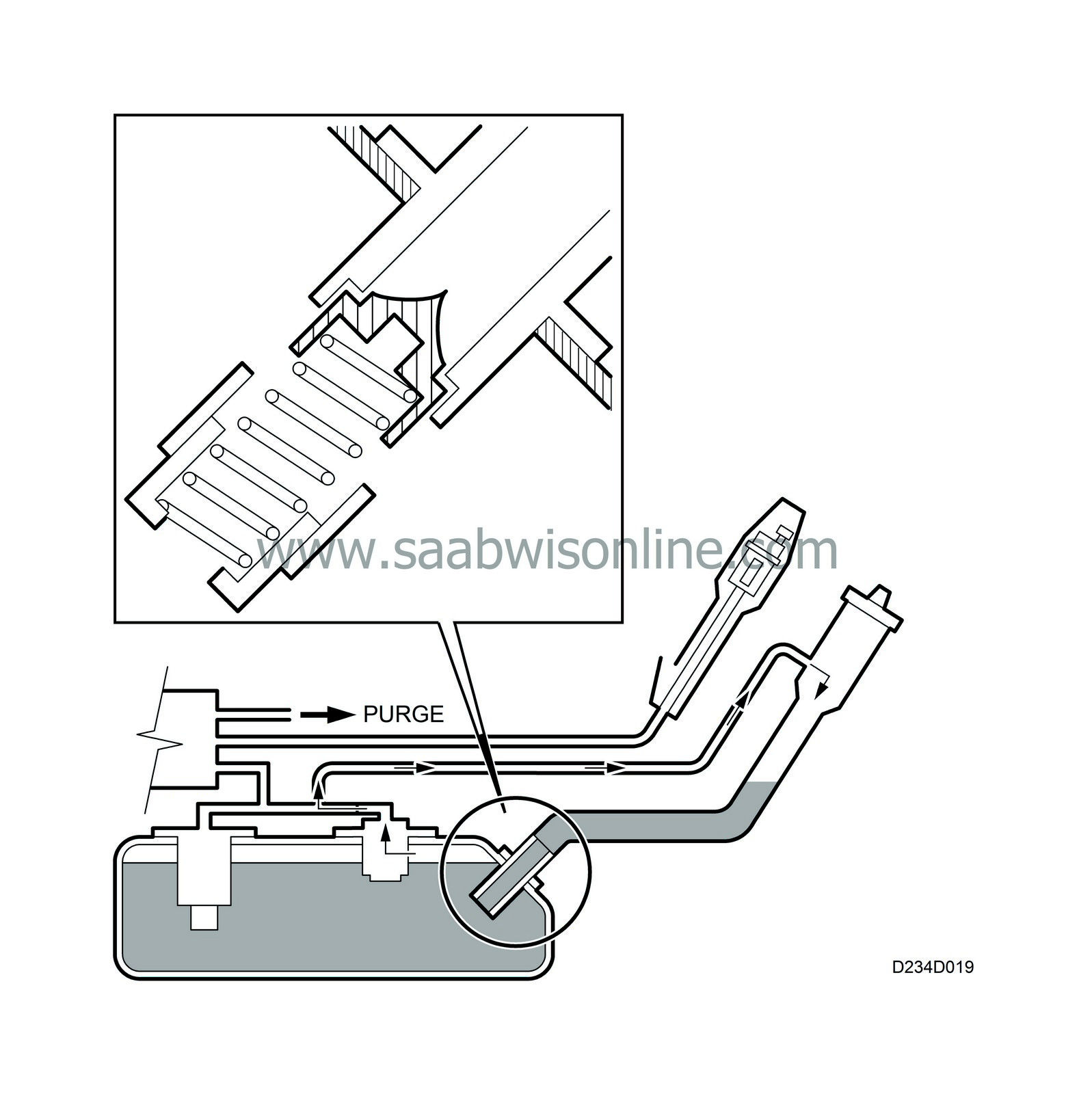

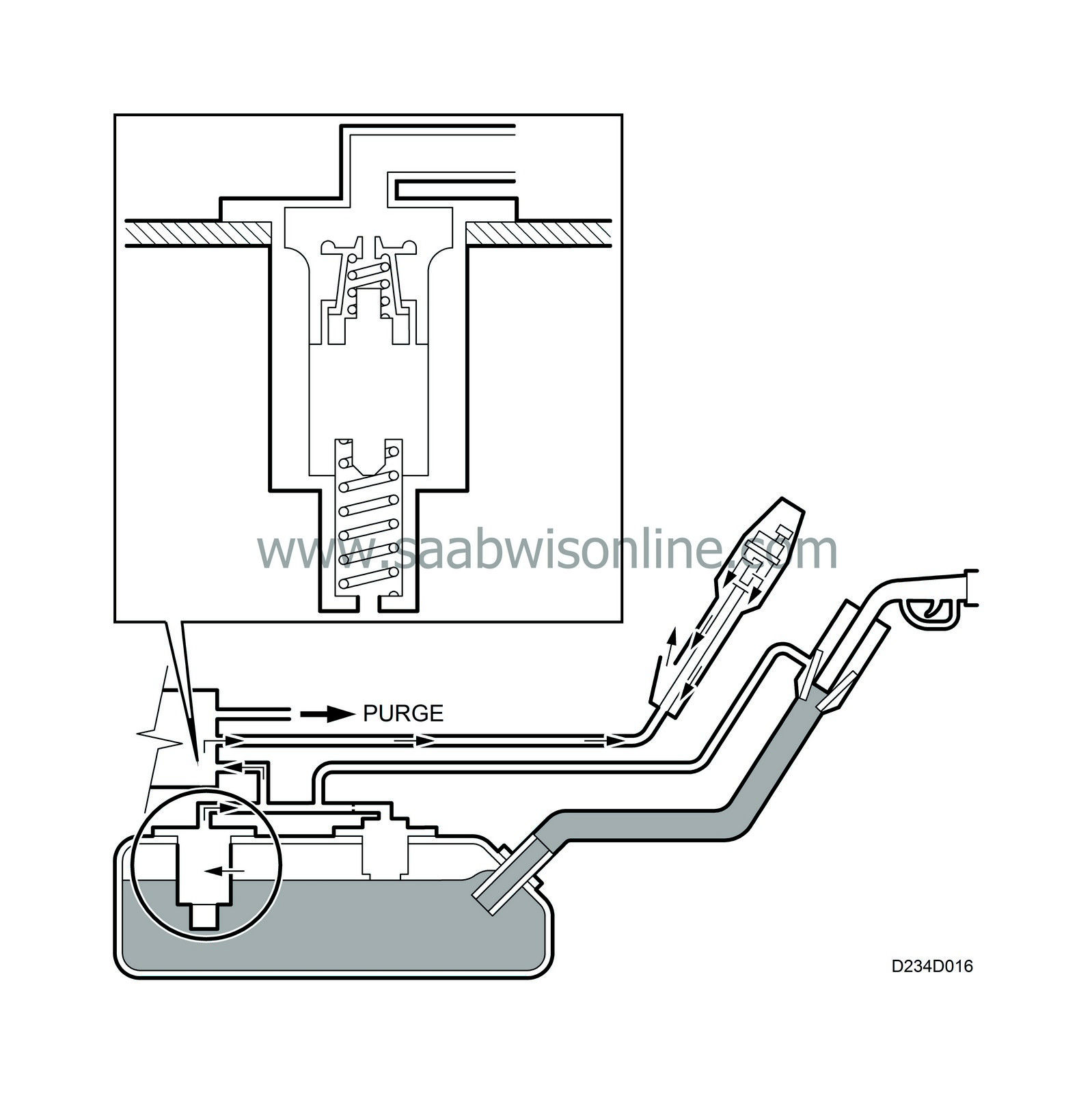

1.

|

An ejector is located in the top part of the filler pipe. The ejector has no moving parts, only flexible slits.

When the filler nozzle is inserted into the filler pipe, the slits in the ejector open. The filler nozzle is support by four ridges in the pipe inside the ejector. When fuel is filled, air from outside the car is drawn through the ejector slits by the ejector effect. Air is mixed with the fuel behind the ejector and passed together with the fuel through the pipe and into the tank.

In this way, hydrocarbons are prevented from being emitted during refueling.

|

|

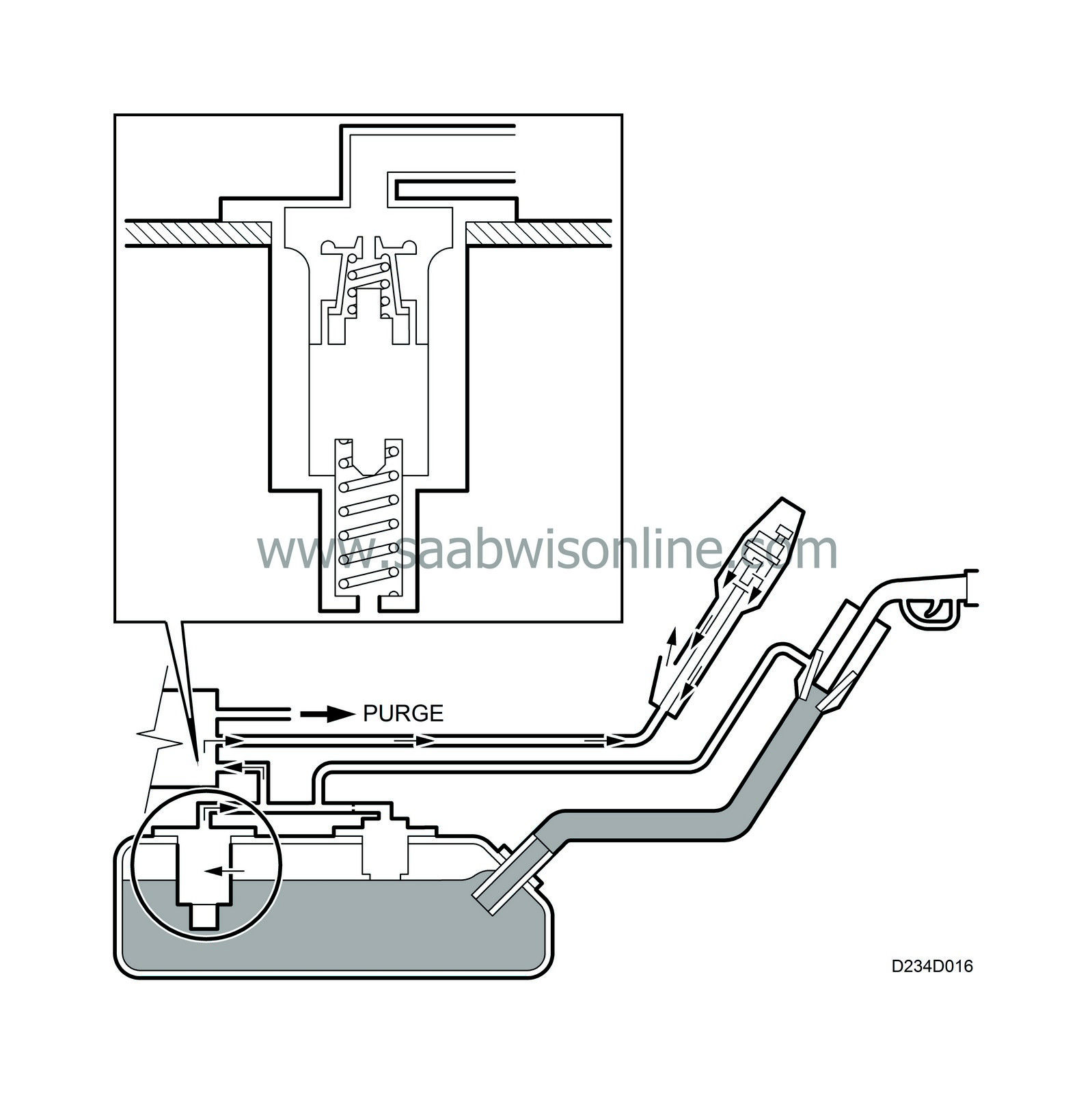

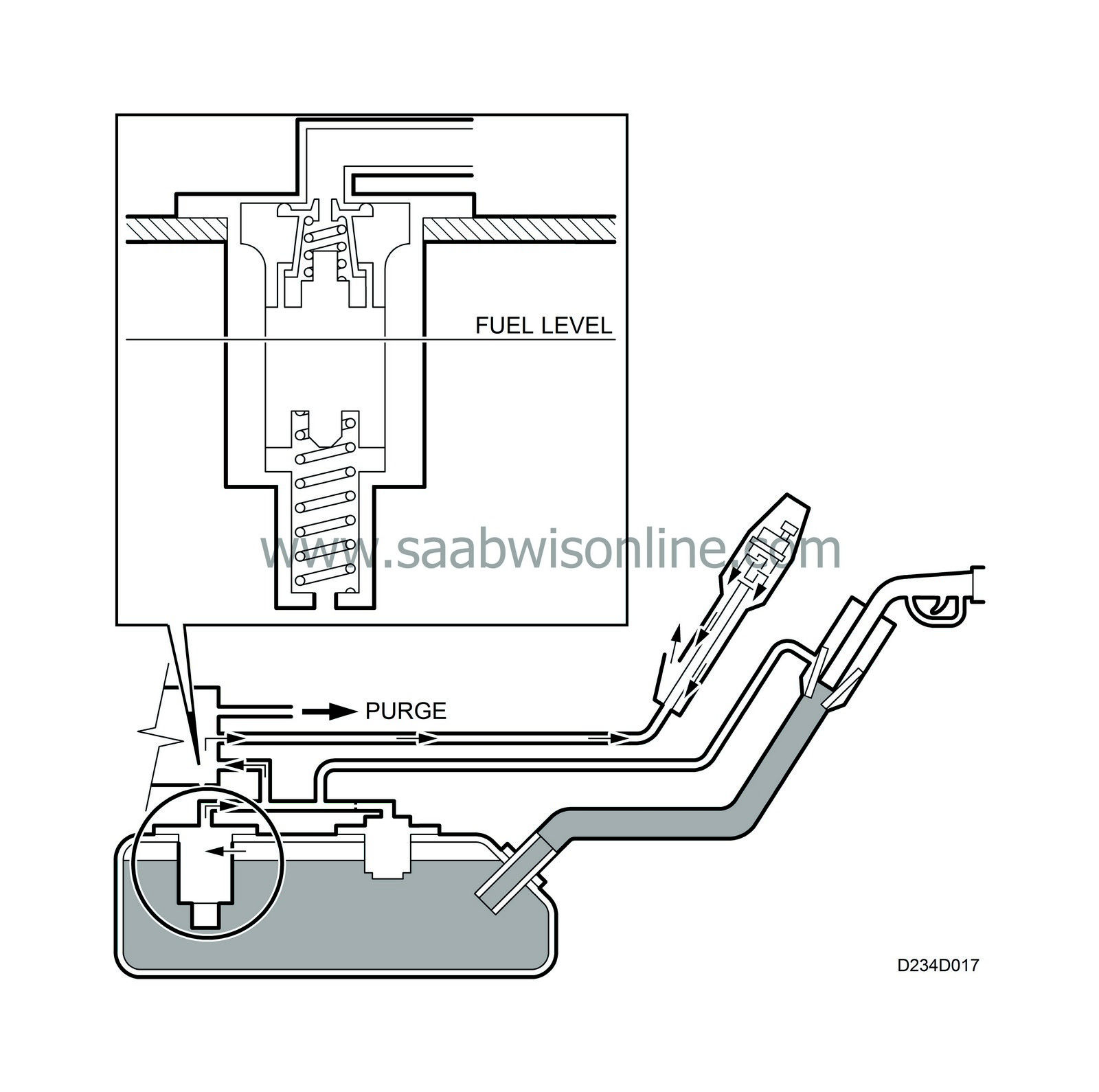

2.

|

At the end of the fuel pipe there is non-return valve. This is normally closed by a spring and allows the fuel to flow only towards the tank.

The valve opens when fuel is filled and closes immediately fuel flows in the opposite direction, i.e. when the tank is full.

In this way, the valve prevents ”back-spit”.

|

|

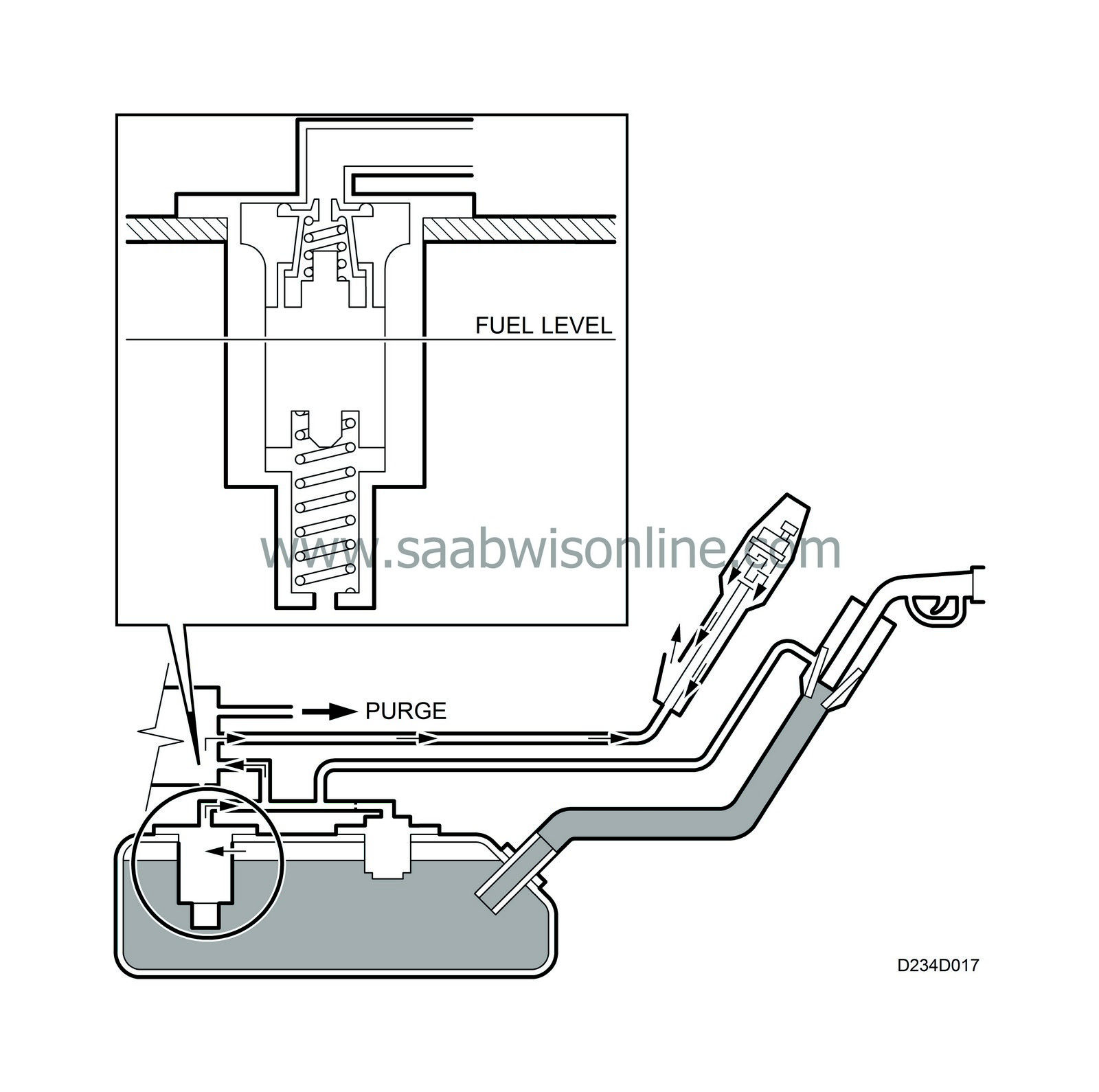

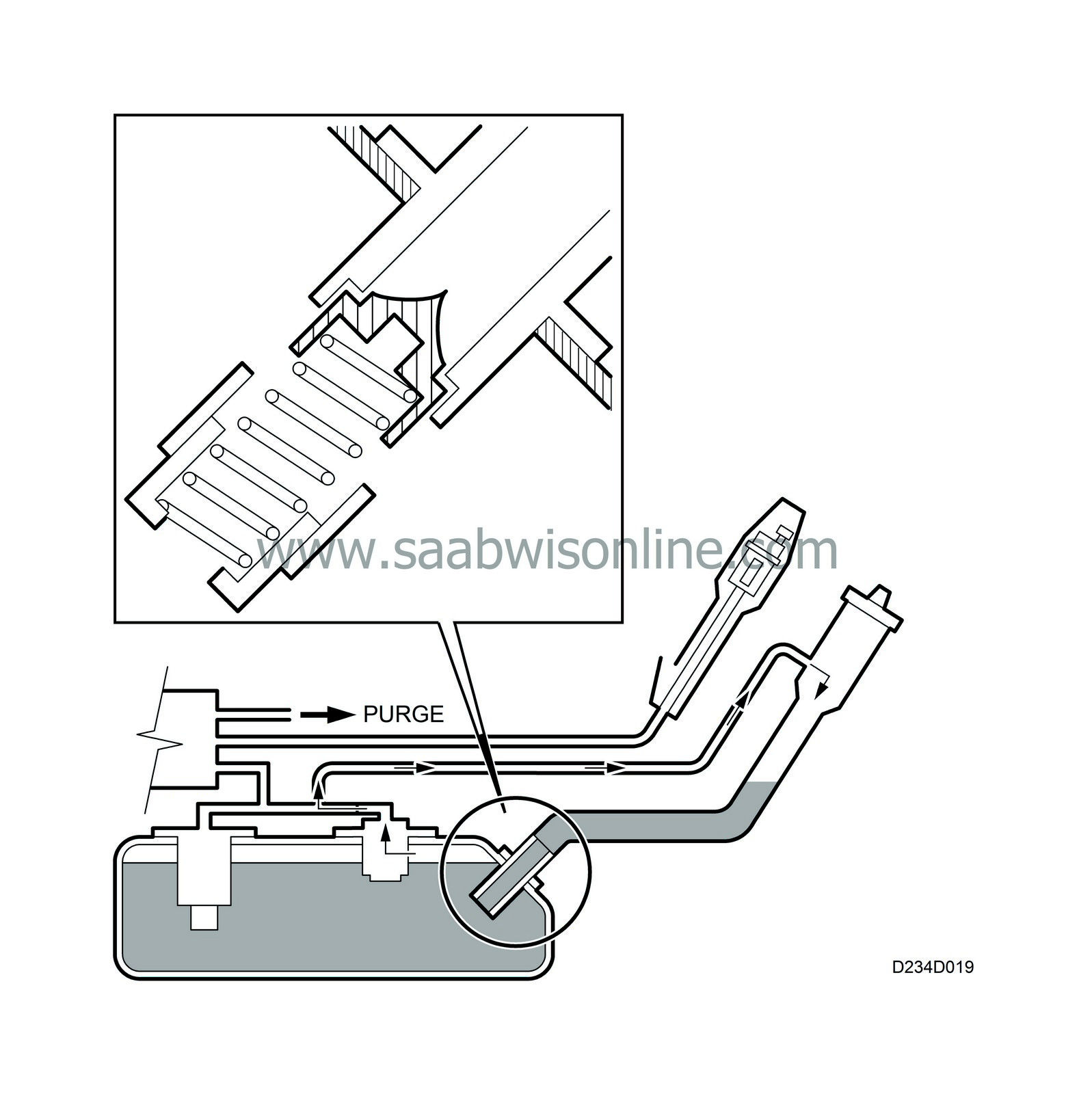

3.

|

Fuel is filled into the tank. A small amount of air from the filler pipe ejector enters together with the fuel. Above the surface of the fuel in the tank there are gaseous hydrocarbons.

As the fuel level rises, the air and gaseous hydrocarbons will be evacuated through the float valve fitted in the top of the tank. The fumes then pass to the EVAP canister, where the hydrocarbons are absorbed. The air, which cannot be absorbed, passes from the EVAP canister to the atmosphere via a vent pipe in the wheel housing next to the filler pipe.

A shut-off valve is fitted to the top of the vent pipe. The shut-off valve can close the EVAP canister connection to the atmosphere and is only used for OBD II diagnosis. ORVR without tank integrity diagnosis does not have a shut-off valve as there is no requirement for diagnosis.

The float valve also acts as a rollover valve and closes in the event that the car rolls over.

|

|

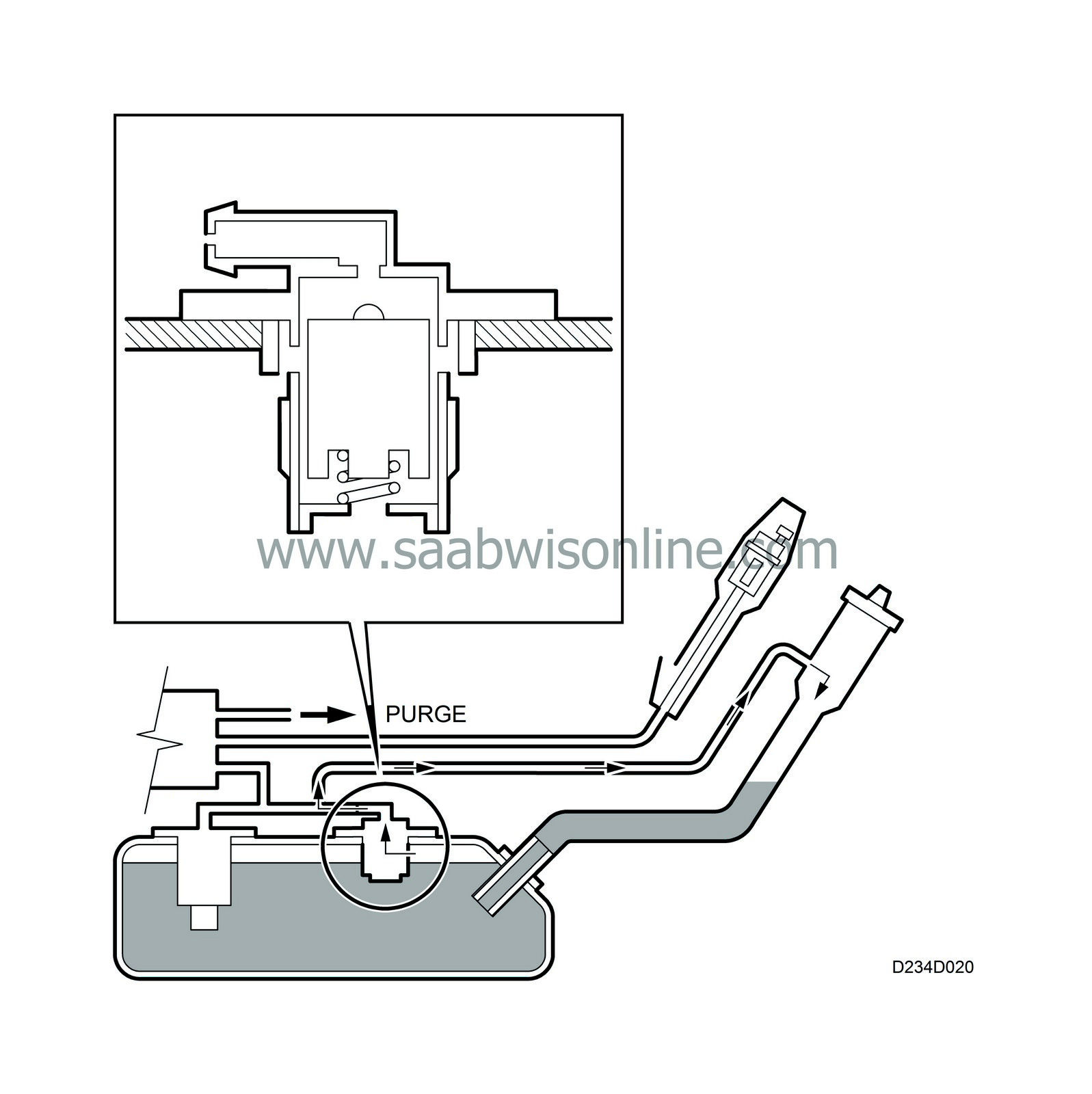

4.

|

When the tank is almost full (approx. 95 %), the float valve closes to its first step, whereby the evacuation of air and gaseous hydrocarbons is greatly restricted.

The pressure in the tank therefore gradually increases as more fuel is filled.

|

|

5.

|

Finally, the float valve closes completely and the counter-pressure in the filler pipe makes the fuel level inside it rise towards the filler nozzle to close it.

Continued refueling is not recommended.

|

|

6.

|

When the fuel nozzle has closed, the non-return valve in the end of the filler pipe will immediately stop the counterflow and prevent ”back-spit”.

|

|

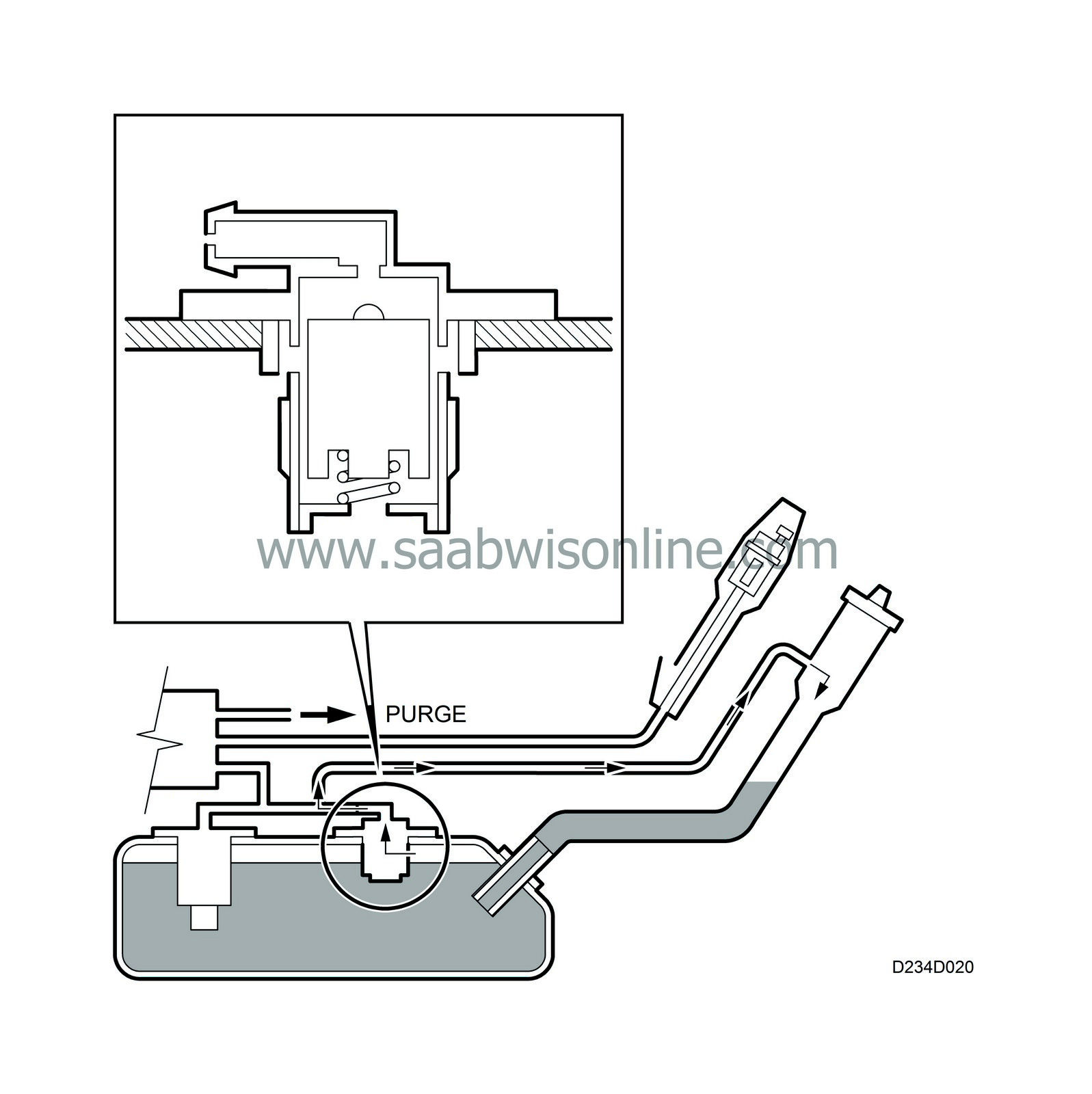

7.

|

At the top of the tank there is a rollover valve with a considerable restriction in the outlet nipple.

The level of the column of fuel that is now in the filler pipe will gradually sink as the remaining fumes are slowly evacuated through the rollover valve.

The top of the filler pipe is connected to the rollover valve to ensure that the level of the fuel column can sink even when the filler cap is fitted securely.

This connection also ensures that the EVAP diagnosis can determine whether the filler cap is secured or not.

|