Exhaust Gas Recirculation (EGR)

| Exhaust Gas Recirculation (EGR) |

With an EGR-system (Exhaust Gas Recirculation), a controlled amount of exhaust emissions are directed to the induction side where they are mixed with the induction air. The result is slower combustion at a lower temperature and maximum pressure, which in turn hampers formation of NOx.

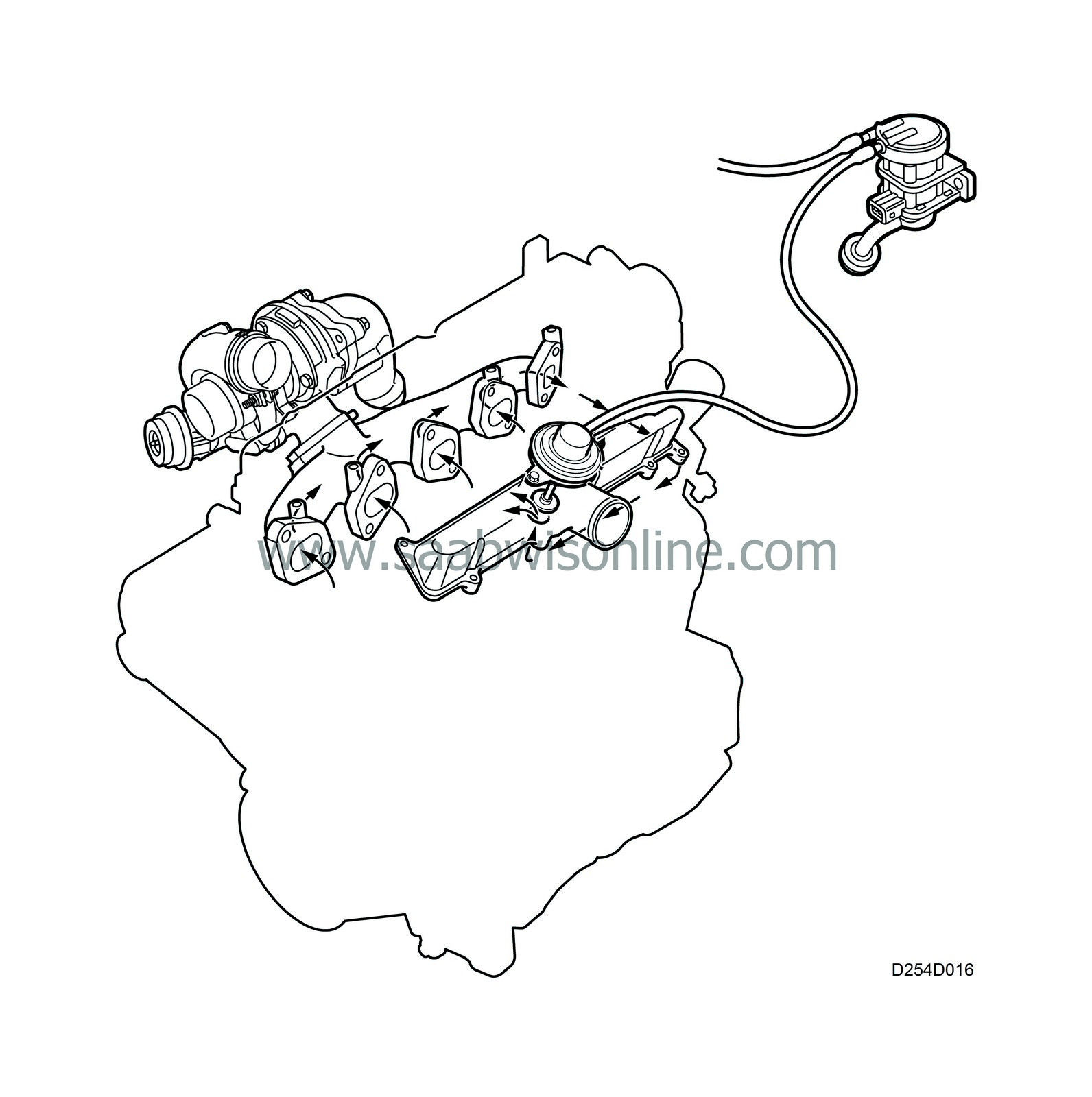

The EGR-system consists of a vacuum controlled valve which opens a connection between the exhaust manifold and the induction manifold as well as an electropneumatic valve for controlling the vacuum signal. This valve is in turn controlled by a PWM-signal from control module EDC 15, where the degree of opening and induction air-exhaust emission mixture can be controlled.

The control is initiated from the fact that a certain amount of induction air should reach the combustion chamber at each induction stroke. Control module EDC 15 calculates this value using a number of parameters where engine load, engine rpm and coolant temperature are the most important. The mass air flow sensor measures the air flow and this is balanced to the correct level using the amount of recirculated exhaust emissions. Thus, the sequence consists of an enclosed control system with the induction air mass being the controlled factor.

Having its own processor means that the EGR valve can perform self-diagnosis. If it catches or seizes for example, this is reported to the ECM with a PWM signal at 100Hz and a fault code is set. If a fault code is present for the EGR control, the engine will reduce torque and shut down the EGR and swirl functions. The Check Engine lamp will also come on.