Part of side panel, 3D

| Part of side panel, 3D |

If the roof is undamaged, the side panel can be cut and joined further down the C-pillar. Damage to the paintwork on the roof can be avoided when the new side panel is welded on.

| Important | ||

|

The C-pillar must only be cut as described below. Otherwise, there is a risk of damaging the reinforcement inside the C-pillar. |

||

| 1. |

Position the car in an aligning bench and cross-measure if necessary.

|

|

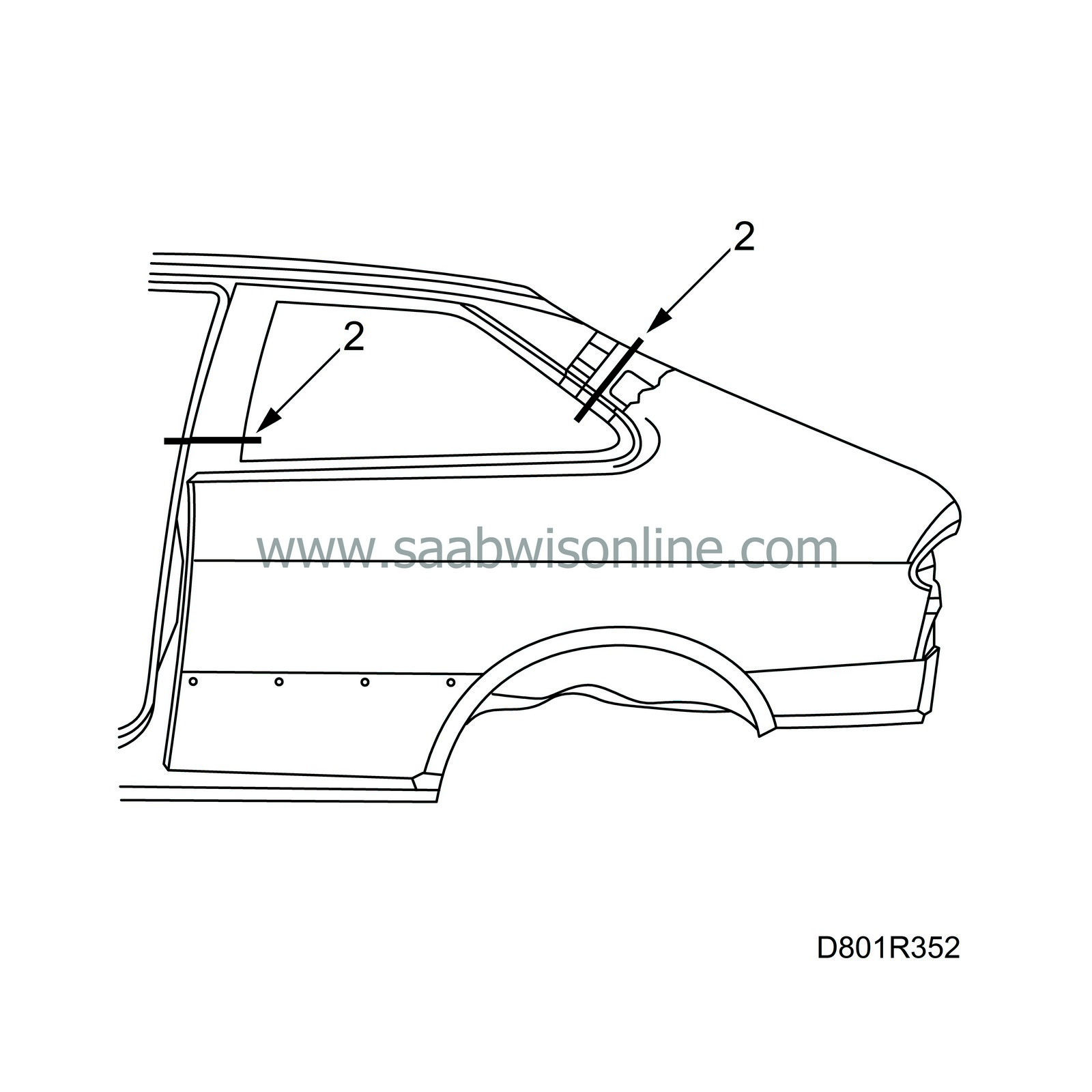

| 2. |

Cut the side panel as illustrated. Do not damage the metal underneath. The C-pillar must be cut 40 mm above the ball joint to which the gas springs are mounted.

|

|

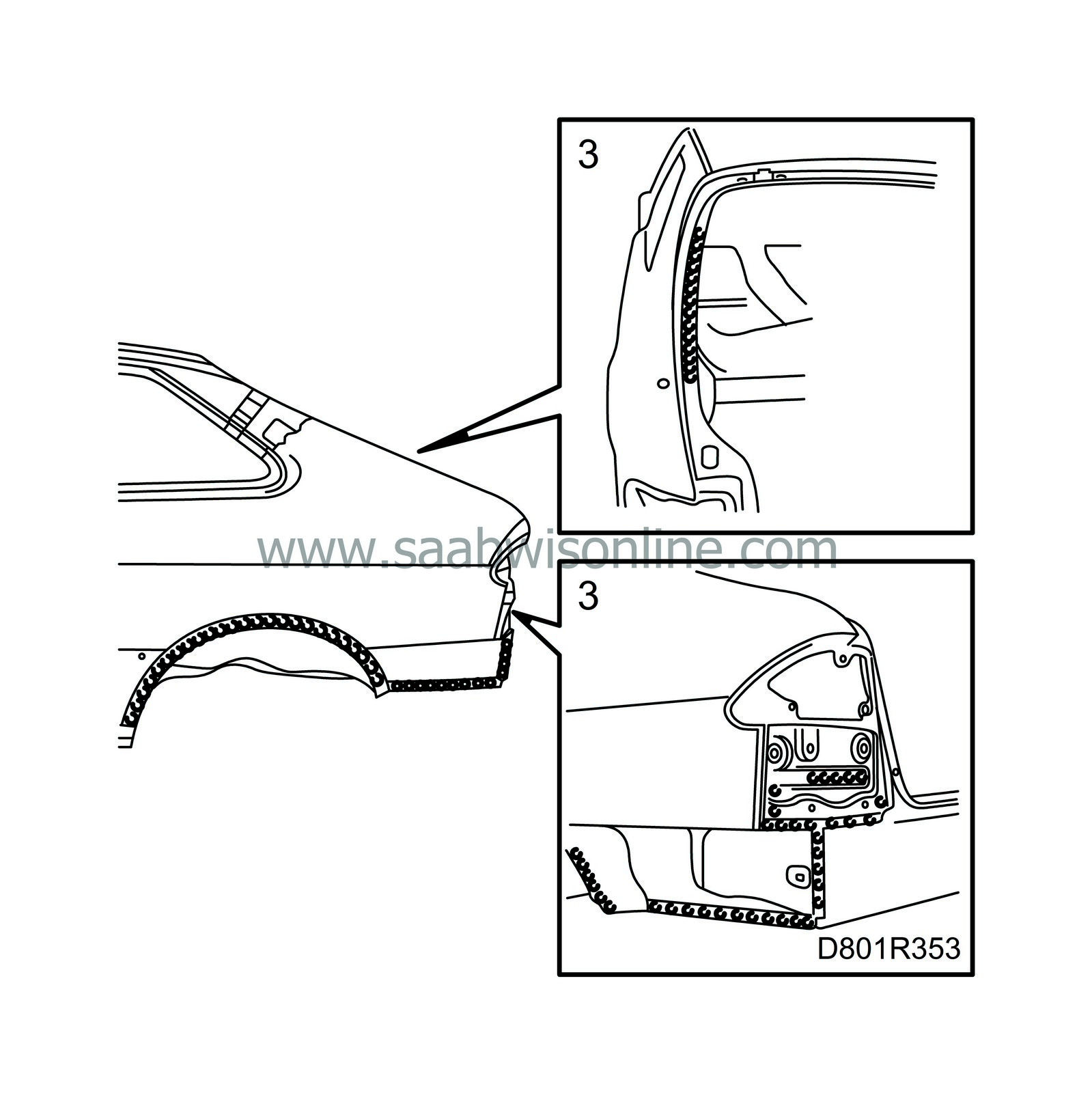

| 3. |

Drill out the spot-welds.

|

|

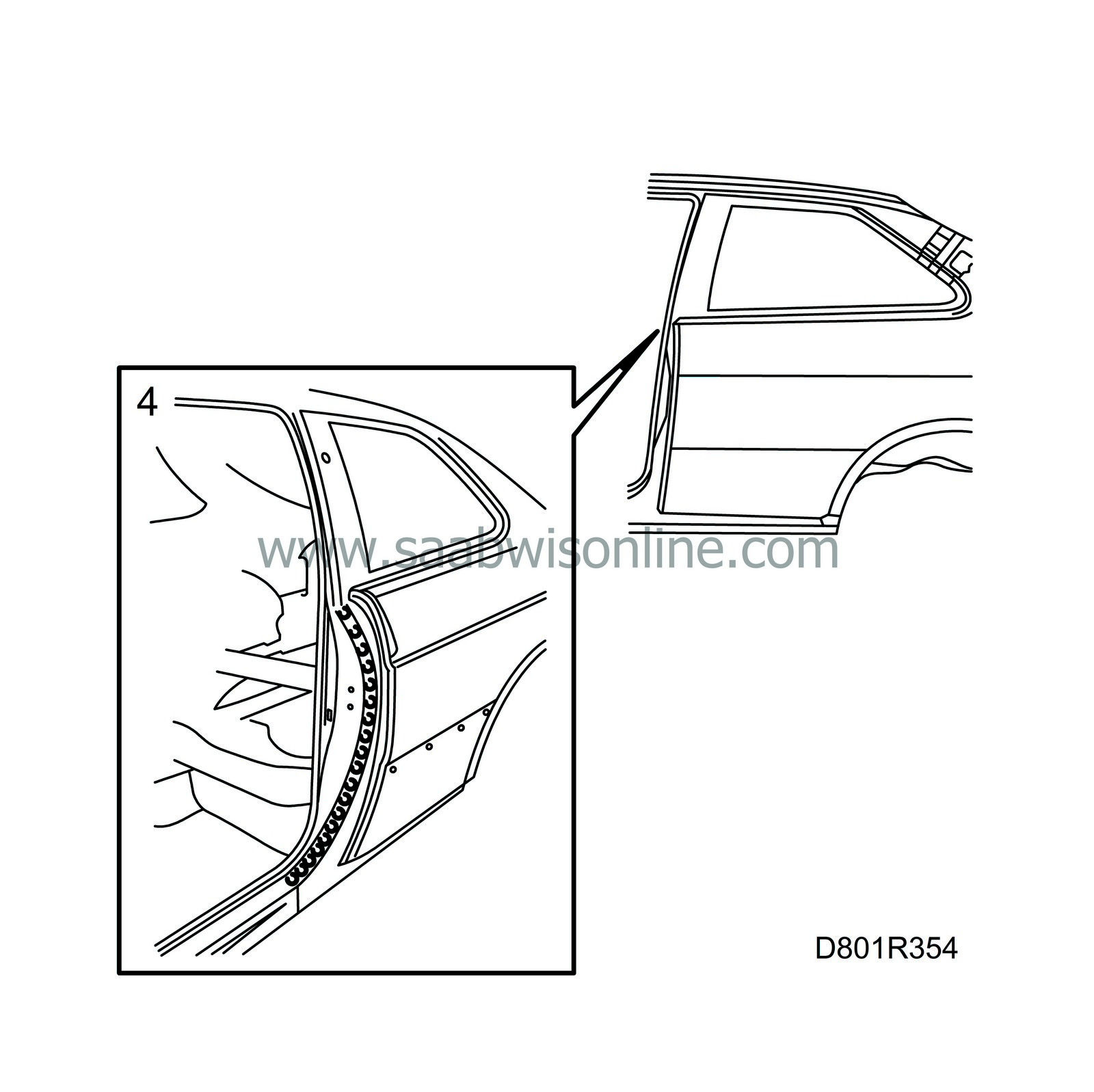

| 4. |

Drill out the spot-welds.

|

|

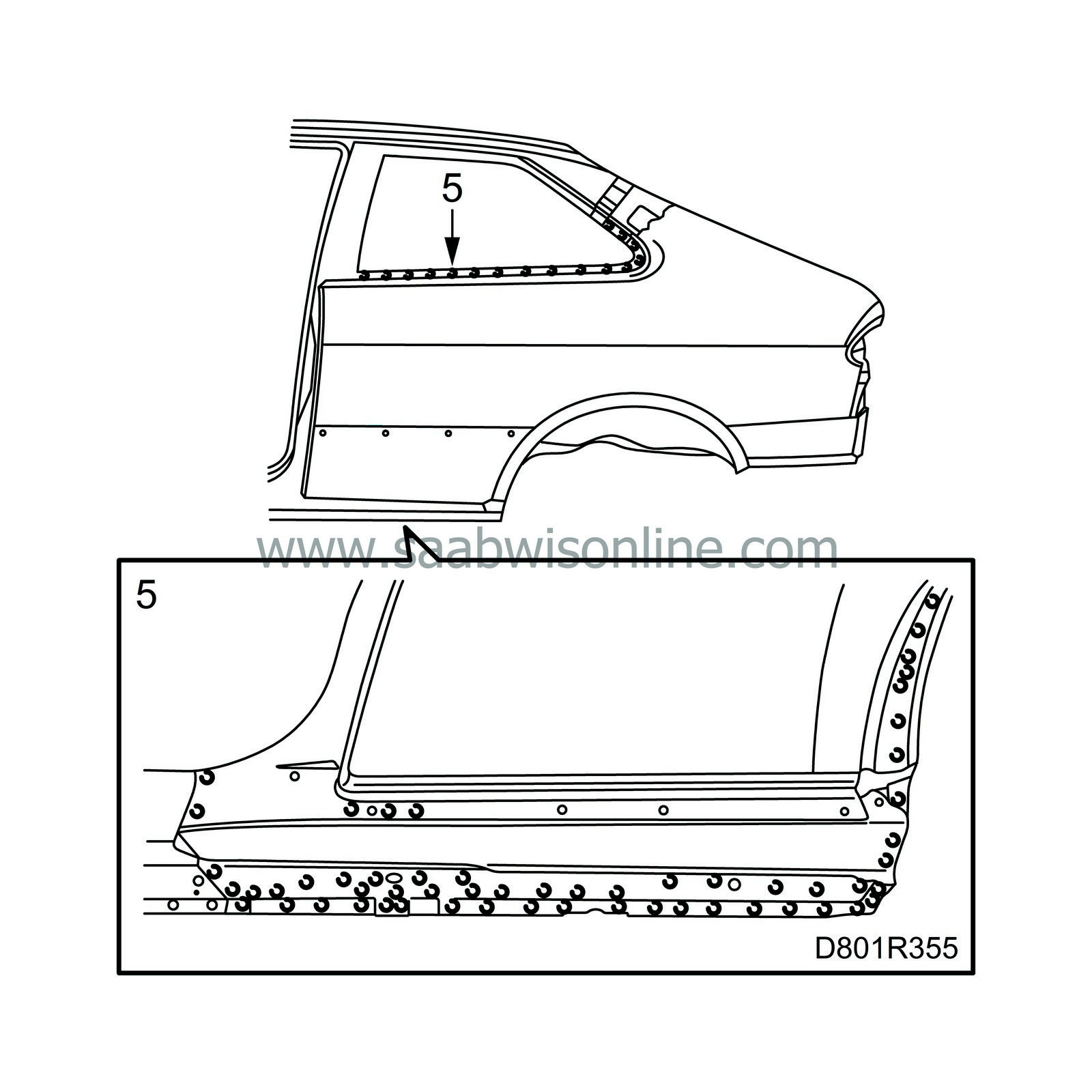

| 5. |

Drill out the spot-welds.

|

|

| 6. |

Tap loose the side panel and align deformed or damaged panels.

|

|

| 7. |

Cut the spare part so that it overlaps the joint by approximately three centimetres.

|

|

| 8. |

Drill holes for plug-welding in the spare part.

|

|

| 9. |

Fit the spare part and fit bolts through the window frame. Fixate the spare part with a couple of welding clamps.

|

|

| 10. |

Cut through the spare part and body at the same time so that the joint can be welded edge-to-edge.

|

|

| 11. |

Remove the spare part and grind clean the surfaces to be welded on the body and the spare part.

|

|

| 12. |

Apply welding primer on the surfaces to be spot-welded. Use Teroson Zinkspray.

|

|

| 13. |

Fit the spare part and fixate with a couple of welding clamps.

|

|

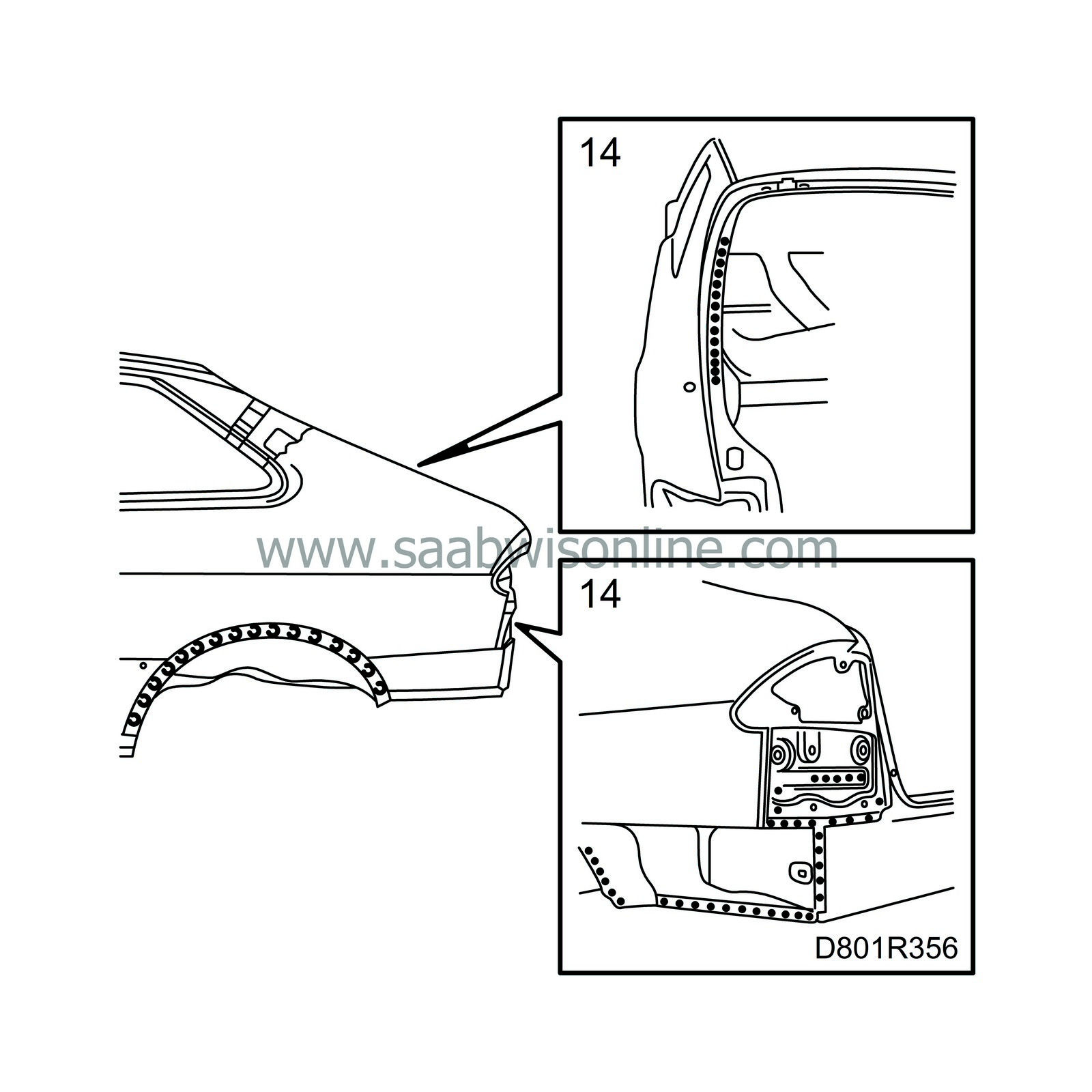

| 14. |

Spot-weld the spare part.

|

|

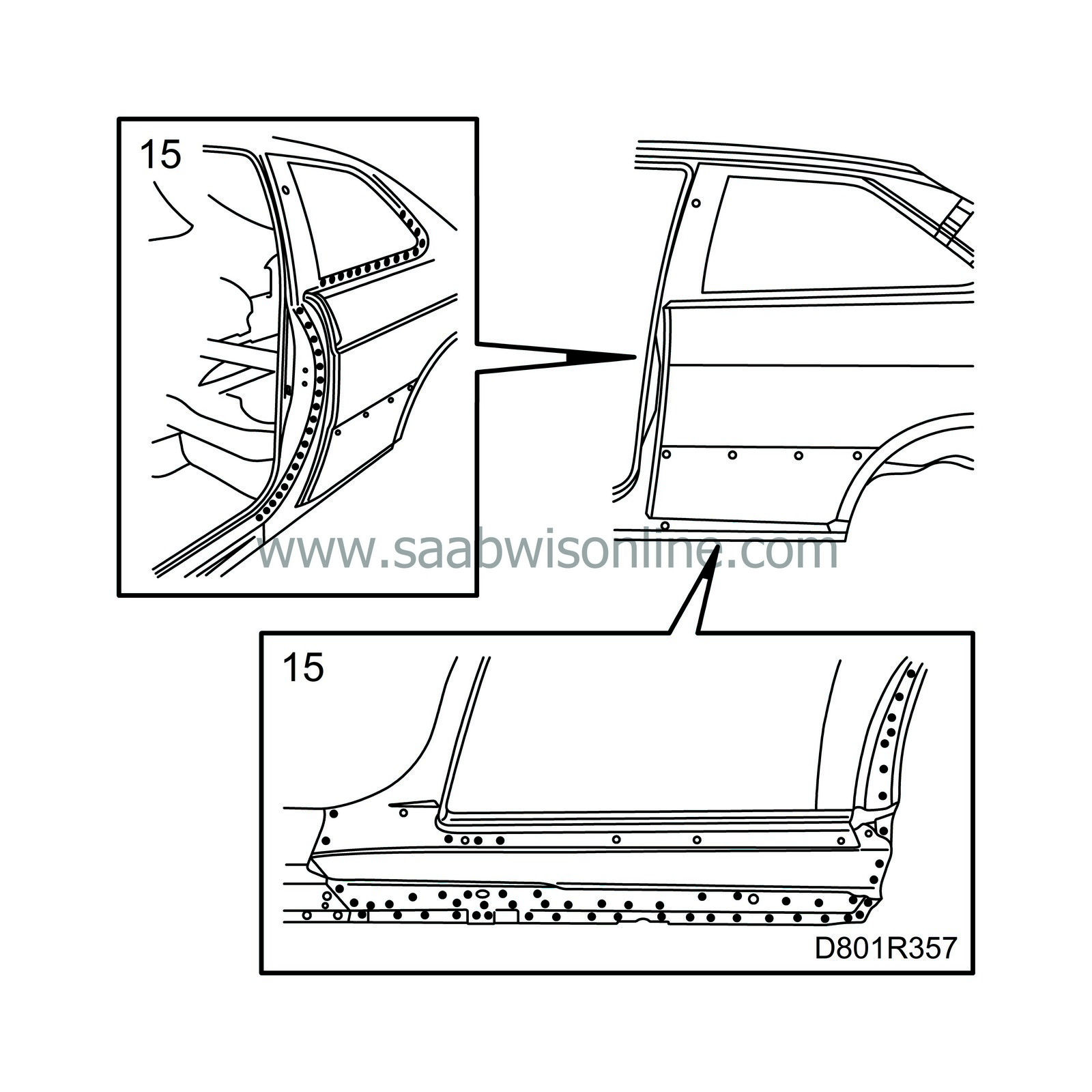

| 15. |

Spot-weld the spare part.

|

|

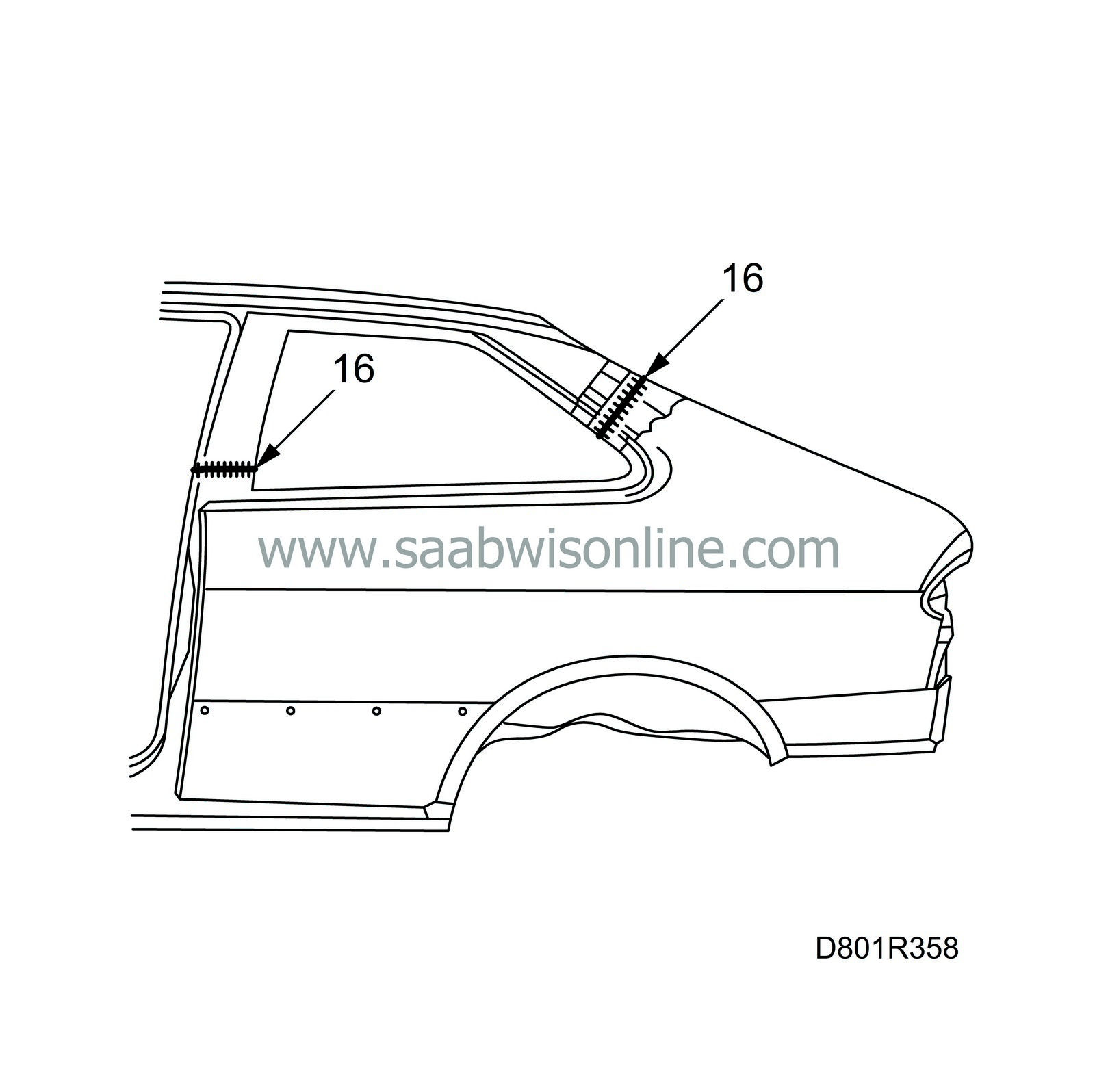

| 16. |

All-weld the joints.

|

|

| 17. |

Grind the welds.

|

|

| 18. |

Remove any remaining welding primer. Welding primer reduces adhesion of paint, filler and sealant.

|

|

| 19. |

Apply primer to all ground surfaces. Use Standox 1K Primer.

|

|

| 20. |

Seal joints and sheet metal flanges with sealant. Use Terostat 1K-PUR.

|

|

| 21. |

Apply anti-corrosion agent to the interior of the side panel. Use Terotex HV 400 or Mercasol 1.

|

|