Checking for leaks in the evaporative emission system

|

|

Checking for leaks in the evaporative emission system

|

|

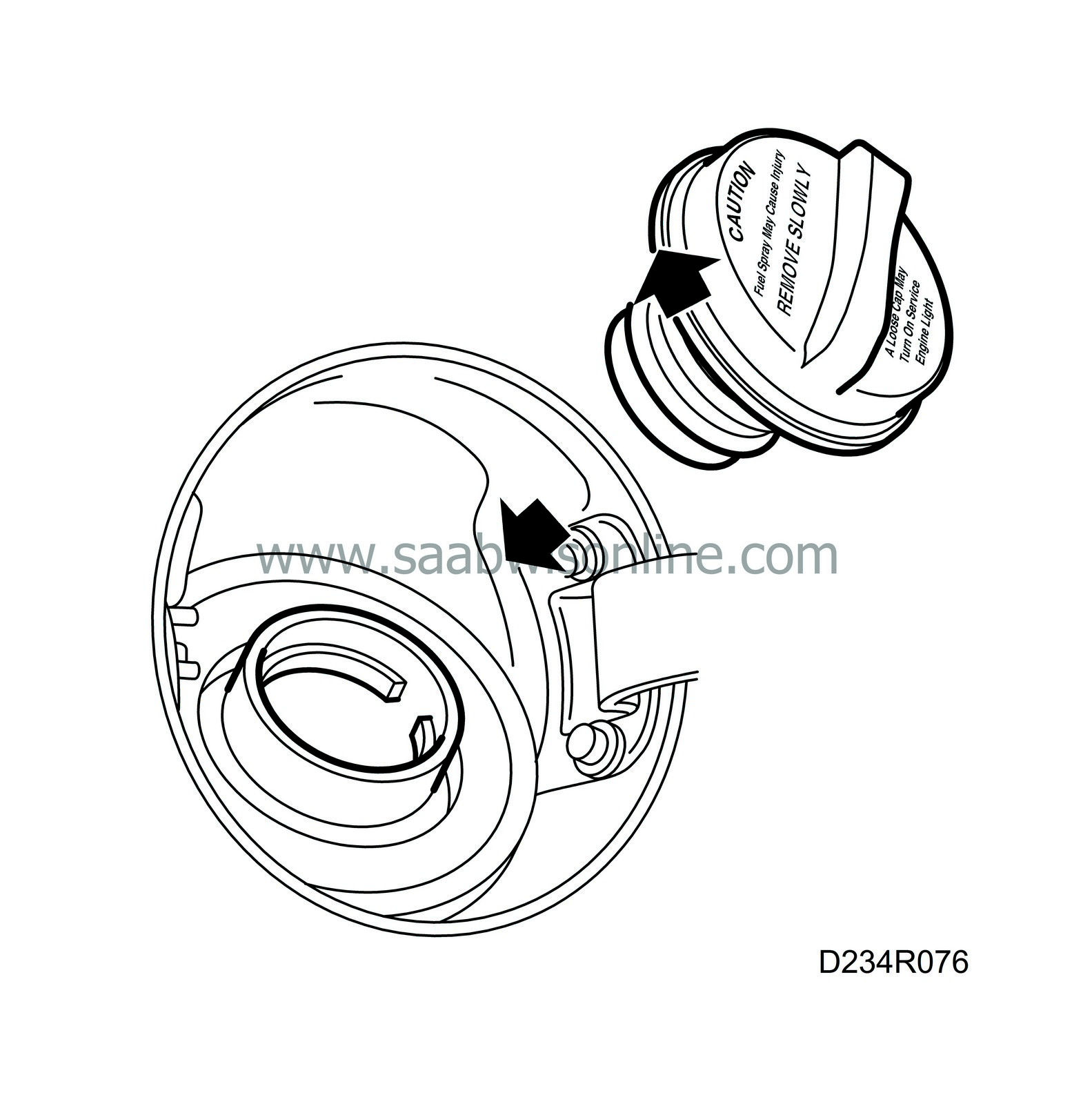

1.

|

The shut-off valve must still be activated.

|

|

2.

|

Detach the line from the purge valve on the intake manifold.

|

|

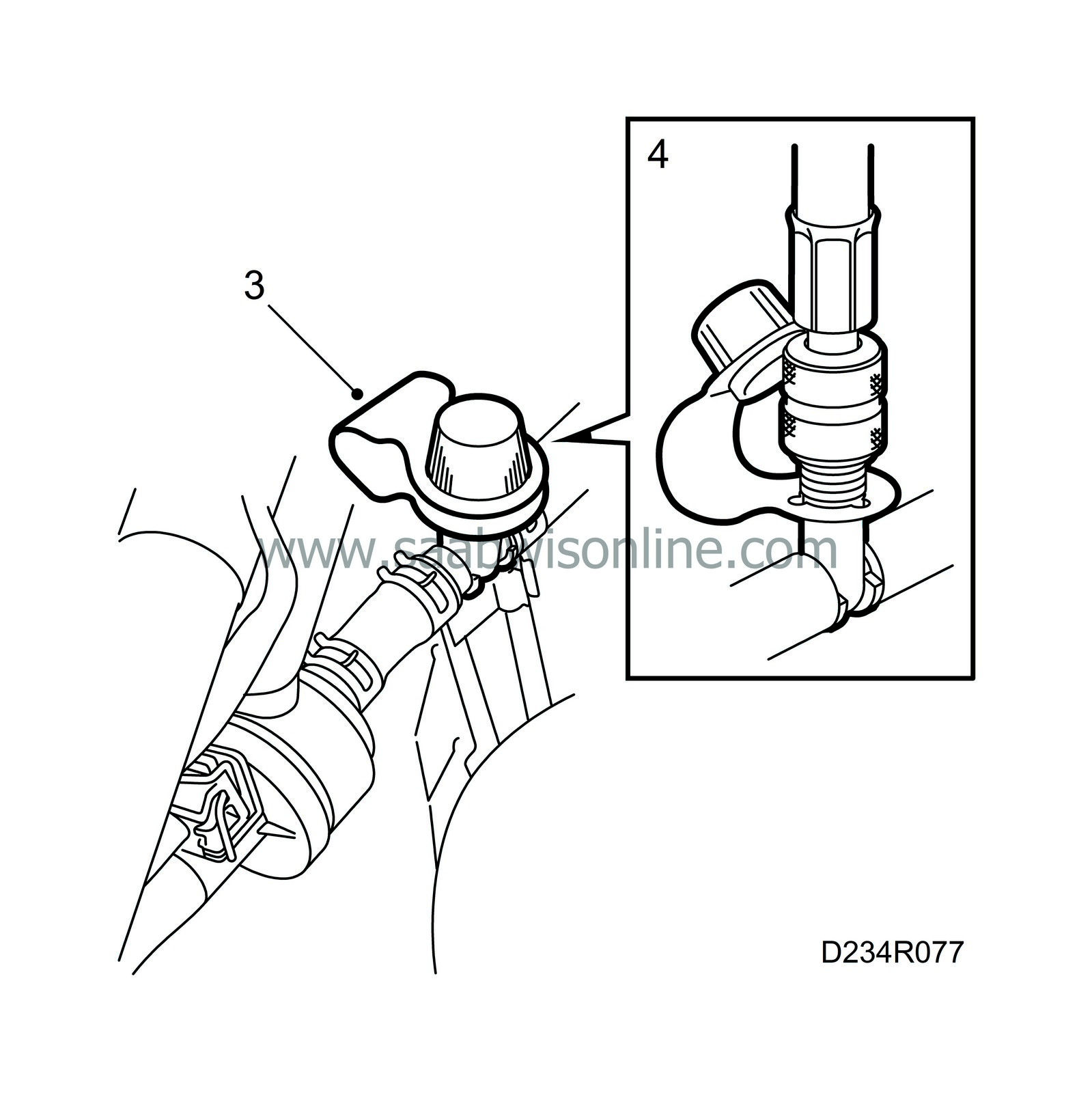

3.

|

Pressurize the system further as described in the Kent-Moore instruction manual.

|

|

4.

|

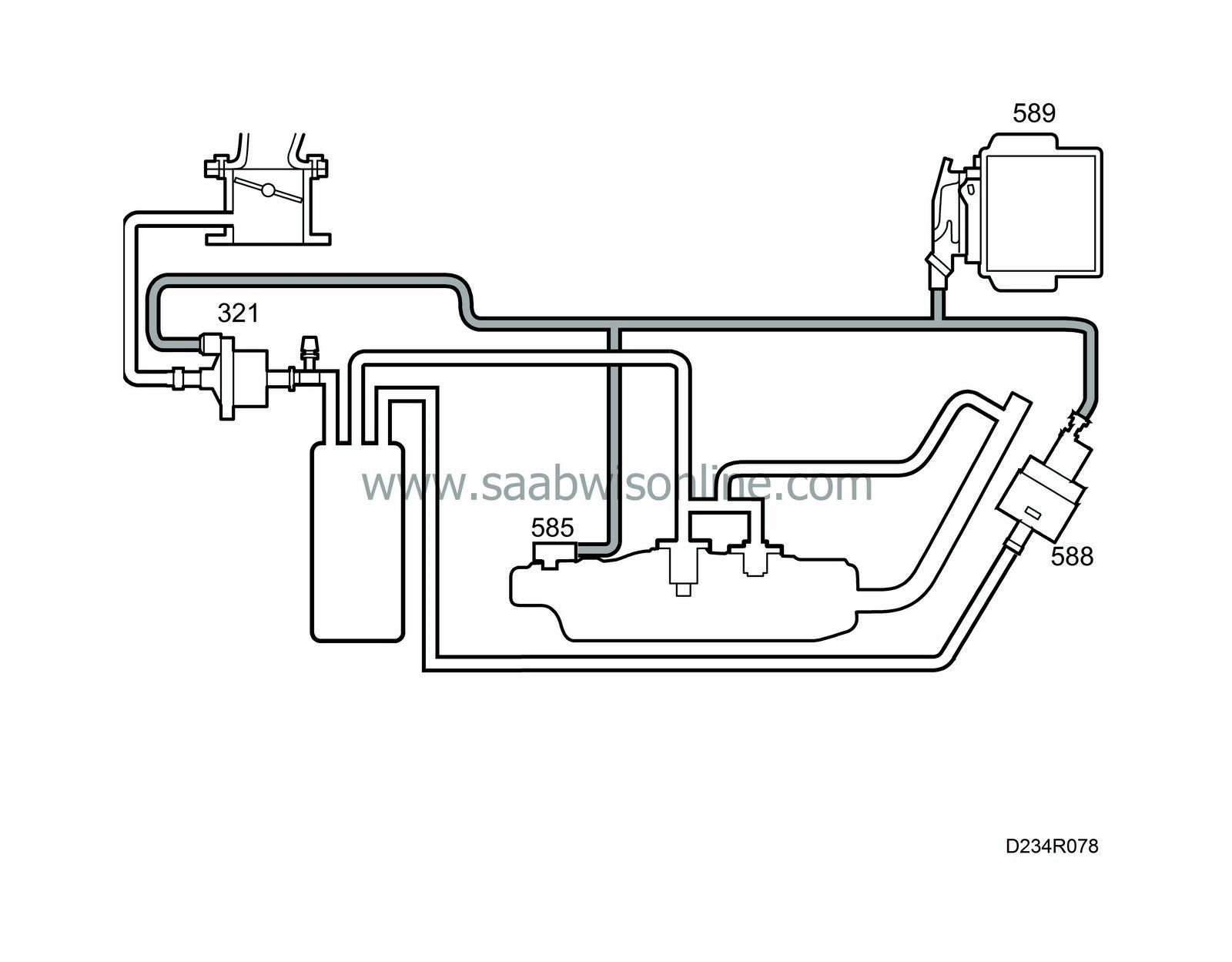

Detect the leak with the Ultrasonic Leak Detector J41416. Start from the line detached from the intake manifold and work through the lines and components in the system. Perform a visual inspection at the same time.

|

Note

|

|

It may be necessary to lower the tank slightly to be able to check for possible leaks in the components on top of the tank.

|

|

Note

|

|

The ultrasonic leak detector is sensitive to ambient noise such as exhaust extractors, pneumatic machines, air nozzles, leaking pneumatic connections, etc.

|

|

The workshop ventilation system can create currents of air that can also affect the equipment.

|

|

Everything mentioned above can cause a similar, but incorrect, result/detection as a leaking EVAP system.

|

|

|

5.

|

Adjust the sensitivity of the detector to filter out ambient, in many cases, interfering noise.

|

Note

|

|

Major leaks such as a defective shut-off valve or loose hose are difficult to detect as they do not have the ”right sound” to be detected by the ultrasonic leak detector.

|

|

Therefore, it is important to perform a visual inspection and component check of the system if there is a very quiet leak.

|

|

|

6.

|

When the leak has been detected and rectified, check the integrity of the system again.

|

|

7.

|

Restore the care to its original state.

|

.

.