(248-2306) Improved fault diagnosis P0314

Symptom: CHECK ENGINE lamp on

Lower performance

Limp home.

|

SERVICE INFORMATION

|

|

Bulletin Nbr:

|

248-2306

|

|

Date:

...........

|

Oktober 2001

|

|

Market:

|

enligt separat lista

|

|

|

Improved fault diagnosis P0314

|

Saab 9-3 with diesel engine and chassis number 12020001 -

This SI supplements the regular fault diagnosis for diagnostic trouble code P0314 in order to find the causes of the most regular faults more easily. This SI is designed so that diagnostic procedure starts at point 1 and continues until the problem is solved.

The following criteria apply to the DTC in question:

The diagnosis has detected a sufficiently large enough number of misfires during a cycle of 60 and 120 combustions respectively.

The diagnosis is carried out between 1100-2300 RPM with more than 8mg of fuel and between 2600-4800 with more than 15mg of fuel.

The coolant temperature must be 60

°

C and higher.

Symptoms

|

1.

|

Connect the diagnostic instrument and turn the ignition key to the ON position.

|

|

2.

|

If diagnostic trouble code P0314 is set, check with the diagnostic instrument if misfiring exists, and if so in which cylinder.

|

|

3.

|

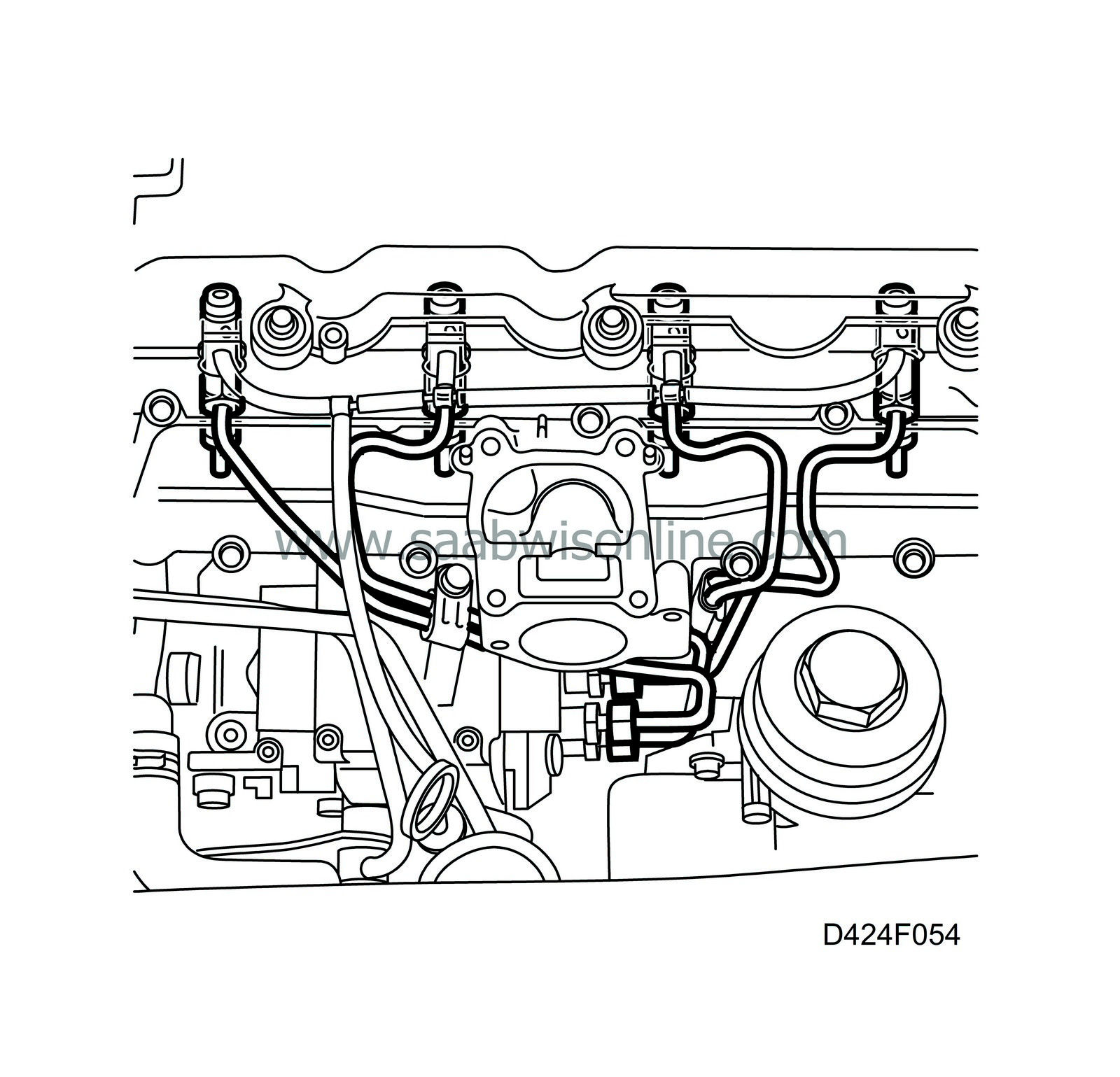

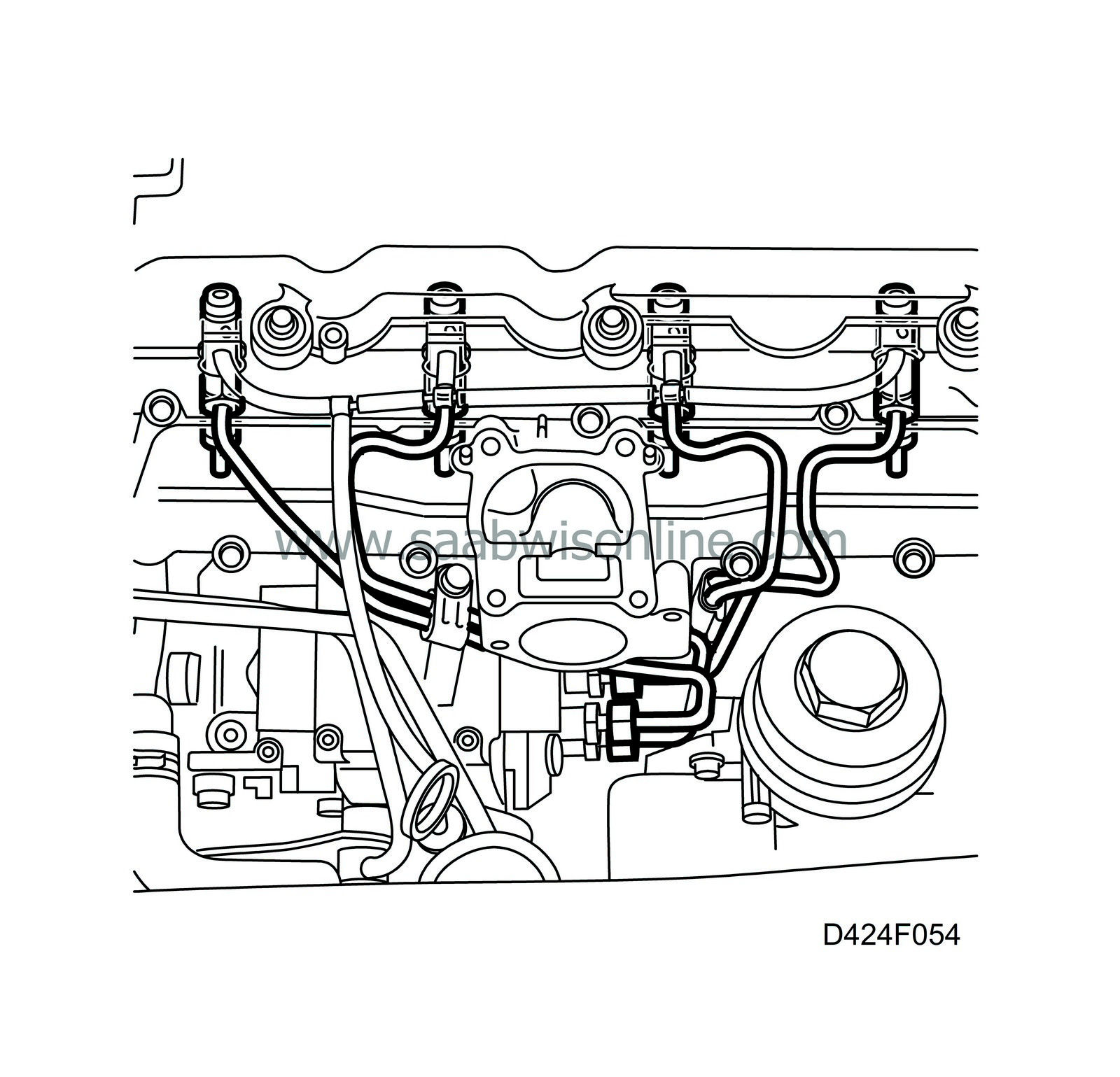

Start the engine and increase the revolutions to 2000 rpm. Check that external leakage does not occur in the fuel system. Check lines and connections. Switch off the engine. Rectify any leaks. If the fault persists, continue with the next point.

|

|

4.

|

Carry out a compression test on the cylinder concerned as described under Standard engine - Adjustment / Replacement - Checking engine compression. Is the compression correct? (32 - 36 bar. Max variation between cylinders ±10%). If

YES,

continue from point 7.

|

|

|

5.a.

|

Remove the camshaft cover, see Basic engine - Adjustment / Replacement - Camshaft cover.

|

|

|

5.b.

|

Check the valve mechanism and valve bridges for damage.

|

|

|

5.c.

|

Check the fuel bridges for leaks. Check that it is correctly fitted. See Fuel system (diesel) - Adjustment / Replacement - Fuel bridge.

|

|

|

5.d.

|

Remove the cylinder head and check if the intake or exhaust valves are damaged. Carry out leakage checks of the valves as described under Basic engine - Adjustment / Replacement - Valve leakage check. Change if necessary according to Basic engine - Adjustment / Replacement - Valve mechanism.

|

|

|

5.e.

|

Check if the cylinder bore and pistons are damaged. If necessary, rectify the faults. Refit the cylinder head.

|

|

6.

|

Carry out the final inspection according to the fault diagnosis schedule for diagnostic trouble codes.

|

|

|

7.a.

|

Drain the fuel filter to see if the fuel is contaminated. If necessary, clean the fuel tank and blow clean the fuel lines, see Fuel system - Adjustment / Replacement - Fuel tank.

|

|

|

7.b.

|

Check fuel low pressure according to the instructions in SI 210-2148, under section B - Suction line to tank.

|

|

|

7.c.

|

Remove the camshaft cover, see Basic engine - Adjustment / Replacement - Camshaft cover.

|

|

|

7.d.

|

Check the fuel bridges for leaks. Check that it is correctly fitted. Rectify any leaks.

|

|

|

7.e.

|

Check the fuel lines for leaks, both delivery and return. Rectify any leaks.

|

|

|

7.f.

|

Change the injection valves where the misfiring exists, see Fuel system, diesel - Adjustment / Replacement - Injection valves. Refit the camshaft cover.

|

|

8.

|

Carry out the final inspection according to the fault diagnosis schedule for diagnostic trouble codes.

|