EGR valve, exhaust gas recirculation

| EGR valve, exhaust gas recirculation |

The engine is equipped with a water-cooled, electrically controlled EGR valve, which leads some of the engine exhaust to the intake manifold. The exhaust gases lower the temperature in the combustion chamber, thus reducing the build-up of nitrous oxide. The EGR valve has its own processor that knows at each moment how much the valve is open. This leads to a short control time when the PSG 16 control module sends a request for a specific EGR condition. This also allows for quick modification of the valve's open position, which helps keep the combustion temperature as low as possible.

| • |

If an EGR-related DTC is generated, engine torque is reduced and the CHECK ENGINE lamp lights.

|

|

| • |

The EGR valve closes after 1 minute of idling to counteract soot build-up.

|

|

| • |

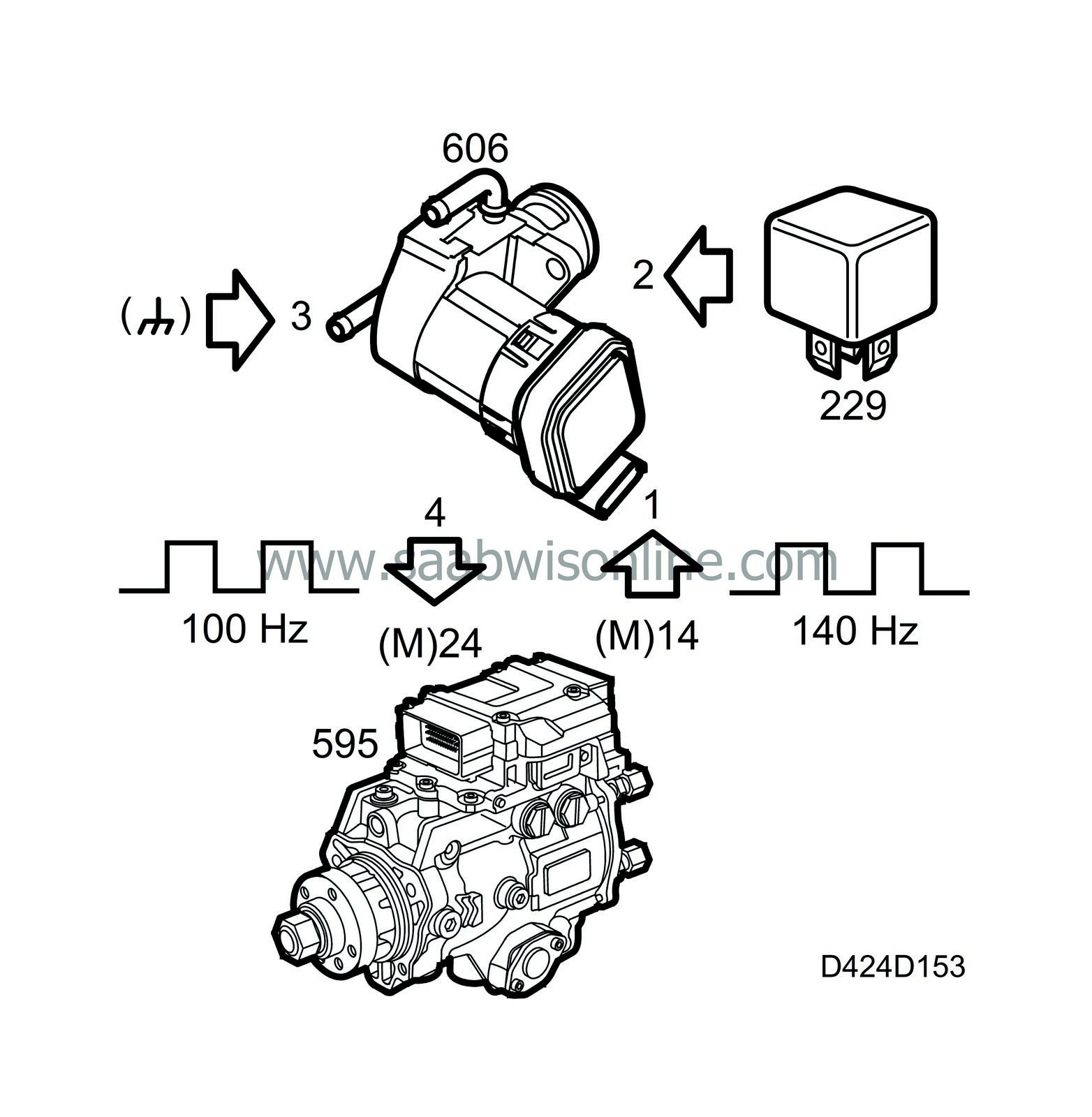

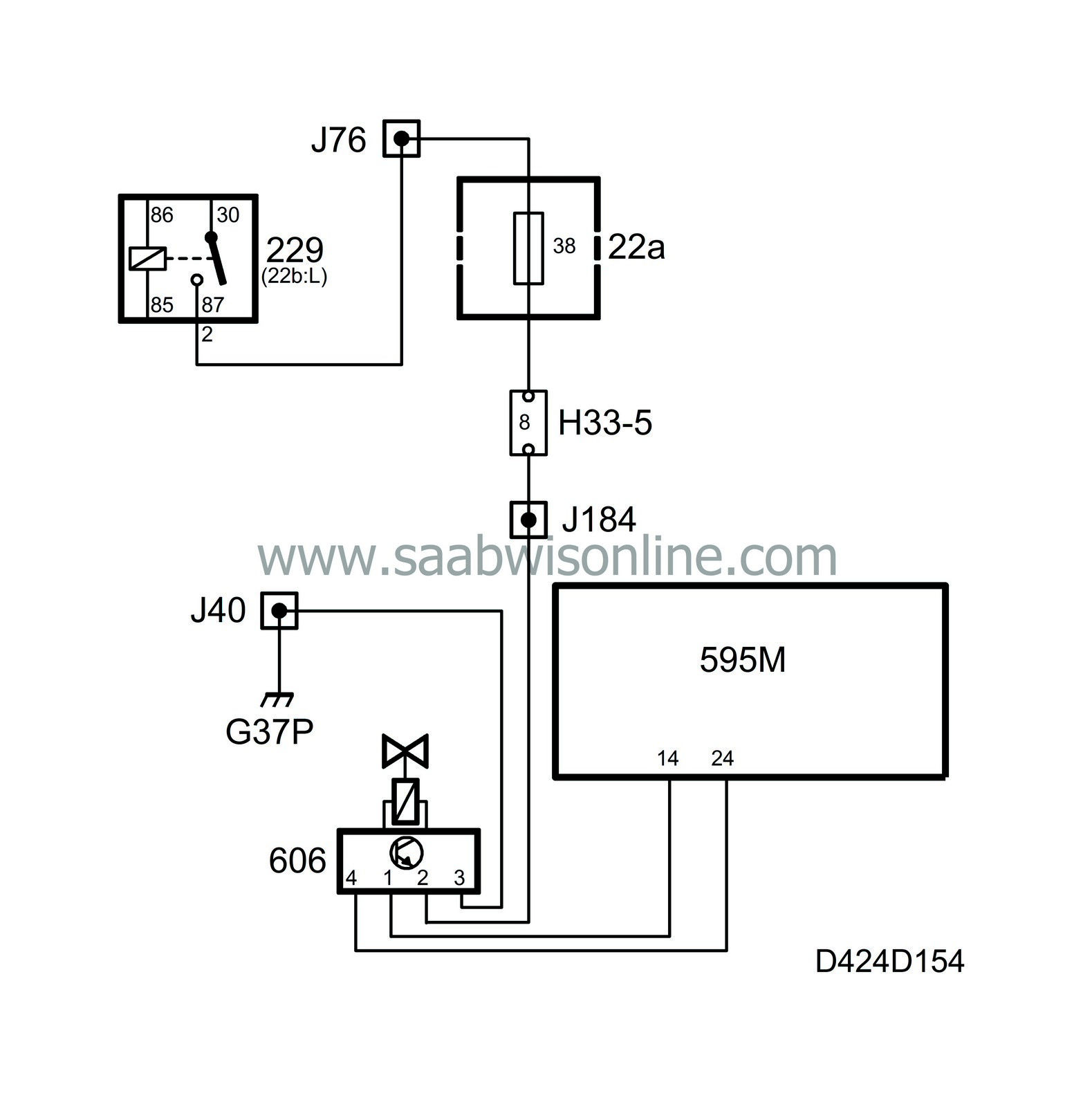

EGR valve Pin 1 receives the PWM signal at 140 Hz.

|

|

| • |

EGR valve Pin 2 has B+ voltage via fuse 38.

|

|

| • |

EGR valve Pin 3 is grounded from grounding pint G37P.

|

|

| • |

The EGR valve data link pin 4, PWM 100 Hz from EGR, is connected to pin M24 on the engine control module.

|

|

| EGR system function |

The EGR function comprises three sub-functions:

| • |

Desired value calculation

|

|

| • |

Air mass calculation

|

|

| • |

EGR control and monitoring

|

|

| Desired value calculation |

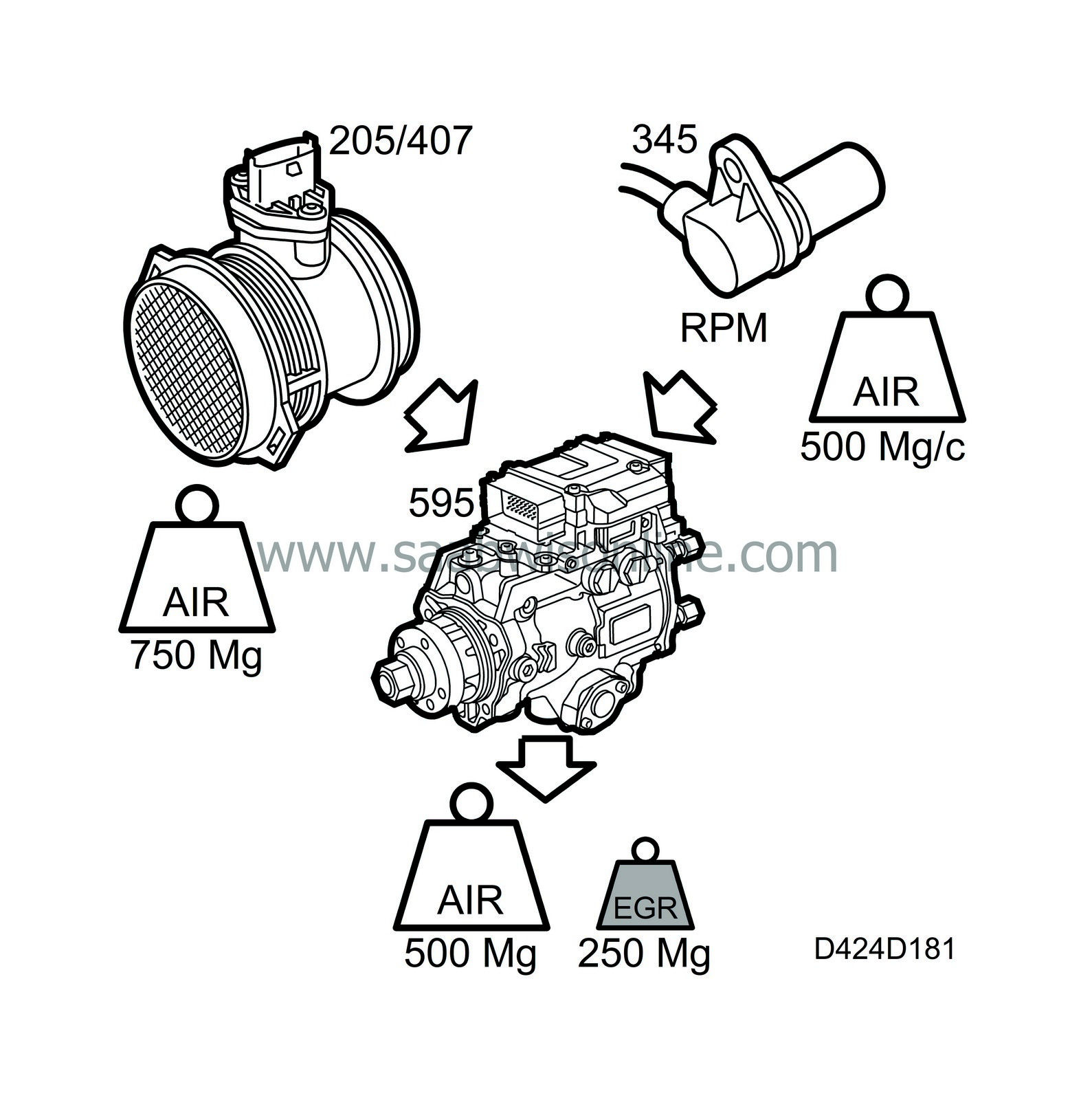

Desired value calculation determines how much air mass/combustion the engine needs at each moment. The control function regulates the EGR valve so as to attain the desired amount of air. Recirculated exhaust gas is released into the intake in the amount needed to reduce the intake air mass/combustion to the value determined by the desired value calculation.

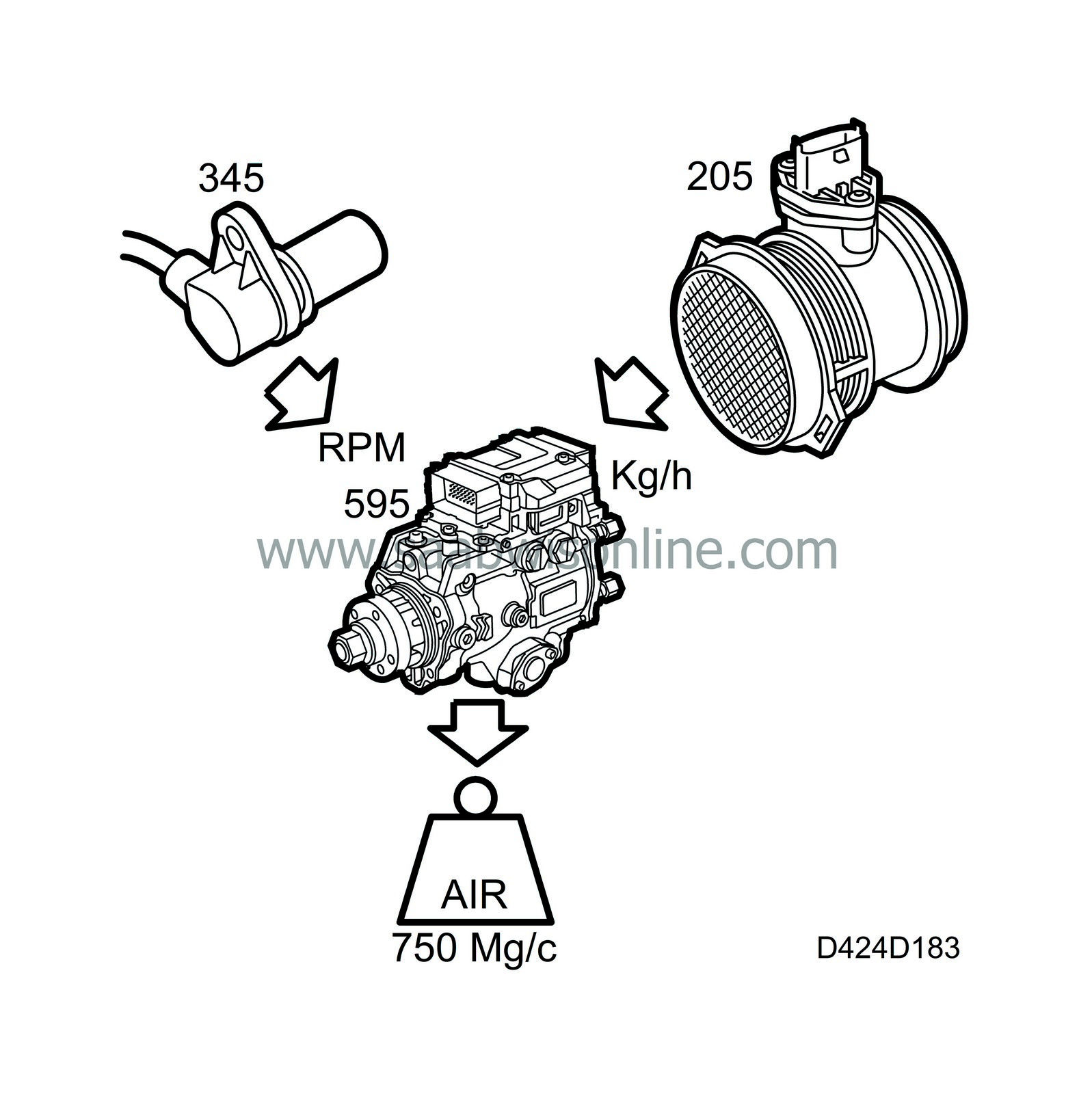

Example

At a certain moment, the engine can pump through 750 mg air/combustion.

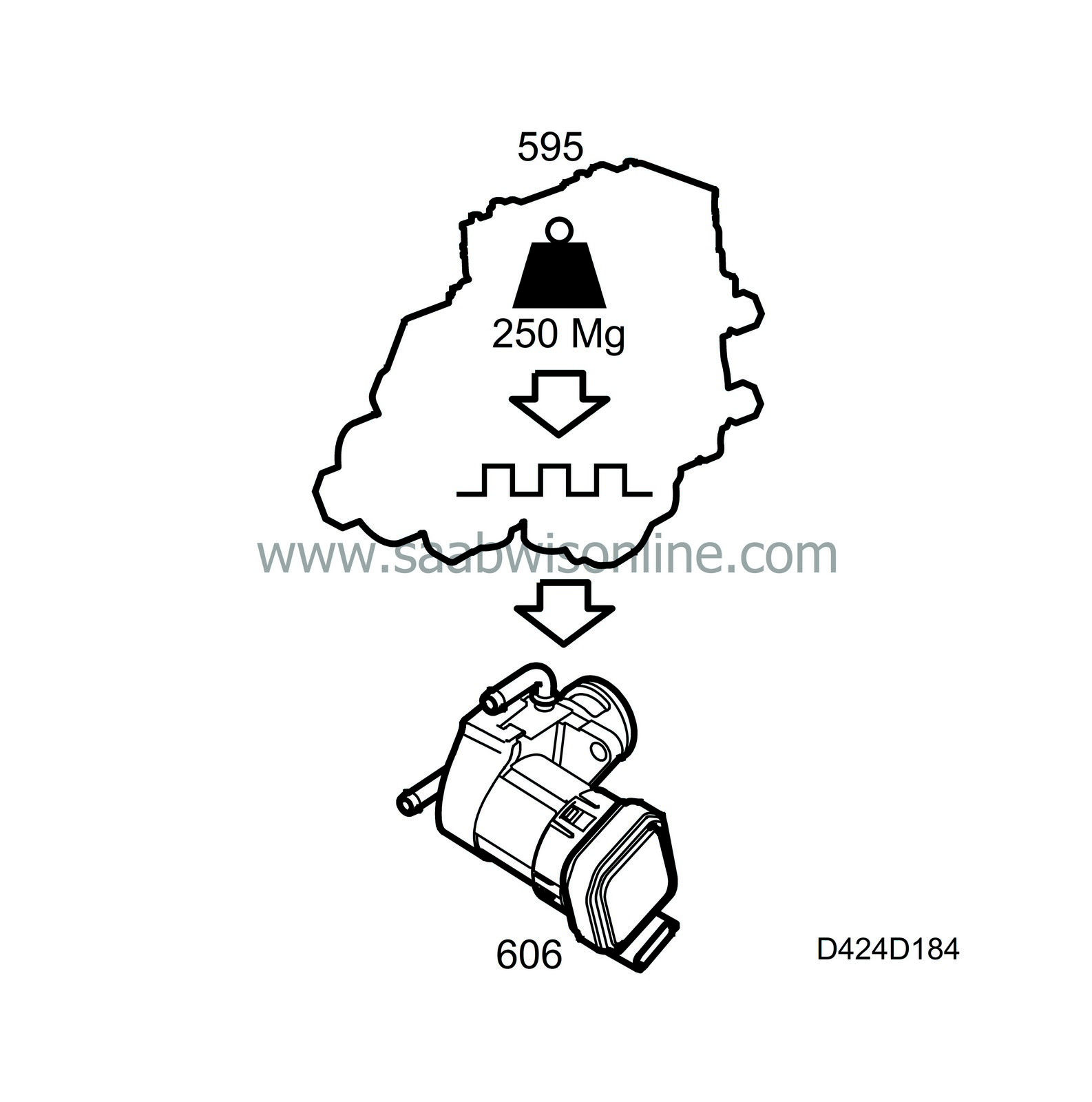

The desired value calculation says that it should be 500 mg air/combustion for these particular operating conditions. The control function will then open the EGR valve to allow just enough exhaust gas to enter to prevent 250 mg air/combustion from entering the engine.

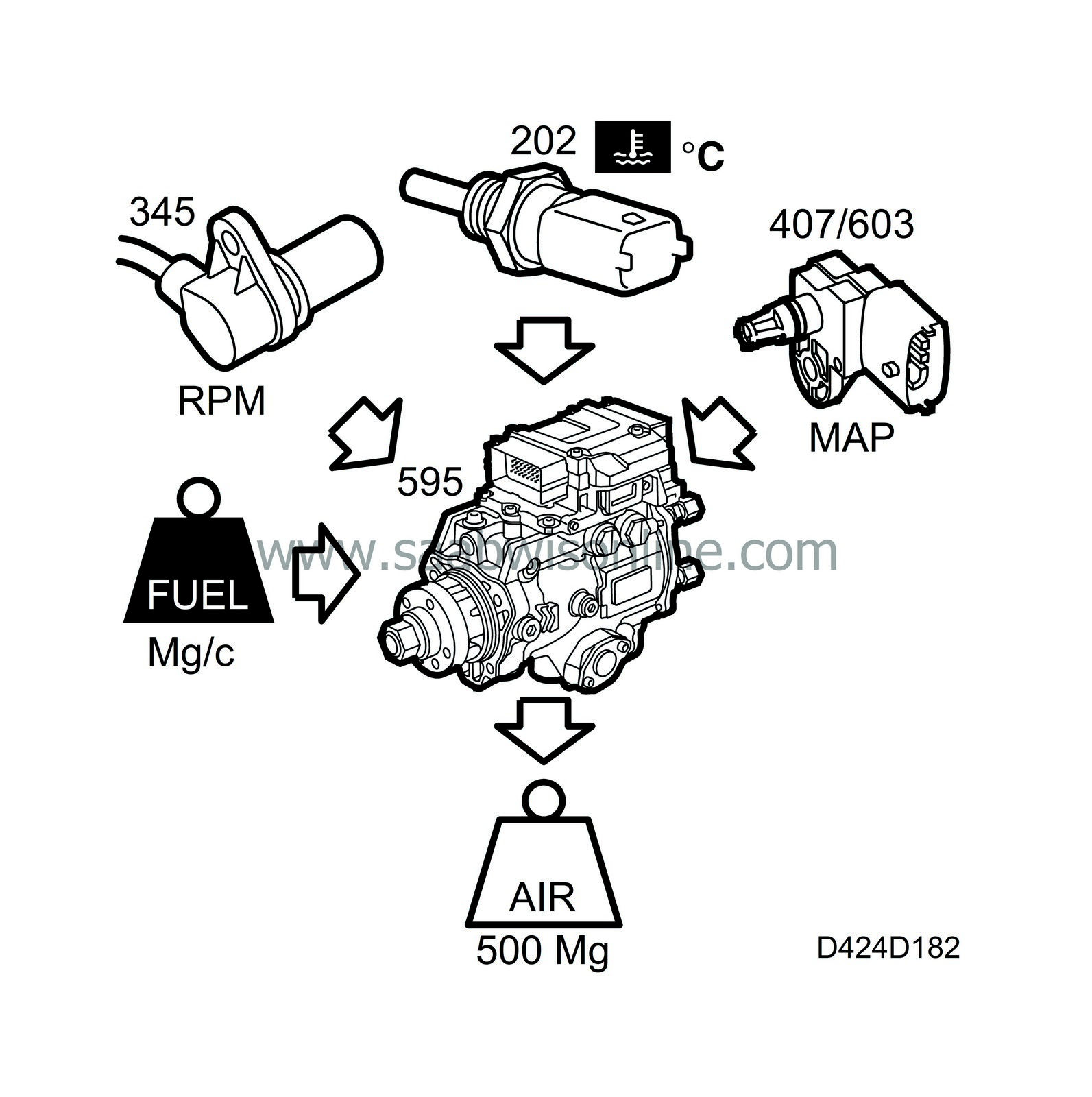

The desired value calculation determines the desired air mass/combustion and makes it available for the other EGR functions. The desired value is a function of

| • |

Engine RPM

|

|

| • |

Injected fuel quantity

|

|

| • |

Coolant temperature

|

|

| • |

Atmospheric pressure

|

|

The result of the desired value calculation is carried forward to EGR control.

| Air mass calculation |

Engine speed, intake air mass from the mass air flow sensor, and air temperature in the mass air flow sensor are the variables used to calculate what is available for combustion.

The signal from the mass air flow sensor is filtered and the measured value is converted to kg/h to mg/combustion

When air mass is converted to mg/combustion, a plausibility check is done by comparing engine speed with intake air mass. Information on intake air mass/combustion is made available for fuel quantity calculation.

| EGR control |

The EGR valve has its own processor, which knows how much the valve is open. Therefore, when a 140 Hz signal comes, the control reacts very quickly. Since the valve has an internal processor, it also has internal diagnostics. The valve sends information back to the engine control module on the same lead from which it receives an order. The signal from the valve to the control module is a 100 Hz PWM signal. When the EGR valve cannot fulfil the request, it informs PSG 16. The EGR control is disengaged after 1 minute idling to prevent the development of smoke in the exhaust. The EGR valve is completely closed when the value in Tech 2 is 95%.

System reaction to a fault

| • |

DTC will be generated and PSG 16 will limit the torque to the engine.

|

|

| • |

Power reduction through reduced torque.

|

|

| • |

The control functions for EGR, swirl throttle and charge air are disengaged.

|

|

| Diagnosis |

If control deviation is more than 20% from the requested EGR position for 3 seconds, DTC P0400 will be generated.

If the exhaust flow through the EGR valve is so low that there was a control deviation of more than 75 mg air/combustion for longer than 7.5 seconds, DTC P0401 will be generated.

If the exhaust flow through the EGR valve is so high that there was a control deviation of more than 75 mg air/combustion for longer than 7.5 seconds, DTC P0402 will be generated.

If the EGR circuit is short-circuited to ground for more than 0.6 seconds, DTC P0403 will be generated.

If the EGR circuit is short-circuited to B+ for more than 0.6 seconds, DTC P0404 will be generated.

If there is an electric fault in the circuit between pin 24 on the control module and pin 4 on the EGR valve due to short-circuit to ground or a break and the feedback signal EGR is less than 5% PWM for more than 0.6 seconds, DTC P0405 will be generated.

If there is a fault in the circuit between control module pin M24 and EGR valve pin 4, DTC P0406 will be generated. The fault refers to short-circuit to B+ (constant high).

If the feedback signal is incorrect, DTC P0409 is generated.

Upon internal fault in the EGR valve, DTC P1400 is generated.

Upon break in the EGR circuit for more than 0.6 seconds, P1404 is generated.