Idle speed control

| Idle speed control |

Idle speed control comprises two sub-functions:

| - |

desired value, idling speed

|

|

| - |

idle speed control

|

|

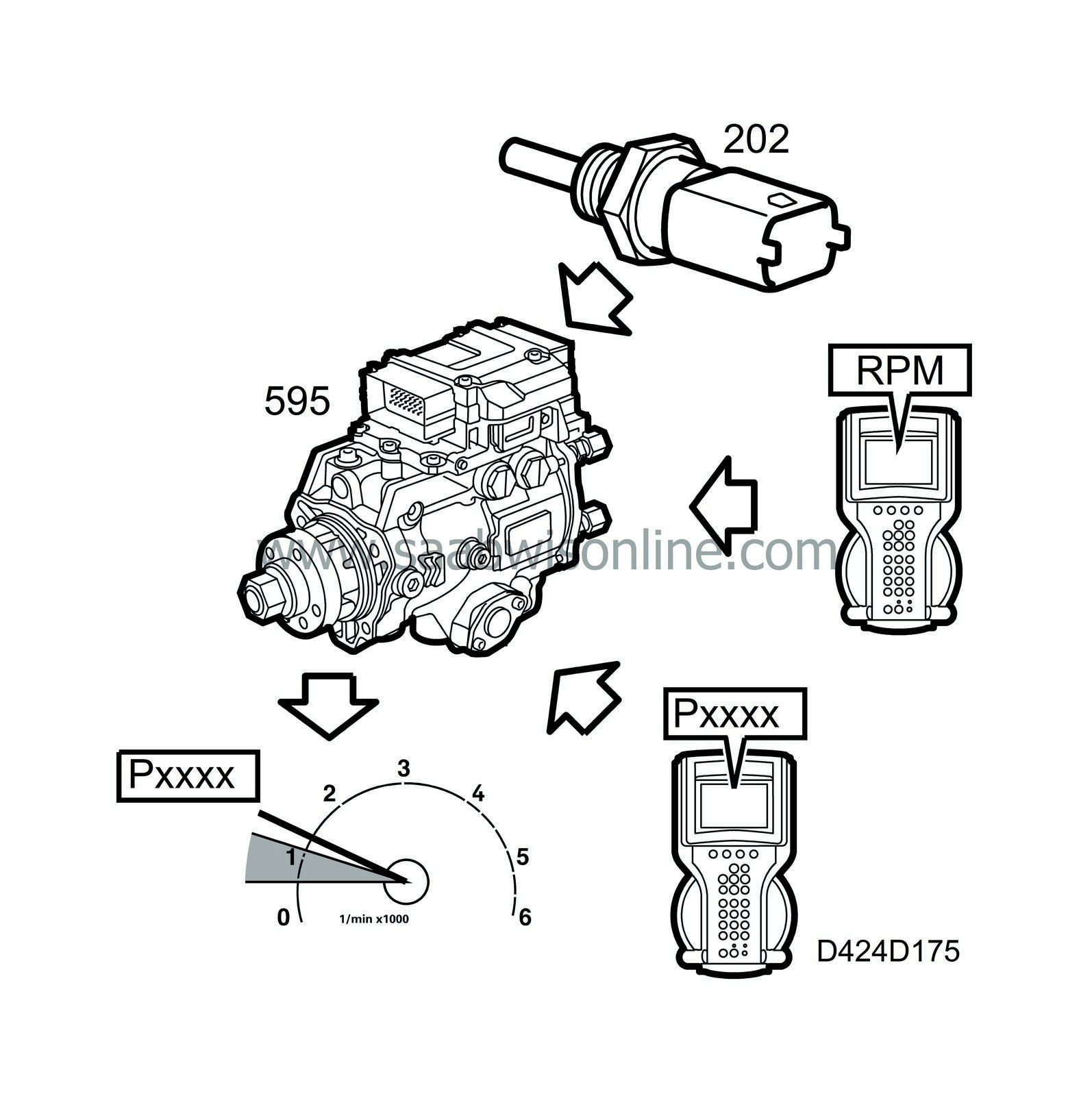

| Desired value, idling speed |

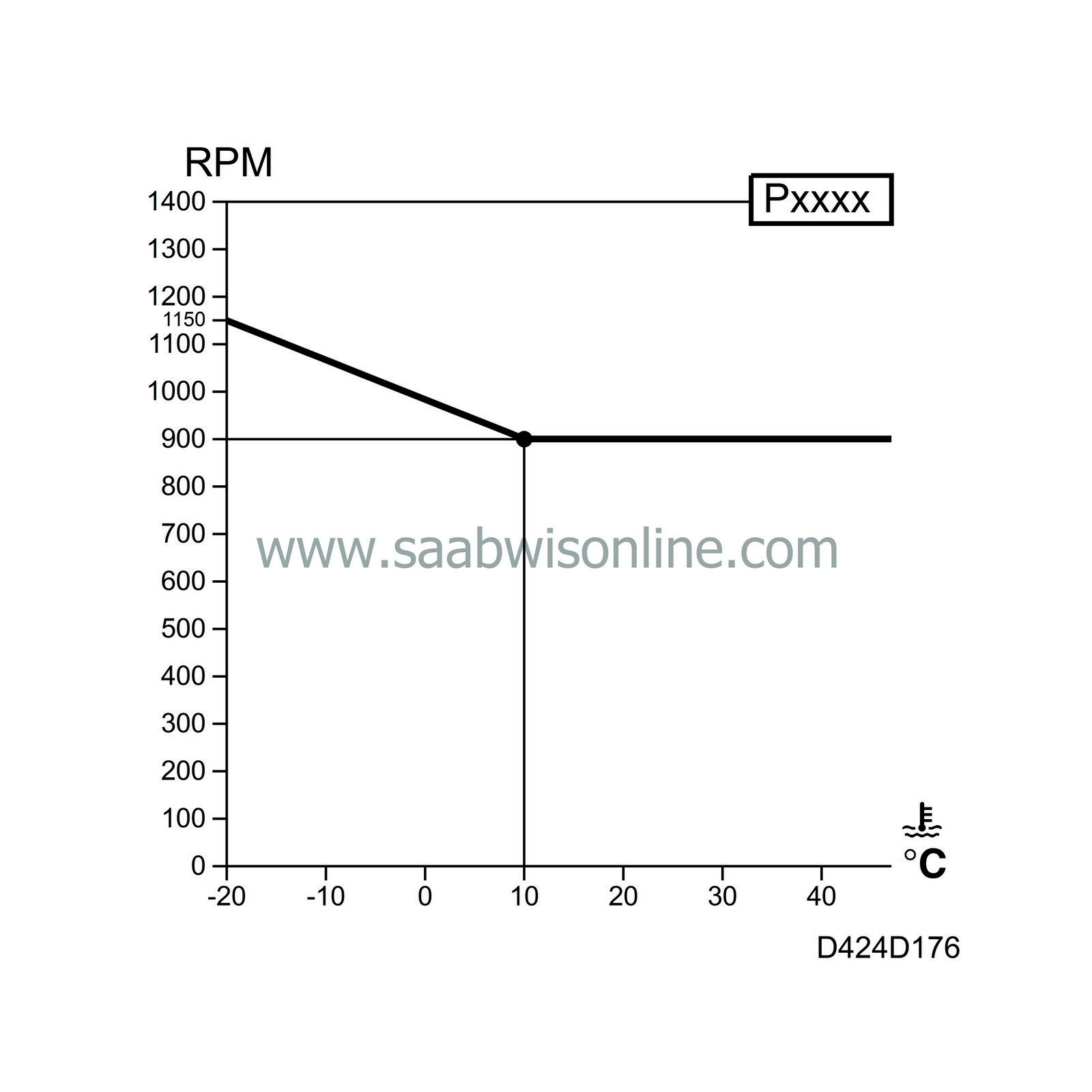

The idling speed that is to apply is based on the engine coolant temperature, intake air temperature, whether the control module has diagnostic communication or if a system fault has occurred (DTC).

Idling speed can vary from approx. 1150 rpm with a cold engine to 900 rpm with a warm engine, depending on the engine coolant temperature and intake air temperature.

The idling speed can be temporarily increased or decreased using the ACTIVATE function in the diagnostic tool. It can be increased to max 2000 rpm and reduced to min 700 rpm. The engine will return to its previously programmed value once the ACTIVATE function has been cancelled. Idling speed 1400 rpm will be set if a system error should occur. A permanent change in the idling speed can be programmed using the diagnostic tool. The ADJUSTMENT function can be used to change the speed by 100 rpm. The calculated idling speed is increased or reduced by the adjusted value if an adjustment of the desired idling speed has been made with the diagnostic tool and the total idling speed is sent on to the idle speed control.

The idling speed desired value is calculated synchronously with time, i.e. the calculation is performed at determined intervals.

| Idle speed control |

The idling speed control sub-function executes the order from "desired value, idling speed".

Idling speed control comprises a number of different internal calculations that are performed synchronously with the engine speed. This involves each new calculation of the fuel quantity being controlled by the engine speed. A new calculation is performed for each power stroke to determine an injection quantity that corresponds with the idling speed.

The fuel quantity from idle speed control is carried forward in the decision process in the control module.