Checking and adjusting basic charging pressure (B235R, B205L/R)

| Checking and adjusting basic charging pressure (B235R, B205L/R) |

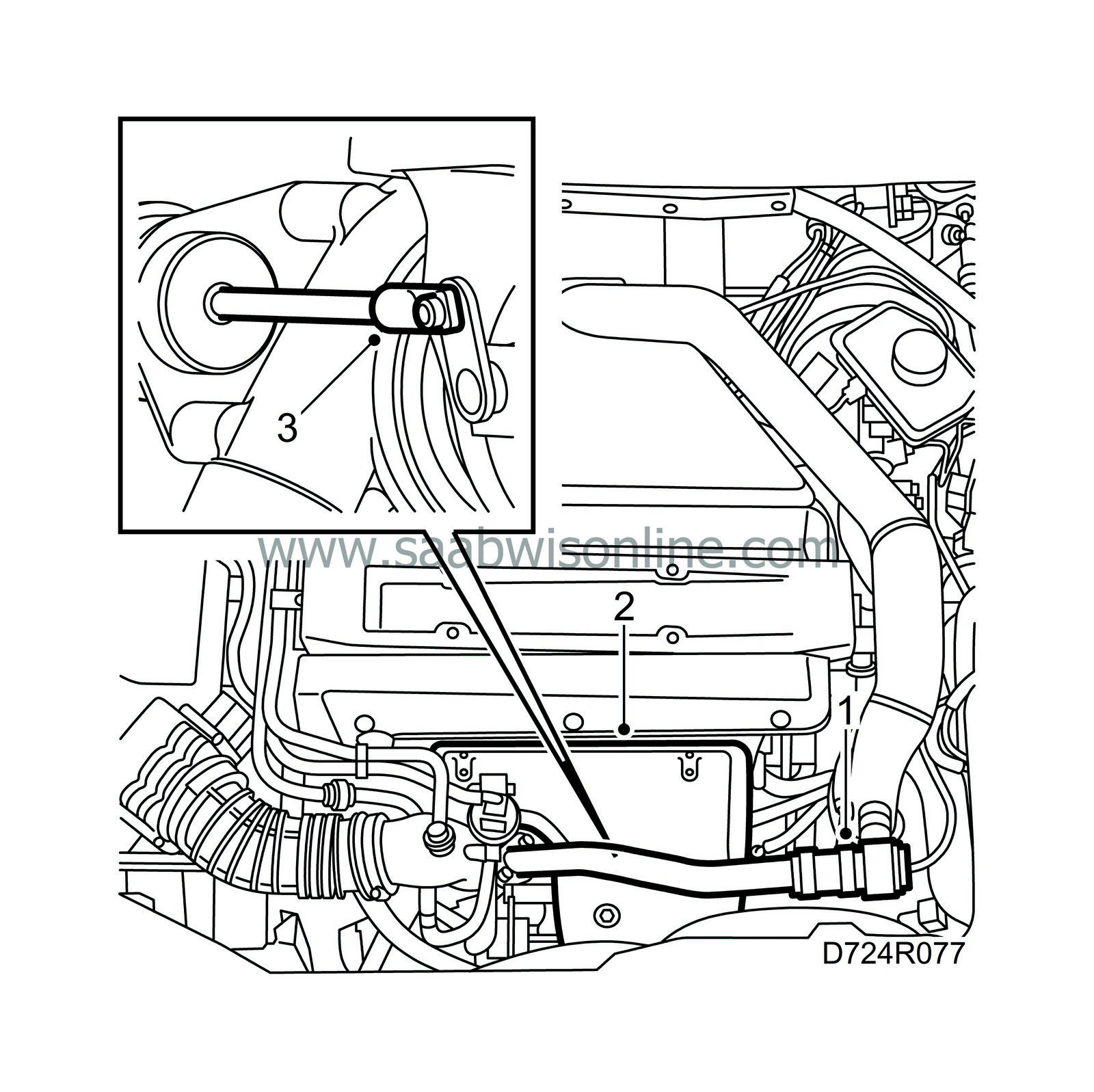

| 1. |

Remove the bypass pipe with valve.

|

|||||||

| 2. |

Remove the exhaust manifold heat shield. The heat shield is attached with a nut and two clips on the underside.

|

|

| 3. |

Remove the control arm circlip using

83 94 538 Circlip tool

.

|

|

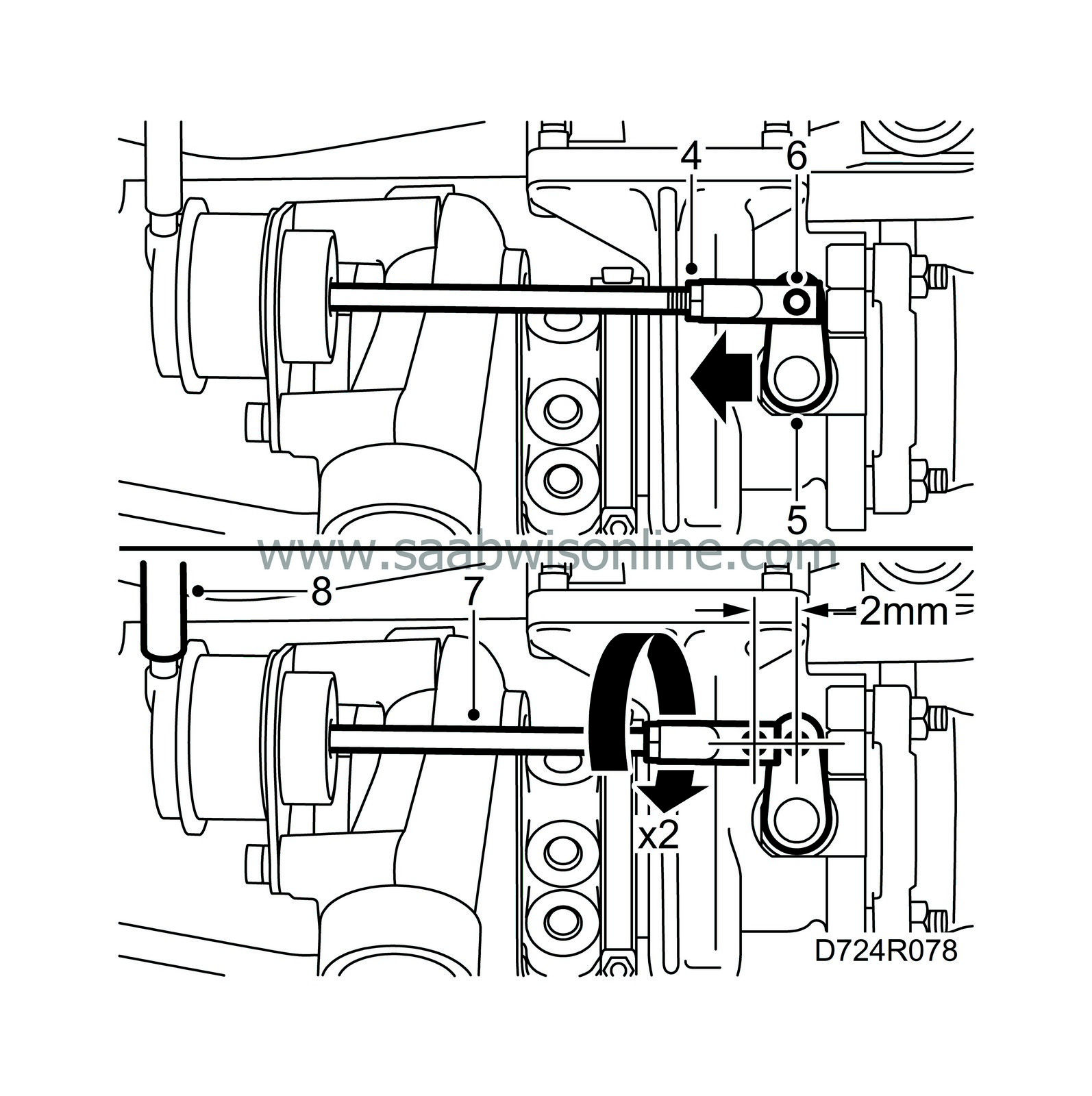

| 4. |

Grip the push rod using

83 94 066 Pliers

or the like. Undo the lock nut using

83 94 520 Wrench, lock nut

or the like.

|

|

| 5. |

Hold the control arm and detach the push rod. Secure the arm. Otherwise, the control arm may ”jump over”.

|

|

| 6. |

Move the control arm on the boost pressure control valve to the ”Closed” position and adjust the end piece so that the push rod can easily be fitted on the control arm pin.

|

|

| 7. |

Detach the push rod from the control arm pin. Turn the end piece clockwise about 2 turns so that a prestress of 2 mm is obtained. Attach the push rod to the control arm pin. Fit the circlip.

|

|

| 8. |

Detach the hose from the diaphragm box.

|

|

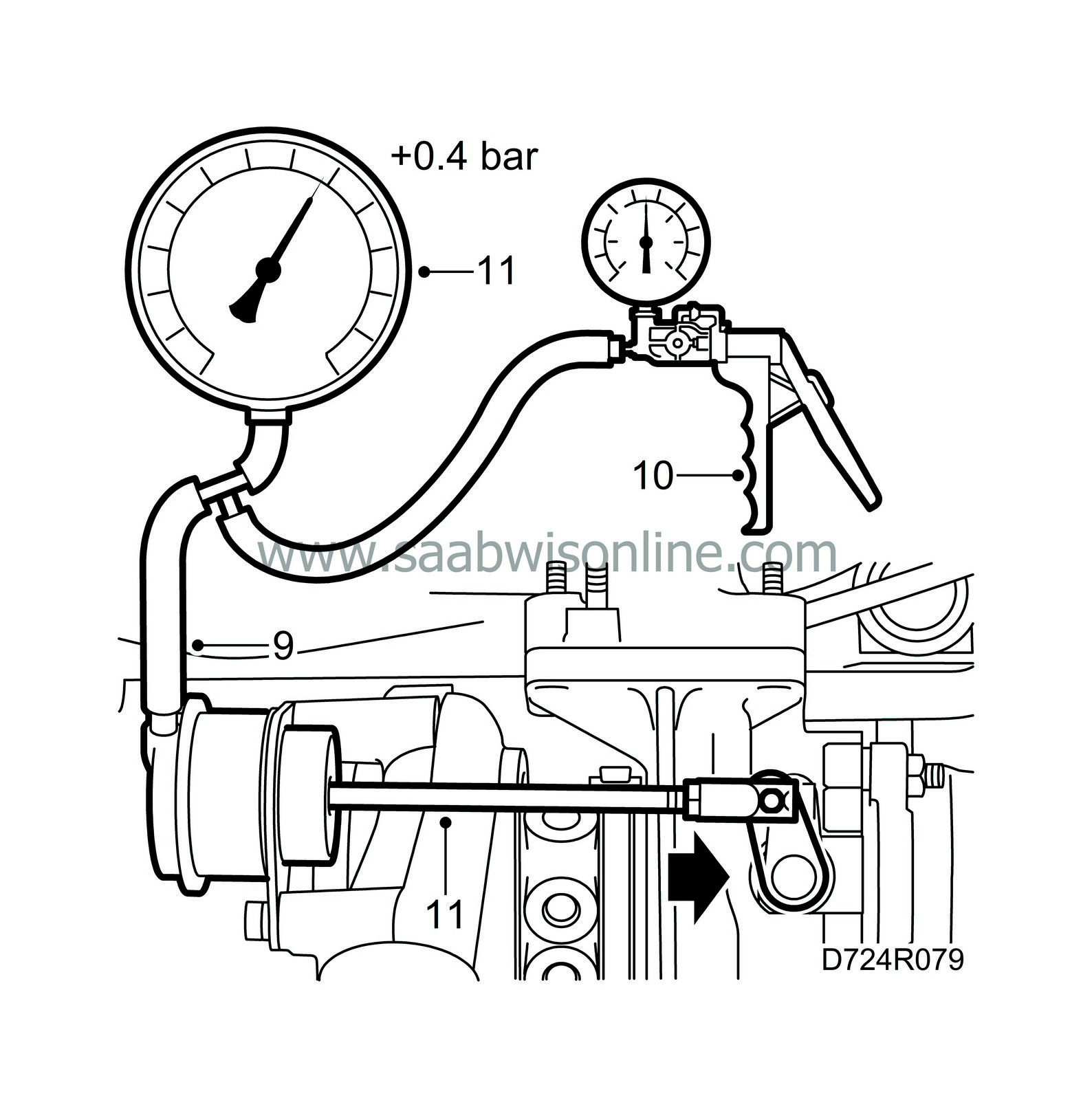

| 9. |

Connect

30 14 883 Pressure/vacuum pump

to the diaphragm box as well as pressure gauge

83 93 514 Boost pressure gauge

.

|

|

| 10. |

Carefully pump up pressure until the control rod moves to regulate the boost pressure.

|

|

| 11. |

Just as the control rod starts to move, read off the pressure on the pressure gauge. It should be 0.45 bar (±0.03 bar).

|

|

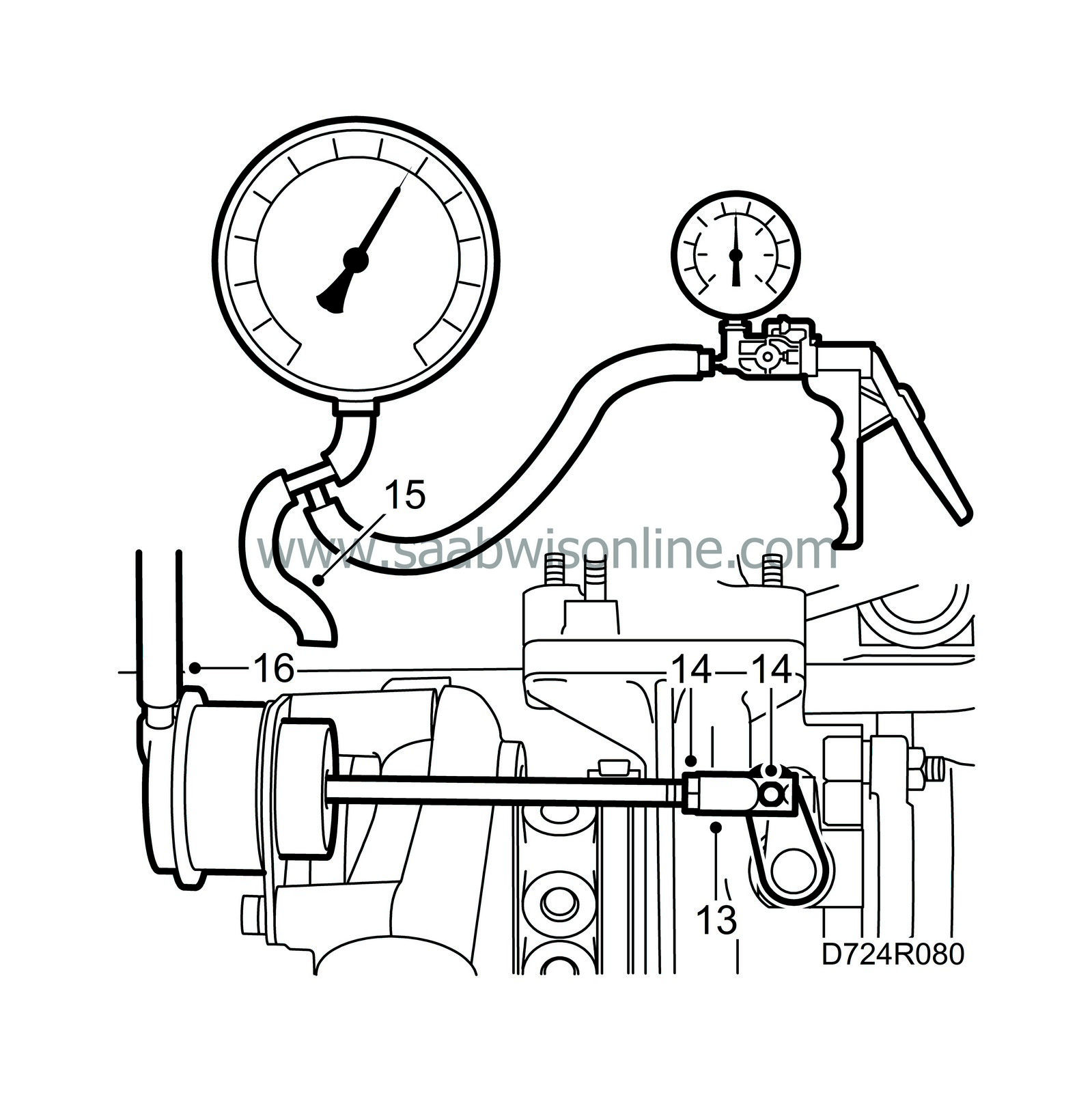

| 12. |

Shorten the rod if the pressure is too low until 0.45 bar is obtained.

|

|

| 13. |

Undo the push rod and apply Molykote 1000, part no. 30 20 971, or equivalent to the pin on the control arm.

|

|

| 14. |

Fit the push rod and clip, grip the push rod with a pair of adjustable pliers and lock the nut.

|

|

| 15. |

Remove the pressure gauge and pump.

|

|

| 16. |

Reconnect the hose to the diaphragm box.

|

|

| 17. |

Fit the heat shield.

|

|

| 18. |

Lubricate the O-ring with acid-free vaseline and fit the bypass pipe.

Tightening torque: 8 Nm (6 lbf ft) |

|