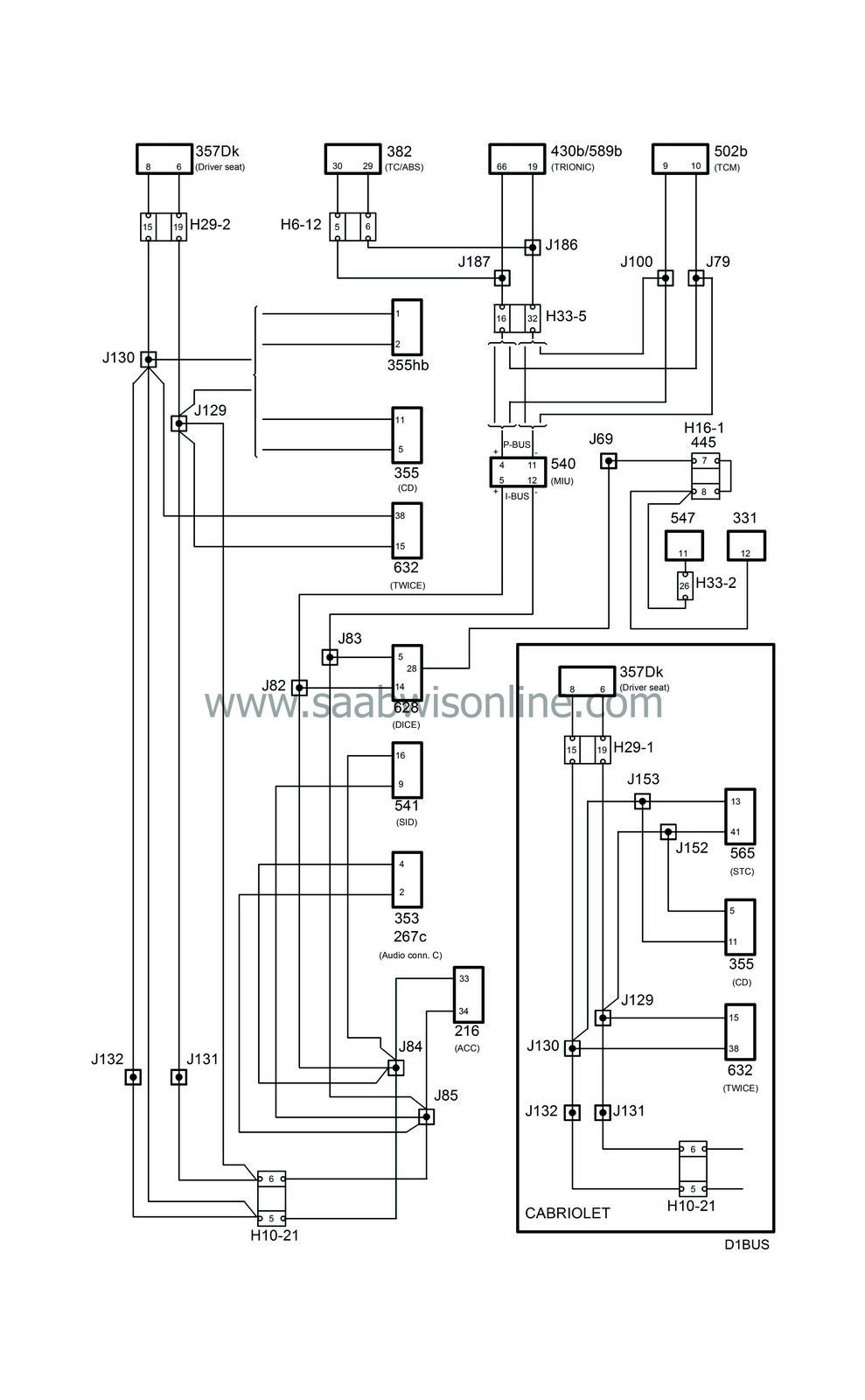

Bus communication

| Bus communication |

| • |

ACC control module (216) |

|

| • |

Radio connector C (267c)

|

|

| • |

Airbag/SRS control module (331)

|

|

| • |

Radio (353)

|

|

| • |

CD changer (355)

|

|

| • |

PSM control module (357Dk)

|

|

| • |

Trionic control module (430)

|

|

| • |

Control module, TCM (502)

|

|

| • |

Control module M2.10.3 (505)

|

|

| • |

MIU (540)

|

|

| • |

SID (541)

|

|

| • |

Control module (ABS) 547

|

|

| • |

STC control module (565)

|

|

| • |

Trionic OBDII control module (589)

|

|

| • |

Auxiliary heater control module (597)

|

|

| • |

DICE control module (628)

|

|

| • |

TWICE control module (632)

|

|

| P-bus and I-bus |

A bus is understood to be the leads over which information is sent digitally and serially. Digital means that the voltage difference between the leads has only two values, roughly 0 V and 5 V. The information is coded so that different combinations of 0 V and 5 V have different meanings.

Serial means that the information is sent in ”packets” which are transmitted one after the other in rapid succession.

The control module is connected to the bus in M01. On B205E/L/R, and B235R engines the TCM is connected to the P-bus, see below.

The buses consist of a P-bus (Powertrain Bus) and an I-bus (Instrument Bus). Both buses are connected to the MIU (Main Instrument Unit). The buses are electrically isolated from each other.

The diagnostic tool is not connected directly to the bus but communicates via the DICE, one of the control modules connected to the I-bus, and so has access to all control modules connected to the bus.

The data transfer rate of the P-bus is ten times faster than that of the I-bus. The reason for this is that the powertrain systems need information with the least possible delay.

All the information sent out from a control module is available to all other bus-connected control modules. The MIU sees to it that information which is available on one bus is also available on the other bus.

The control modules send out information on the bus at regular intervals. The time between two transmissions depends on what information is being transmitted and varies between 10 milliseconds (0.010 seconds) and 1 second. Information is also transmitted by the control module whenever the information changes.

The transfer of information between the control modules takes place on two leads, bus+ (green lead) and bus- (white lead). The two leads are twisted to reduce sensitivity to electrical interference.

| Diagnostics |

It is necessary for all units in a bus system to communicate with each other. For example, the engine cannot be started if Trionic does not receive immobilizer information sent by TWICE.

| Permanent bus faults |

All communication between Tech 2 and systems connected to a bus is via DICE. Irrespective of which system is contacted, Tech 2 will first check with the aid of the DICE that all systems in the car connected to a bus are awake and in communication. If any control module connected to a bus is missing, this will be displayed on Tech 2. Thus, all control modules connected to a bus are communicating correctly if Tech 2 does not give a warning.

| Intermittent bus faults |

The Trionic control module and the transmission control module (TCM) continuously check that all control modules from which they obtain information are communicating correctly. If intermittent faults occur in bus communication, diagnostic trouble codes will be generated in the Trionic and transmission control modules. The cause of the fault may be that the control module concerned has lost power or one of the bus leads is disconnected.

| Incorrect values on the bus |

A diagnostic trouble code will be generated in the Trionic and transmission control modules if any information they obtain from the bus is incorrect. The trouble code text indicates the system where the fault has occurred. For further information on the bus, see Bus and Diagnostic Communication.

| TCM uses the following information |

|

Information

|

Unit

|

Sensor system

|

Description

|

|

Engine torque

|

Nm

|

Trionic

|

The current air mass/combustion is converted into torque and given in Nm

|

|

Pedal position

|

%

|

Trionic

|

The highest air mass/combustion value requested from the pedal position or Cruise Control system is selected. The value is converted into a corresponding pedal position and given as a percentage.

|

|

Engine speed

|

rpm

|

Trionic

|

Current engine speed given in rpm. The value is also used to compare engine speed and speed of the input shaft when lock-up is active. If the difference between engine speed and input shaft speed is greater than 100 rpm, diagnostic trouble code P0741 is generated.

|

|

Brake lights

|

ON/OFF

|

TWICE

|

Brake lights, units ON/OFF.

|

| TCM sends the following information: |

|

Information

|

Unit

|

Used by

|

Description

|

|

Maximum permitted torque

|

Nm

|

Trionic

|

The TCM sends the maximum permitted torque, unit Nm. The value is used in the mass air flow control circuit for torque limitation.

|

|

SPORT

|

ON/OFF

|

Trionic, MIU

|

The TCM sends SPORT mode, ON/OFF. The value is used in the mass air flow control circuit to correct the pedal position's conversion into the requested air mass/combustion. The MIU turns on the SPORT indicator lamp.

|

|

Selector lever position

|

P, R, N, D, 3, 2, 1

|

Trionic, MIU

|

The TCM sends the selector lever position, units P, R, N, D, 3, 2 and 1. The Trionic system uses the value in the mass air flow control circuit for idle speed control. The MIU uses the value to light up the relevant segment in the selector lever display.

|

|

CHECK GEARBOX lamp

|

ON/OFF

|

MIU

|

ON is sent when on-board diagnostics reports that the lamp should be lit, unit ON/OFF. The value is used by the MIU.

|

|

WINTER lamp

|

ON/OFF

|

MIU

|

When the WINTER driving program is selected, WINTER ON information is sent, units ON/OFF. The MIU turns on the WINTER indicator lamp.

|

|

Text message HIGH TRANSMISSION FLUID TEMPERATURE

|

Text message

|

SID

|

When the transmission fluid temperature exceeds 170°C, HIGH TRANSMISSION FLUID TEMPERATURE, units ON/OFF is sent. The SID unit will display the corresponding message.

|