Intermediate shaft (Petrol)

|

|

Intermediate shaft (Petrol)

|

|

1.

|

Disconnect the battery's negative lead.

|

|

2.

|

Place wing protectors over the wings and remove the upper engine cover.

|

|

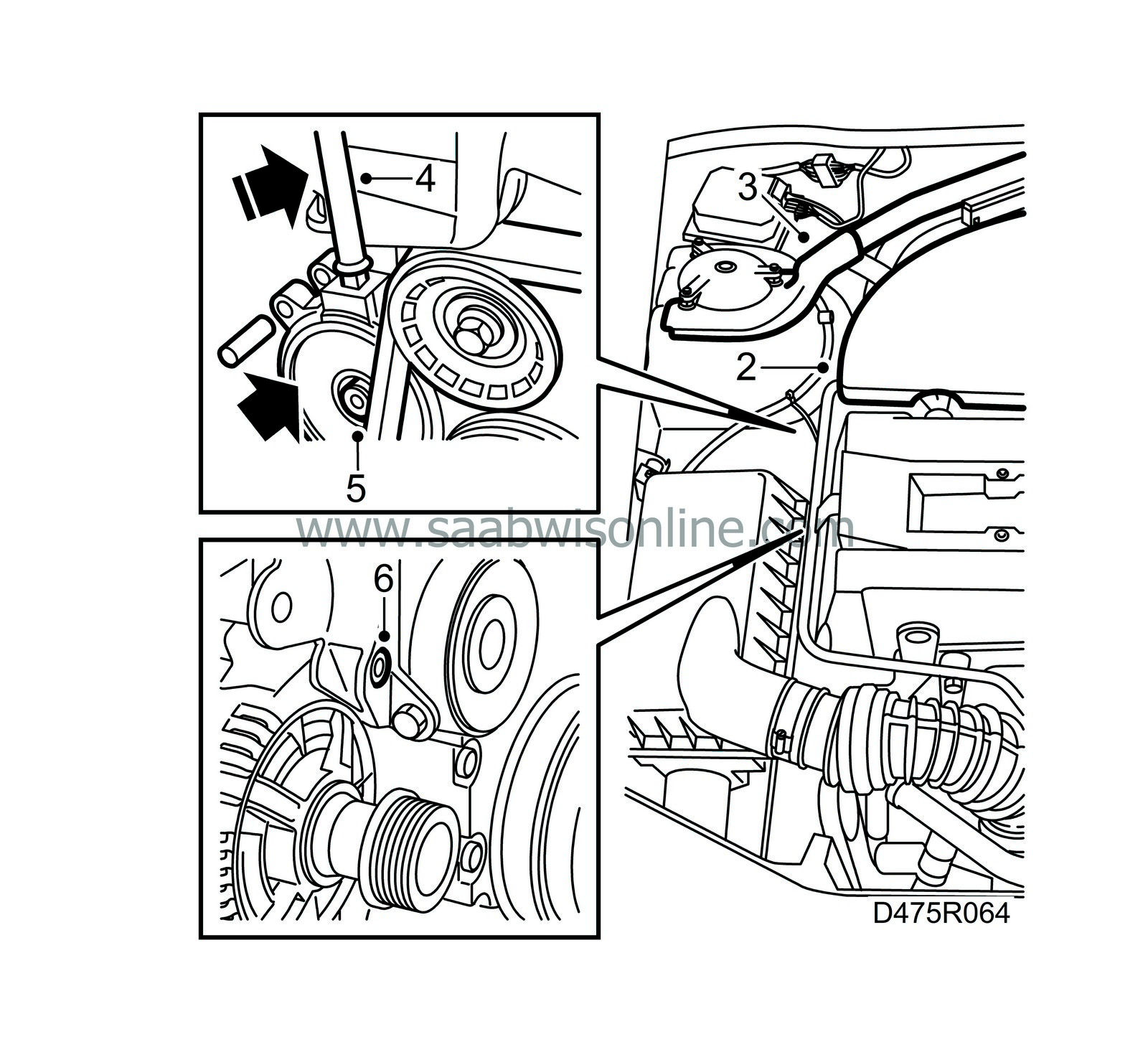

3.

|

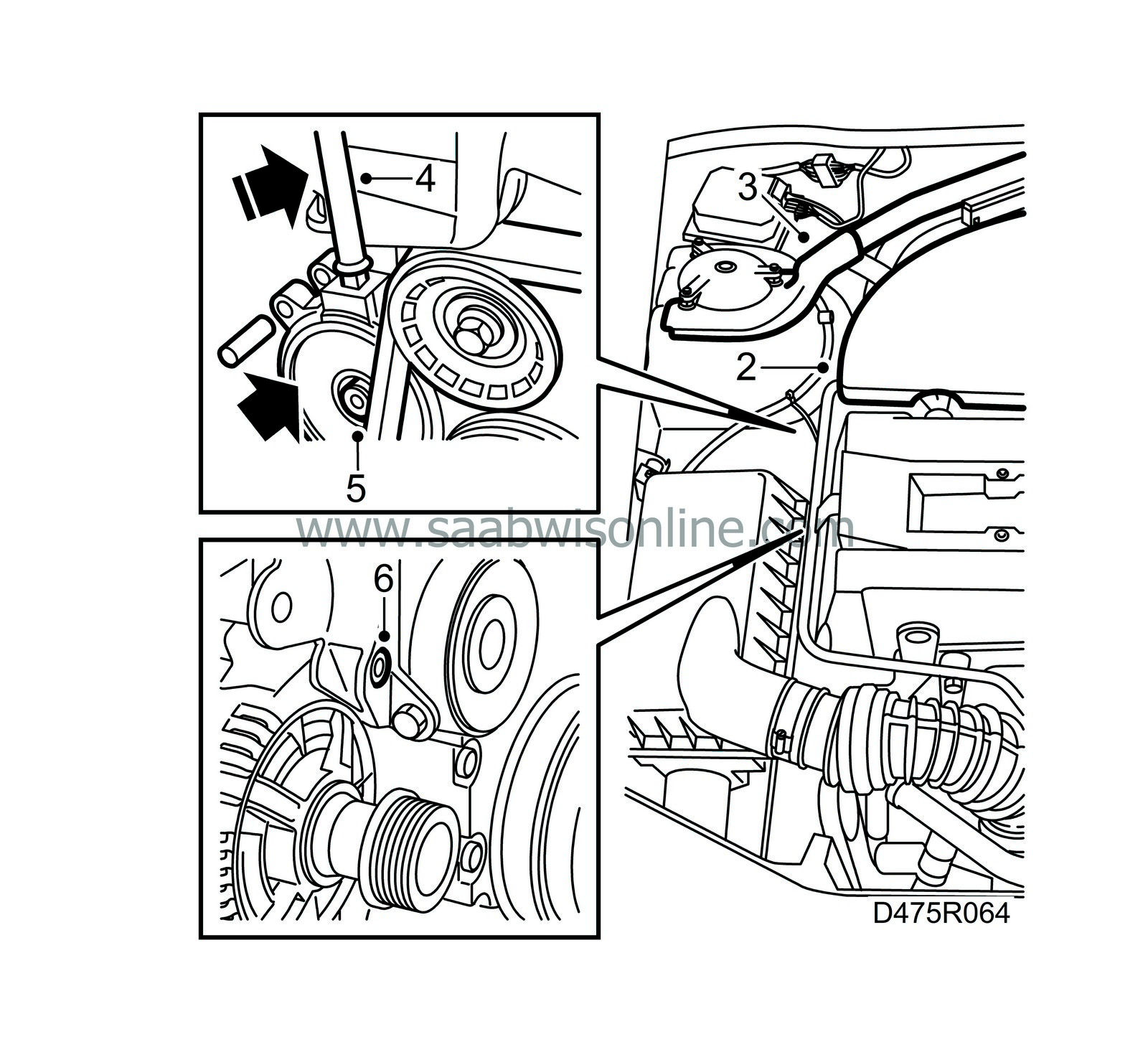

Remove the stay between the suspension strut towers

(RHD only)

.

|

|

4.

|

Use a ½" flexible handle to relieve the belt tensioner of tension.

|

|

5.

|

Remove the belt tensioner, using an 8 mm Allen key.

|

|

6.

|

Remove the generator's upper screw, using an 8 mm Allen key.

|

|

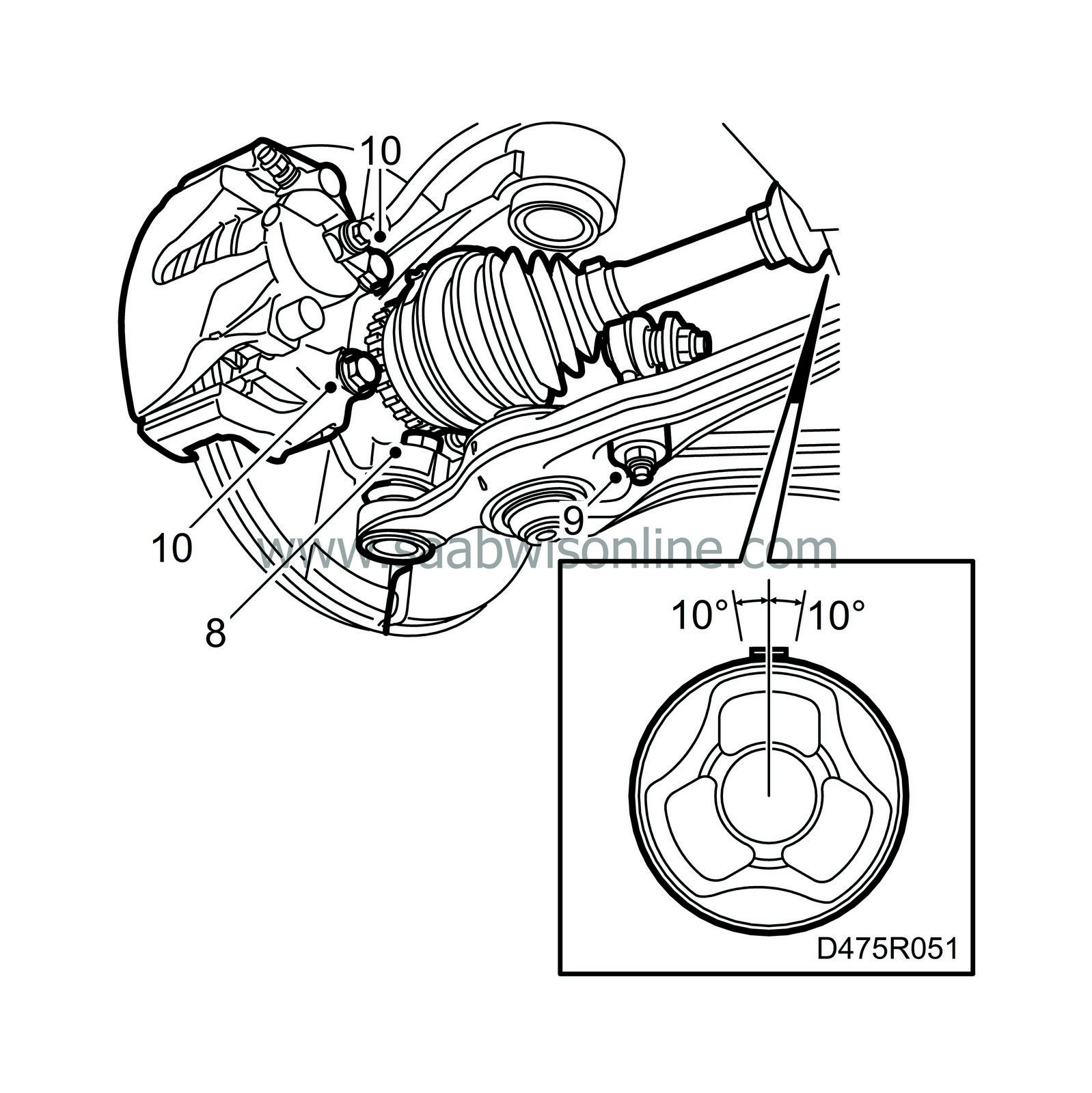

8.

|

Remove the right-hand wheel.

|

|

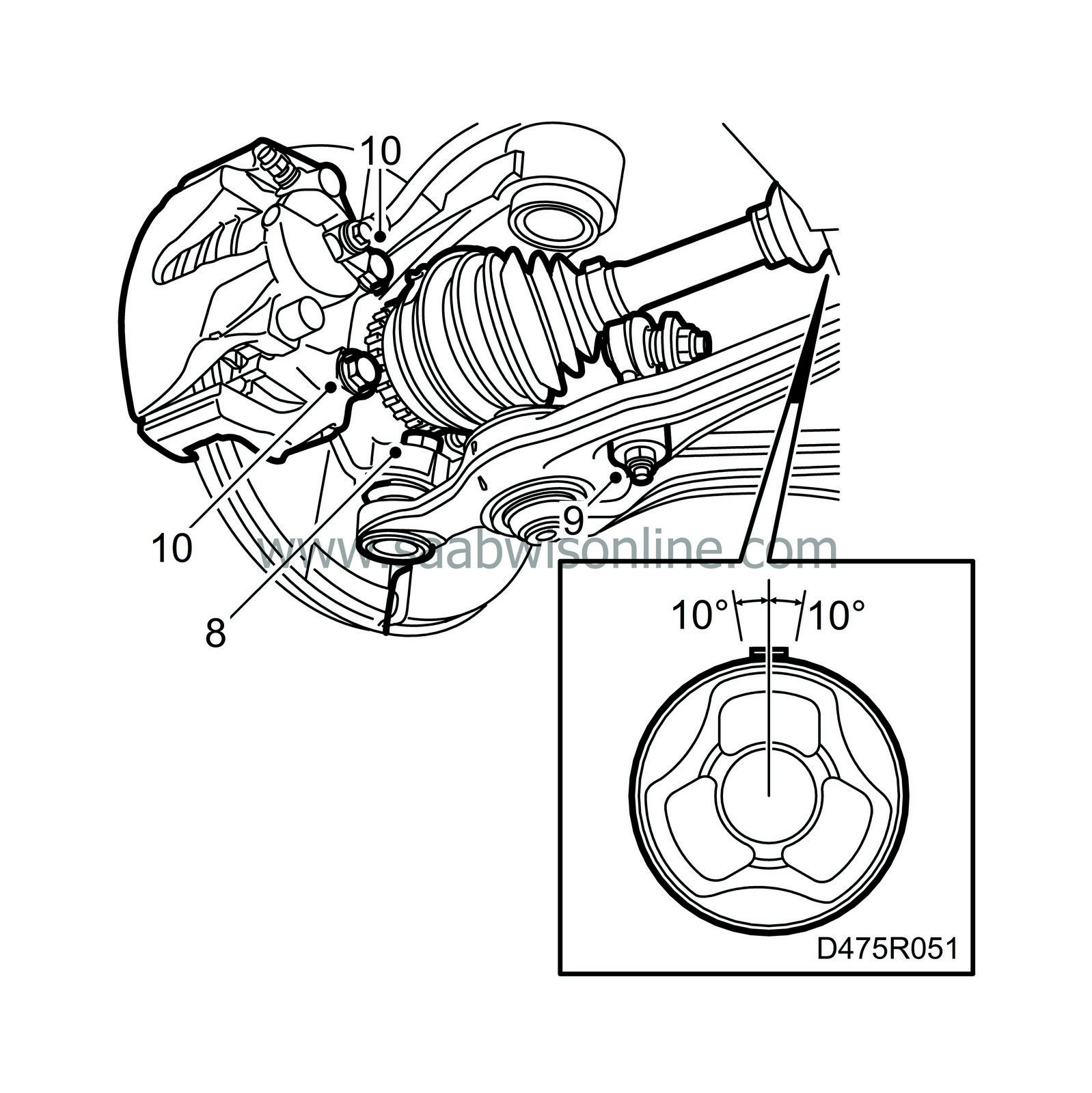

9.

|

Remove the belt circuit cover.

|

|

10.

|

B235R:

Loosen and suspend the brake caliper.

|

|

11.

|

Undo the nuts securing the anti-roll bar and the suspension arm's ball joint. Use

89 96 696 Puller

.

|

|

12.

|

Lower the suspension arm and fix it in position with a block of wood inserted between the suspension arm and the anti-roll bar.

|

|

13.

|

Remove the clamp and pull down the gaiter.

B235R:

Tap loose the driver shaft from the intermediate shaft with a brass drift/hammer.

|

|

14.

|

Swing the wheel to the left to facilitate removal of the drive shaft.

B235R:

Tap out the drive shaft further if necessary.

Take hold of the MacPherson strut and pull. The drive shaft will then follow out. Then fold it down in front of the suspension arm.

|

Important

|

|

Make sure that no dirt gets into the universal joint.

|

|

Cover the universal joint and driver with plastic bags or the like.

|

|

|

|

|

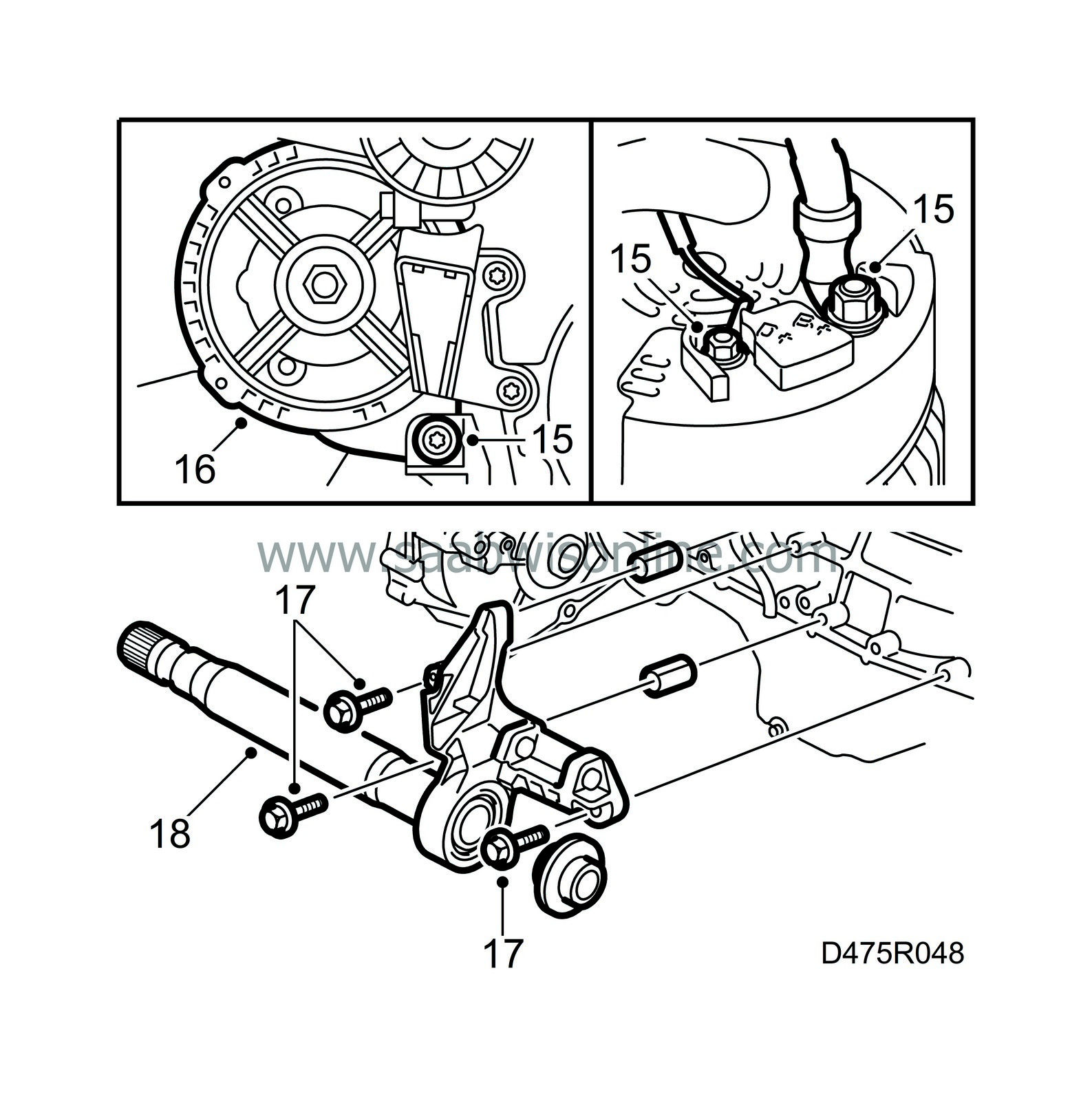

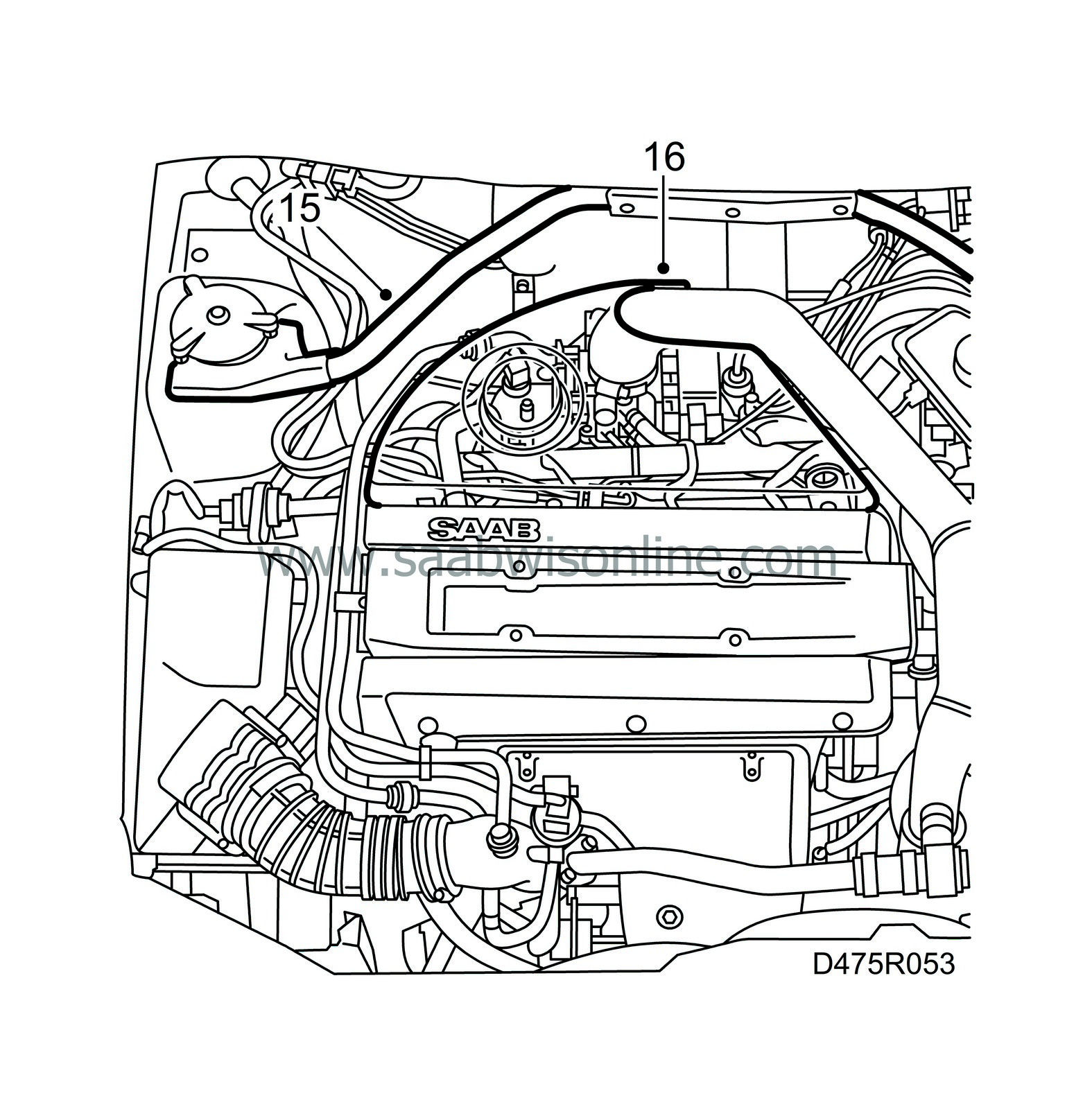

15.

|

Disconnect the generator cables and the generator bracket's lower bolt.

|

|

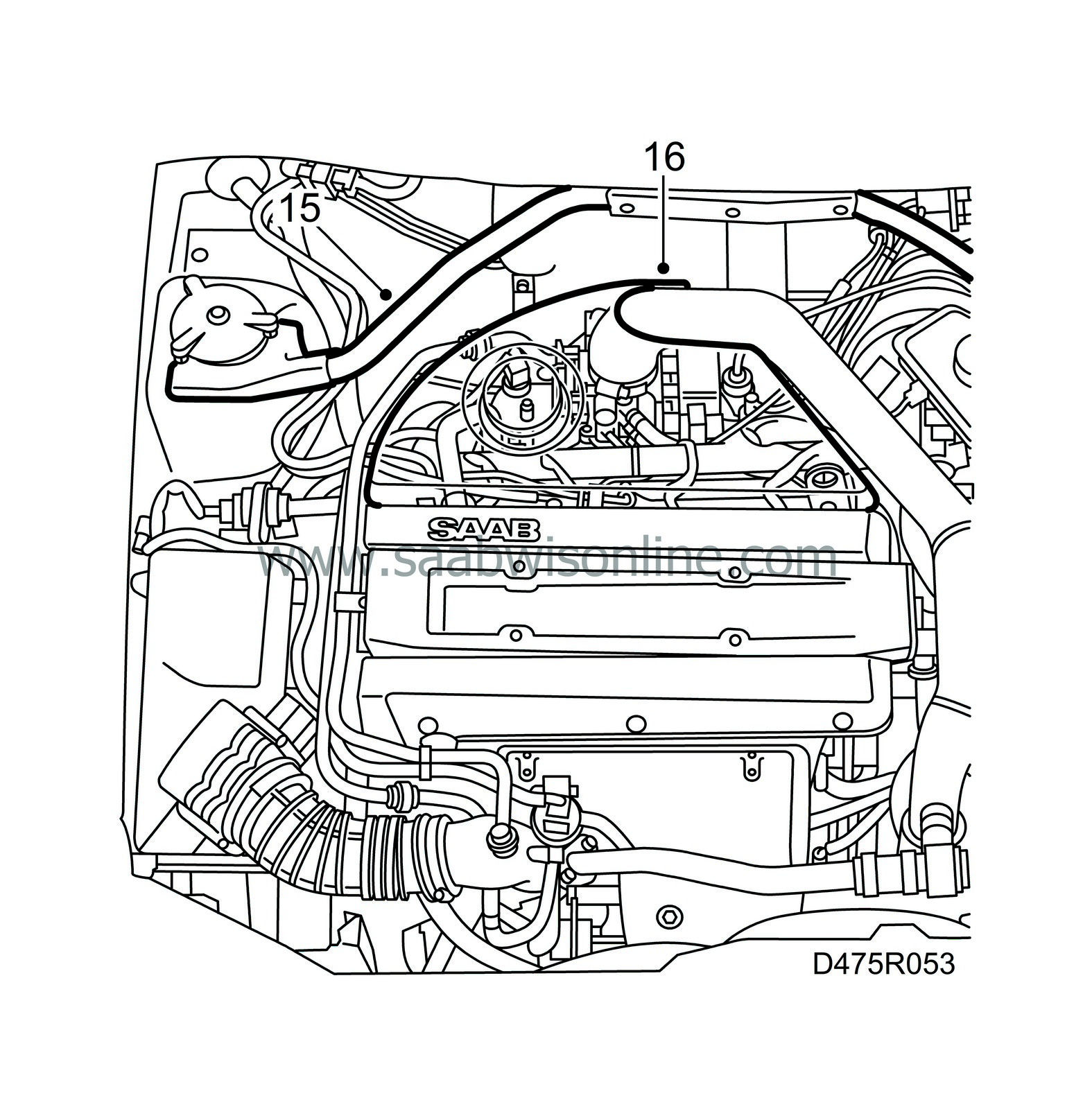

16.

|

Move the generator aside.

|

|

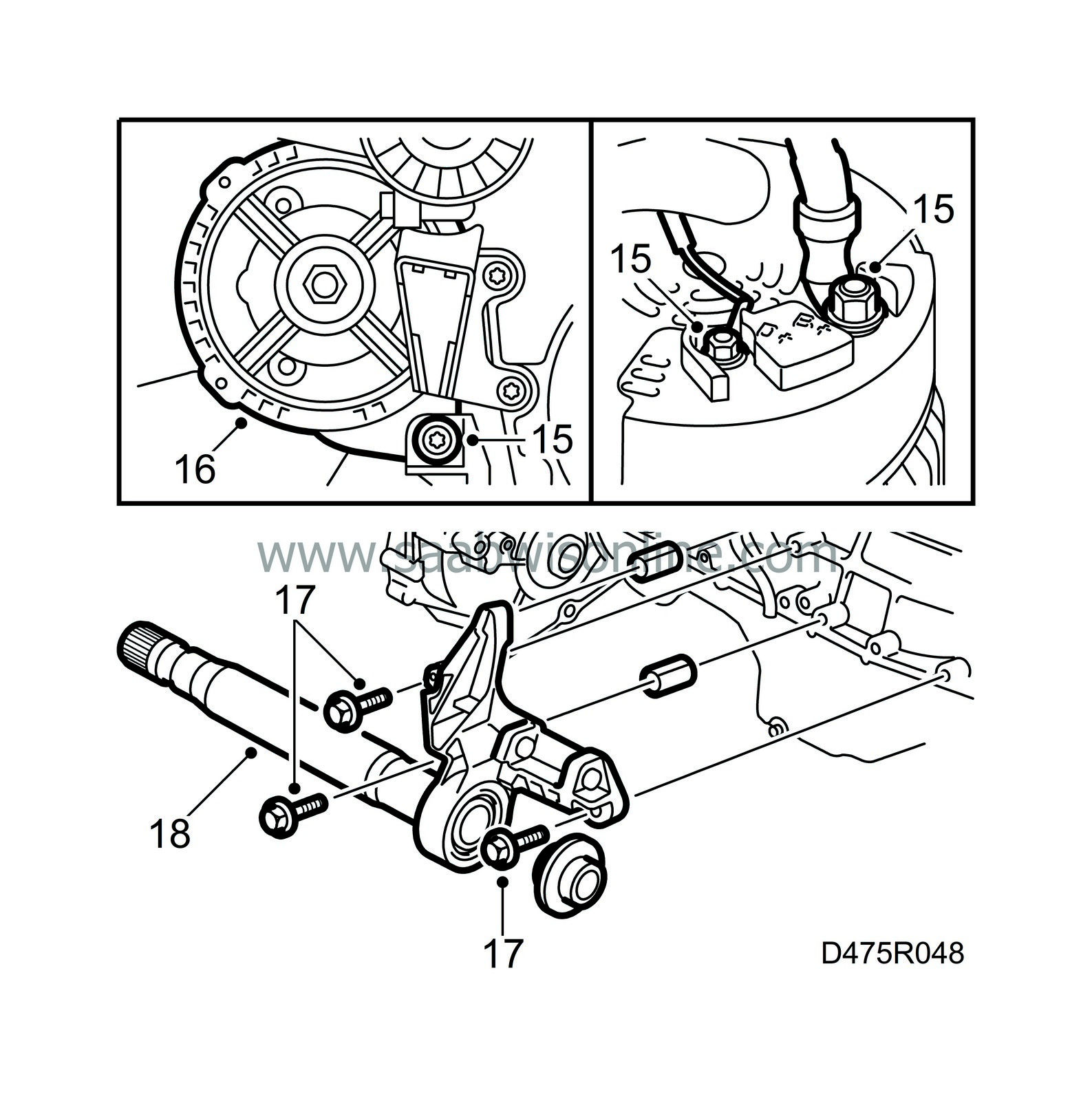

17.

|

Unscrew the support bearing bracket bolts.

|

Important

|

|

Place a receptacle under the gearbox to avoid spilling oil on floor.

|

|

|

|

|

18.

|

Pull the support bearing bracket away from the guide pins in the engine block and withdraw the intermediate shaft from the gearbox.

|

|

2.

|

Make sure that the intermediate shaft is clean and then fit the shaft in the tool.

|

Important

|

|

Insert the intermediate shaft in the gearbox until about 20 mm of it remains and withdraw the tool before the shaft's sealing surface reaches the shaft seal.

|

|

|

|

|

3.

|

Insert the remainder of the shaft.

|

|

4.

|

First guide the support bearing bracket to the upper guide pin and then tighten the bearing bracket.

Tightening torque 24 Nm (18 lbf ft)

|

|

5.

|

Make sure that the adjusting sleeves are tapped out about 1 mm to facilitate fitting the generator on the mountings. Then fit the two generator retaining bolts and tighten the lower one.

Tightening torque 47 Nm (35 lbf ft)

|

|

6.

|

Connect the generator cables.

|

|

7.

|

Fill grease, (16) 87 92 624, in the gaiter and driver and connect the universal joint to the driver. Fit a new clamp on the gaiter and wipe away excess grease. It is important that the clamp is fitted as illustrated.

B235R:

Bend out the MacPherson strut and connect the drive shaft to the intermediate shaft until the circlip snaps in place. Lubricate with universal paste 87 81 684. See

List of lubricants and sealants

.

|

|

8.

|

Remove the wooden block, swing the suspension arm back and connect it to the steering swivel member. Fit the bolt and tighten it.

Tightening torque: 75 Nm (55 lbf ft)

|

|

9.

|

Secure the anti-roll bar.

|

|

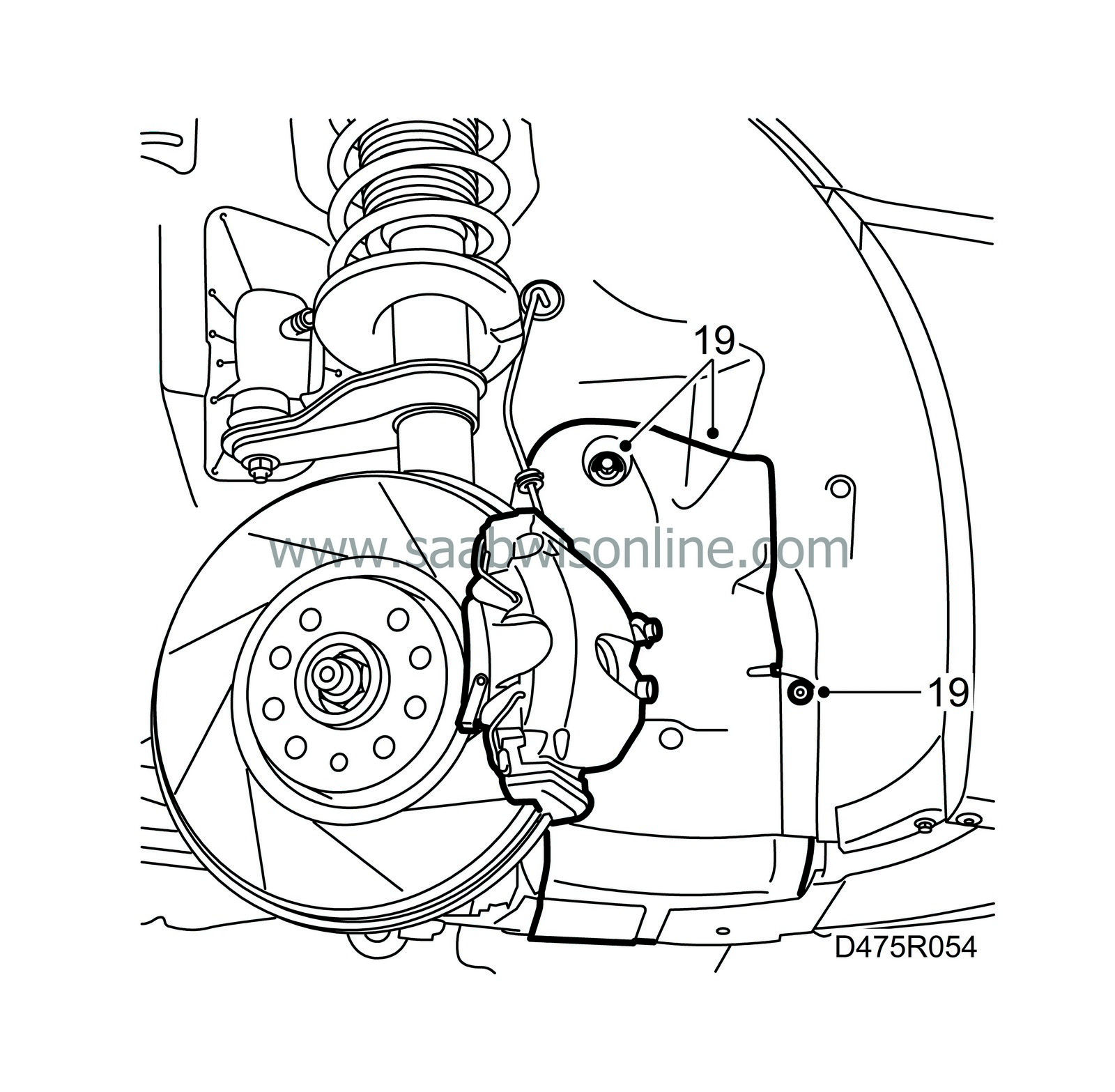

10.

|

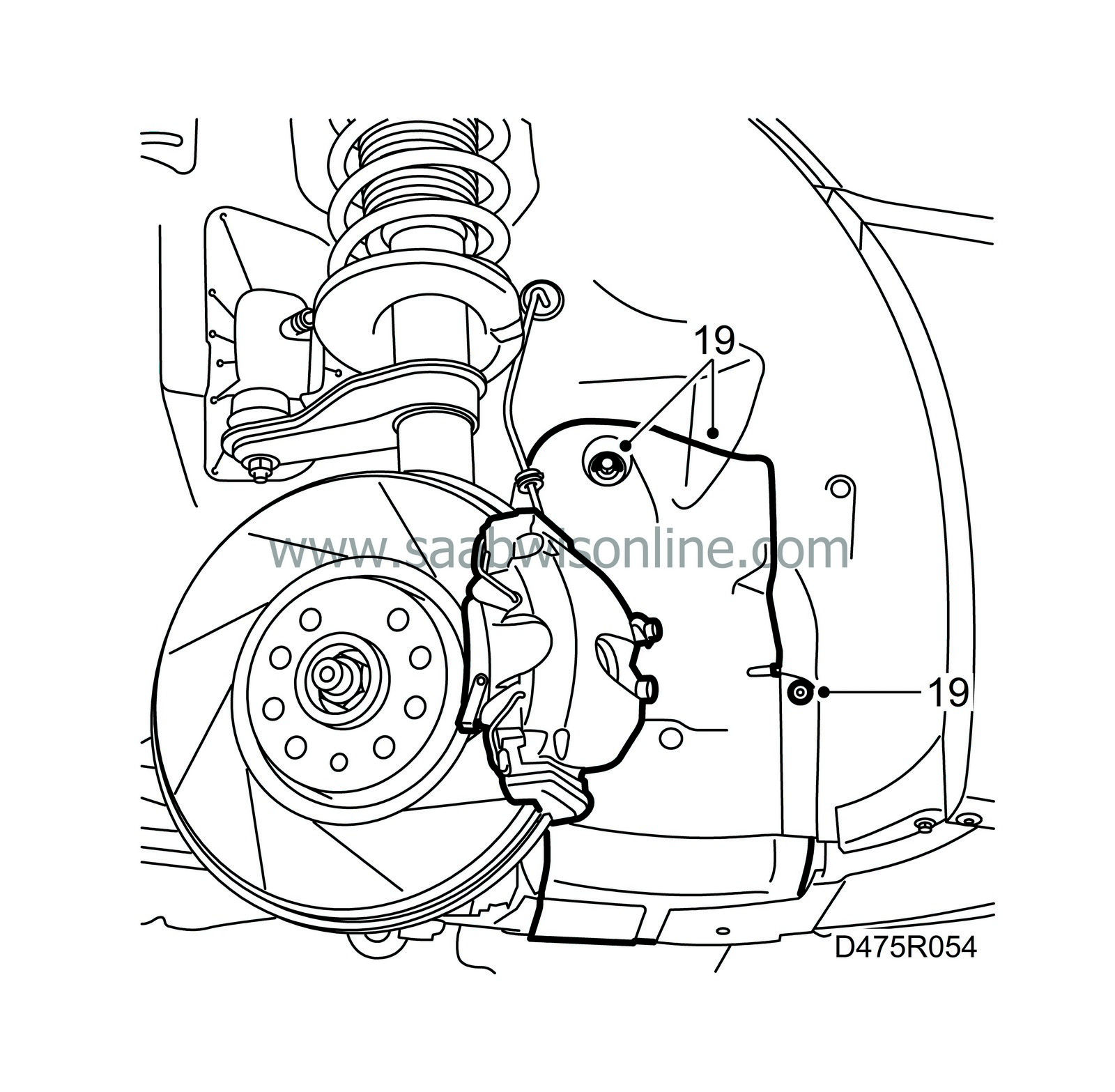

B235R:

Fit the brake caliper. Apply Loctite 242, part no. (16) 74 96 268, to the screws. See

List of lubricants and sealants

.

Tightening torque 110 Nm (81 lbf ft)

|

|

11.

|

Lower the car to the floor.

|

|

12.

|

Tighten the generator's upper bolt.

Tightening torque 47 Nm (35 lbf ft)

|

|

13.

|

Fit the belt tensioner.

|

|

15.

|

Fit the stay between the suspension strut towers and press the protective caps in place

(RHD only)

.

Tightening torque 24 Nm (18 lbf ft)

|

|

16.

|

Press the cover over the intake manifold into place.

|

|

17.

|

Connect the negative lead to the battery.

|

|

18.

|

Fill the gearbox with oil to the correct level.

|

|

19.

|

Raise the car and fit the cover over the belt circuit.

|

|

20.

|

Fit the wheel.

Tightening torque: 110 Nm (81 lbf ft)

|

Important

|

|

The wheel should hang freely when the wheel bolts are tightened.

|

|

|

|

|

21.

|

Lower the car to the floor.

|

|

22.

|

Set the clock and any radio code.

|