To dismantle

| To dismantle |

| 1. |

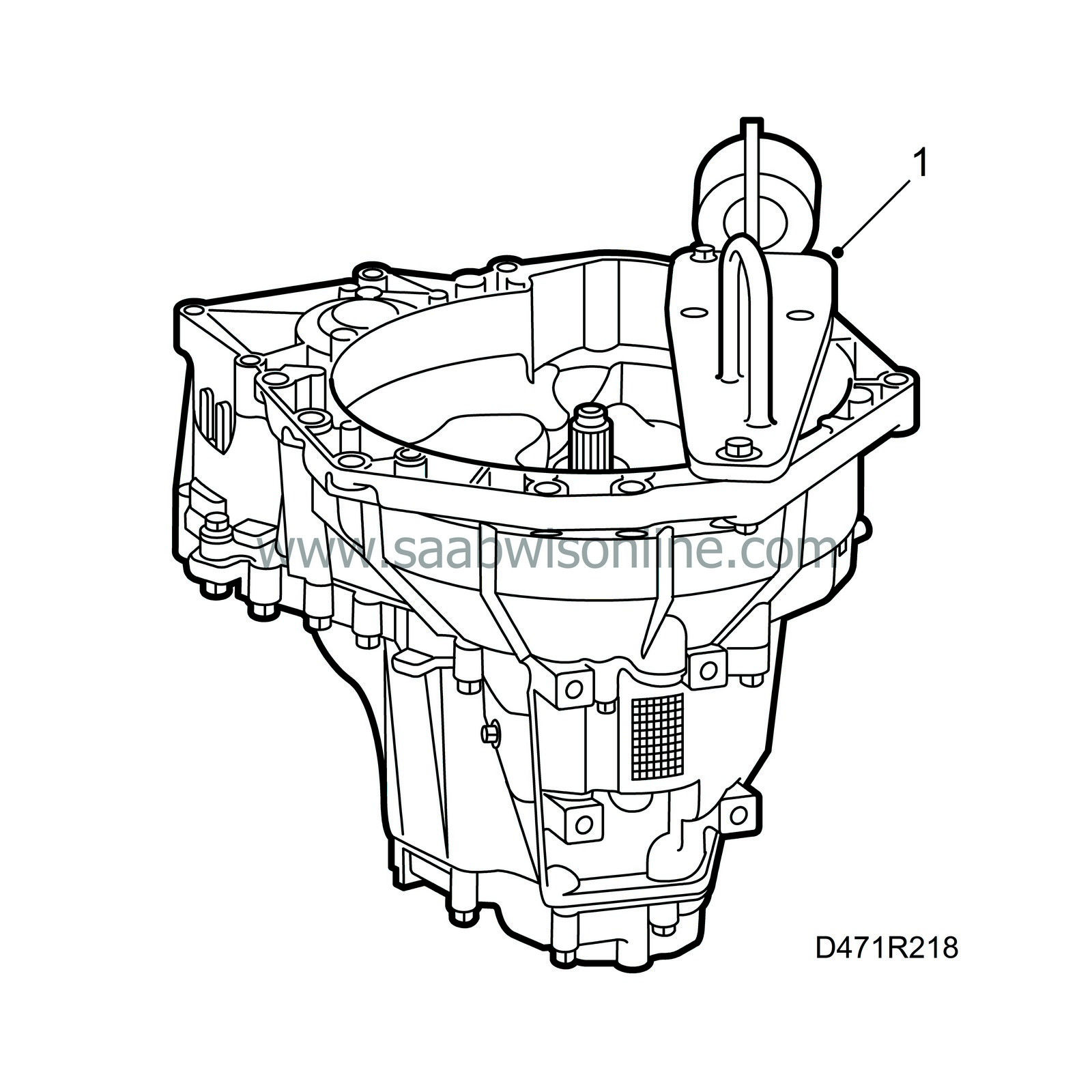

Place the gearbox in a work stand with

87 92 228 Holder, transmission

.

|

|

| 2. |

Detach the delivery line. Compress the sleeve on the inside using pliers and push the delivery line forward. Prise up the catch on the sleeve and press in the delivery pipe to detach it.

|

|

| 3. |

Undo the slave cylinder screws and remove it.

|

|

| 4. |

Unscrew the reverse shaft. Note the O-ring.

|

|

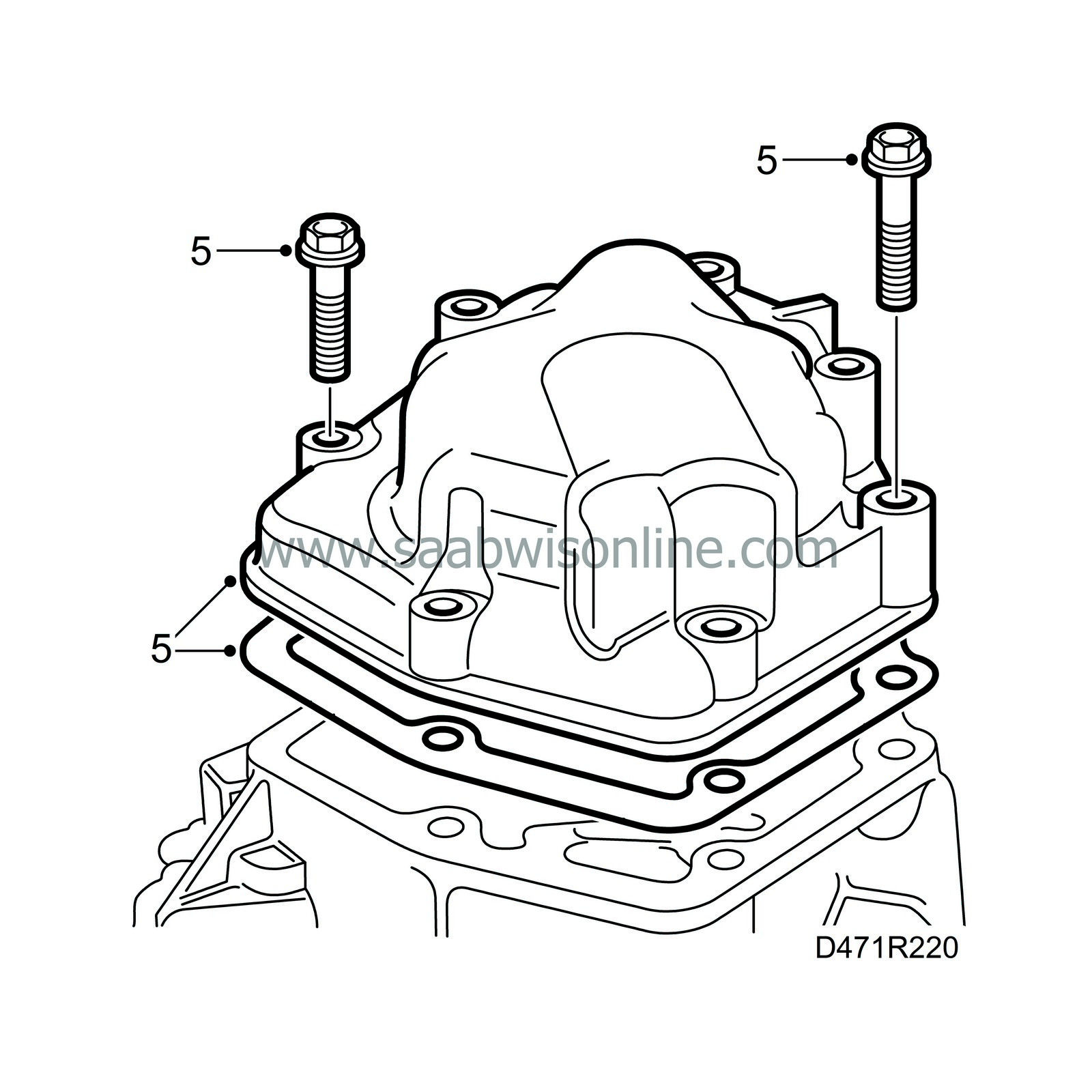

| 5. |

Unscrew the end cover. Remove the cover and the gasket.

|

|

| 6. |

Engage 1st gear to secure the gearbox and prevent the selector mechanism detent balls from coming out. Tap out the retention pin for the 5th gear selector fork.

Remove the fork and synchromesh sleeve and then refit the synchromesh sleeve. |

||||||||||

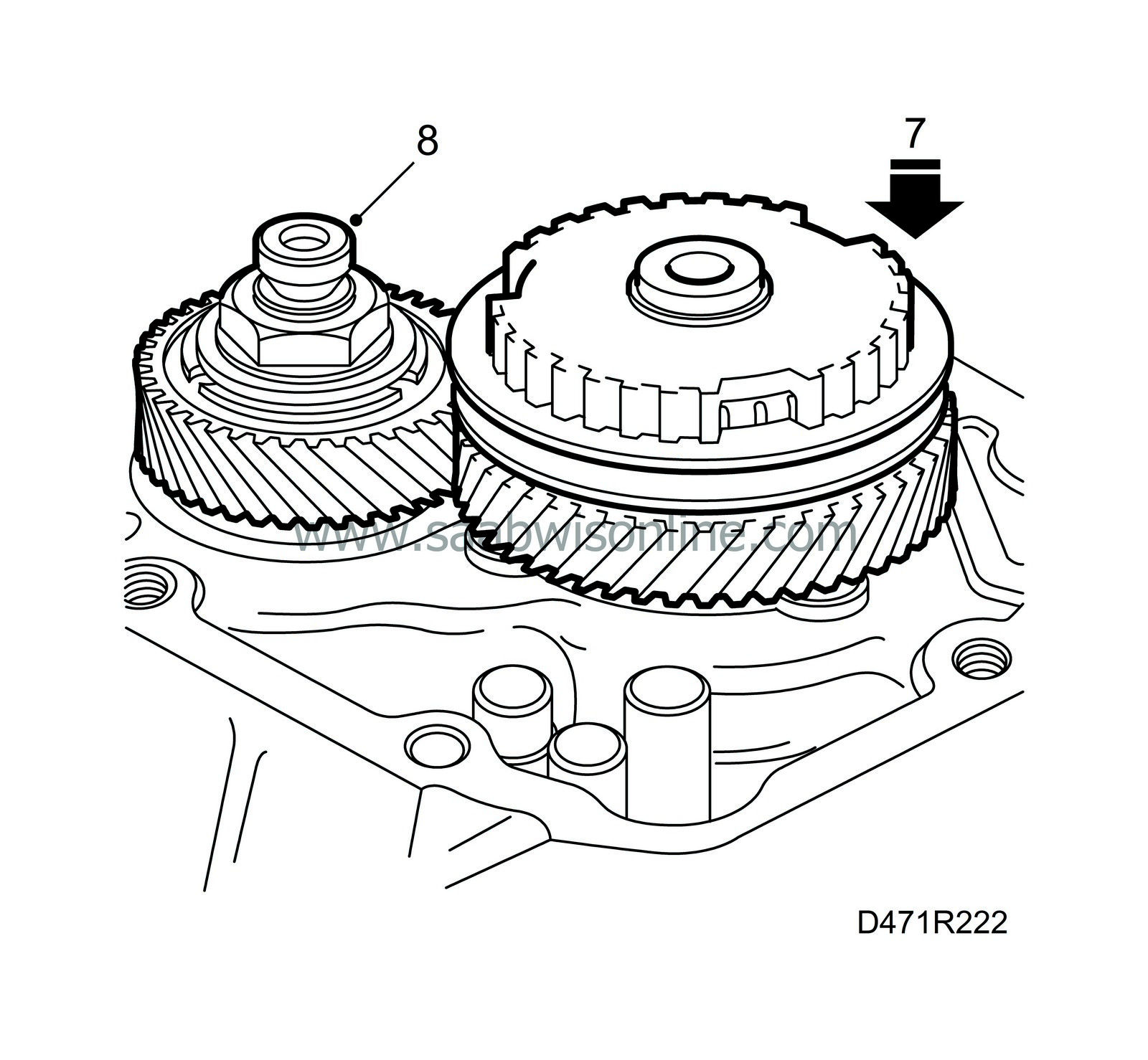

| 7. |

Press down the synchromesh sleeve so that 5th gear is engaged. Two gears must be engaged simultaneously when the nut on the output shaft is unscrewed.

Note that the synchromesh sleeve may only be placed on the synchromesh hub when the high lugs on the sleeve are opposite the tooth gaps on the synchromesh hub that are opposite the deep tooth gaps. |

|

| 8. |

Tap off the lock on the output shaft nut using a drift.

Remove the nut.

|

||||||||||

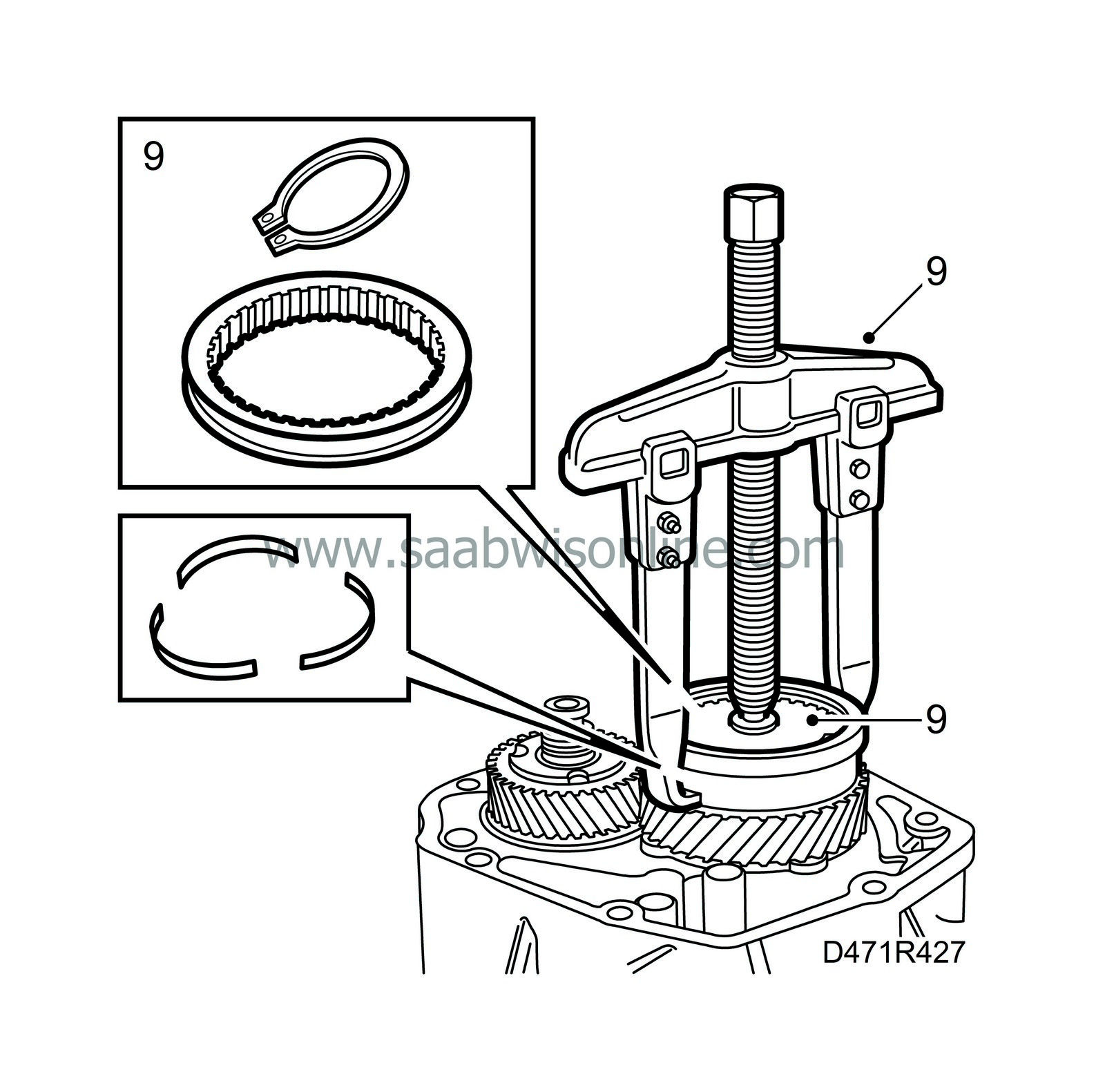

| 9. |

Remove the circlip for 5th gear synchromesh hub. This is made easier by first carefully tapping down the hub.

Lift off the synchromesh sleeve. Then use 87 91 287 Puller, 150 mm , 87 91 303 Arm, 150 mm and 87 92 640 Removal tool to lift off 5th gear's synchromesh hub (use grease on the tip of the puller). Keep the leaf springs in a safe place. Then lift up the pinion, baulk ring and needle bearing. |

|

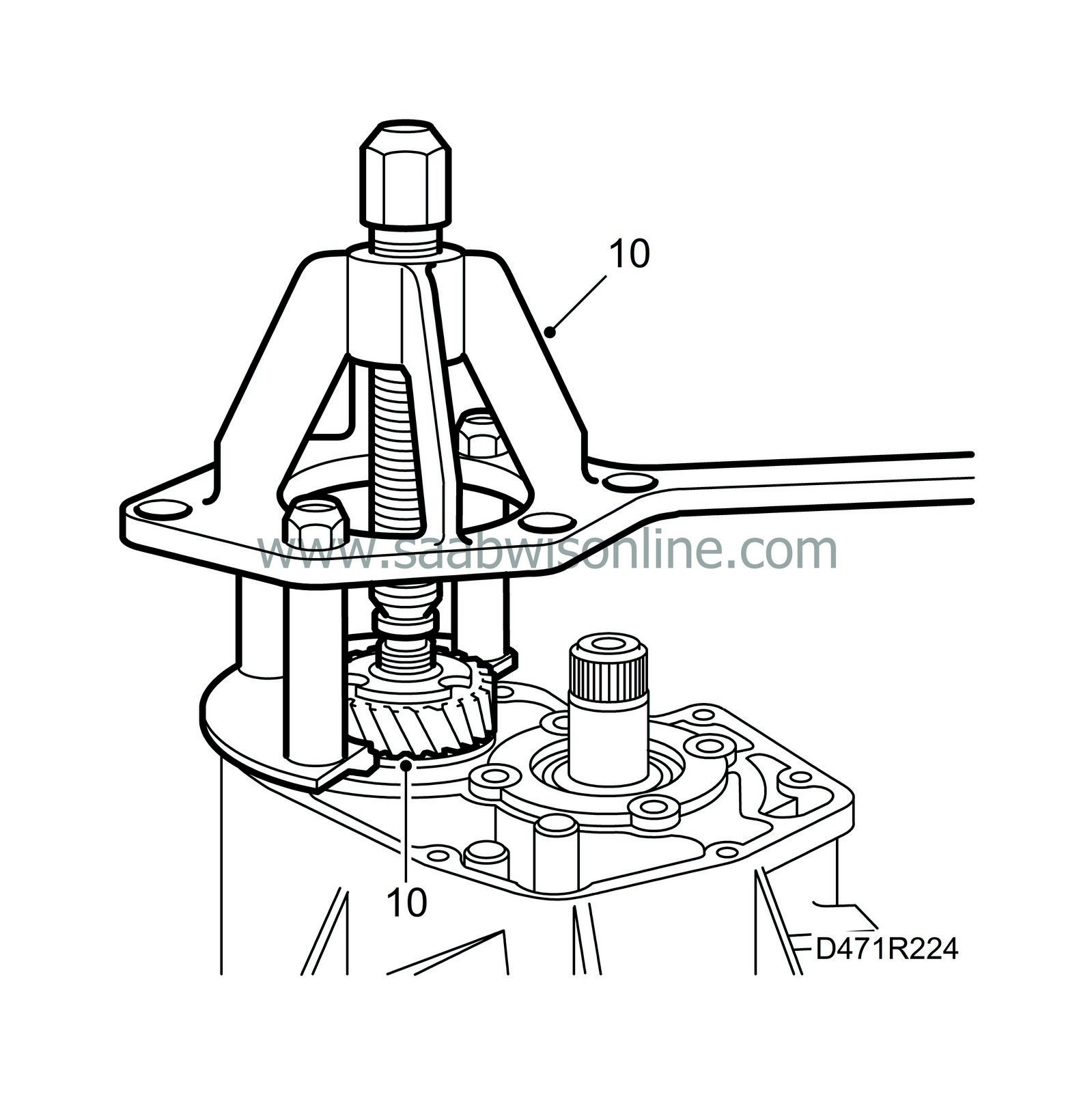

| 10. |

Remove 5th gear's gear wheel with

89 96 084 Puller, wheel hub

,

87 92 566 Puller

and

87 91 410 Sleeve

.

|

|

| 11. |

Undo the screws for the differential seal retainer.

|

|

| 12. |

Remove the seal retainer and keep the shims.

|

|

| 13. |

Undo the screw for the reverse shaft support in the gearcase.

|

|

| 14. |

Undo and remove the bolts from the mating surface between the gearcase and the clutch housing. Tap down the 2 locating sleeves.

|

|

| 15. |

Check that a gear is engaged. This prevents the input and output shafts from coming along out. Screw in two

87 92 129 Attaching lugs

.

87 91 410 Sleeve

is fitted on the output stub axle. Hook on

87 91 287 Puller, 150 mm

with

87 91 303 Arm, 150 mm

in the tools and carefully pull off the housing until the pinion and bearing release from the shaft. Tap carefully to loosen the mating surface.

|

|

| 16. |

Remove tools. Lift off the gearcase.

|

|

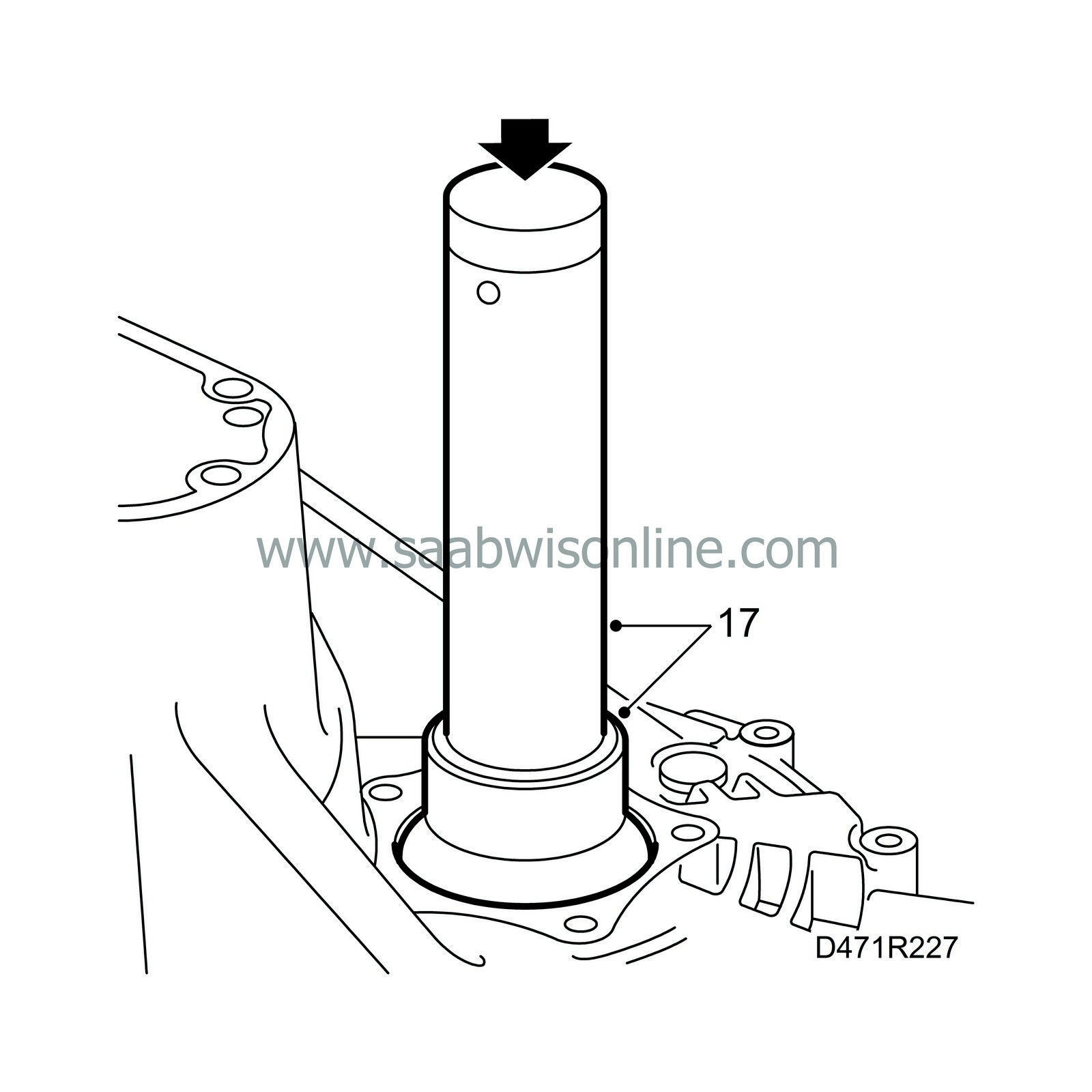

| 17. |

Knock out the differential bearing race. Use

87 92 202 Sleeve

,

87 91 204 Sleeve, bearing race

and

87 91 410 Sleeve

.

|

|

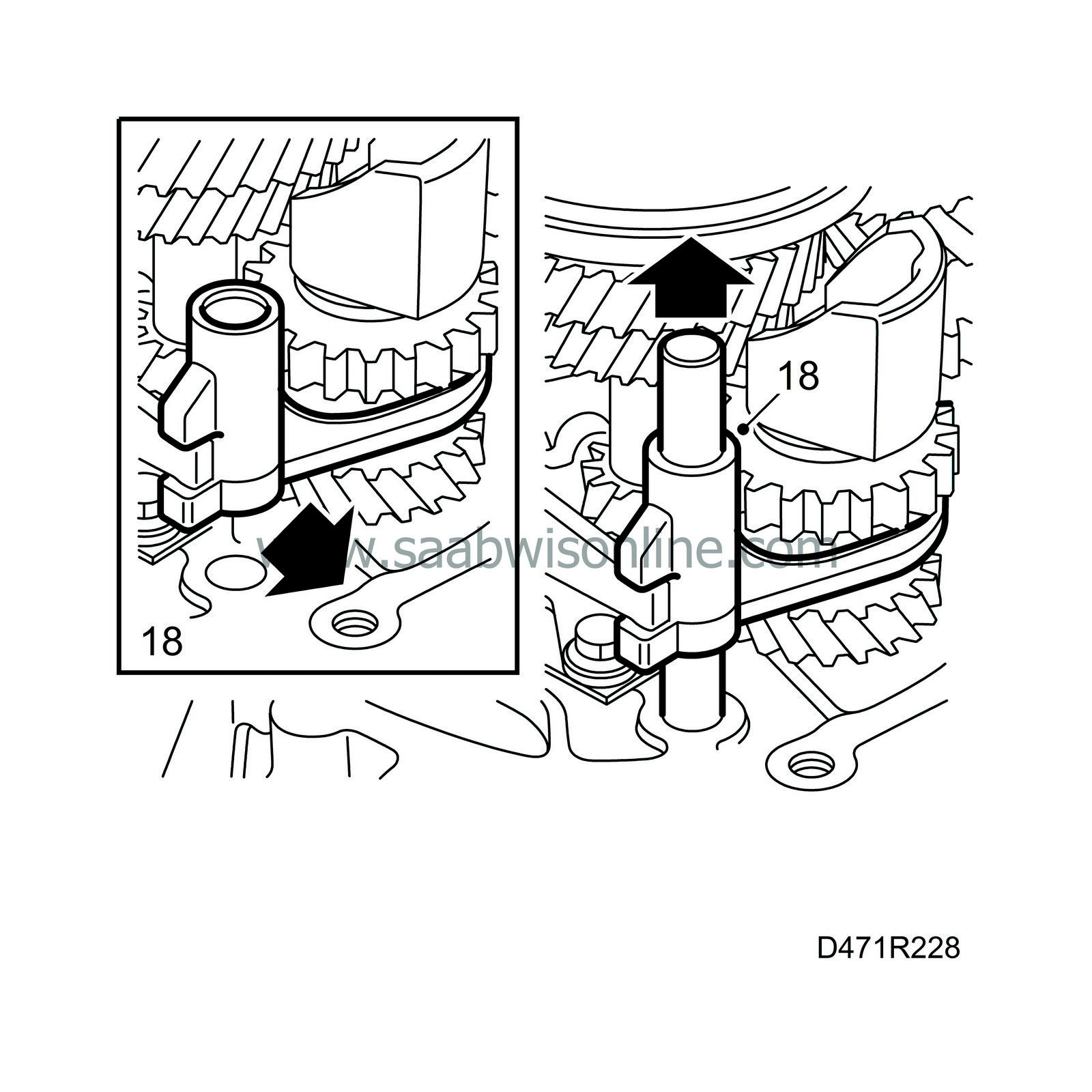

| 18. |

Remove shaft and selector fork for reverse.

|

|

| 19. |

Unscrew and remove the reverse gear selector fork.

|

|

| 20. |

Engage reverse gear on the selector mechanism to gain access to the screw for the selector rod.

|

|

| 21. |

Remove the screw for the driver on the selector rod. Withdraw the shaft and keep the driver.

|

|

| 22. |

Disengage reverse. Remove the screw and lift the selector mechanism slightly to lift the locating sleeves from their seats. Lift off the sleeves.

Pull the selector mechanism back towards the differential and angle it out slightly. Lift out the selector mechanism. |

|

| 23. |

Lift the input shaft slightly and lift the reverse shaft and pinion (reverse gear).

|

|

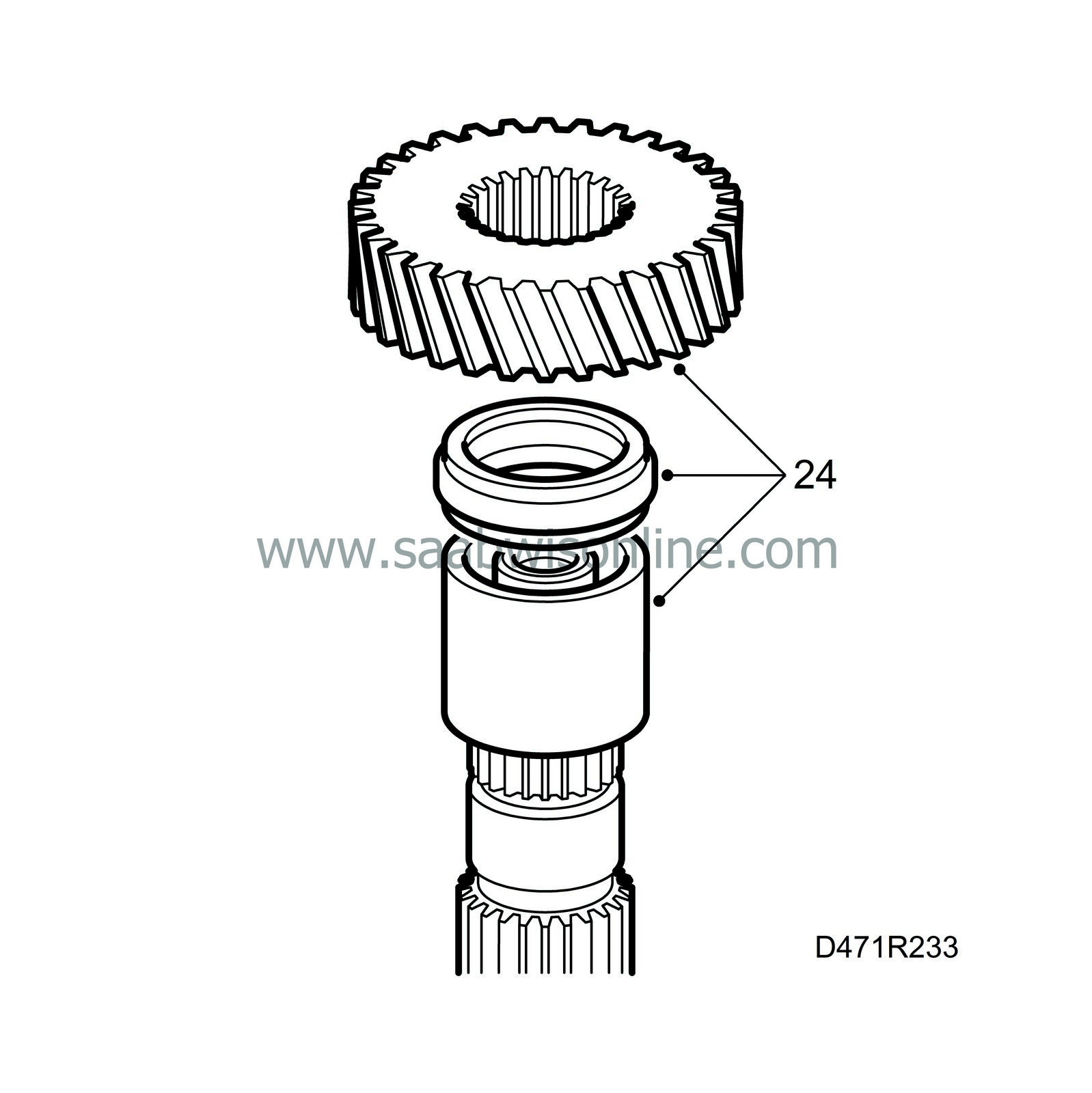

| 24. |

Lift off the 4th gear wheel, leaving the collet and spacer sleeve in place on the shaft.

|

|

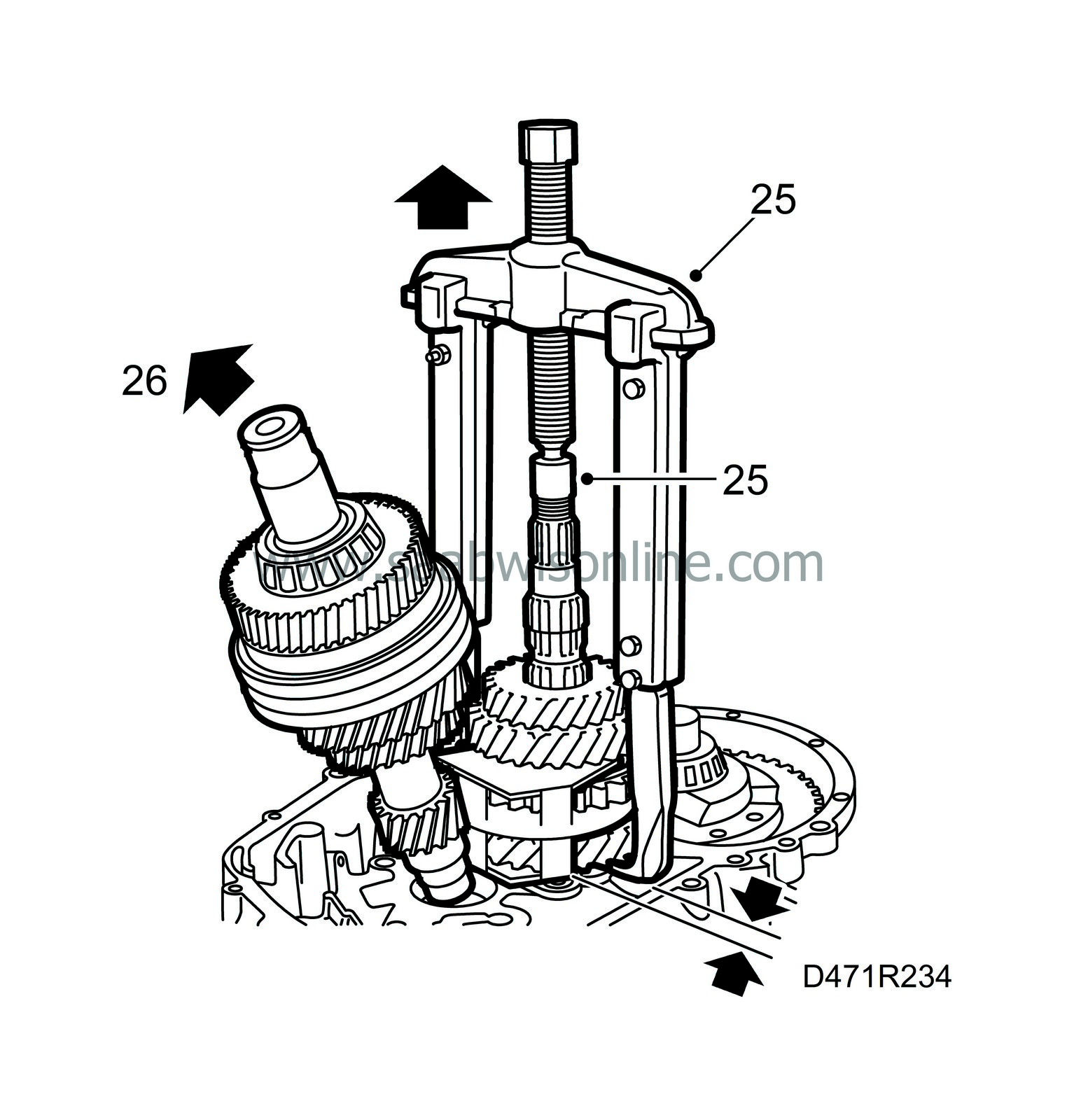

| 25. |

Place

87 91 287 Puller, 150 mm

with

87 91 295 Arm, 300 mm

under 1st gear's wheel on the output shaft. Lift up the drive assembly with two screwdrivers so that the shanks go in under 1st gear's pinion. Place

87 91 410 Sleeve

on the output shaft as protection. Tighten slightly and fit

87 92 103 Assembly fixture

which holds together 1st and 2nd gears' synchromesh assembly. Attach a cable tie around the tool and pinion assembly. Pull up all gear wheels of the output shaft about 15 mm.

|

|

| 26. |

Lift out the input shaft.

|

|

| 27. |

Tighten until the gear wheels on the output shaft become detached.

|

|

| 28. |

Lift off the gear wheels (1st, 2nd and 3rd gears') and the baulk rings and synchromesh sleeves which are held together by

87 92 103 Assembly fixture, 1st and 2nd gear hubs

.

|

|

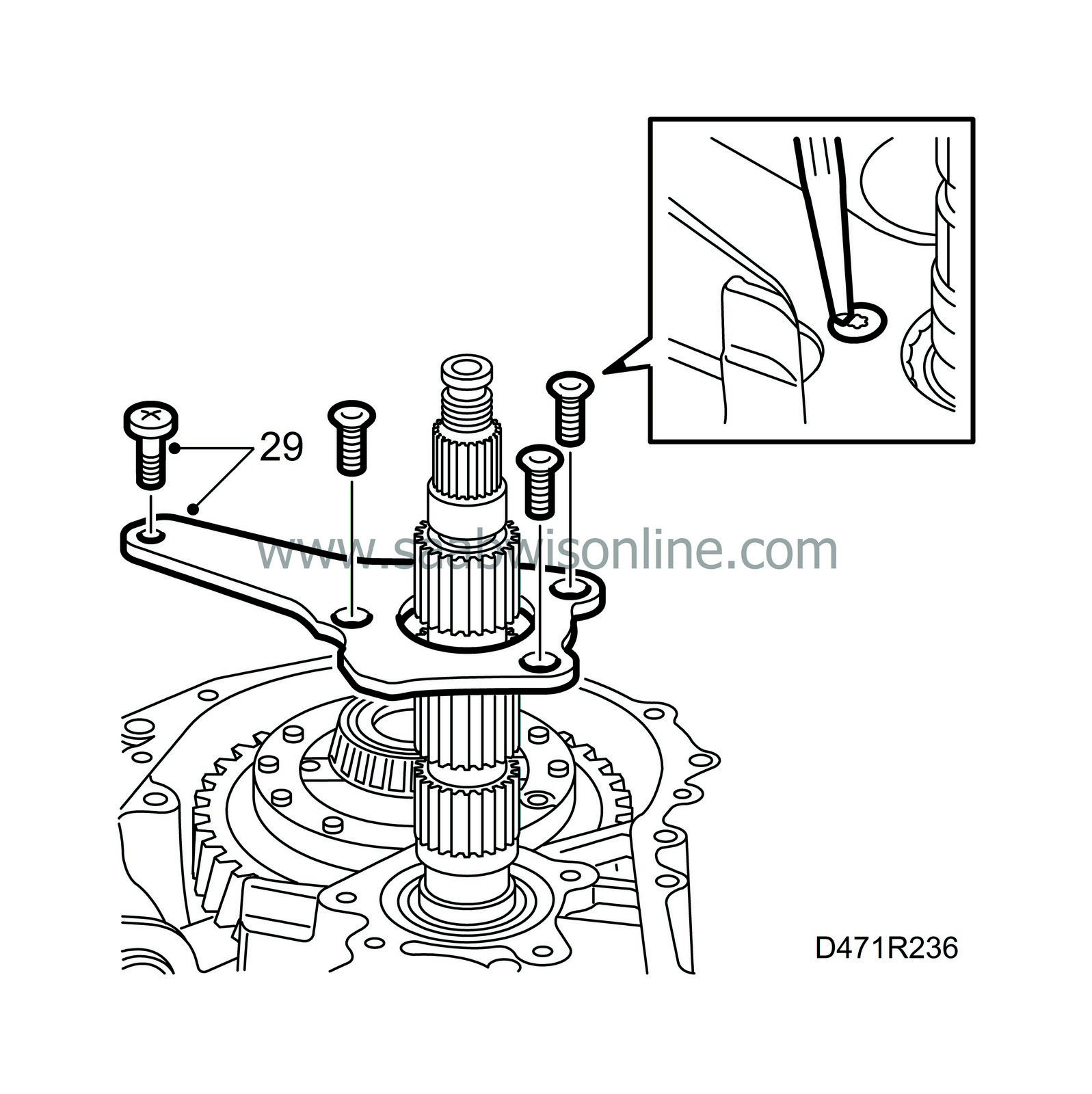

| 29. |

Undo 4 bolts and remove the output shaft bearing support.

|

|||||||

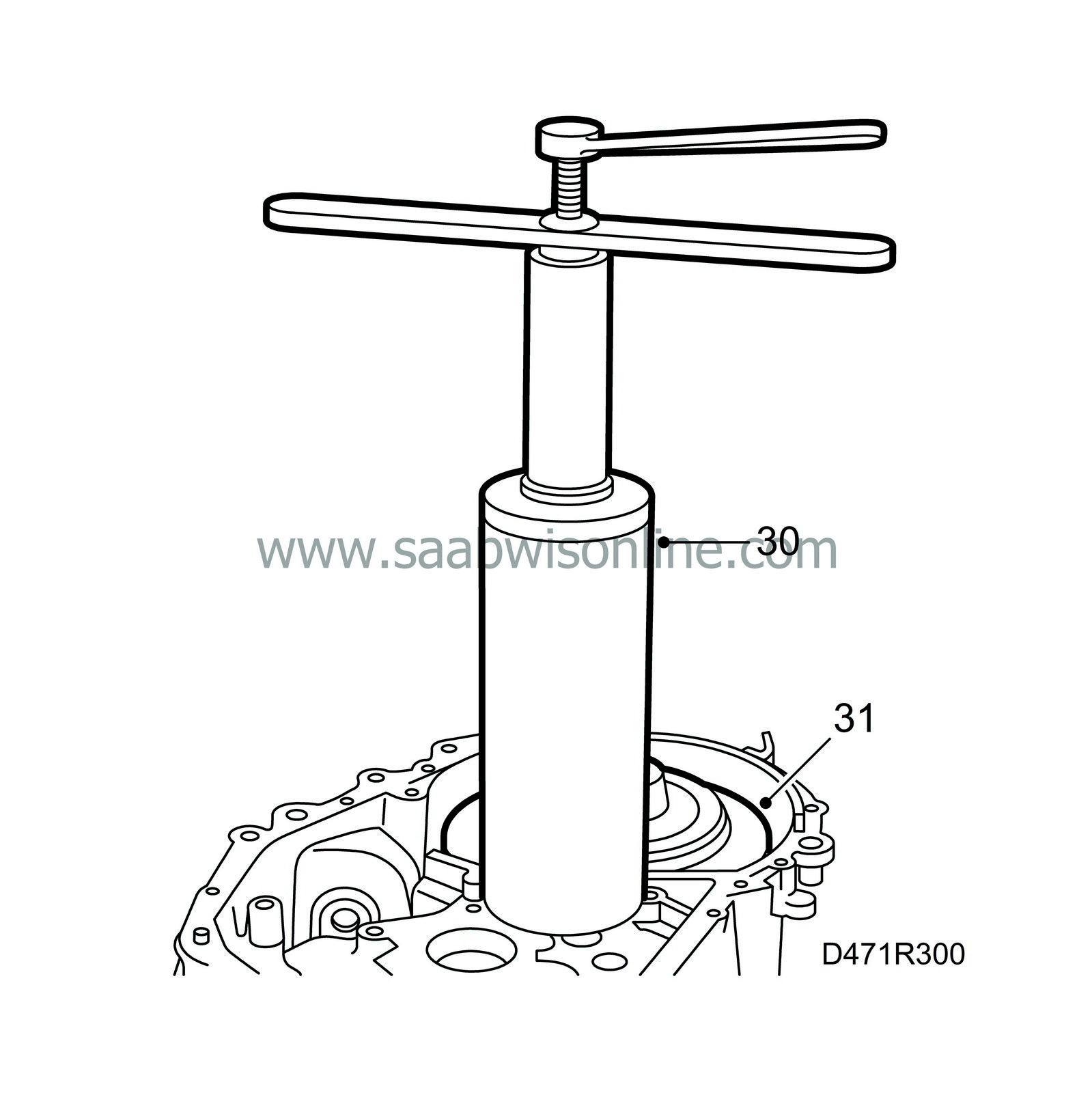

| 30. |

Pull up the output shaft. Use

87 91 188 Support, removing pinion shaft

,

87 91 972 Ring

and

87 91 261 Puller, pinion

.

|

|

| 31. |

Lift out the differential.

|

|