Welding

| Welding |

|

|||||||||||||

The characteristics of the body deformation zones and cabin enclosure must not be changed or deteriorate after repair. Therefore, it is important that all welding work is done according to method descriptions and that the correct welding method is used in the correct places. Spot-weld rather than plug-weld if space allows for it. Always check the number of spot-welds and their location before removing the damaged part and use the same number in the same positions when fitting the spare part. When spot-welding, the diameter of the electrodes must not exceed 6 mm. The core of the spot-weld must be at least 5 mm in diameter to ensure high strength. It should be possible to put a screwdriver between two spot-welds and strike it with a hammer without the welded joint braking open. Welding primer must always be applied between the metal sheets being spot-welded. Use Teroson Zinkspray.

When MAG-welding, make sure that the grounding of the welding unit is 100% and connect the ground cable as close to the welding point as possible. This is important in order to be able to weld without first removing all electronic units from the car.

| Important | ||

|

If good grounding is not ensured, electronic components can be damaged by current surges through the metal. |

||

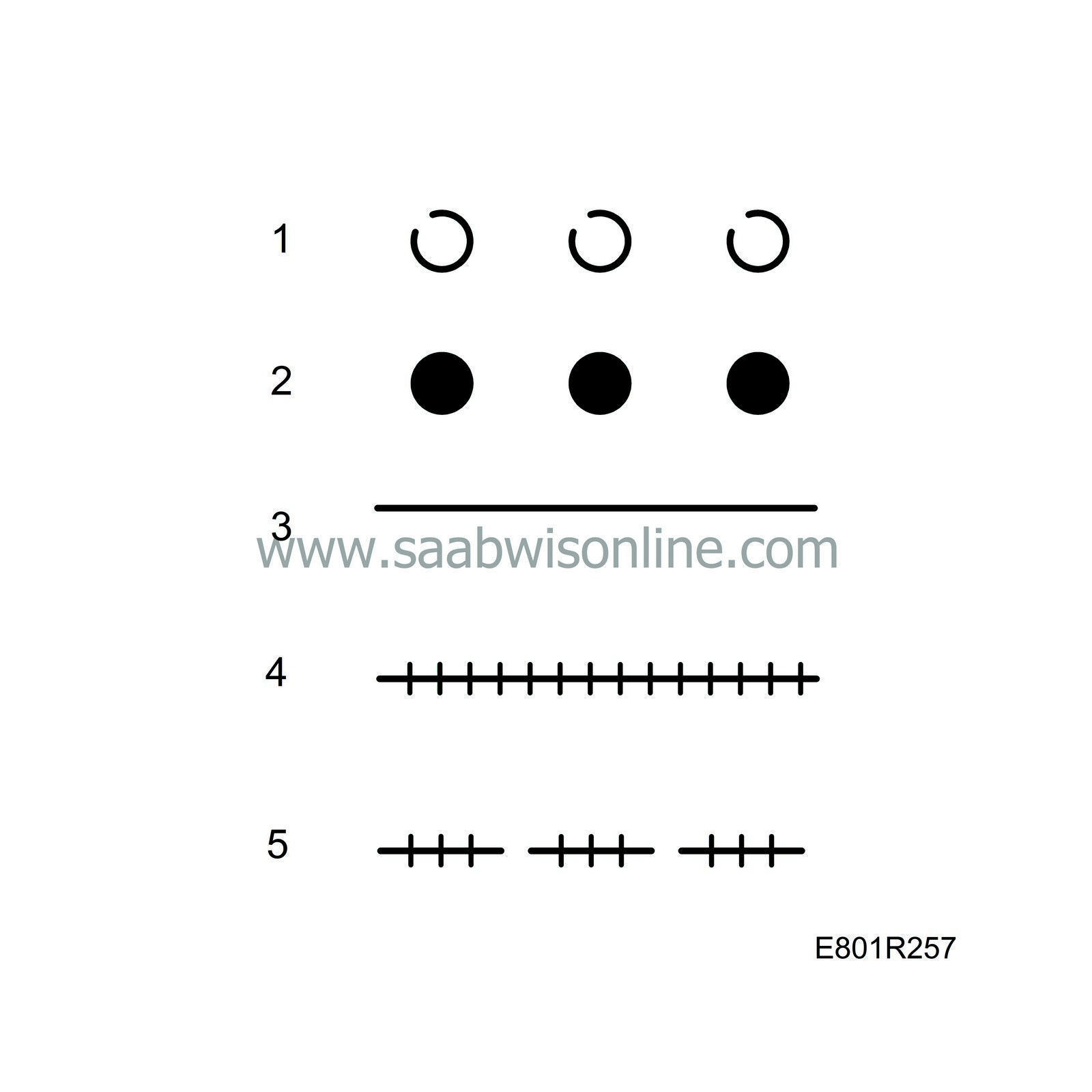

The following symbols are used for the different welding methods in method descriptions:

| 1. |

Spot-welding drill

|

|

| 2. |

Spot-welding unit

|

|

| 3. |

Cutting

|

|

| 4. |

Continuous weld, continual seam

|

|

| 5. |

Seam weld

|

|

Warning

Warning