Compressor (diesel)

| Compressor (diesel) |

A lot of power is needed to achieve this pressure increase, and the power is taken from the crankshaft by the compressor via a belt circuit that also drives, among other things, the alternator and the power steering pump.

Cut-in and cut-out is achieved through an electromagnetically controlled mechanical clutch that is integrated with the compressor belt pulley. The compressor adjusts its pump capacity to existing conditions and operates normally without cyclical cut-ins and cut-outs caused by the anti-freeze sensor on the petroleum engine. However, the same type of anti-freeze sensor is mounted here but it is relatively seldom activated to prevent freezing in the evaporator.

There is no overheating protection installed since the operating temperature is considerably lower than for the compressor on petroleum engines.

The compressor is equipped with a non-return valve located on the outlet on the high-pressure side. The non-return valve prevents refrigerant from flowing back to the low-pressure side during the normal operation of the compressor but also when it has been stopped. There is also a non-return valve on the low-pressure side.

The compressor has a variable stroke, also called displacement. A compressor with a variable stroke adjusts the stroke to the existing requirements and conditions for cooling of the cabin.

As the swept volume always is adjusted to the need for cooling, the evaporator temperature will remain constant for the most part. This means that the compressor will not cycle as much as when a compressor with a fixed displacement is used.

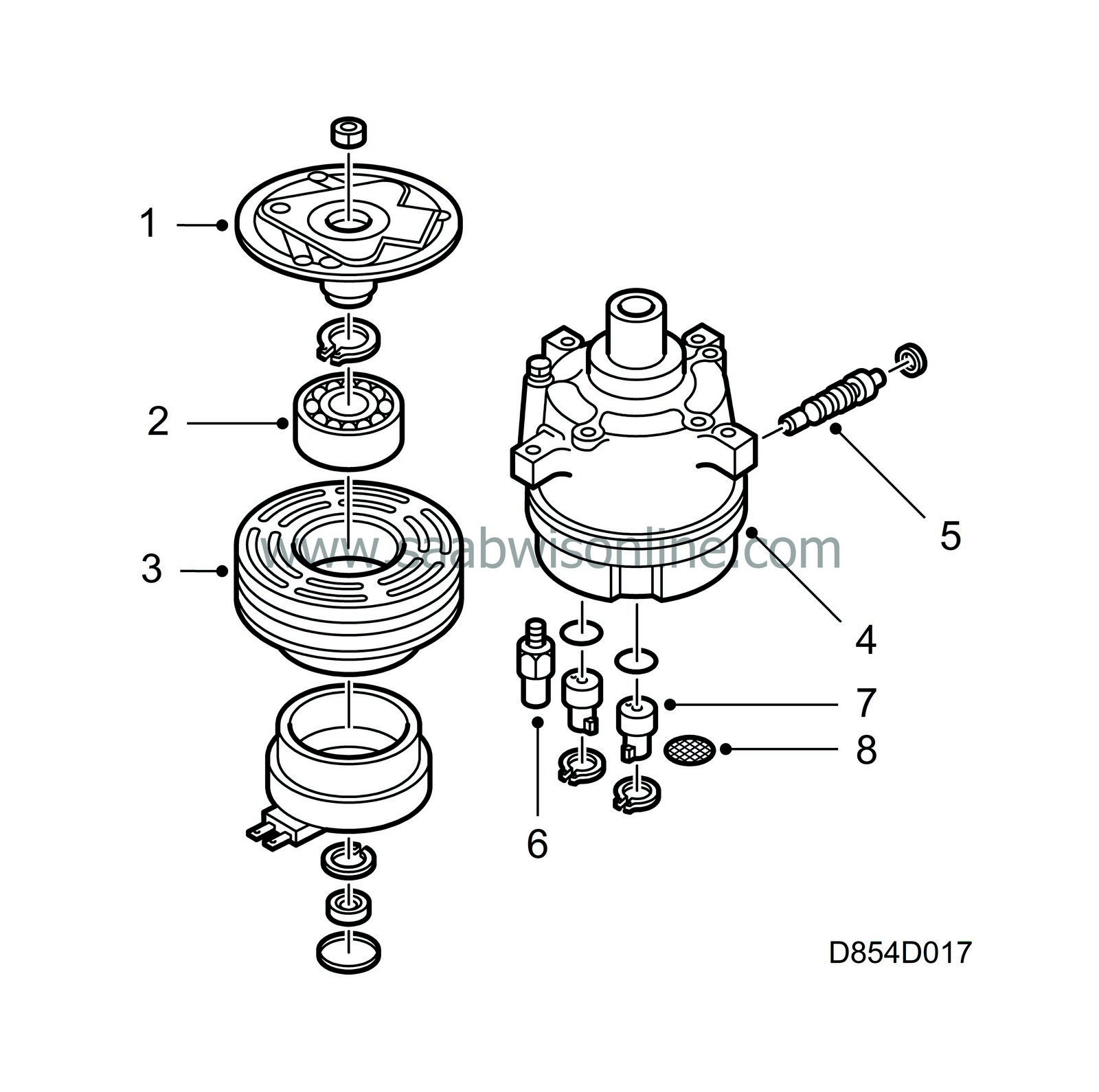

| 1. |

Clutch end plate, input

|

|

| 2. |

Clutch bearing

|

|

| 3. |

Rotor, clutch

|

|

| 4. |

Compressor housing

|

|

| 5. |

Control valve

|

|

| 6. |

Overflow valve

|

|

| 7. |

Inlet and outlet valves

|

|

| 8. |

Strainer, inlet

|

|

The compressor is of the piston type with five axial cylinders.

The pistons move back and forth in the cylinders and create, along with the action of the inlet and outlet valves, a refrigerant pumping action. The power from the rotating compressor shaft is transformed to the back and forth movement of the pistons using a rocker disc. The pistons are guided on each side by piston guides which are in contact with the rocker disc on both sides.

The stroke of the pistons is changed in order to change the swept volume of the compressor. By changing the angle of the rocker disc against the compressor shaft, the stroke of the pistons either increases or decreases.

The pressure differential between the compressor cylinders and the compressor housing is used to change the angle of the rocker disc. If the pressure in the housing is lower than the pressure on top of the pistons, the pistons and the rocker disc are moved together axially in the direction of the belt pulley. Through a linkage between the rocker disc and the shaft, the angle of the rocker disc will continually increase as the pistons and the rocker discs move. The increased angle results in an increased swept volume.

Control of swept volume

Control of the compressor swept volume is regulated by the control valve, located in the compressor rear end plate. The control valve attempts to keep the compressor low-pressure side at a constant pressure. In order to achieve this constant pressure, the control valve changes the pressure in the compressor housing as follows:If the compressor low-pressure side has a low pressure and, accordingly a low need for cooling, the control valve opens a passage for refrigerant from the high-pressure side to the housing. As the pressure increases in the housing, the stroke is decreased and so is the capacity of the compressor.

If the compressor low-pressure side has a high pressure and, accordingly, a high need for cooling, the control valve closes the refrigerant passage from the high-pressure side to the housing. The pressure in the housing decreases and the stroke increases, and the compressor can operate at a higher capacity.

There is always a small amount of refrigerant passing between the housing and low-pressure side through a slight opening in the control valve.