Bumpers and spoilers, severe scoring and cracks

|

|

Bumpers and spoilers, severe scoring and cracks

|

|

1.

|

Clean off dirt from the components. It is imperative that there is no gravel or other particles in the area to be welded.

|

|

2.

|

Wash the repair area with Teroson FL cleaner.

|

|

3.

|

Identify the plastic. See

or

or

|

|

4.

|

Select the appropriate welding wire and set the correct working temperature on the welding pistol so that it corresponds with the type of plastic. See

|

|

5.

|

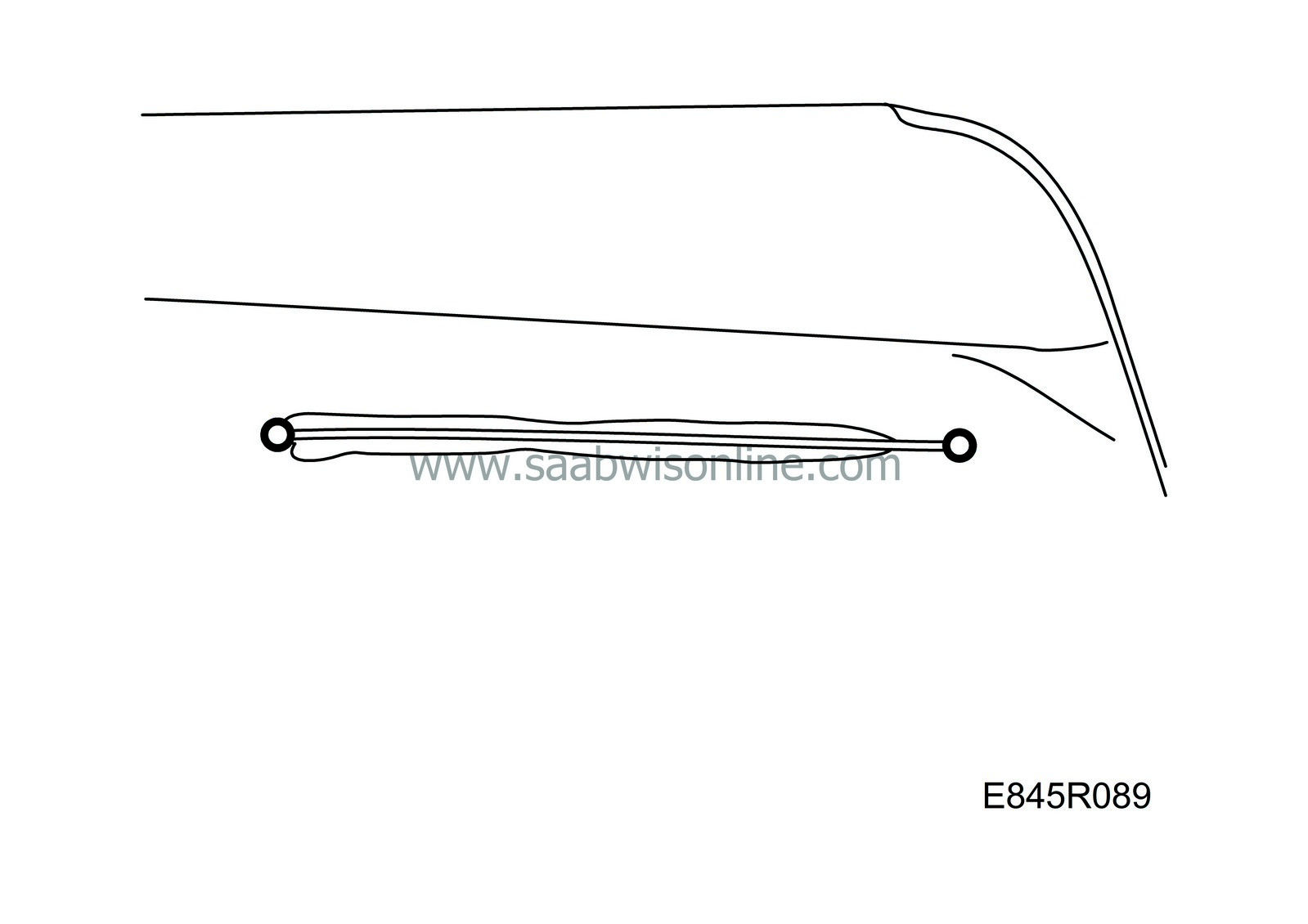

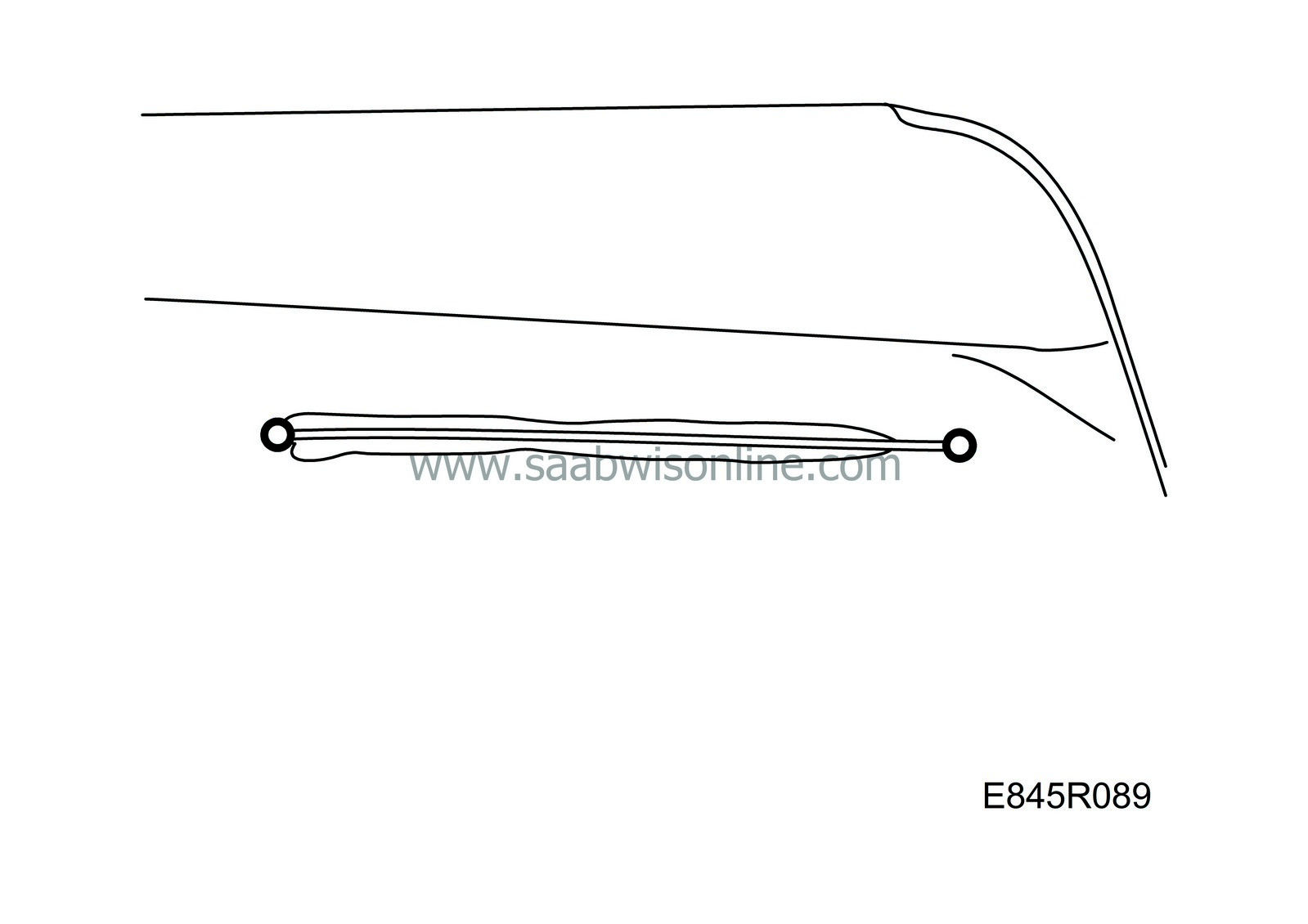

If a crack is being repaired, first drill a hole with a 3.5 mm drill at each end of it so that the damage does not become worse.

|

|

6.

|

Machine a 90° V-joint on the back. Make sure to use a low-speed machine.

|

|

7.

|

Set the correct working temperature on the welding pistol so that it corresponds with the type of plastic. See

.

.

|

|

8.

|

Weld the crack from the rear.

|

|

9.

|

Sand away any paint on the front around the damaged area.

|

|

10.

|

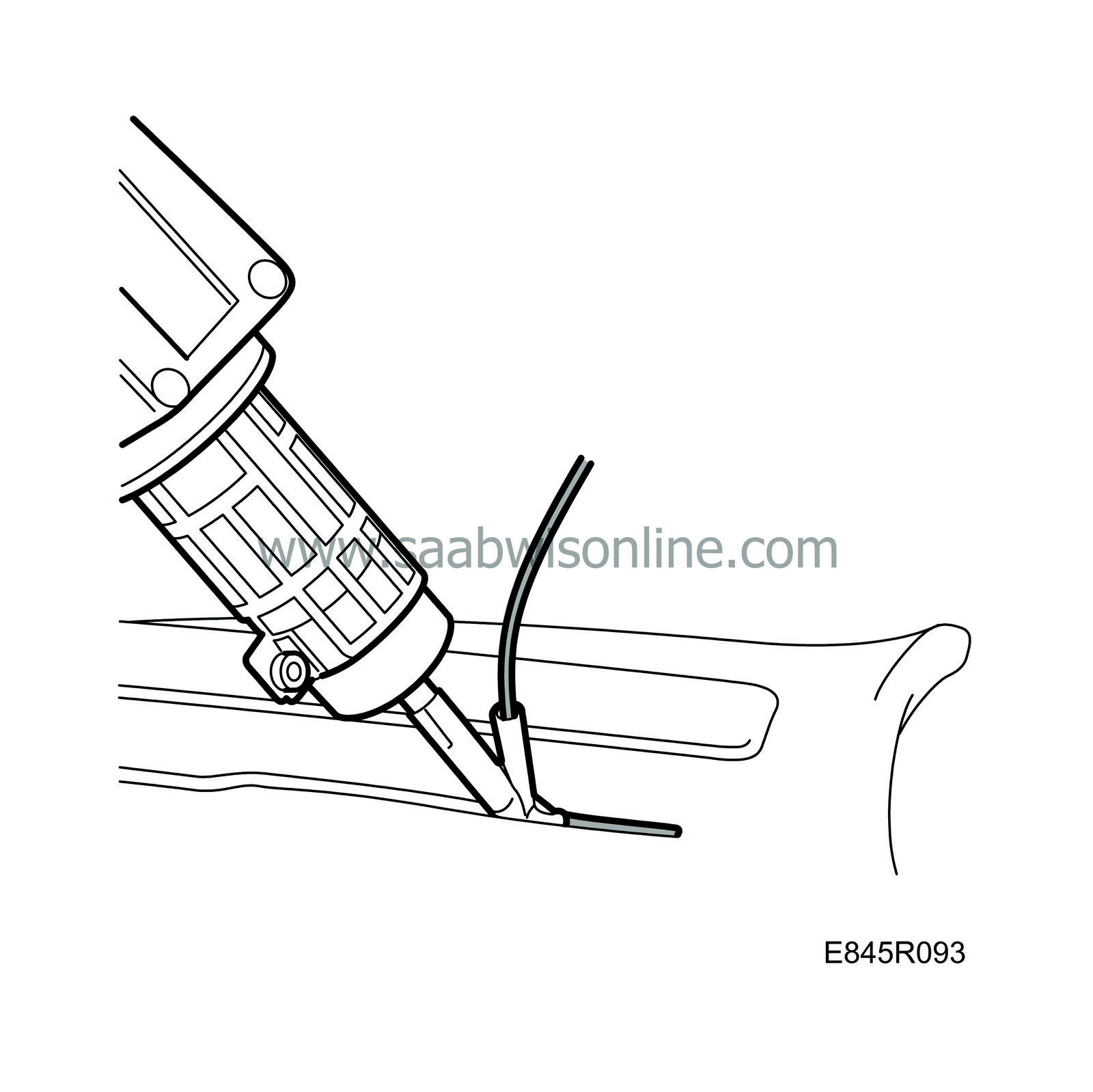

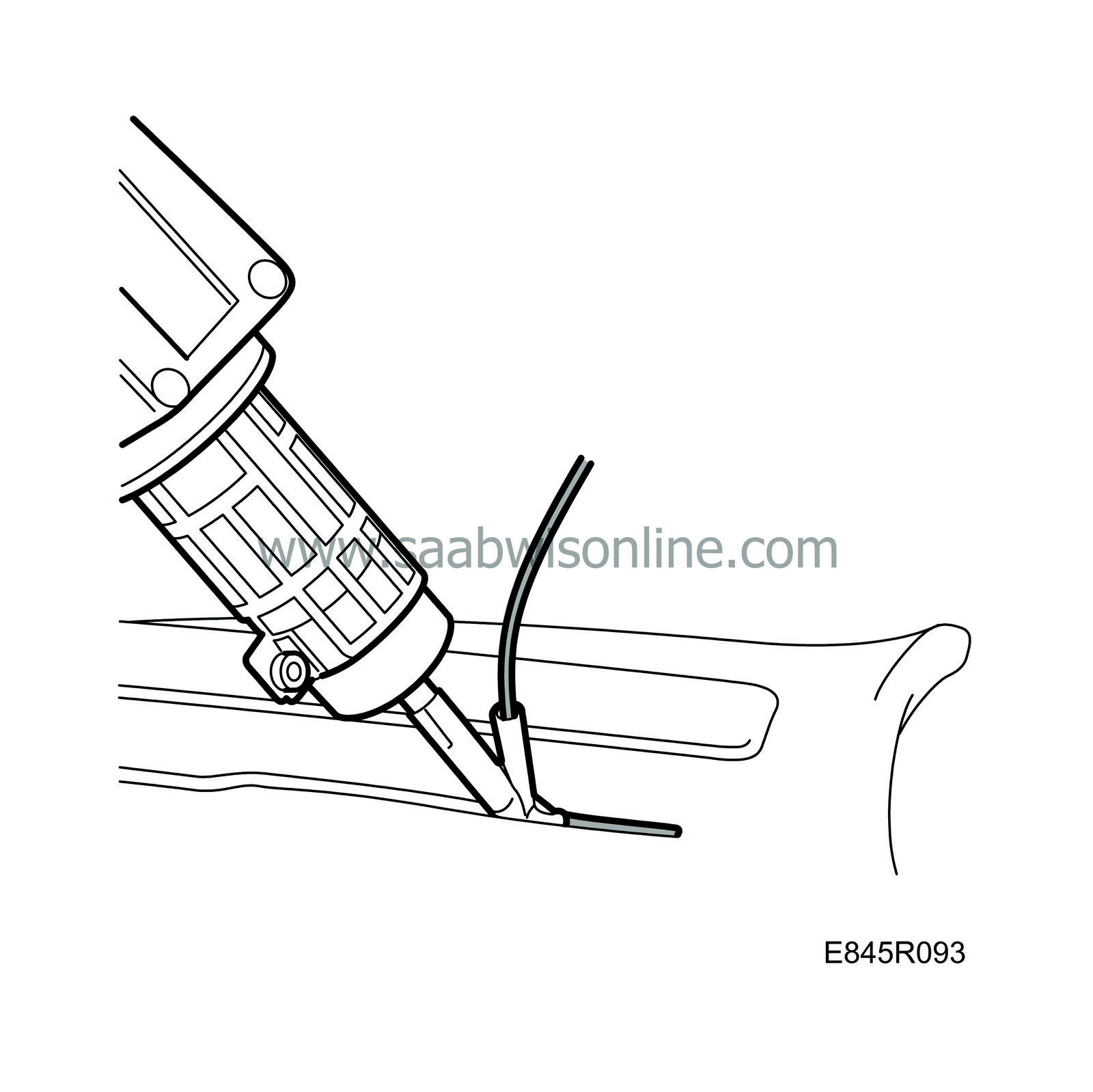

Check the working temperature of the welder.

|

|

11.

|

Weld the front with welding rod.

|

|

12.

|

Allow the welded area to cool.

|

|

13.

|

Sand the welded area free from excess welding material.

|

|

14.

|

Perform the concluding work 1 - 10. See

|

or

or

.

.