General information on thermoforming

|

|

General information on thermoforming

|

As already stated, thermoplastic is affected by heat. Thermosetting plastic on the other hand has obtained its final form and this cannot be changed.

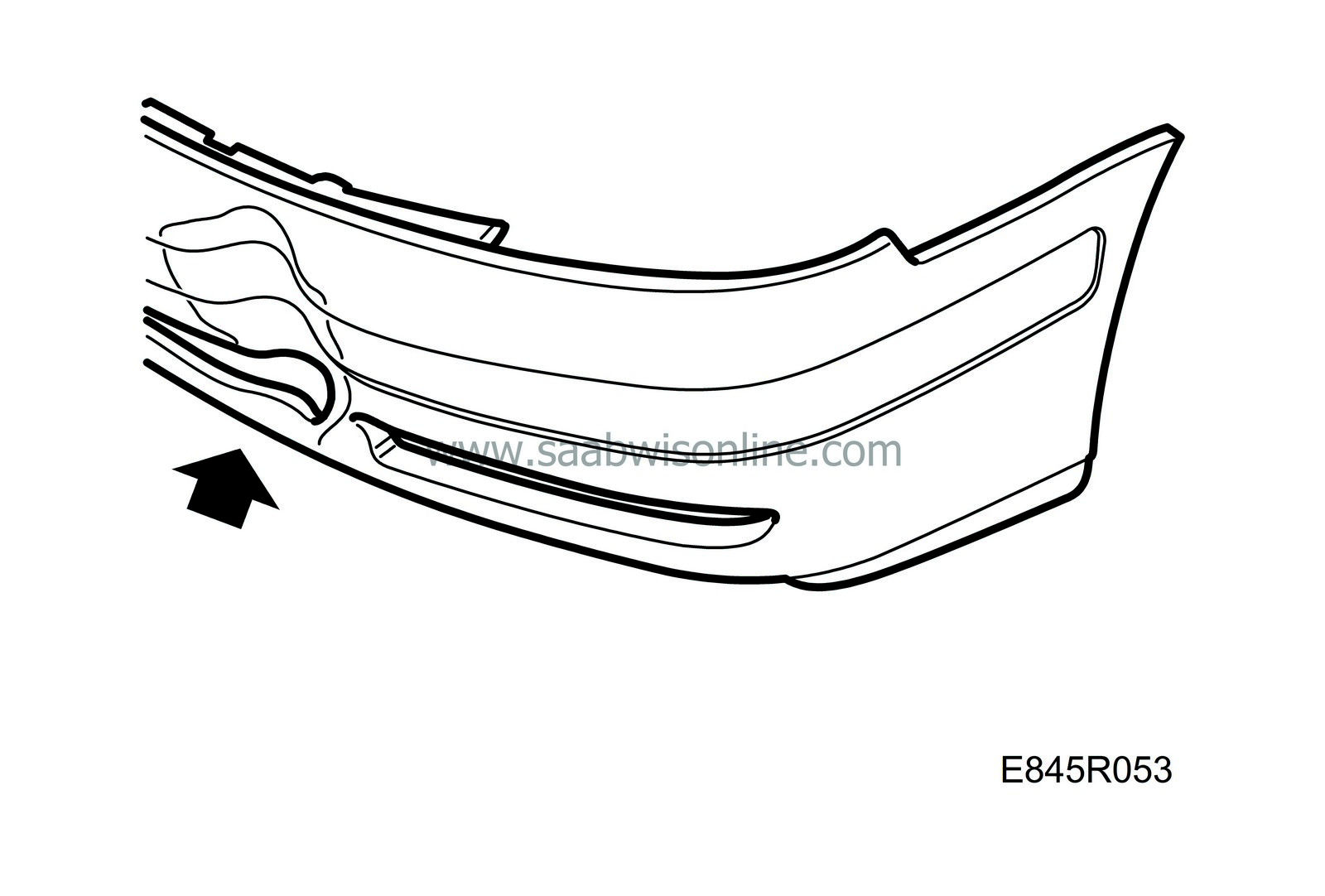

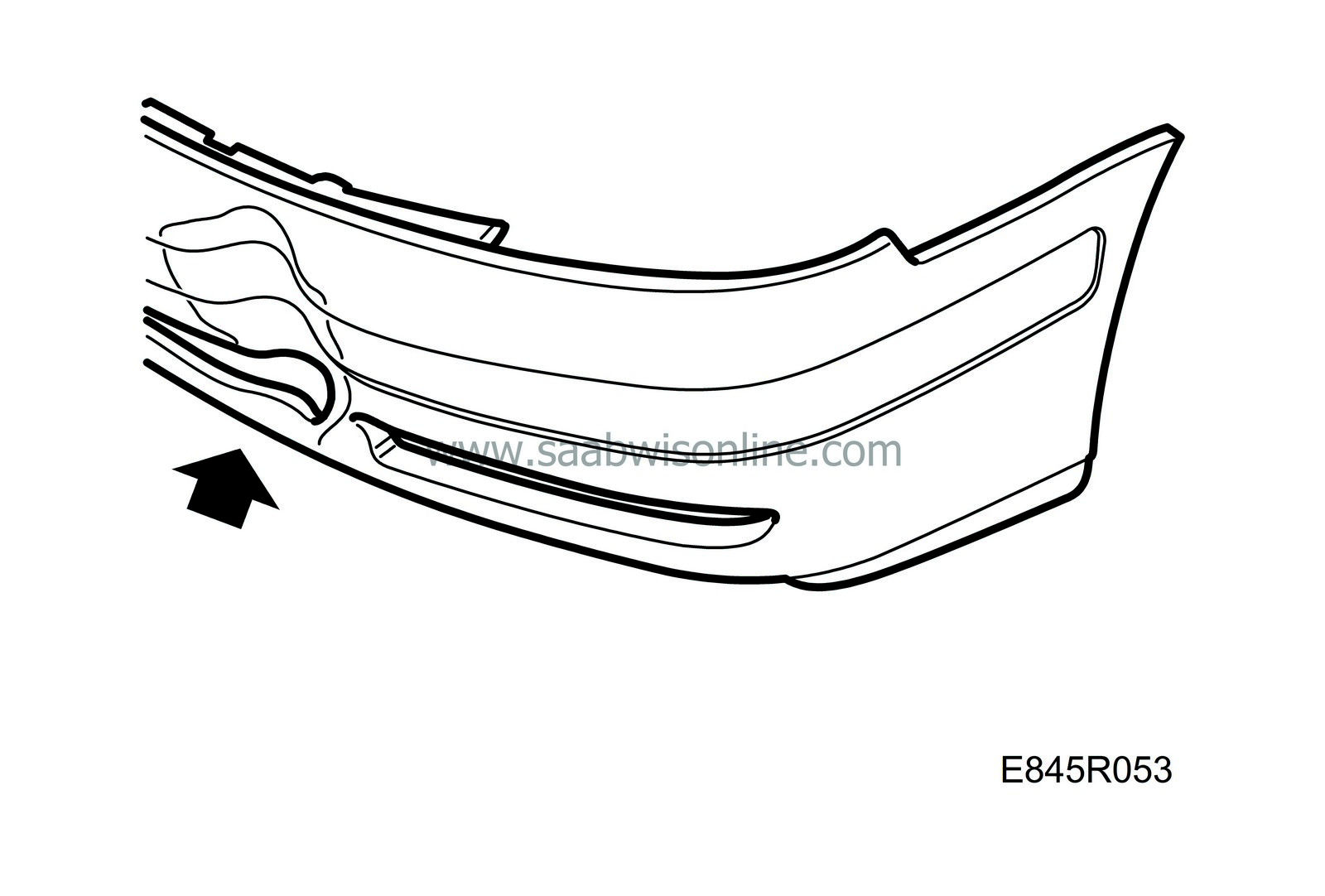

Thermoplastic components that have been deformed for some reason can, therefore, be adjusted with a hot-air gun or in a varnishing oven. Thermoforming in a oven is suitable if the component has become warped or “dented” without breaking. The “buckle” can be seen in dark-coloured plastic as white areas at the edge of the buckle. Proceed as follows:

|

2.

|

Heat the oven to 65°C and place the component to be aligned in the oven. Make sure it is lying flat.

|

|

3.

|

Leave it in the oven for about one hour.

|

|

4.

|

Inspect the result. Rectify any damage to the finish by sanding-filling-painting.

|

|

Minor buckles can be adjusted as follows:

|

|

2.

|

Heat the rear of the plastic component with a hot-air gun. Heat an area at least twice the size of the area to be adjusted.

|

|

3.

|

Heat to such a temperature that you are just able to hold your hand on the front of the plastic detail, approx. 70°C.

|

|

4.

|

Adjust the plastic with a wooden block or flat iron. "Over-adjust" by about 10% and retain that position while cooling the adjusted area with a sponge and cold water.

|

|

5.

|

Inspect the result. Rectify any damage to the finish by sanding-filling-painting.

|