Timing cover

| Timing cover |

(in-car)

| To remove |

| Important | ||

|

The cylinder head must be removed only if the engine is at room temperature. |

||

| 1. |

Note any radio code.

|

|

| 2. |

Place the engine on a lift, lay out wing covers, disconnect the battery cables, remove the battery and open the expansion tank cap.

|

|

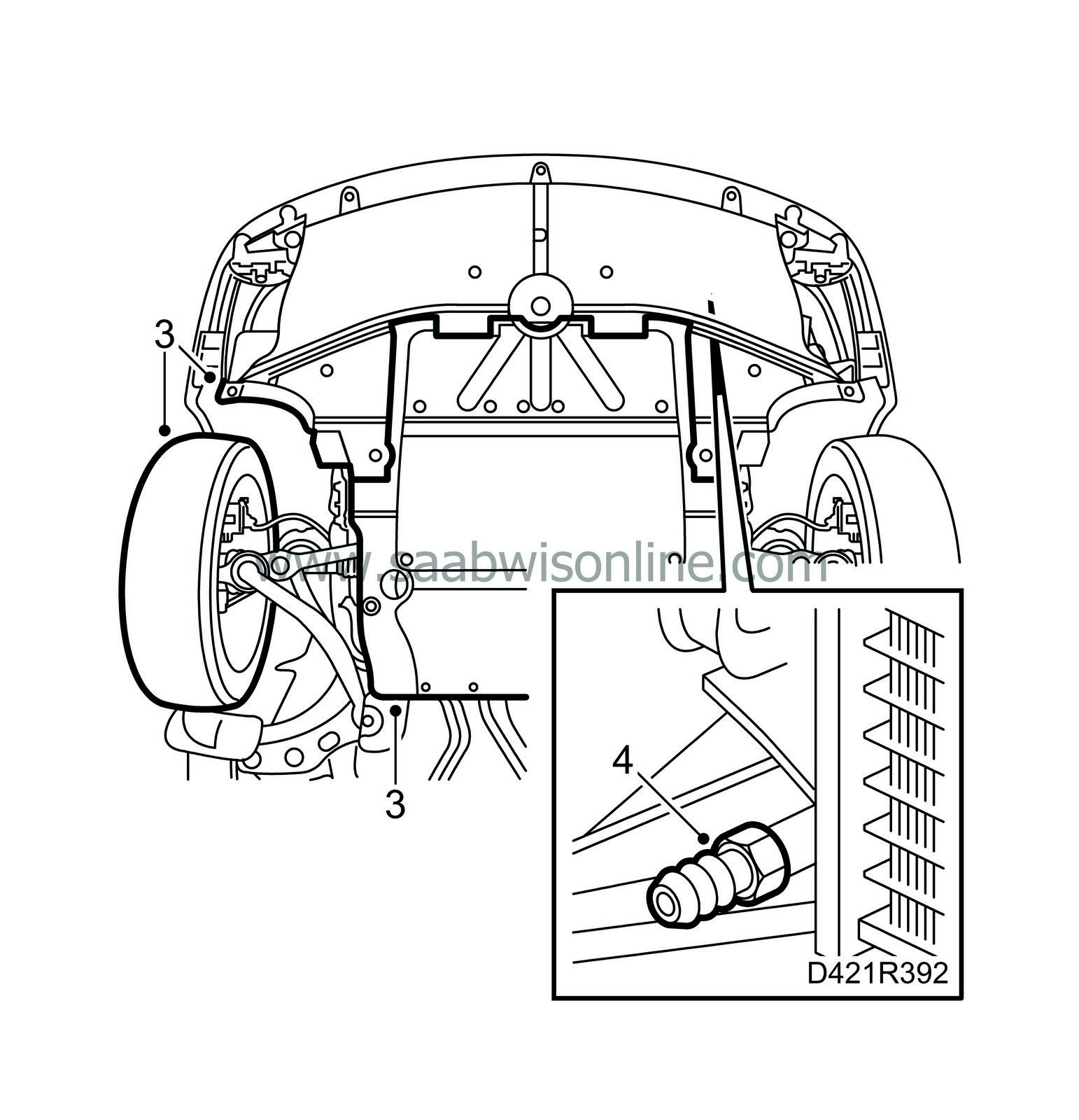

| 3. |

Raise the car, remove the lower engine cover, belt circuit cover and right front wheel.

|

|

| 4. |

Place a receptacle under the car and open the radiator drain plug.

|

|

| 6. |

Lower the car, split the fuel lines with

83 95 261 Tool, fuel line divider

and seal them.

|

|

| 7. |

Remove the air cleaner with mass air flow sensor and hoses.

|

|

| 8. |

Remove the upper engine cover.

|

|

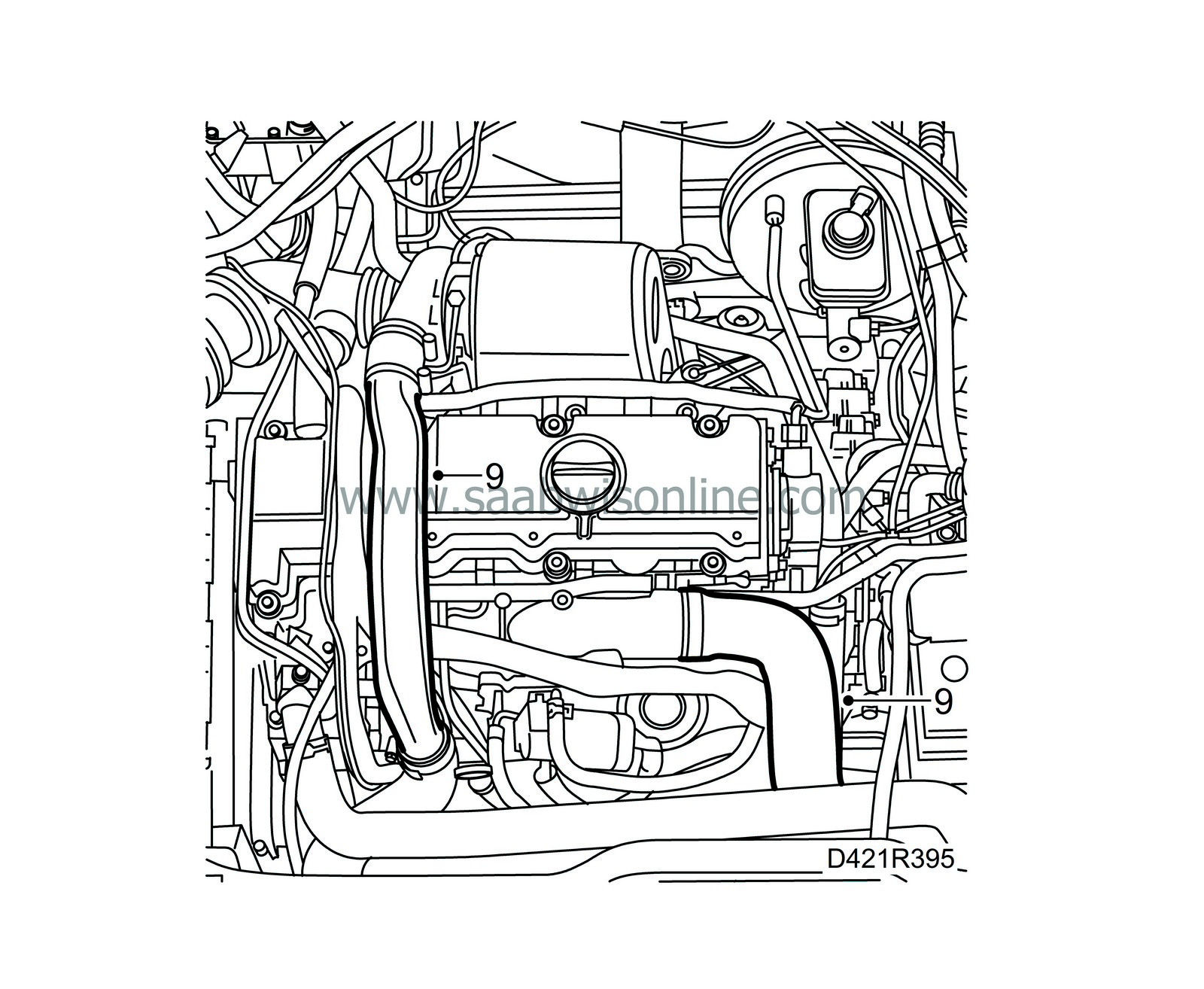

| 9. |

Remove the charge air pipe (2 bolts under the wiring harness) and seal the hose and turbocharger openings. Detach the hose to the throttle body.

|

|

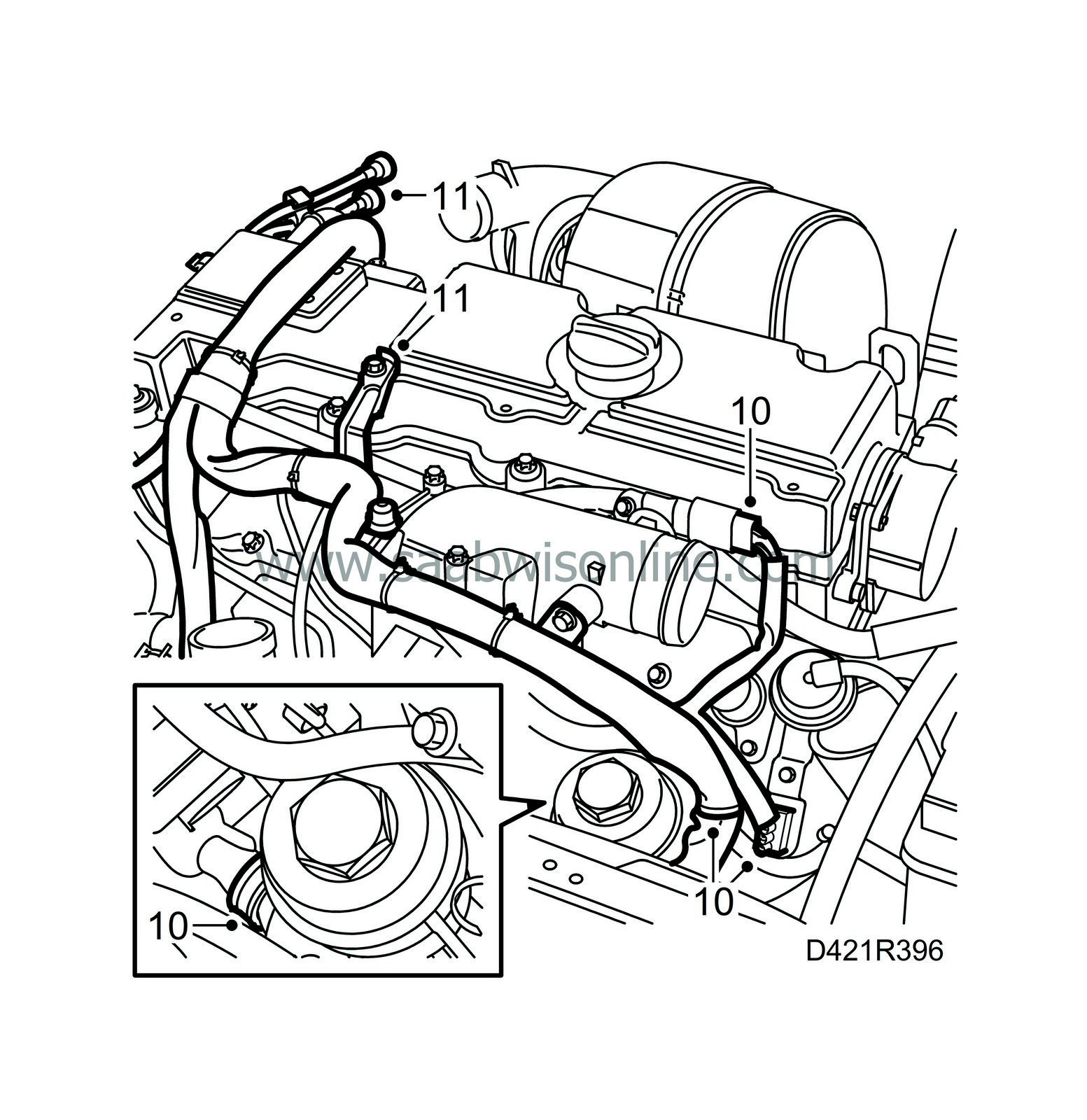

| 10. |

Unplug the connectors to the atmospheric pressure sensor, coolant temperature sensor, control module (2), EGR-valve, timing sensor and pressure sensor. Cut off the lower cable tie.

|

||||||||||

| 11. |

Remove the wiring harness cable duct from the cylinder head and remove the fuel lines from the camshaft cover.

|

|

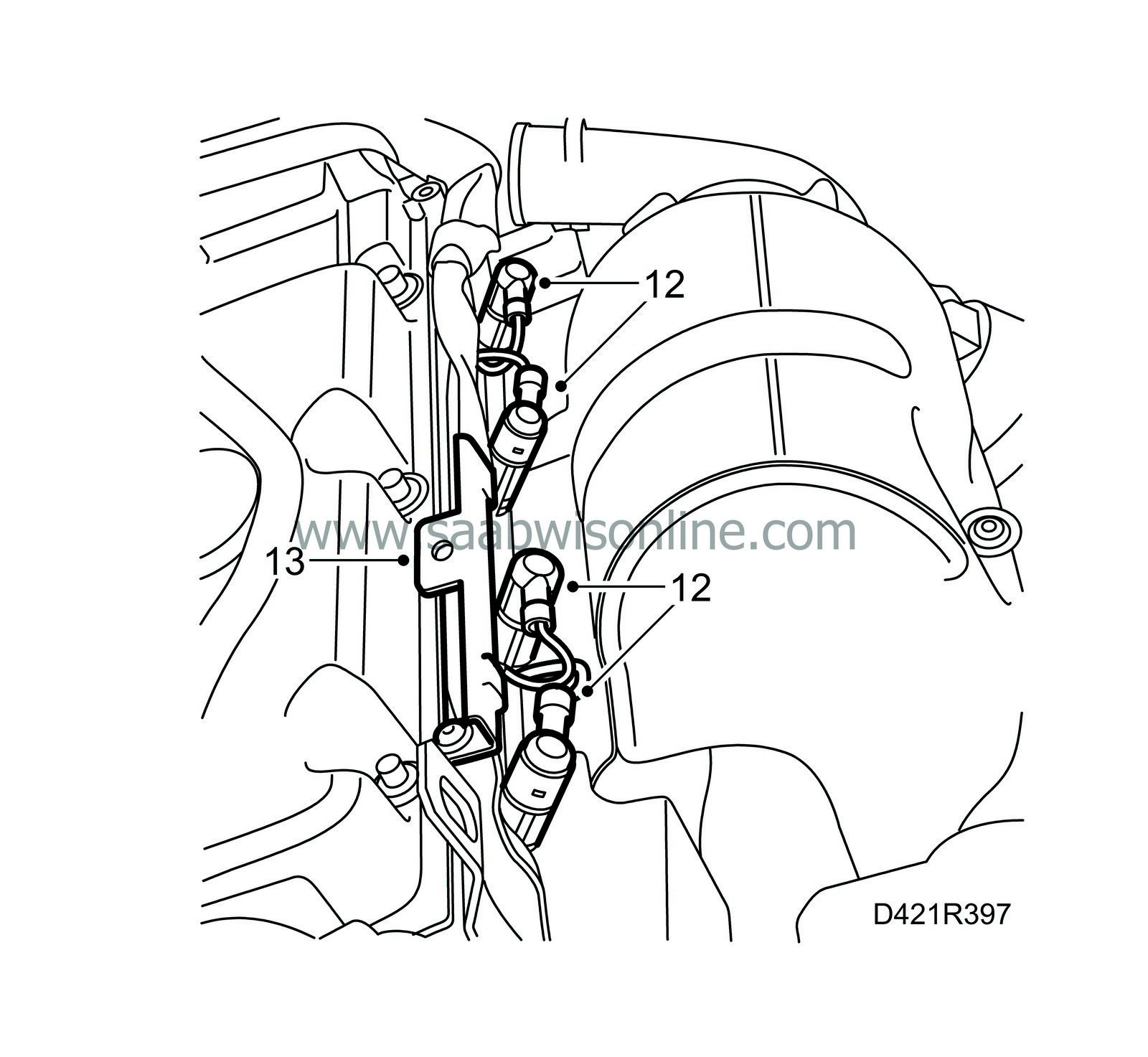

| 12. |

Detach the glow plug cable connections.

|

|

| 13. |

Unplug the wiring harness from the rear mounting and remove the harness with bracket from the engine mounting.

|

|

| 14. |

Detach the vent hose from the thermostat housing and put it to one side.

|

|

| 15. |

Remove the throttle body. Remove the EGR-valve and move it to one side.

|

|

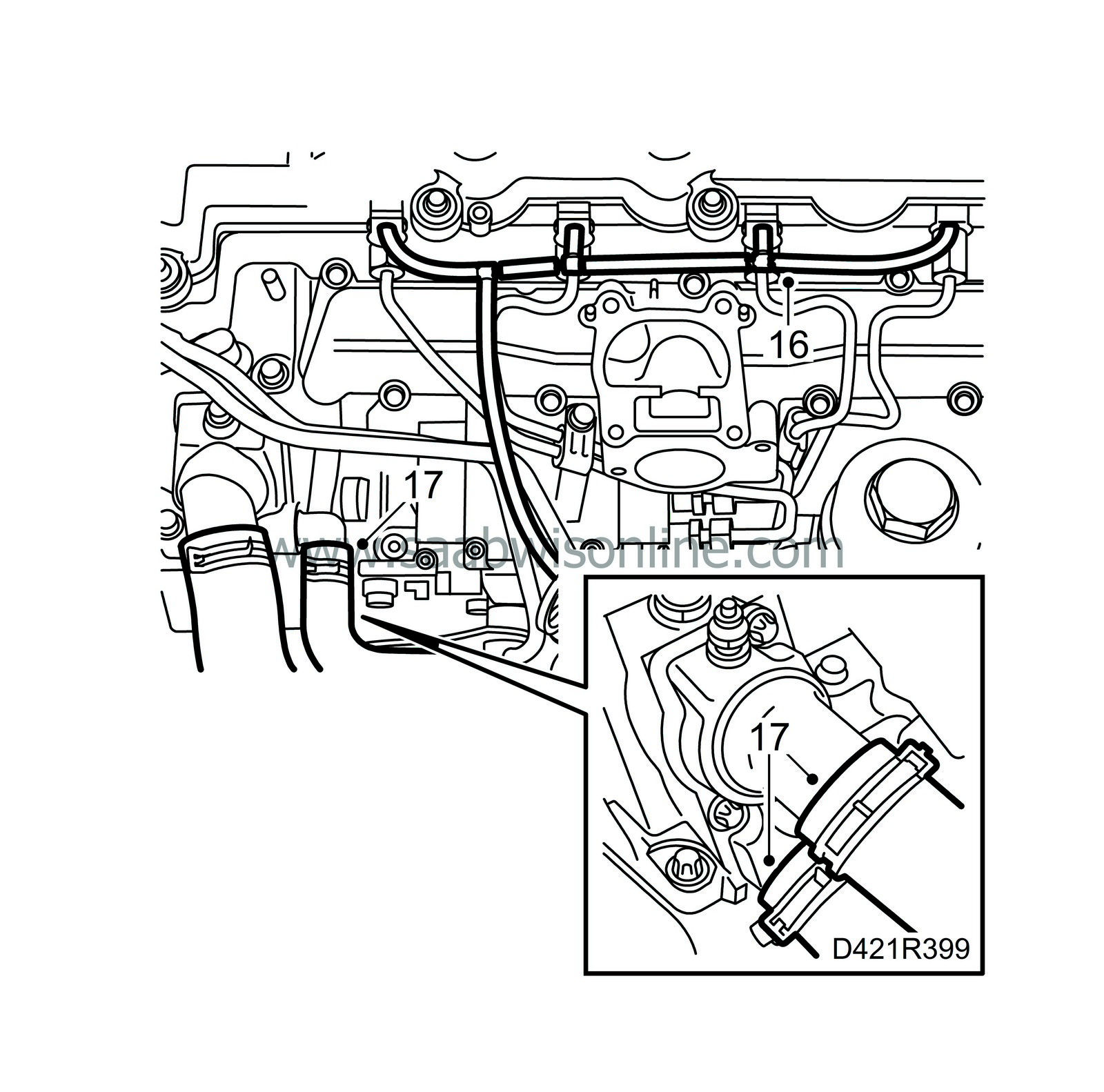

| 16. |

Remove the fuel return hoses.

|

|

| 17. |

Remove the hoses from the thermostat housing.

|

|

| 18. |

Remove the fuel lines from the fuel distribution pump.

|

|

| 19. |

Mark the position of the fuel rails and clamps. Remove the rails.

|

|

| 20. |

Remove the vacuum hose from the swirl throttle control valve.

|

|

| 21. |

Detach the hook for the coolant hose from the rear lifting eye.

|

|

| 22. |

Remove the heat shields from the turbocharger, starter motor and exhaust manifold. Undo the nut on the rear engine mounting.

|

|

| 23. |

Remove the vacuum hose from the wastegate.

|

|

| 24. |

Remove the front exhaust pipe at the turbocharger.

|

|

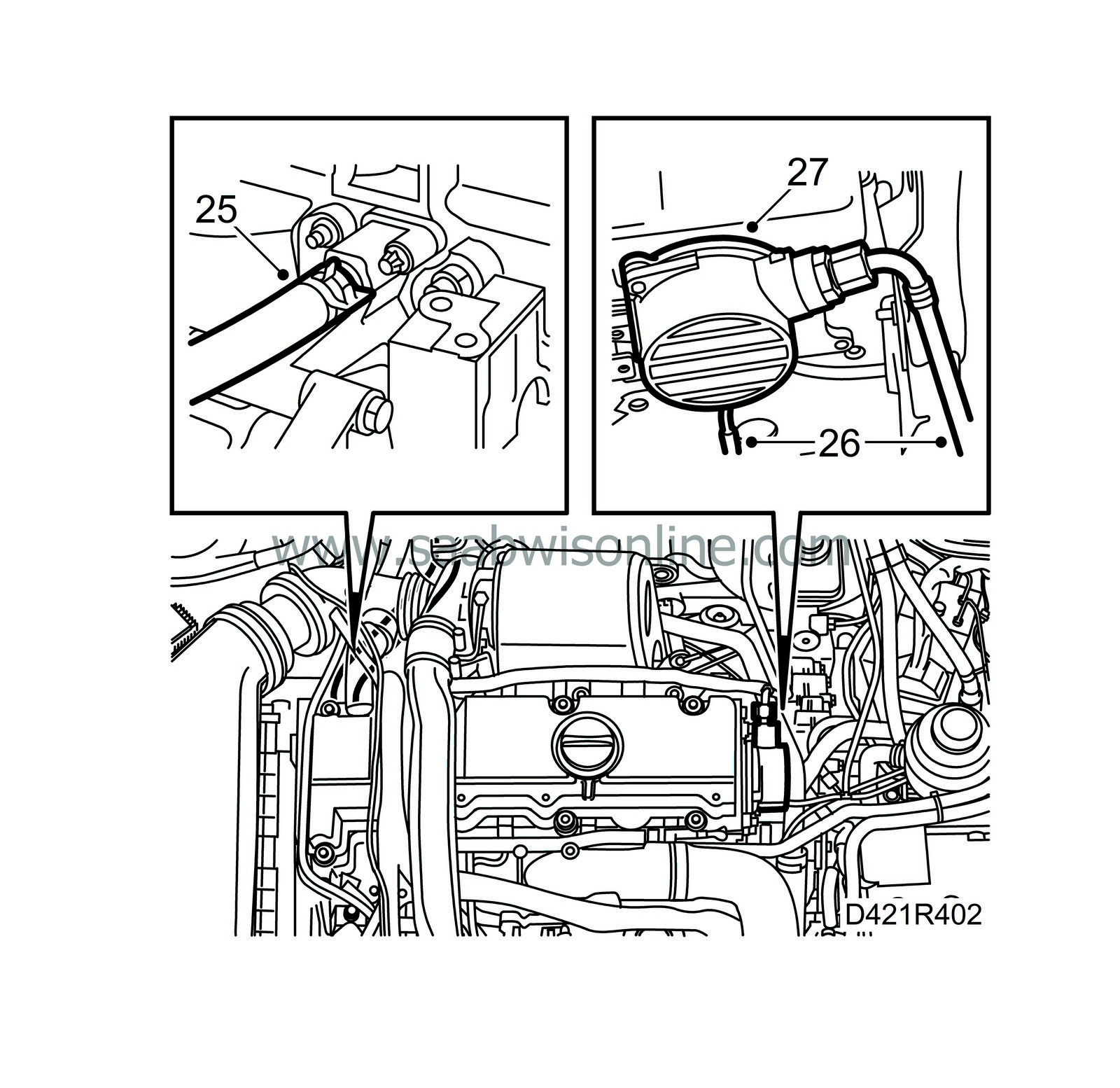

| 25. |

Cover the generator to protect it against coolant spill and remove the coolant hose from the generator bracket.

|

|

| 26. |

Remove the vacuum hose to the brake servo and the vacuum hose connected to the underside of the vacuum pump.

|

|

| 27. |

Remove the vacuum pump with adapter.

|

||||||||||

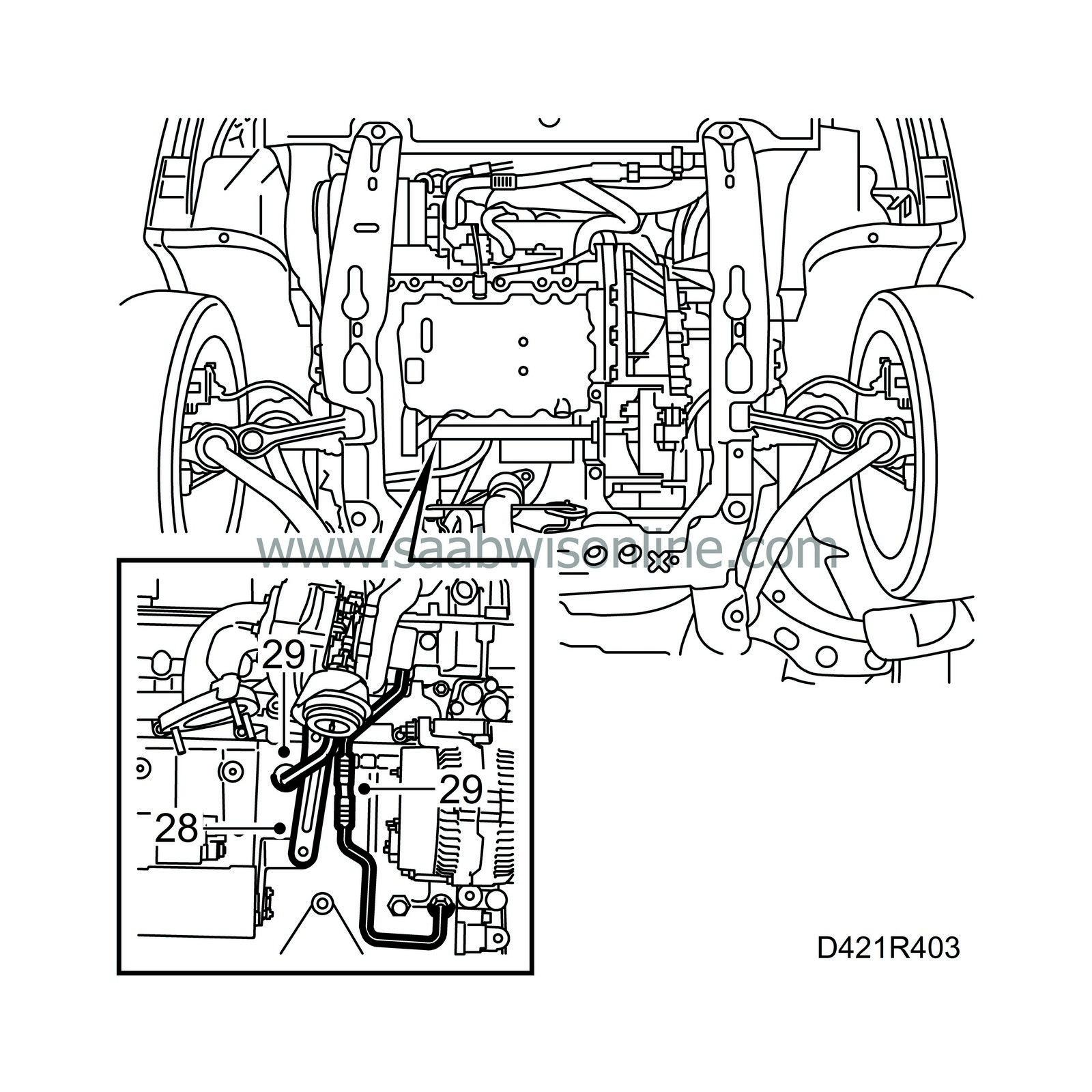

| 28. |

Remove the top bolt on the exhaust manifold support and loosen the bottom bolt so that the support can be twisted aside.

|

|

| 29. |

Raise the car and detach both turbocharger oil pipes from the cylinder block. Seal the pipes.

|

|

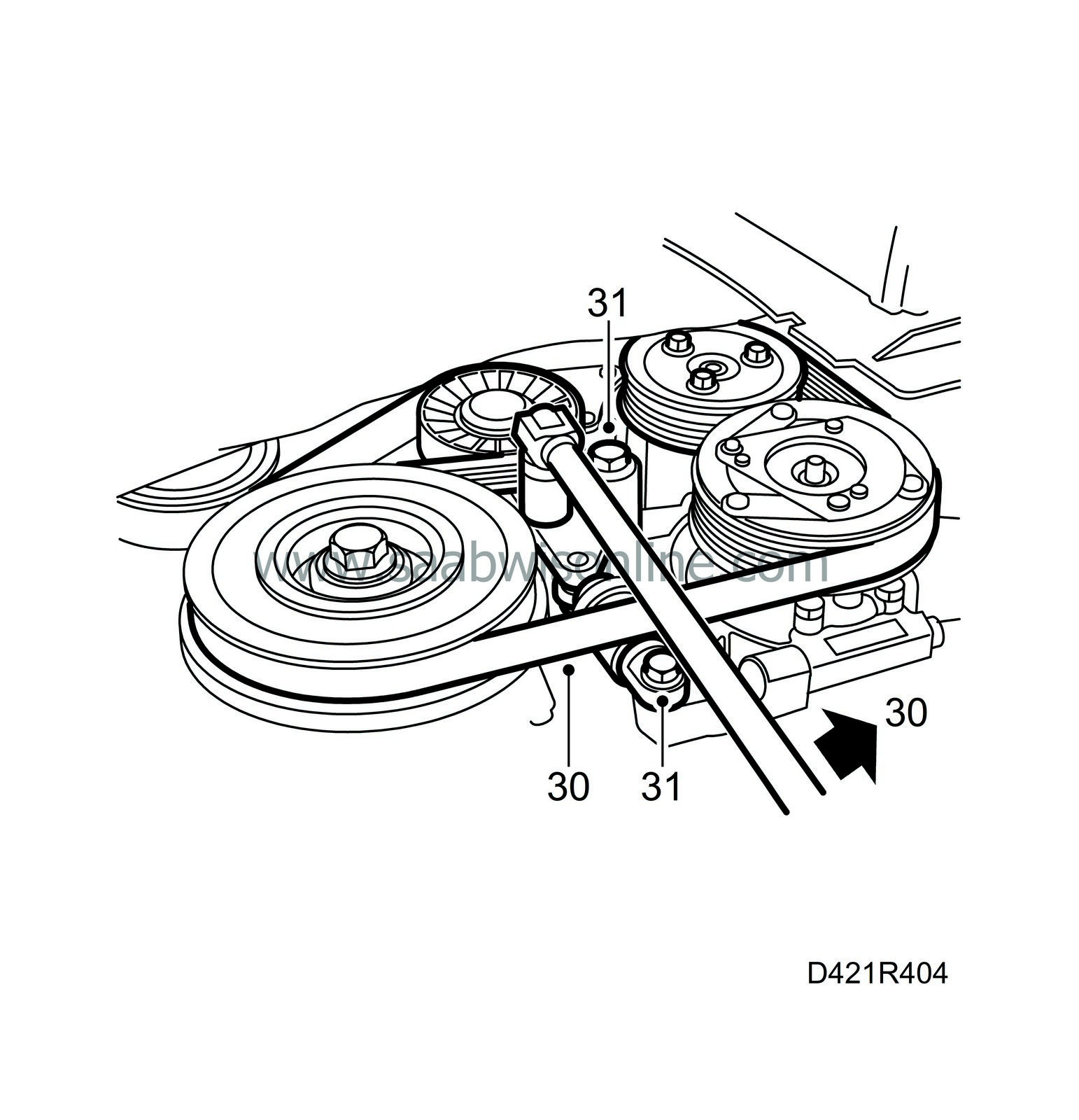

| 30. |

Relieve the tension on the belt tensioner by turning it anticlockwise with a 19 mm wrench. Remove the belt.

|

|

| 31. |

Remove the belt tensioner.

|

|

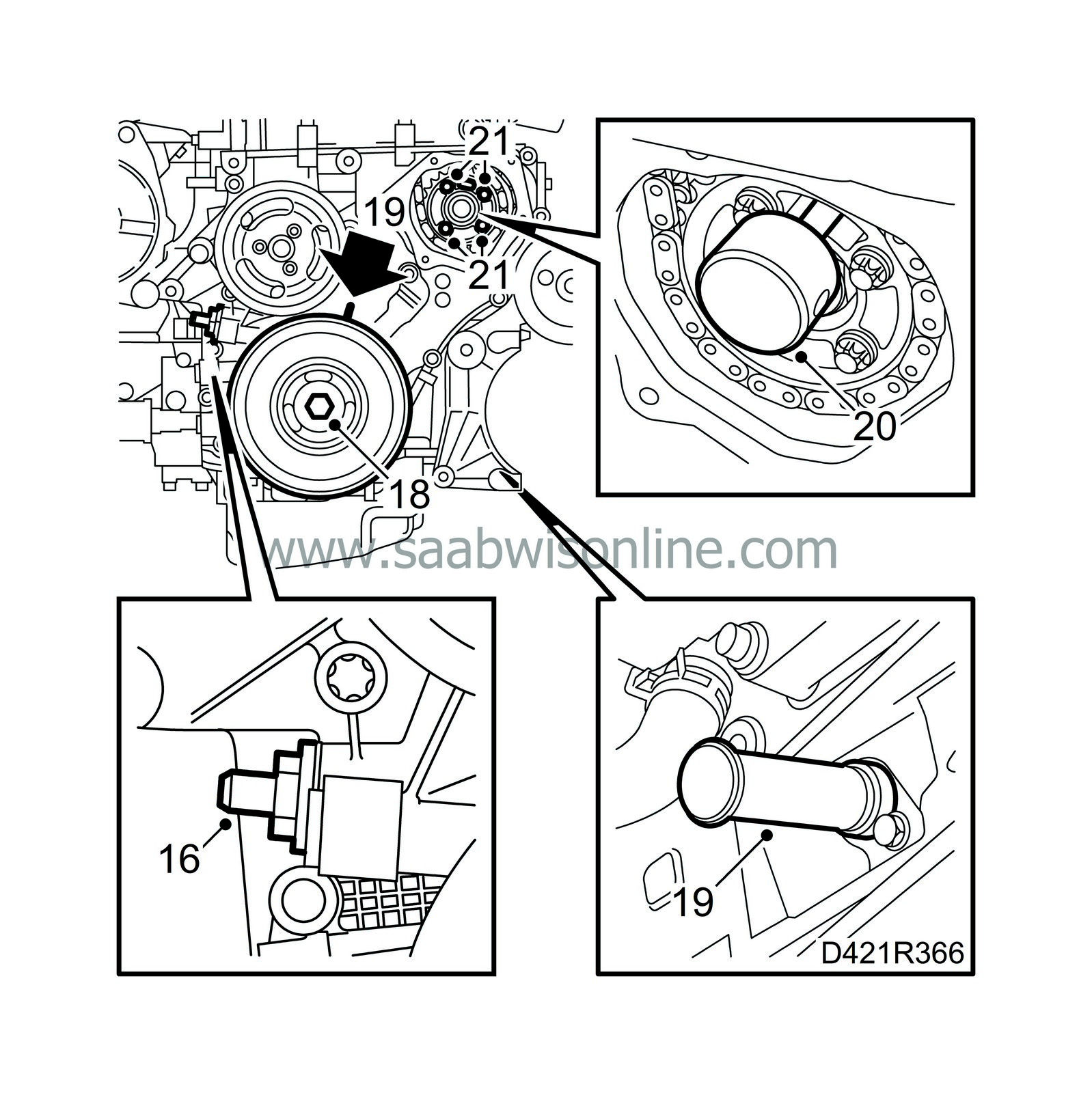

| 32. |

Remove the crankshaft position sensor with O-ring and lower the car.

|

|

| 33. |

Place a jack with a wooden block on top under the oil sump and carefully lift the engine to take the weight off the right-hand engine mounting.

|

||||||||||

| 34. |

Remove the right-hand engine mounting with bracket from the engine and body.

|

|

| 35. |

Remove the camshaft cover.

|

|

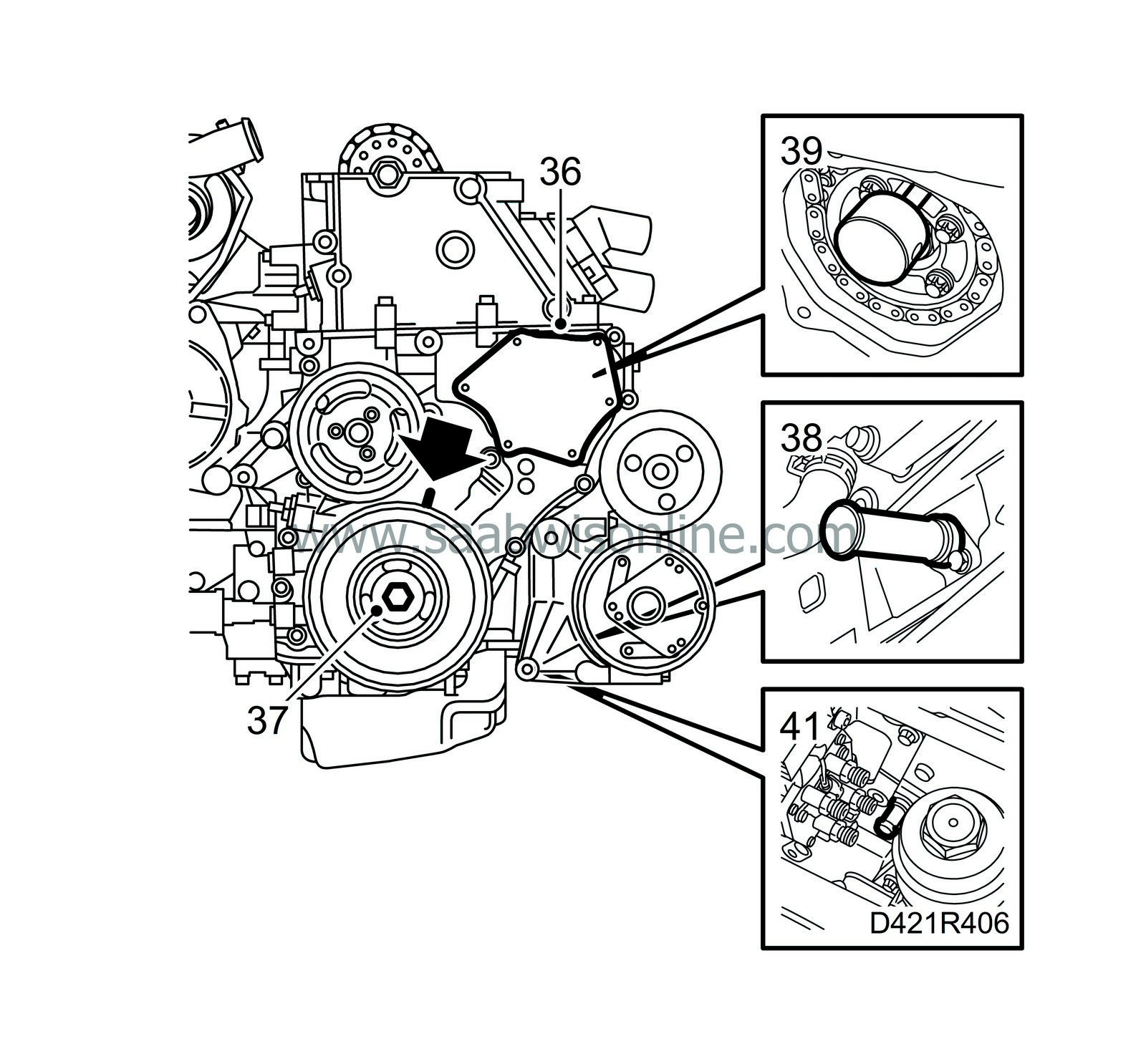

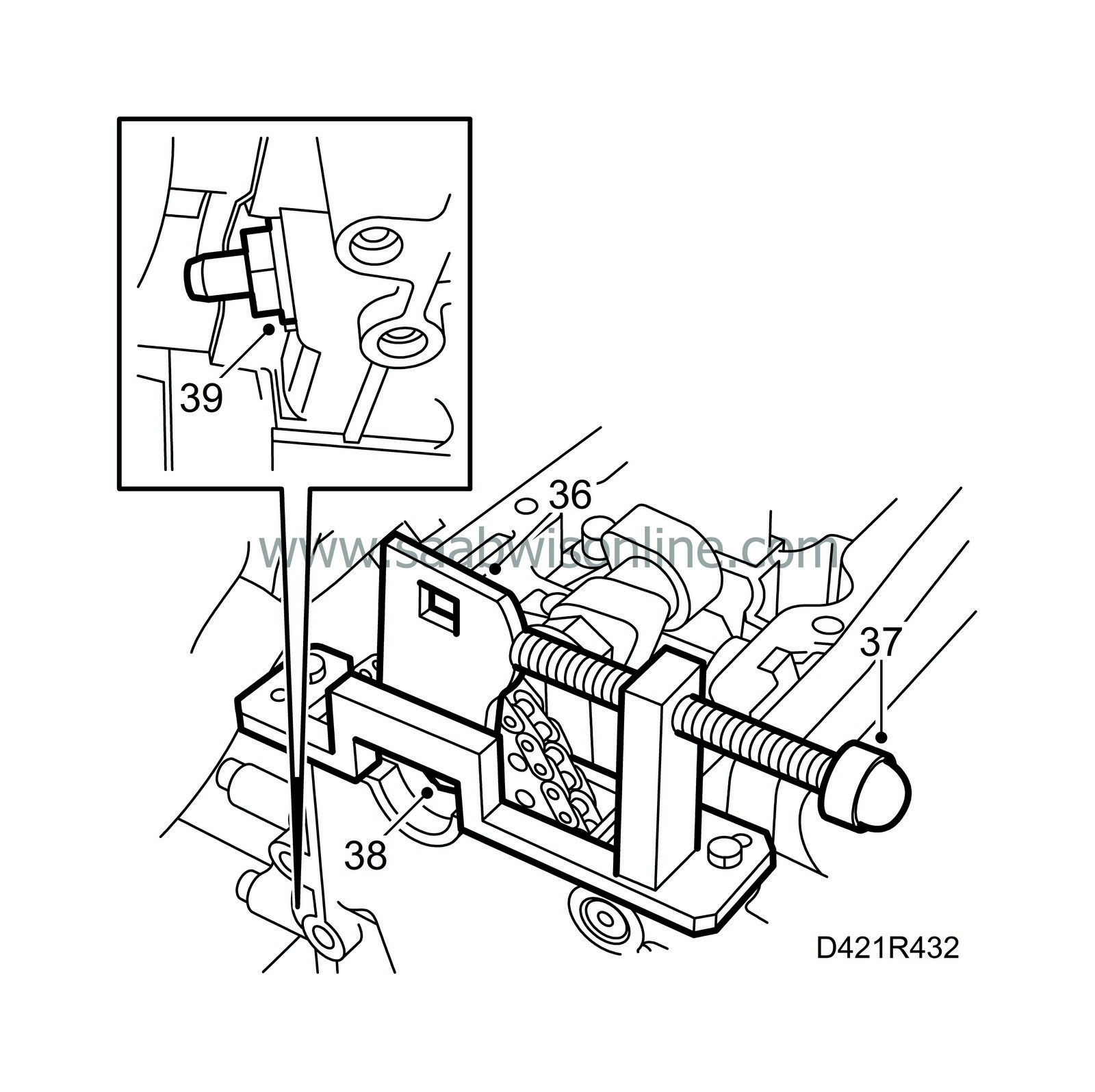

| 36. |

Remove the pump drive cover plate screws, carefully insert a putty knife behind the cover and carefully prise it off.

|

||||||||||

| 37. |

Turn the crankshaft two revolutions with the centre bolt on the pulley until it nearly reaches the mark for top dead centre in cylinder 1. Make sure both cam lobes for cylinder 1 are pointing upwards.

|

|

| 38. |

Position

Crankshaft locking tool

83 95 352 inside the hole for the crankshaft position sensor. Press the tool inwards slightly at the same time as the crankshaft is turned to the zero mark. The tool will then enter a recess in the crankshaft and secure it.

|

|

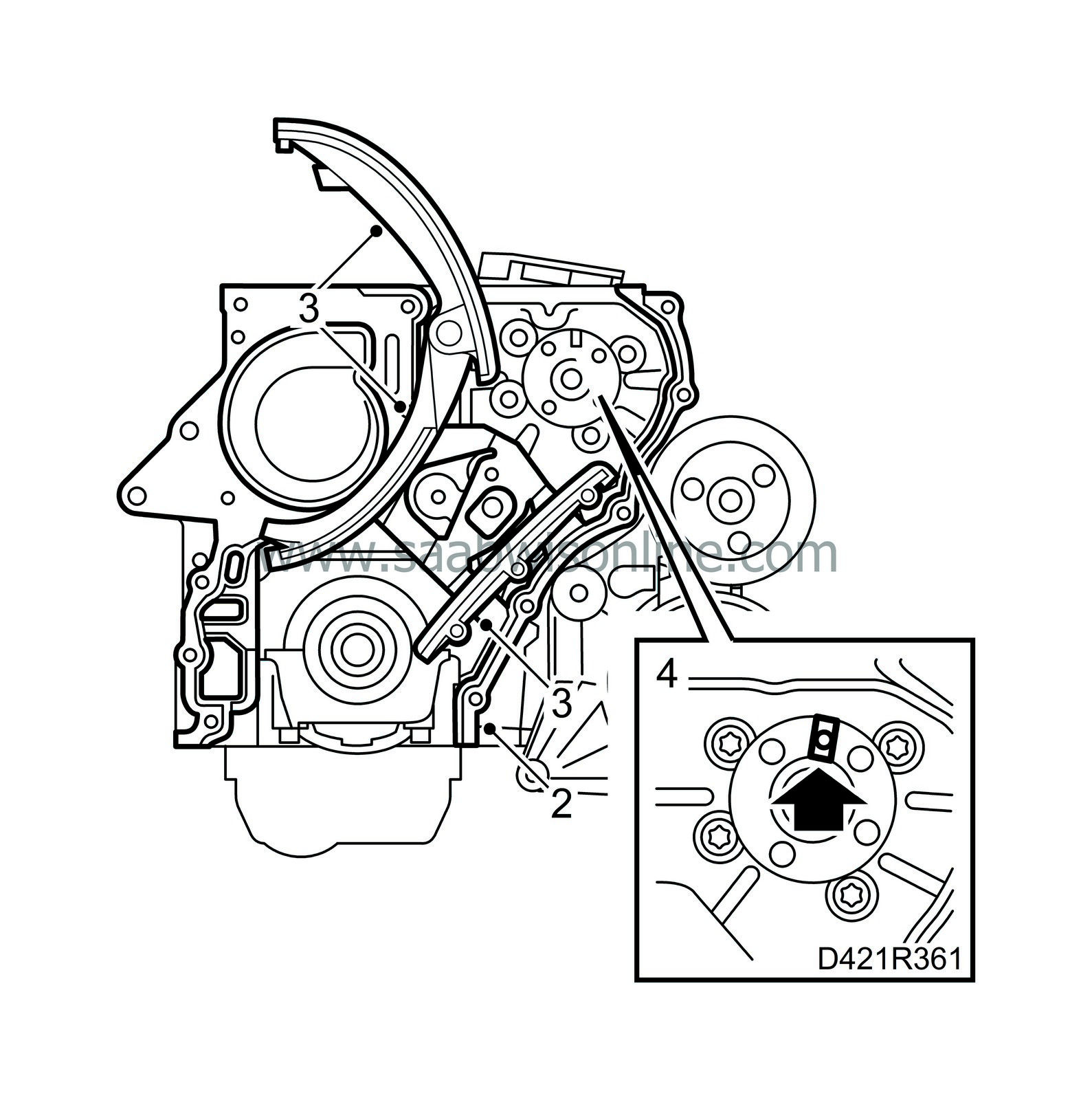

| 39. |

Make sure the marks on the crankshaft pulley and the timing cover are aligned. The arrow on the single cam chain sprocket on the fuel distribution pump must be aligned with the recess in the pump. Fit

83 95 337 Adjustment tool, fuel pump

into the hole.

|

|

| 40. |

Remove all inspection gauges.

|

|

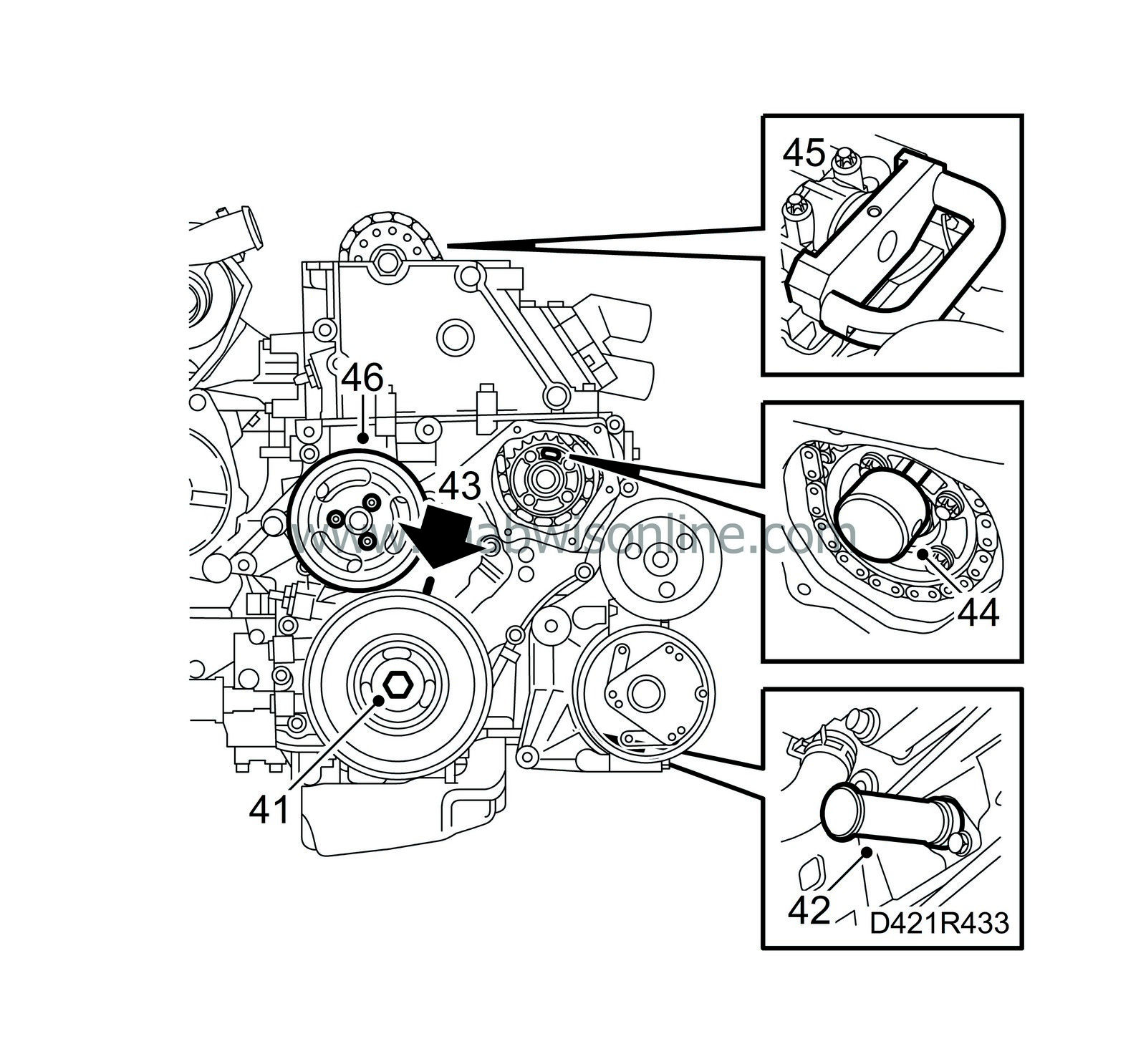

| 41. |

Connect a hose to the cylinder block drain plug. Place a receptacle under the car and drain the coolant. Use an 8 mm Allen key. Close the drain plug.

|

|

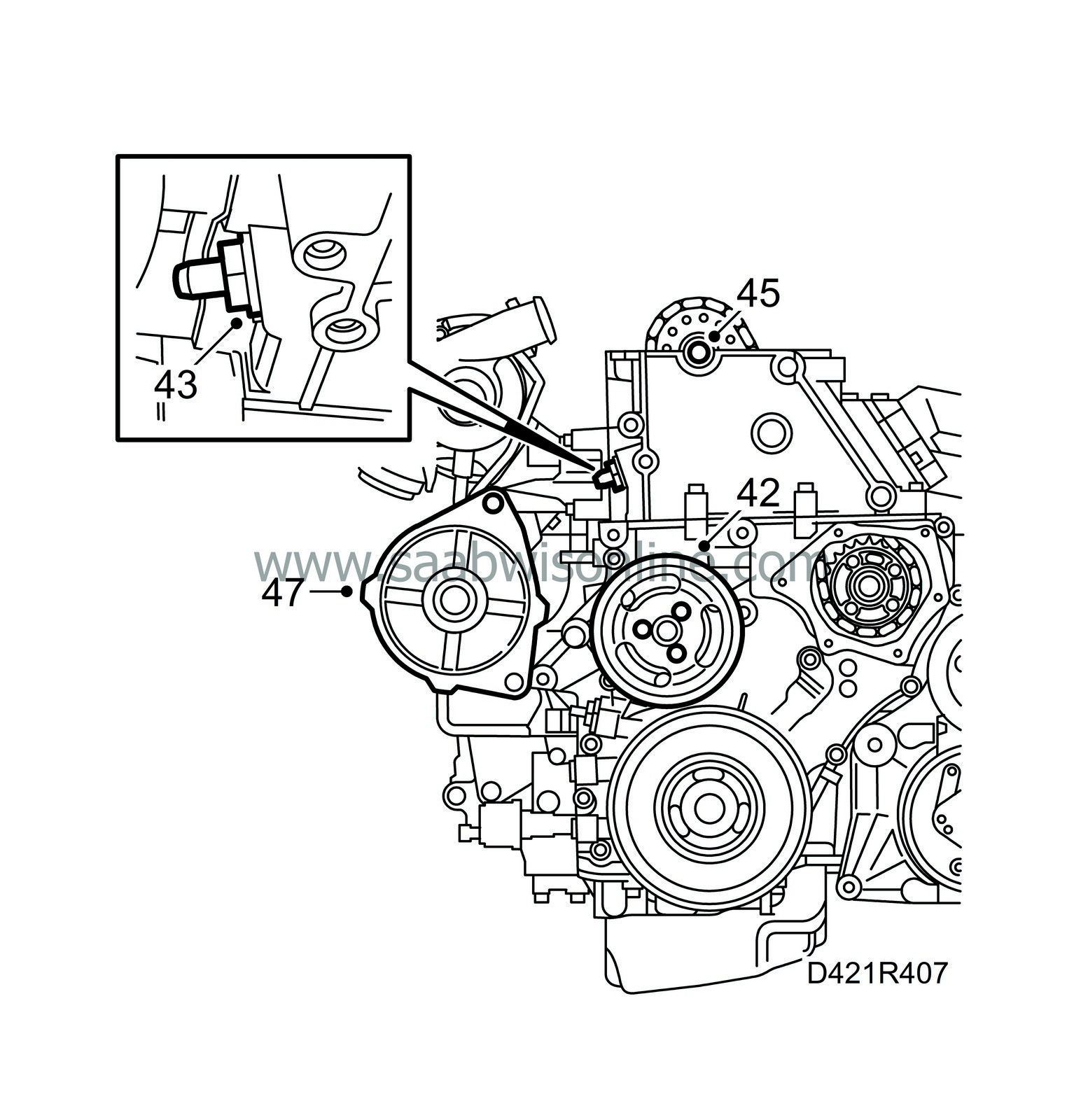

| 42. |

Remove the coolant pump pulley and the coolant pump.

|

|

| 43. |

Remove the upper timing chain tensioner.

|

|

| 44. |

Attach a long cable tie to the timing chain. This is to be used as a handle.

|

|

| 45. |

Remove the camshaft sprocket. Use an open wrench as a support in the six-sided recess on the camshaft.

|

|

| 46. |

Carefully place the chain to one side.

|

|

| 47. |

Remove the upper generator mounting bolt and loosen the bottom one so that the generator can be rotated downwards.

|

|

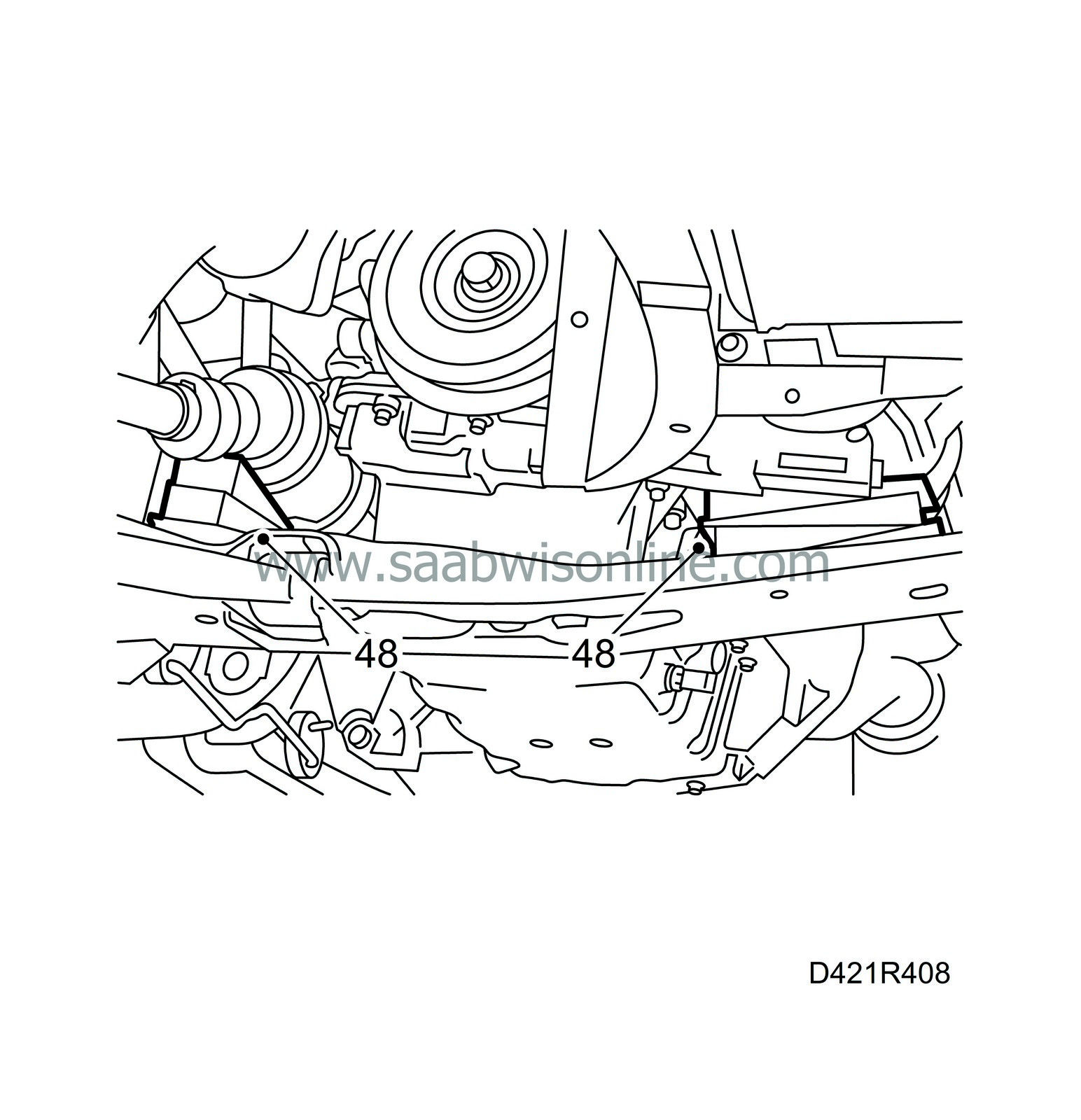

| 48. |

Place

83 95 238 Wedges

between the oil sump and subframe so that the engine is properly supported. Lower the engine and remove the jack.

|

|

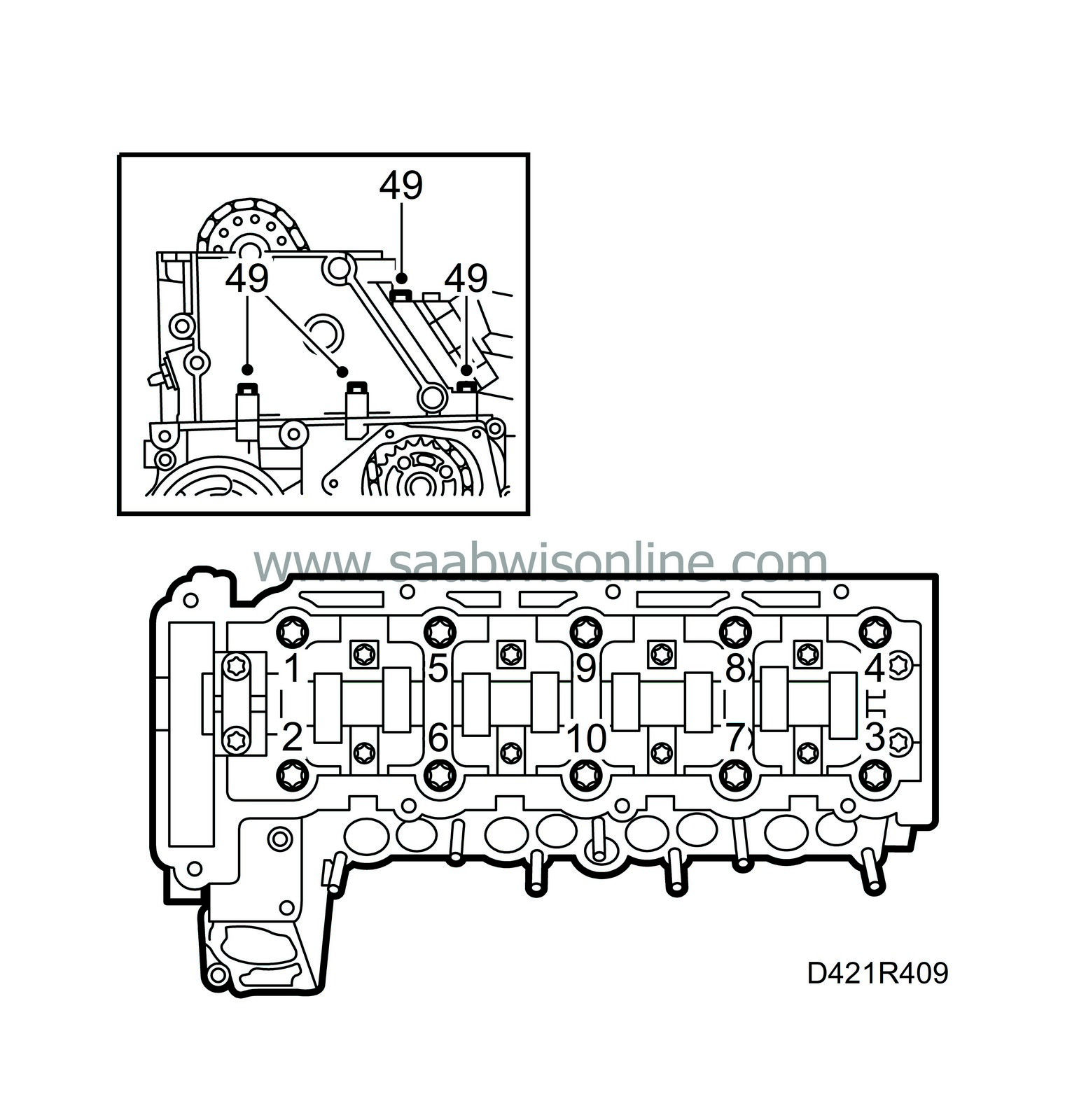

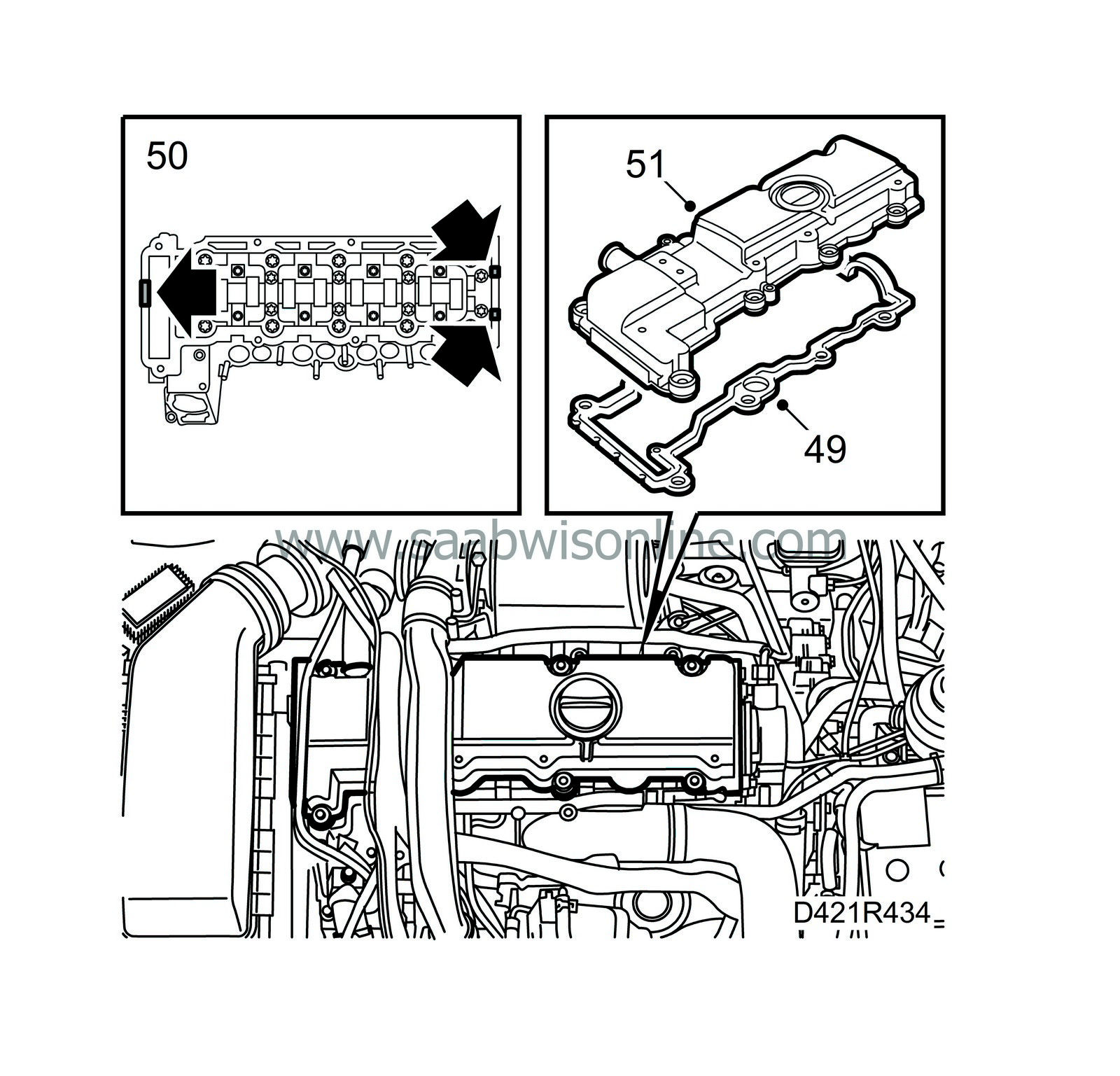

| 49. |

Undo the four bolts securing the cylinder head to the timing cover.

|

||||||||||

| 50. |

Remove the cylinder head by undoing the bolts in order shown in the illustration. Lift the cylinder head

straight up

and place it in such a way so the fuel injectors, glow plugs or valves are not damaged.

|

|

| 51. |

Raise the car, place a receptacle under the engine, undo the oil drain plug and drain the engine oil.

|

|

| 52. |

Remove the crankshaft pulley using

Support, diesel

83 95 360S.

|

|

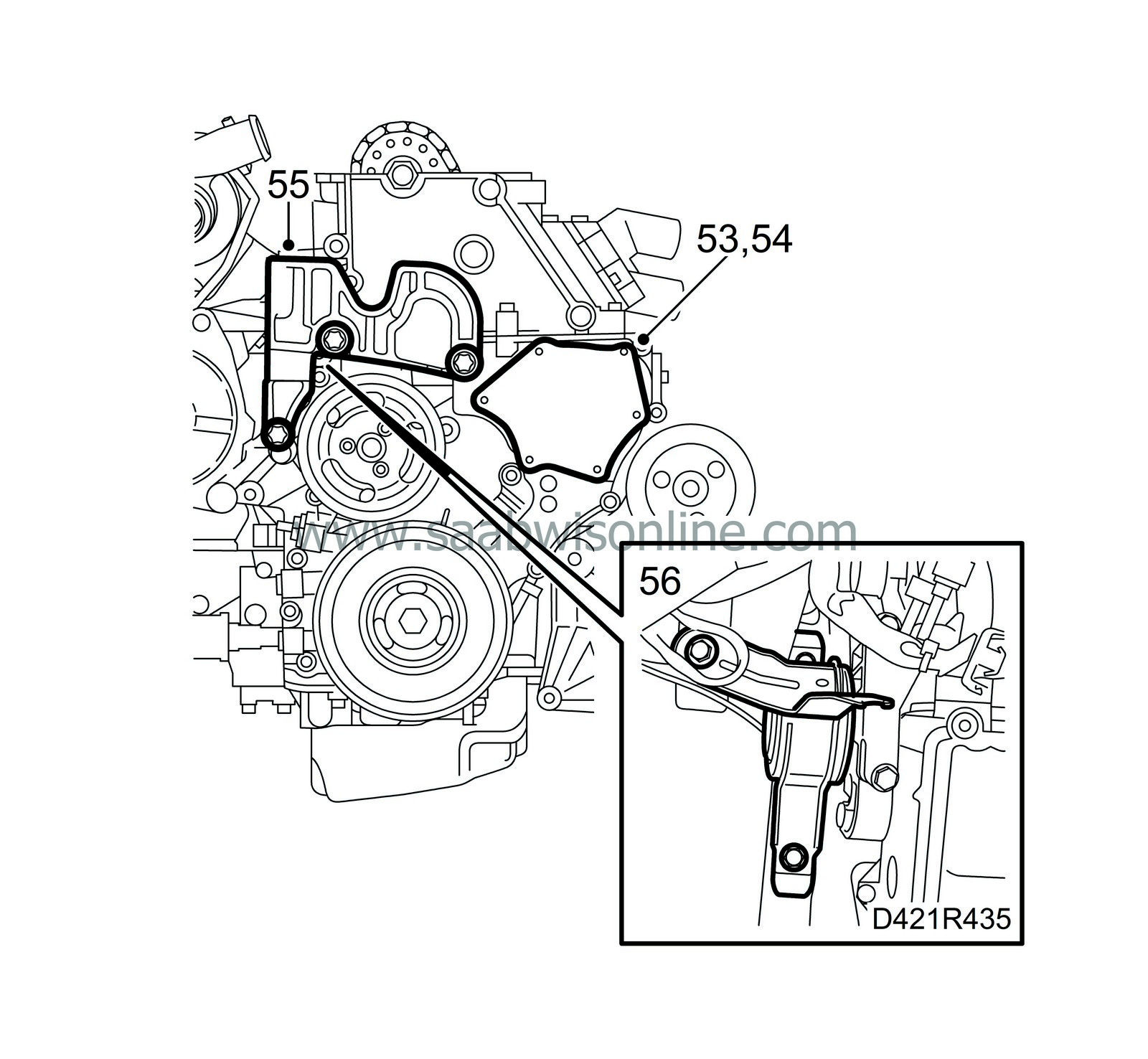

| 53. |

Remove the lower timing chain tensioner.

|

|

| 54. |

Remove the oil sump. Clean away dropping oil.

|

||||||||||

| 55. |

Undo all the bolts on the timing cover.

|

||||||||||

| 56. |

Undo the four bolts on the upper timing chain gear and remove the chain and gear.

|

||||||||||

| 57. |

Carefully remove the lower timing chain together with the gears, suspending them without changing their relative positions.

|

|

| 58. |

Remove all the catenary rules.

|

|

| 59. |

Remove the timing cover gasket.

|

|

| 60. |

Remove the front crankshaft seal from the timing cover.

|

|

| To fit |

| 1. |

Clean the sealing surfaces, check all the parts and replace as necessary.

|

|

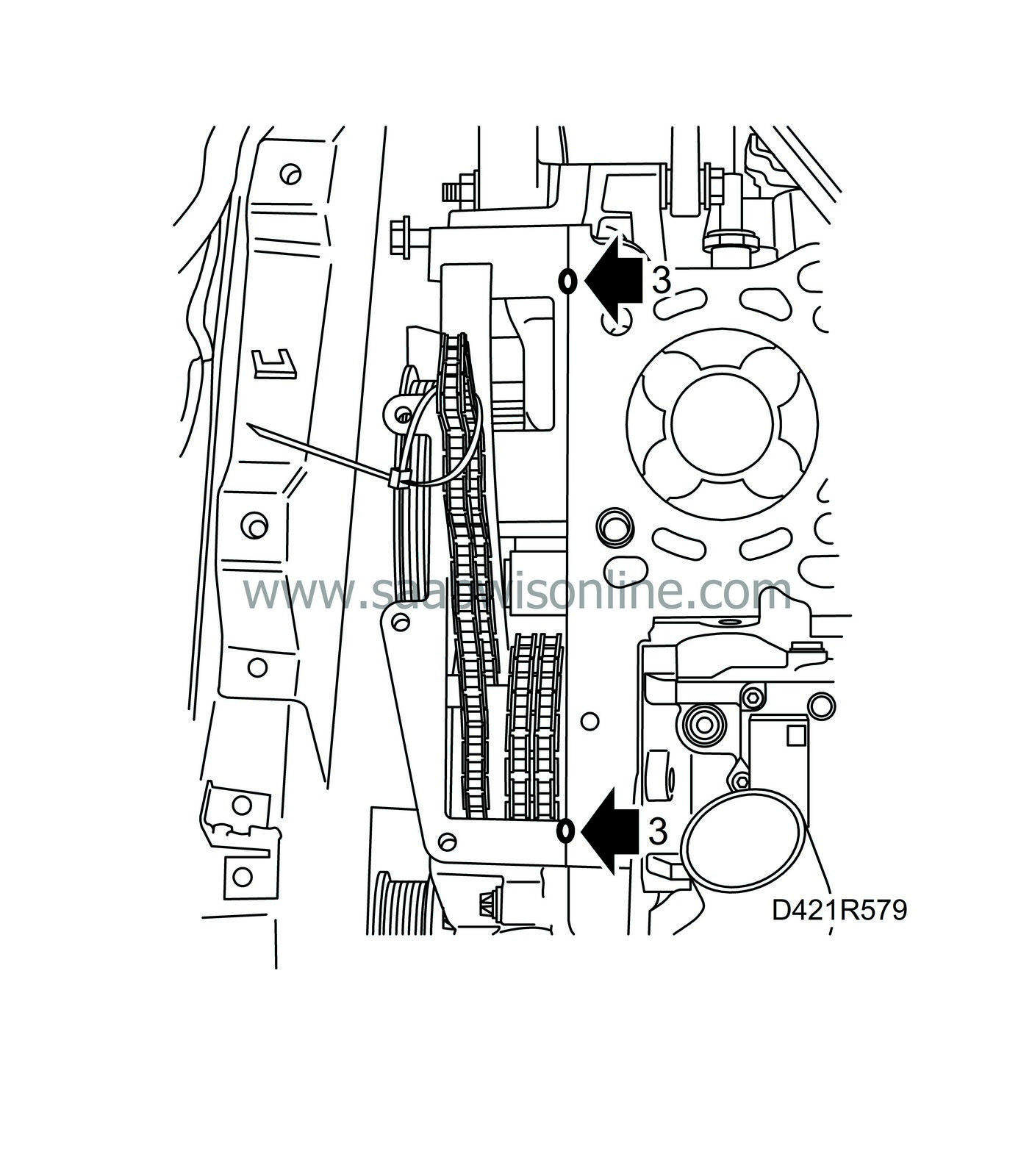

| 2. |

Fit a new gasket on the cylinder block.

|

|

| 3. |

Refit all the catenary rules.

|

|

| 4. |

Use

83 95 337 Setting tool, fuel pump

to make sure the recess in the fuel distribution pump flange is aligned with the hole in the pump. Remove the gauge.

|

|

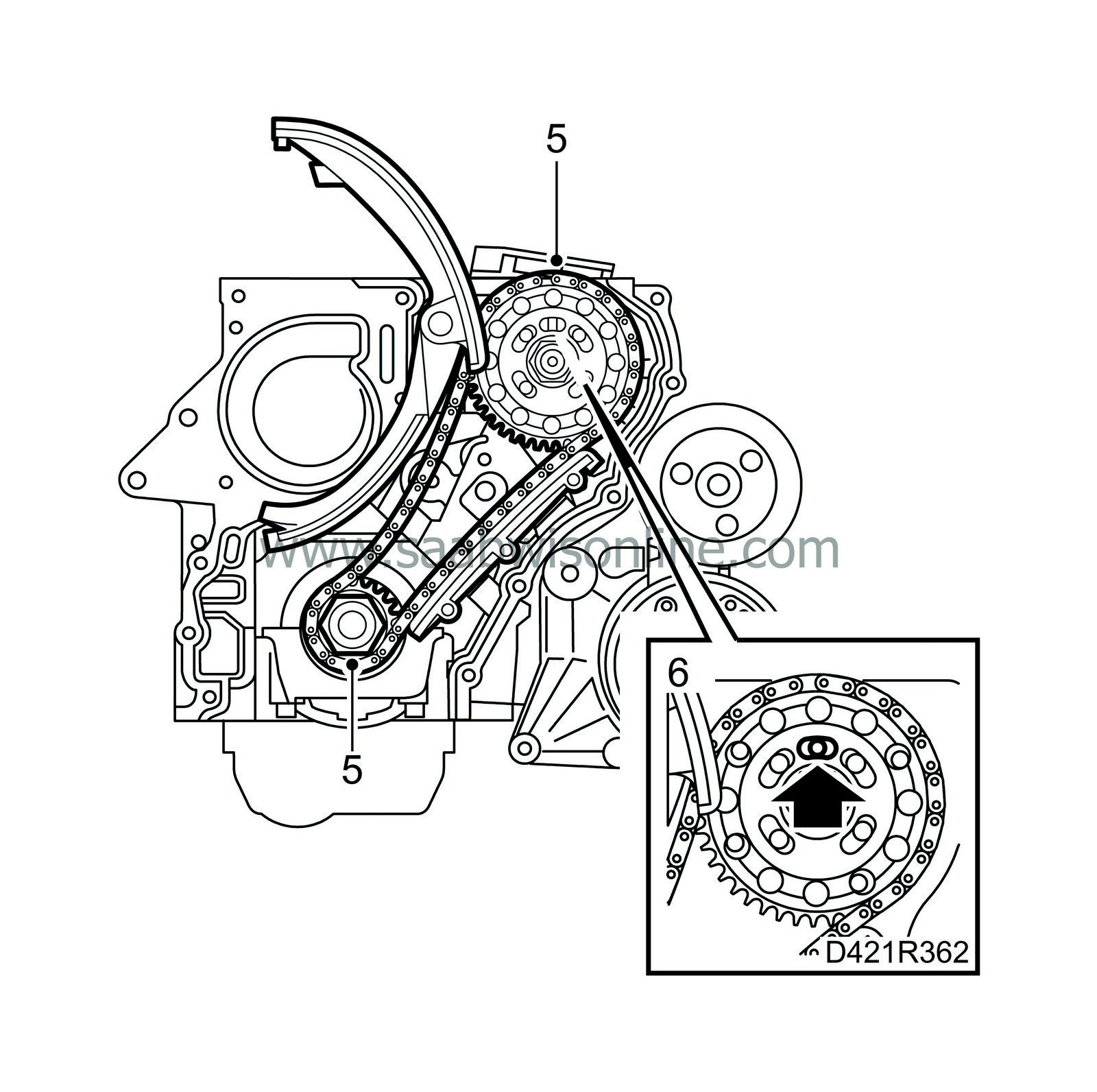

| 5. |

Refit the gears on the crankshaft and fuel distribution pump together with the lower timing chain. Make sure the recess in the fuel distribution pump flange is aligned with the hole in the pump and that they are visible through the hole in the gear. The lower part of the timing chain must be taut.

|

|

| 6. |

Position

83 95 337 Setting tool, fuel pump

in the recess in the fuel distribution pump and check the position of the pump shaft. Remove the gauge.

|

|

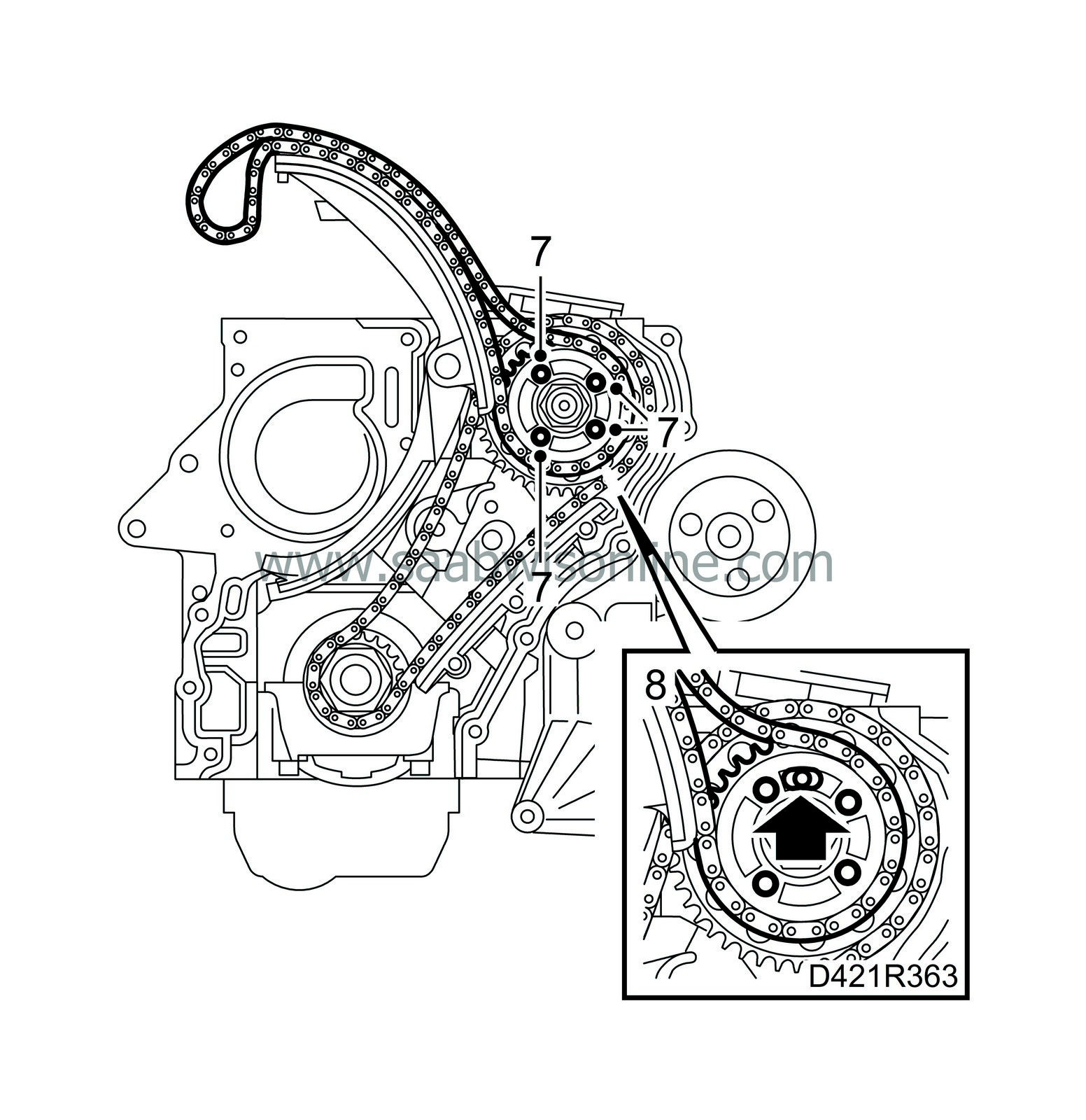

| 7. |

Fit the upper timing chain and fasten the gear on the fuel pump shaft without tightening the bolts.

|

|

| 8. |

Insert the

83 95 337 Adjustment tool, fuel pump

in the fuel distribution pump recess.

|

|

| 9. |

Fit the timing cover with the bolts in their original positions.

Tightening torque 20 Nm (15 lbf ft).

|

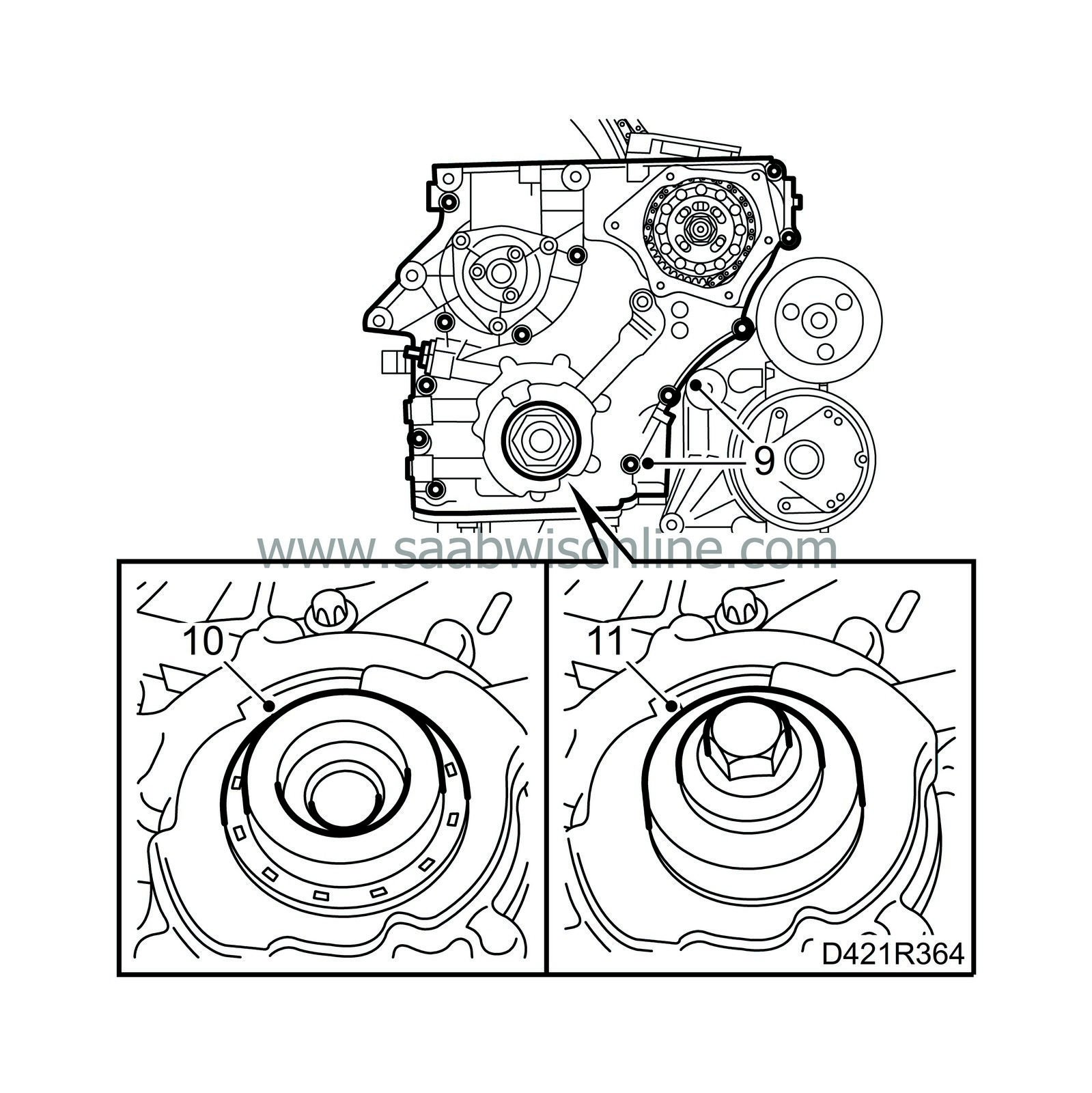

|

| 10. |

Lubricate the new crankshaft sealing ring with acid-free vaseline and position it on

Fitting tool, crankshaft seal

83 95 410 (KM-935-1).

|

|

| 11. |

Position the sealing ring with protective sleeve and tool 83 95 410 (KM-935-2) on the crankshaft. Press in the sealing ring using the bolt for the crankshaft belt pulley until it is flush with the timing cover.

|

|

| 12. |

Check that there are no impurities or other foreign matter in the oil sump and clean the sealing surfaces with benzene.

|

|

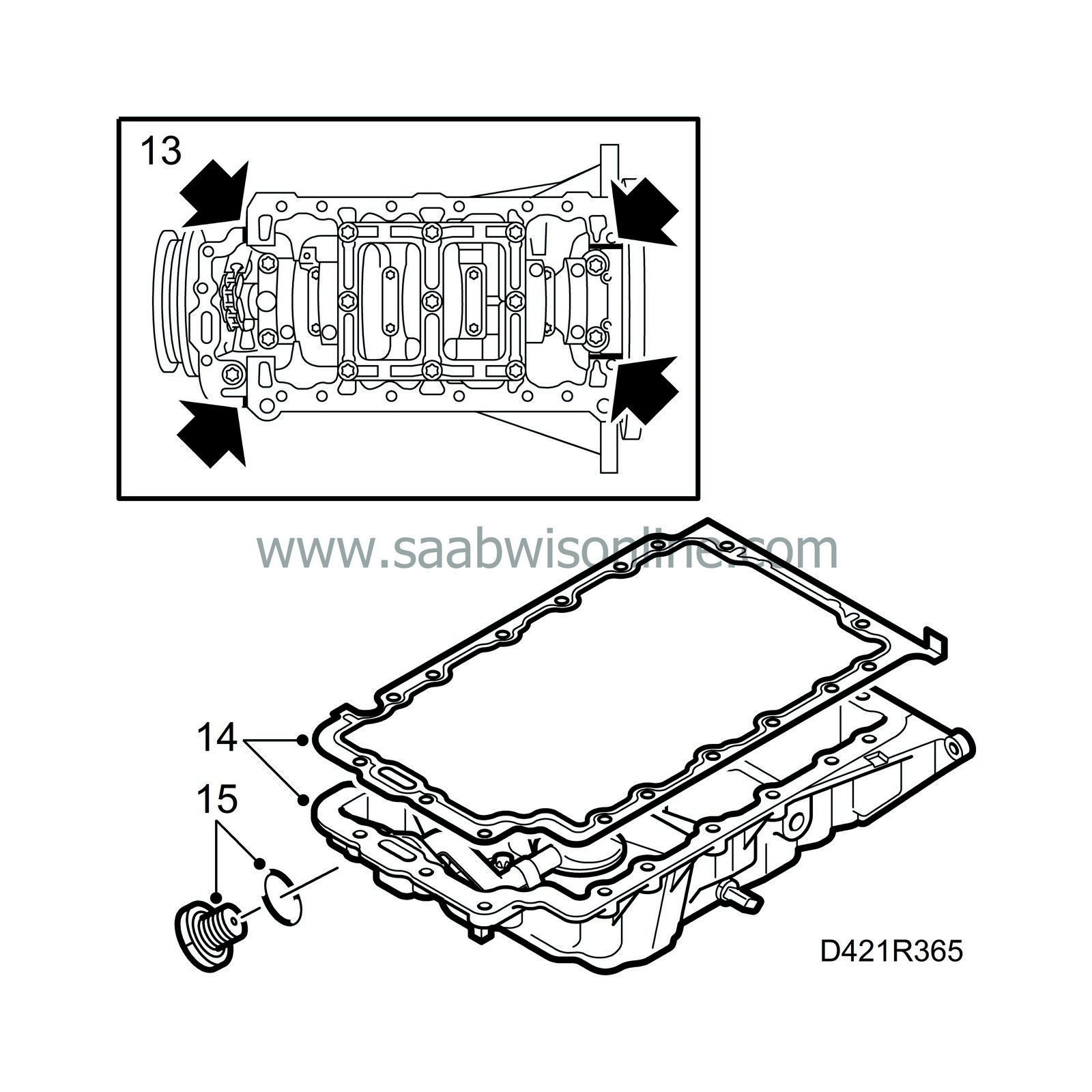

| 13. |

Apply sealing compound 87 81 841 to the mating surfaces, see illustration.

|

|

| 14. |

Position the oil sump against the gearbox and fit it with new gaskets. If the gearbox has been dismantled, a steel rule must be put against the sealing surface to the gearbox to guide the position of the oil sump.

Tightening sequence: 1 Tighten all bolts by hand. 2 Tighten the bolts in the cylinder block and timing cover: 20 Nm (15 lbf ft) 3 Tighten the bolts in the gearbox M8: 20 Nm (15 lbf ft), M10: 40 Nm (30 lbf ft) |

|

| 15. |

Refit the oil plug with a new seal.

Tightening torque 18 Nm (13 lbf ft) |

|

| 16. |

Fit the chain tensioner for the lower timing chain with a new gasket. Do not confuse the lower chain tensioner with the upper chain tensioner. See lower timing chain tensioner.

Tightening torque 60 Nm (44 lbf ft)

|

|

| 17. |

Remove tools 83 95 352 and 83 95 337.

|

|

| 18. |

Fit the crankshaft belt pulley with a new bolt. Use

Support, diesel

83 95 360.

Tightening torque 150 Nm (111 lbf ft) + 45° |

|

| 19. |

Replace

Crankshaft locking tool

83 95 352 and make sure the markings on the crankshaft pulley and the timing cover are aligned.

|

|

| 20. |

Insert the

83 95 337 Adjustment tool, fuel pump

in the fuel distribution pump recess.

|

|

| 21. |

Remove locking tool 83 95 337 and tighten the bolts securing the timing chain gears to the fuel distribution pump.

Tightening torque 20 Nm (15 lbf ft) |

|

| 22. |

Check that the locking tool 83 95 337 can be easily fitted and removed.

|

|

| 23. |

Blow clean the bolt holes in the cylinder block using compressed air.

|

|

| 24. |

Clean any gasket remains from the sealing surfaces on the cylinder head and cylinder block.

|

|

| 25. |

Apply a small amount of flange sealant 87 81 841 to the points shown in the illustration.

|

|

| 26. |

Check with a steel rule that the sealing surfaces on the cylinder head and cylinder block are flat and not damaged.

|

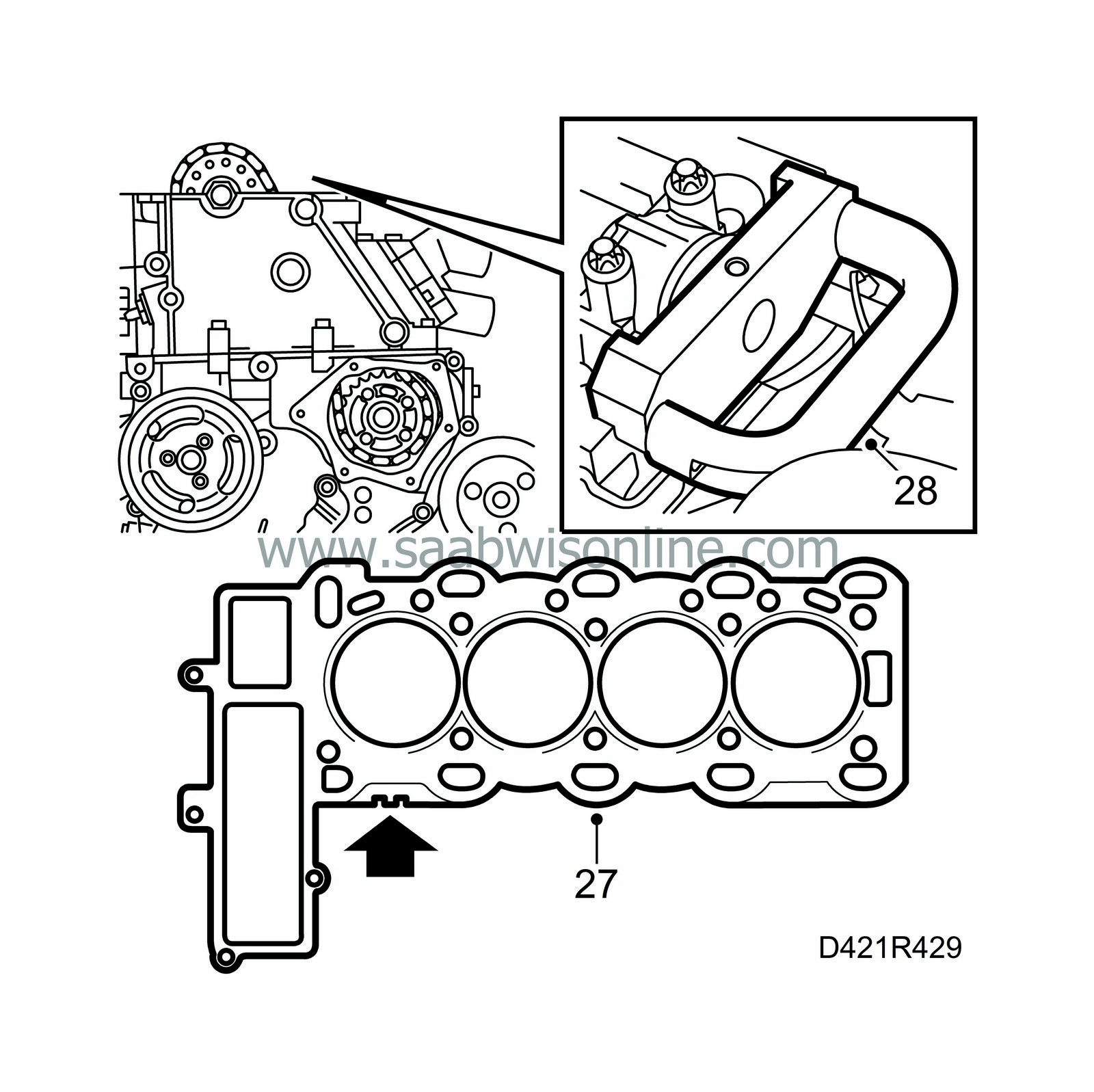

|

| 27. |

Fit a new gasket with the same thickness marking as the old gasket on the cylinder block. (1 groove = 1.3 mm, 2 grooves = 1.4 mm gasket thickness.)

|

|

| 28. |

Position

Setting tool, camshaft

83 95 386 on the camshaft and cylinder head. The camshaft can be turned slightly if necessary with an open wrench in the hexagonal recess on the camshaft at the same time as the gauge is put into the correct position.

|

|

| 29. |

Position the cylinder head on the cylinder block while pulling the timing chain up to its correct position.

|

|

| 30. |

Tighten the cylinder head with new bolts in the order shown in the illustration.

Tightening torques Stage I: 25 Nm (18.5 lbf ft) Stage II: 65° Stage III: 65° Stage IV: 65° Stage V: 65° |

||||||||||

| 31. |

Tighten the bolts on the timing cover as previously fitted.

Tightening torque 20 Nm (15 lbf ft).

|

|

| 32. |

Place a jack with wood block under the oil sump, carefully raise the engine and remove the wedges between the engine and the subframe.

|

|

| 33. |

Fit the generator.

Tightening torque 35 Nm (26 lbf ft). |

|

| 34. |

Lift up the timing chain and position the camshaft gear so that it runs freely on the camshaft, and fit it with a new bolt. Tighten by hand.

|

||||||||||

| 35. |

Insert the

83 95 337 Adjustment tool, fuel pump

in the fuel distribution pump recess.

|

|

| 36. |

Fit the adapter for

Timing chain adjuster

83 95 394 on the camshaft sprocket and mount the timing chain adjuster on the cylinder head.

|

|

| 37. |

Secure the position of the adapter on the camshaft sprocket by turning it slightly anticlockwise with a ratchet handle. Tighten the adjuster screw on the tool.

|

||||||||||

| 38. |

Tighten a new bolt for the camshaft sprocket using an open wrench in the hexagonal recess on the camshaft as support.

Tightening torque 90 Nm (67 lbf ft) + 60° |

|

| 39. |

Fit the chain tensioner for the upper timing chain with a new gasket.

Tightening torque 60 Nm (44 lbf ft) |

|

| 40. |

Remove all tools and gauges.

|

|

| 41. |

Turn the crankshaft two revolutions until it nearly reaches the mark for top dead centre in cylinder 1. Make sure both cam lobes for cylinder 1 are pointing upwards at a slight angle.

|

|

| 42. |

Position

Crankshaft locking tool

83 95 352 inside the hole for the crankshaft position sensor. Press the tool inwards slightly at the same time as the crankshaft is turned to the zero mark. The tool will then enter a recess in the crankshaft and secure it.

|

|

| 43. |

Make sure the marks on the crankshaft pulley and the timing cover are aligned. The arrow on the single cam chain sprocket on the fuel distribution pump must also be aligned with the recess in the pump.

|

|

| 44. |

Align

83 95 337 Adjustment tool, fuel pump

in the fuel distribution pump recess. If the gauge does not fit, adjust the engine valve timing. See

Adjusting valve timing

.

|

|

| 45. |

Position inspection gauge 83 95 386 to the camshaft and cylinder head. If the gauge does not fit, the engine valve timing must be adjusted. See

Adjusting valve timing

.

|

|

| 46. |

Fit the coolant pump and its pulley. Use a new O-ring.

Tightening torque 20 Nm (15 lbf ft). |

|

| 47. |

Remove all special tools.

|

|

| 48. |

Clean any gasket remains from the sealing surfaces on the camshaft cover.

|

|

| 49. |

Position a new gasket on the camshaft cover. There are sleeves on the bolts on which the gasket fits.

|

|

| 50. |

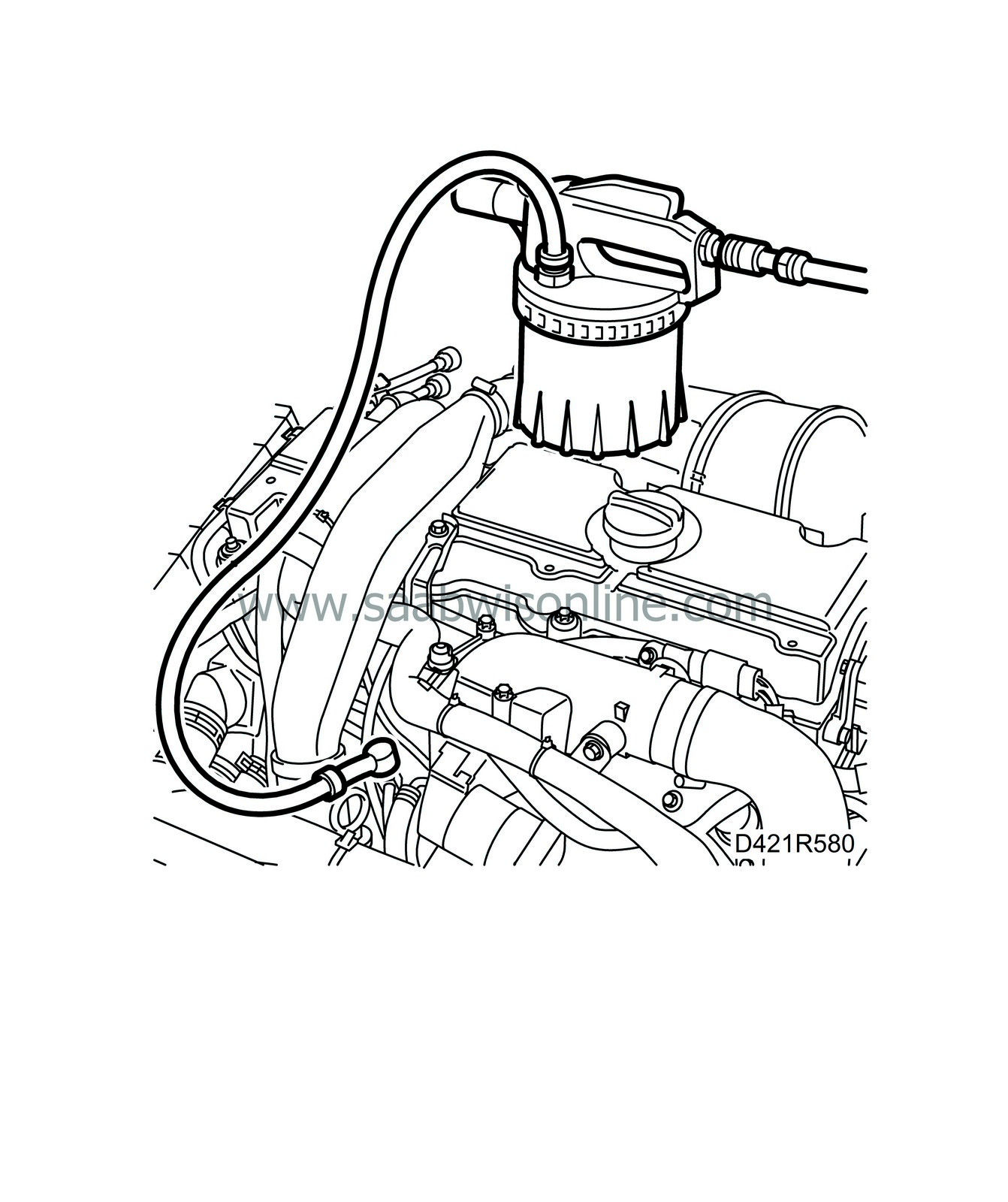

Apply sealing compound 87 81 841 to the sealing surface, see illustration.

|

|

| 51. |

Position the transmission cover on the cylinder head and tighten the bolts.

Tightening torque 8 Nm (6 lbf ft). |

|

| 52. |

Place the wiring harness back over the engine.

|

|

| 53. |

Cover the opening in the timing cover with a lint-free cloth and remove any remains from the old gasket from the sealing surface. Clean the sealing surface on the cap.

|

|

| 54. |

Apply a bead (approx. 2 mm thick) of flange sealant 87 81 841 to the cap, remove the cloth from the timing cover and fit the cap.

Tightening torque 6 Nm (5 lbf ft). |

|

| 55. |

Fit the right-hand engine mounting with bracket to the engine.

Tightening torque 47 Nm (35 lbf ft). Carefully lower the engine and remove the jack. |

|

| 56. |

Make sure the engine is suspended evenly and tighten the right-hand engine mounting.

Tightening torque 47 Nm (35 lbf ft). |

|

| 57. |

Raise the car and fit the crankshaft position sensor with a new O-ring.

Tightening torque 8 Nm (6 lbf ft).

|

|

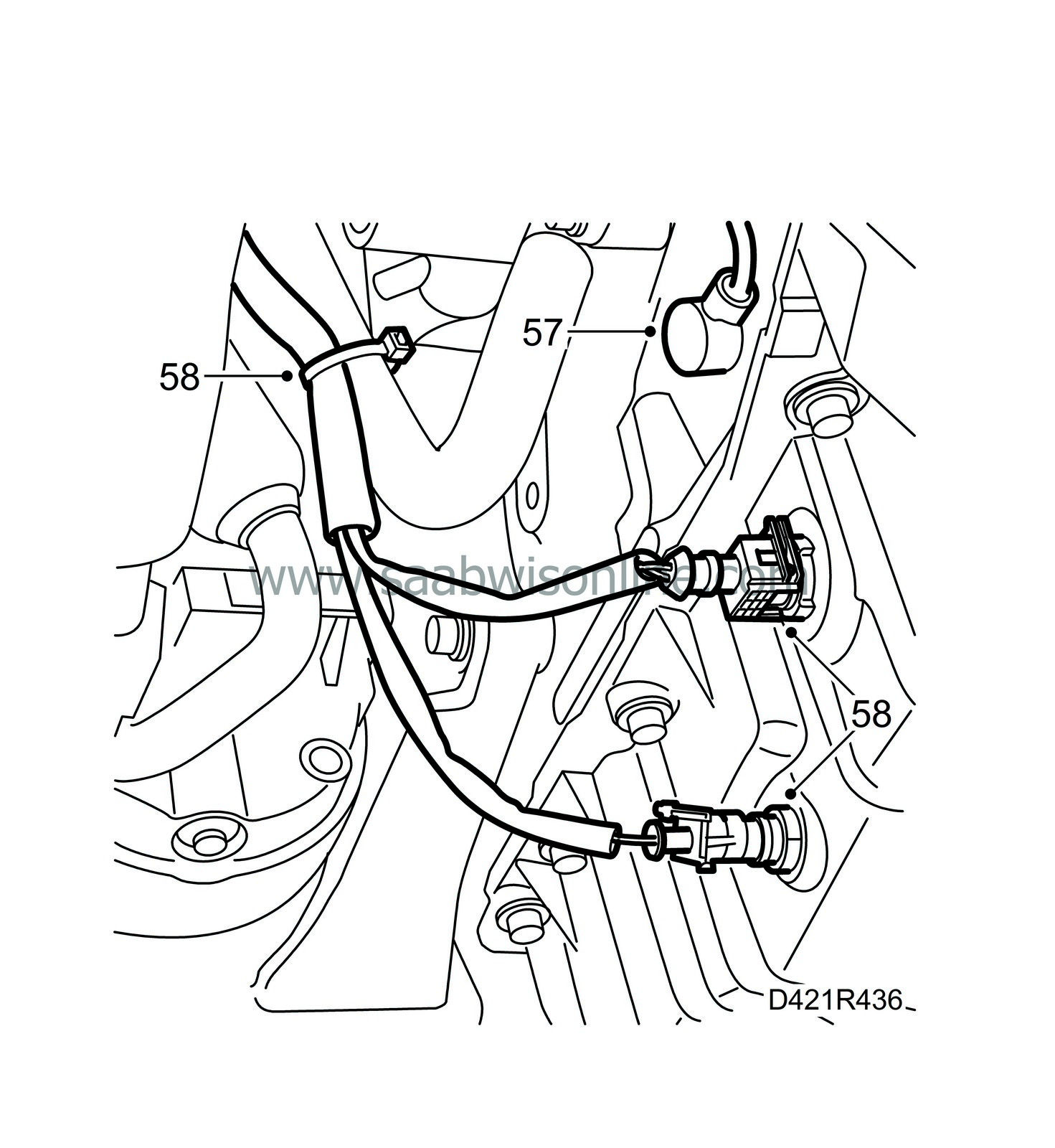

| 58. |

Plug in the connectors to the oil level sensor and oil temperature sensor. Secure the cables to the coolant manifold with cable ties.

|

|

| 59. |

Fit the belt tensioner, tightening the top bolt first.

Tightening torque 42 Nm (31 lbf ft). Tighten the bottom bolt. Tightening torque 23 Nm (17 lbf ft).

|

|

| 60. |

Fit the multigroove V-belt on all the pulleys. Relieve the tension on the belt tensioner by turning it anticlockwise (towards the rear of the car) with a 19 mm wrench and fit the belt on its pulley. Make sure the belt is positioned correctly on all the pulleys.

|

|

| 61. |

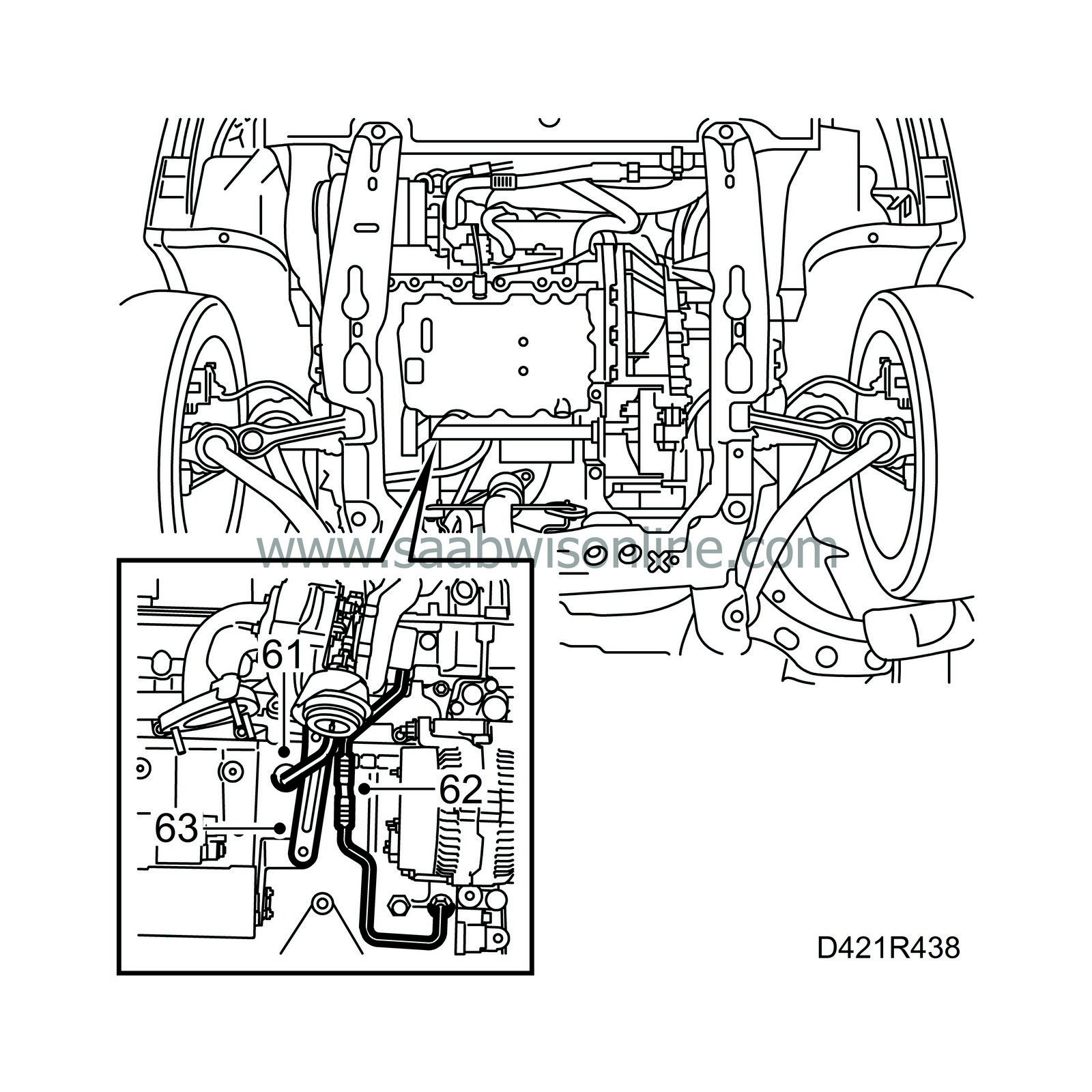

Connect the turbocharger oil return pipe to the cylinder block.

Tightening torque 30 Nm (22 lbf ft).

|

|

| 62. |

Connect the turbocharger oil delivery pipe to the cylinder block.

Tightening torque 20 Nm (15 lbf ft). |

|

| 63. |

Lower the car, put the exhaust manifold support back in place and tighten the screws.

Tightening torque 25 Nm (19 lbf ft). |

|

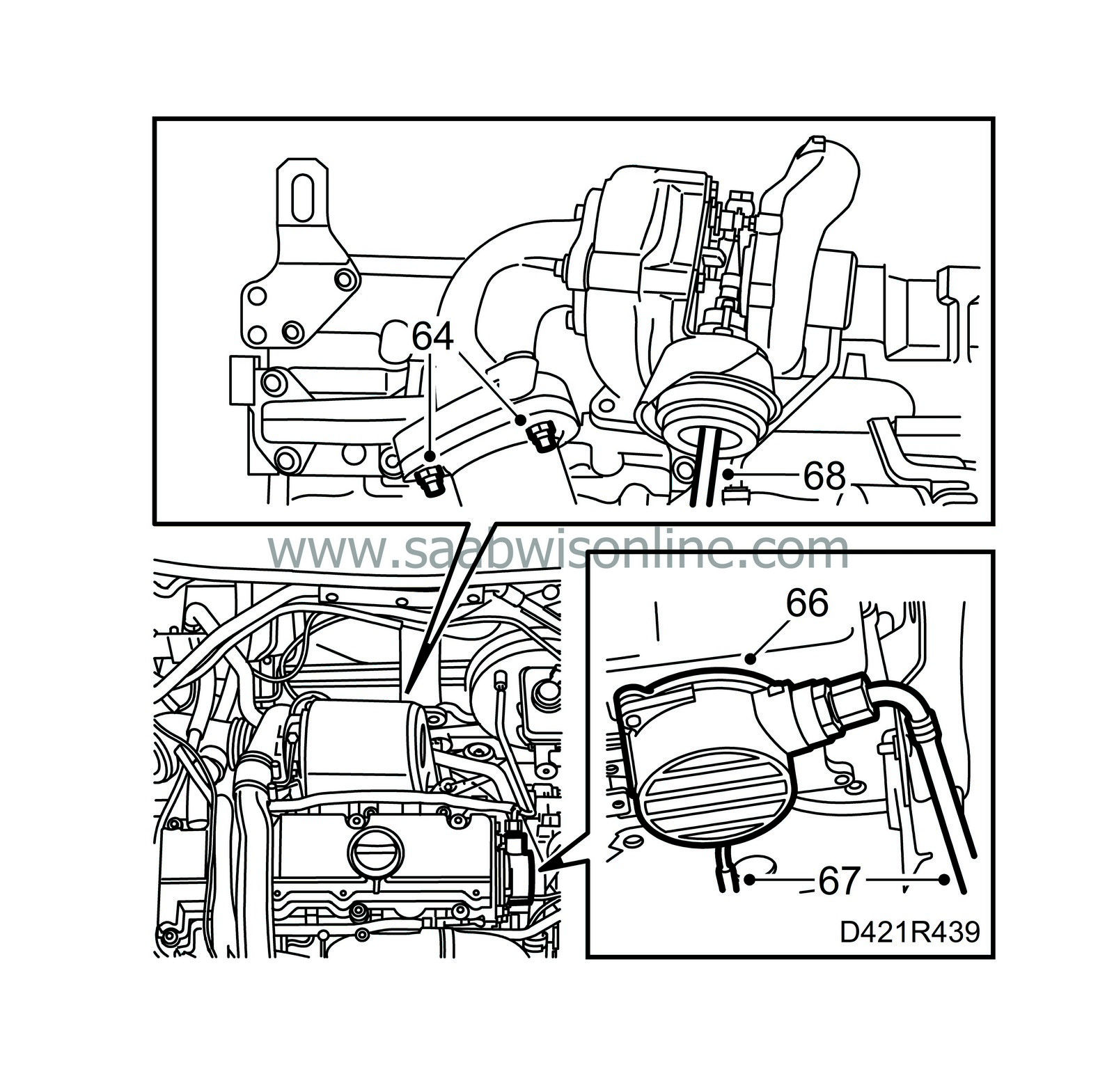

| 64. |

Fit the exhaust pipe with a new gasket and new nuts. Tighten.

Tightening torque 25 Nm (19 lbf ft)

|

|

| 65. |

Clean the sealing surfaces on the vacuum pump.

|

|

| 66. |

Fit a new gasket on the vacuum pump and fit the pump together with the adapter.

Tightening torque 8 Nm (6 lbf ft).

|

||||||||||

| 67. |

Connect the vacuum hose for the brake servo to the vacuum pump.

Tightening torque 18 Nm (13 lbf ft). Connect the vacuum hose to the bottom of the vacuum pump. |

|

| 68. |

Connect the vacuum hose to the wastegate vacuum box.

|

|

| 69. |

Attach the coolant hose to the generator bracket.

|

|

| 70. |

Refit the heat shields over the starter motor, exhaust manifold and turbocharger.

|

|

| 71. |

Tighten the nut on the rear engine mounting.

Tightening torque 47 Nm (35 lbf ft). |

|

| 72. |

Fit the hook for the coolant hose on the rear lifting eye.

|

|

| 73. |

Connect the vacuum hose to the swirl throttle control valve.

|

|

| 74. |

Attach the fuel rails with clamps in their original positions.

Tightening torque 25 Nm (19 lbf ft). |

|

| 75. |

Connect the fuel lines to the fuel distribution pump with new seals.

Tightening torque 25 Nm (19 lbf ft). |

|

| 76. |

Connect the hoses to the thermostat housing.

|

|

| 77. |

Connect new fuel return lines to the fuel bridges. Detach the connection at the fuel pump and connect

30 14 883 Pressure/vacuum pump

. Pump up a vacuum of 750 mbar and wait 1 minute. Make sure the dial indicator on the tool has not moved.

|

|

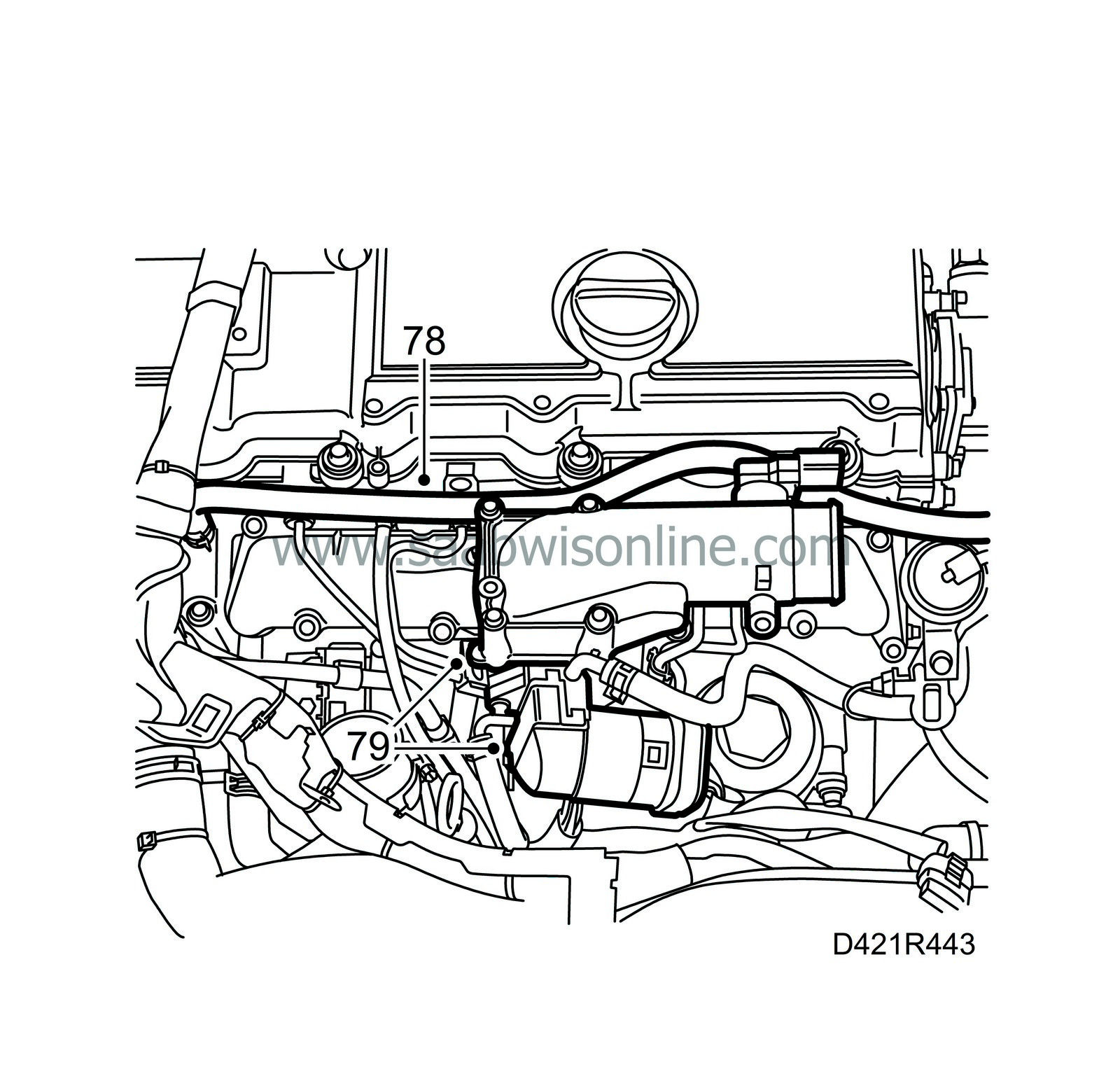

| 78. |

Connect the vent hose to the thermostat housing.

|

|

| 79. |

Fit the EGR-valve with a new O-ring and the throttle body. Plug in the connectors.

|

|

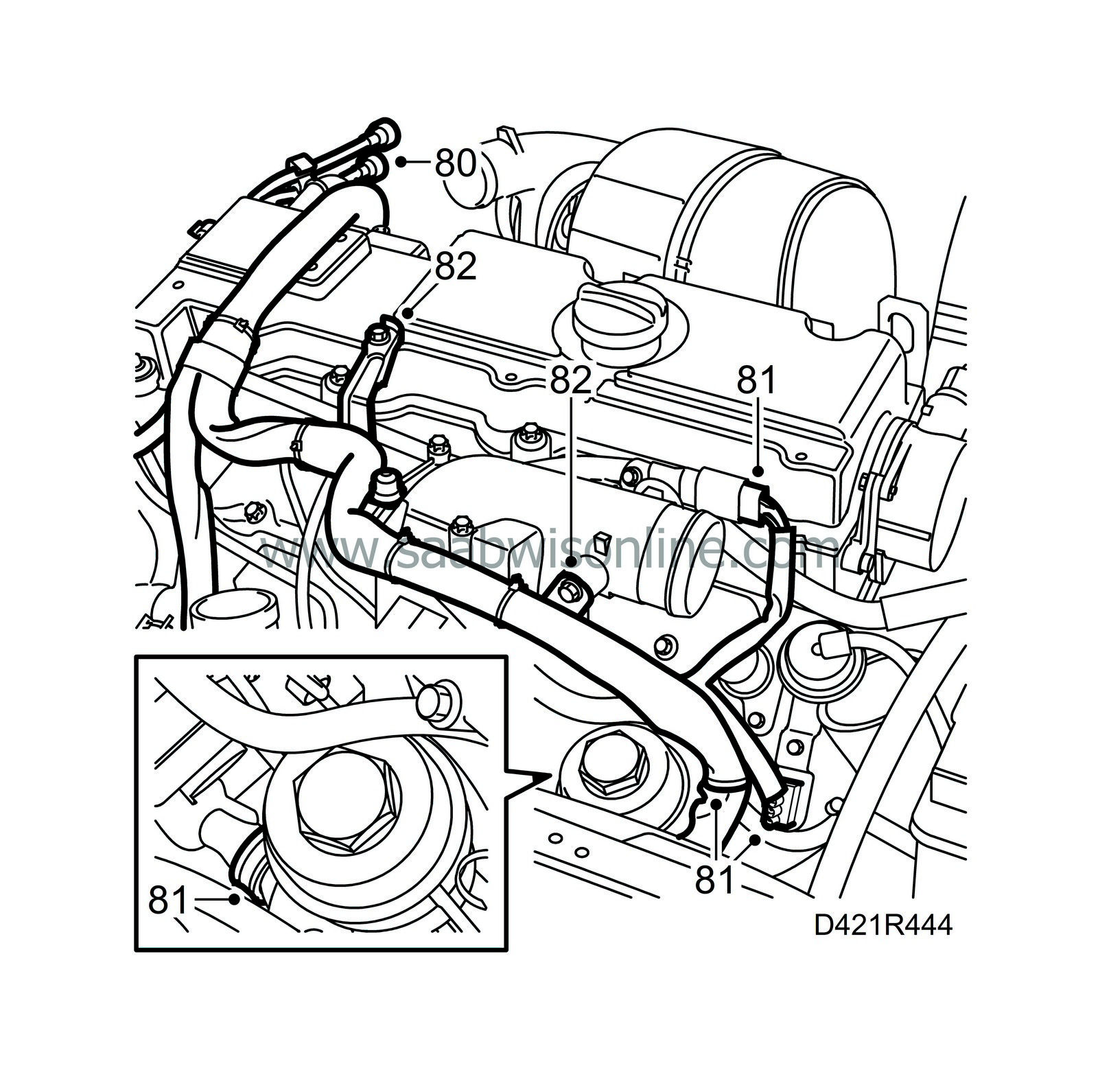

| 80. |

Fit the wiring harness bracket to the engine mounting and press the fuel lines on the bracket.

|

|

| 81. |

Fit the wiring harness ducts to the cylinder head. Plug in all connectors, including those for the control module and glow plugs. Secure the wiring harness.

|

||||||||||

| 82. |

Fit the cable duct to the throttle body and camshaft cover.

|

|

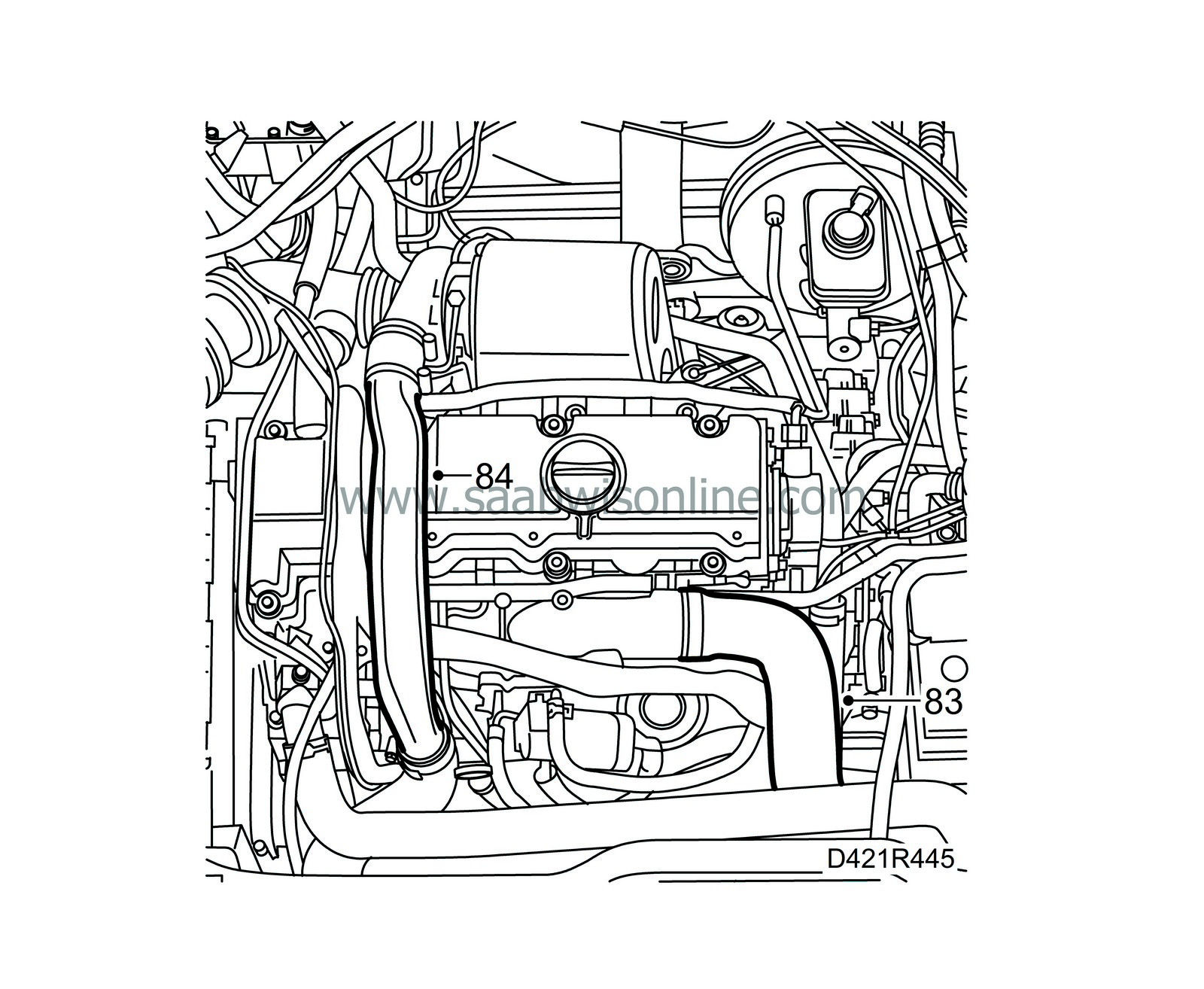

| 83. |

Connect the hose to the throttle body.

|

|

| 84. |

Refit the charge air pipe.

|

|

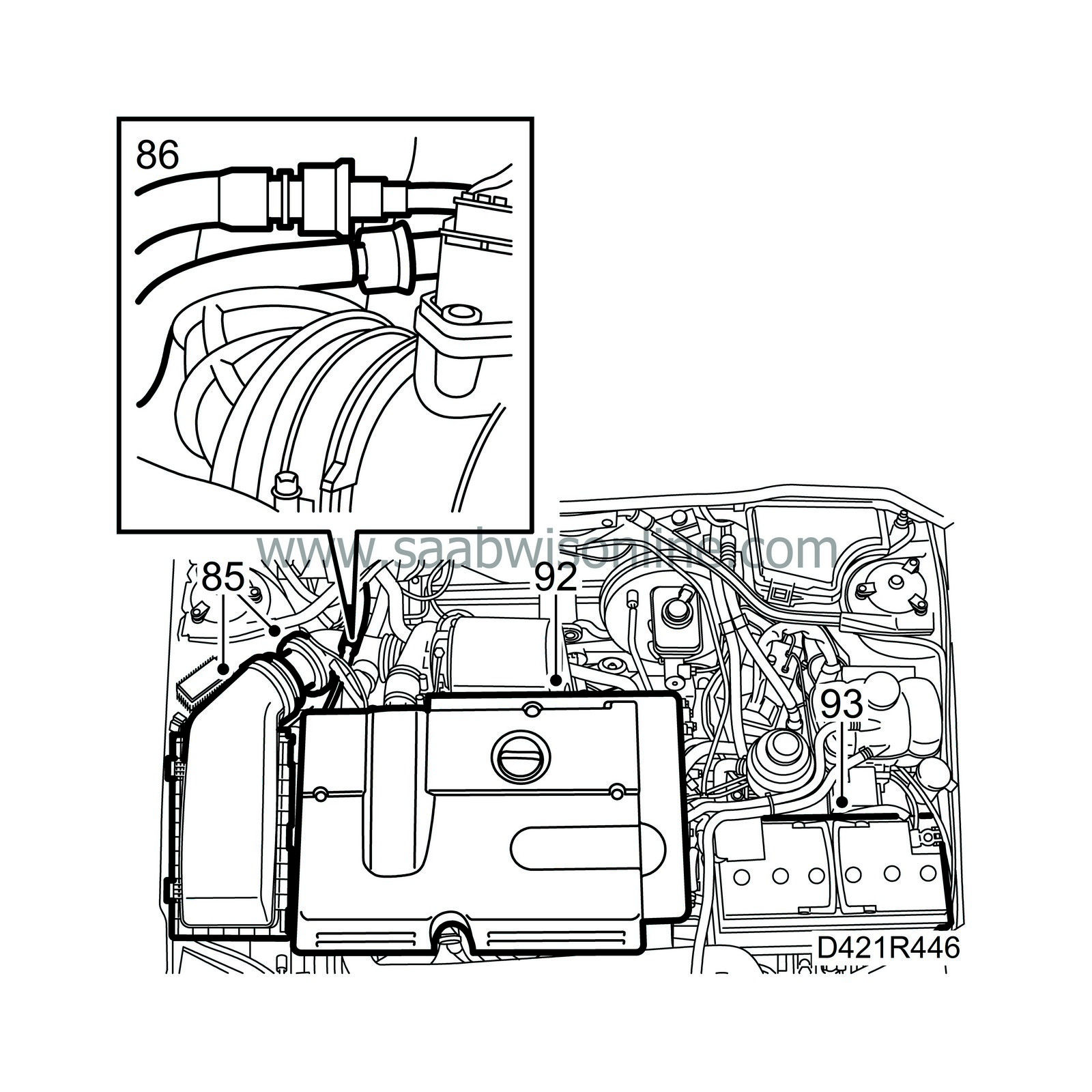

| 85. |

Refit the air cleaner with mass air flow sensor and hoses.

|

|

| 86. |

Connect the fuel lines.

|

|

| 87. |

Connect

30 31 069 Nipple, bleeding equipment

to

88 19 096 Bleeding equipment

or equivalent and start the suction device.

|

|

| 88. |

Remove the end cap and connect the nipple to the service outlet on the fuel pump feed line.

|

|

| 89. |

Suction until a constant flow of fuel is seen in the suction line to the brake-bleeding tool.

|

|

| 90. |

Remove the bleed nipple from the service outlet while the device is still providing suction (to avoid fuel spillage and air entering the system.)

|

|

| 91. |

Put on the end cap for the service outlet.

|

|

| 92. |

Refit the engine cover.

|

|

| 93. |

Fit the battery and connect the cables.

|

|

| 94. |

Top up engine oil according to specifications, see

Lubricating system

|

|

| 95. |

Fill with coolant, check the integrity of the system and bleed it as follows:

|

|||||||

| • |

Connect exhaust hoses to both the engine exhaust system and the auxiliary heater exhaust system and start the engine.

|

| • |

Check that there is a continuos flow of coolant in the hose from the thermostat housing to the expansion tank. NOTE: Important.

|

| • |

Start the parking heater with the diagnostic tool (Body, SID, Activate, Heater). The parking heater stops when the engine temperature has reached 80°C or if the parking heater menu is exited.

|

| • |

Run the engine until the thermostat has opened. Top off if necessary.

|

| 96. |

Restore the engine bay to its original condition.

|

|

| 97. |

Adjust the clock in the car and press 5 times on the remote control lock/unlock button.

|

|

| 98. |

Raise the car. Fit the lower engine cover and belt circuit cover. Fit the wheel.

Tightening torque 110 Nm (81 lbf ft) Lower the car to the floor.

|

|

Warning

Warning