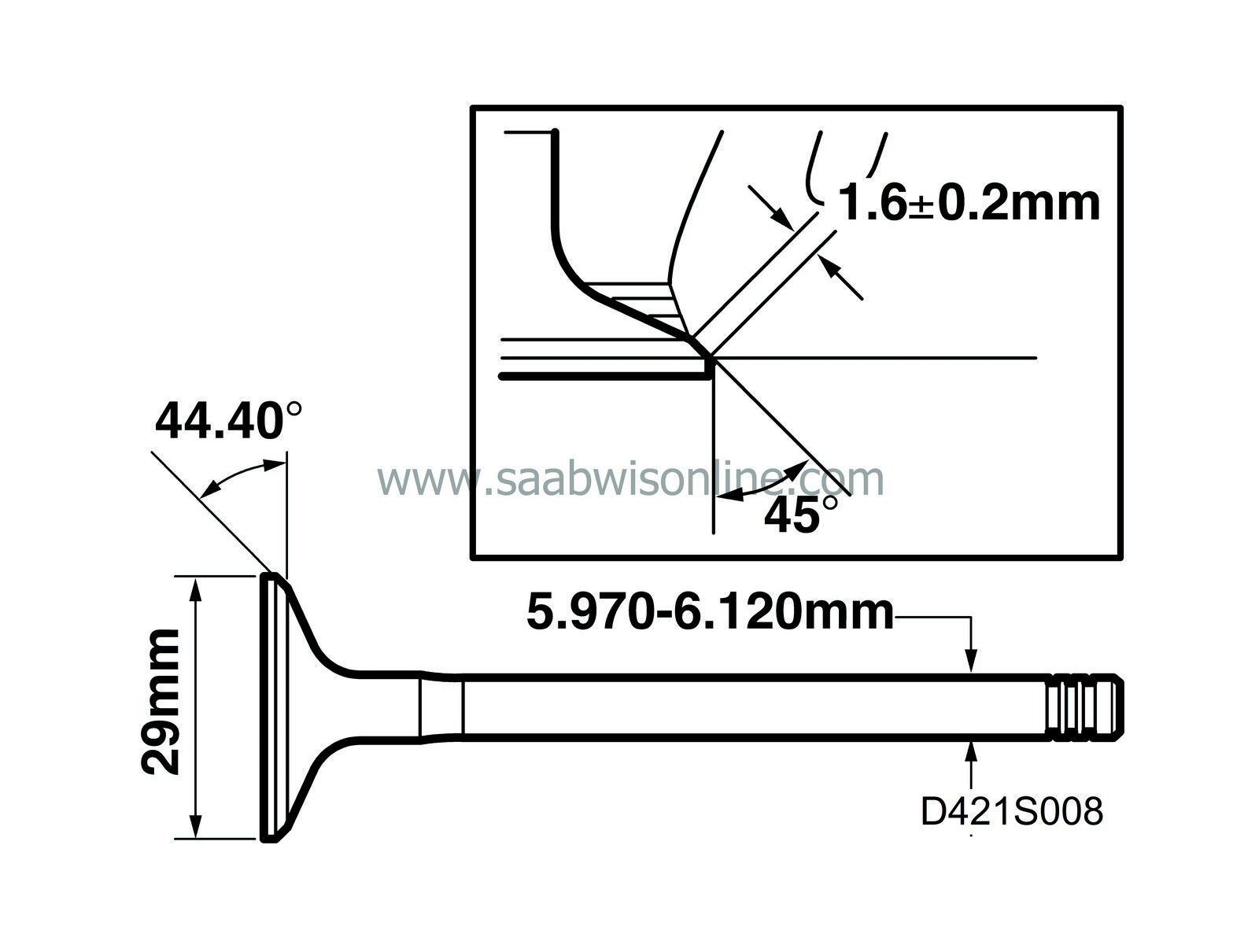

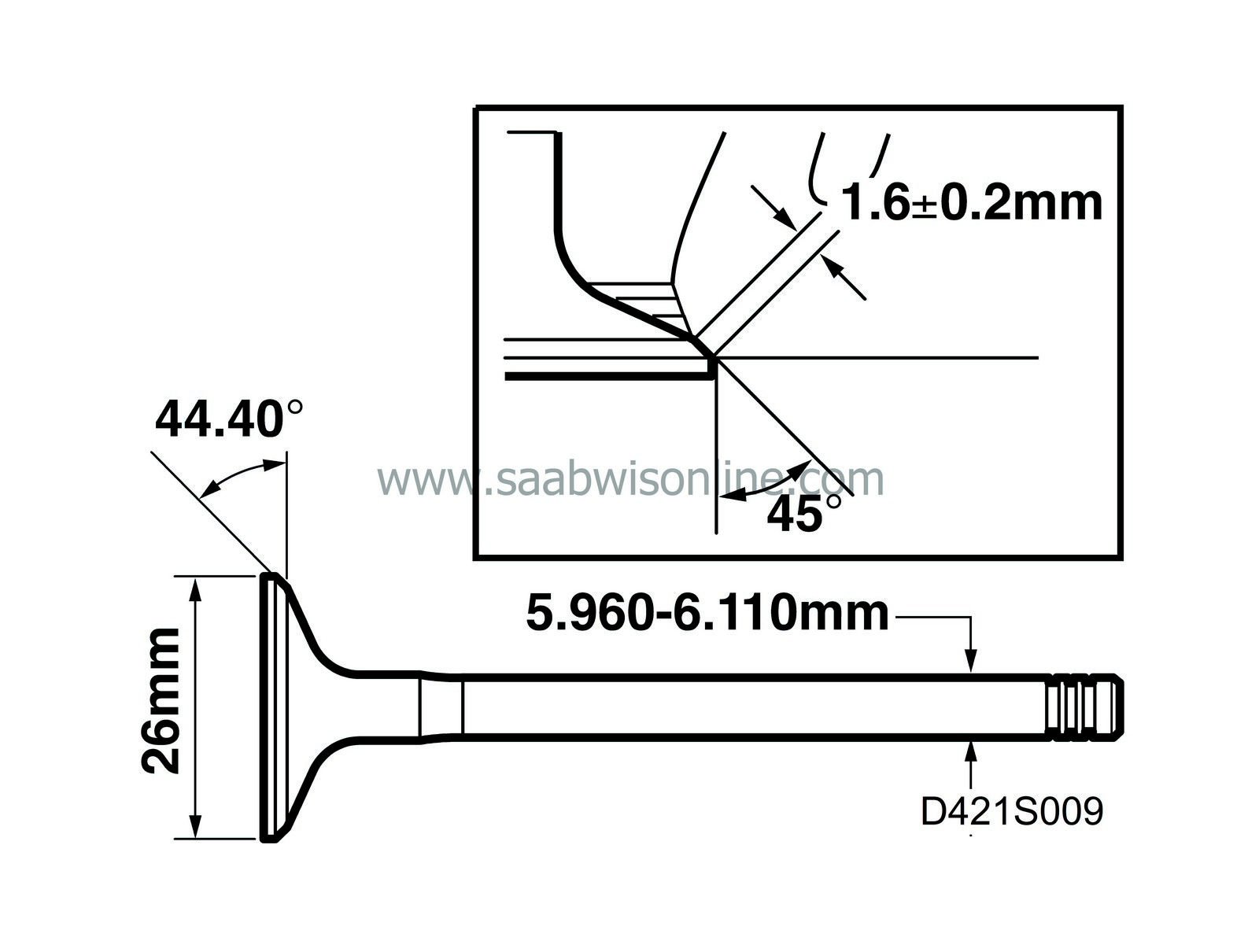

Valve seats, machining and grinding

| Valve seats, machining and grinding |

| To remove |

Use a valve cutter set with 78 61 065 T-handle

83 95 204 Guide spindle, 5 mm , 83 93 936 Valve seat cutter, 60° and 78 61 040 Valve seat cutter, 11° and 45° Ø34.5 mm .

Valve seat angles, intake and outlet valves: 45°.

Correction angle: 60°.

Valve seat breadth: Intake and outlet valves 1.6 ±0.2 mm

| 1. |

Perform the work on a dismantled cylinder head.

|

|