Intake manifold, upper and lower sections

| Intake manifold, upper and lower sections |

| To remove |

|

|||||||

| • |

Make provision for good ventilation! If approved ventilation for extracting fuel fumes is available then it must be used.

|

|

| • |

Use protective gloves! Prolonged contact with fuel may irritate the skin.

|

|

| • |

Keep a class BE fire extinguisher close at hand! Watch out for sparks, e.g. in connection with breaking electric circuits, short-circuits, etc.

|

|

| • |

Smoking is absolutely forbidden.

|

|

| 1. |

Remove the upper engine cover and charge air pipe (2 bolts under wiring harness). Cut the cable tie and plug the hoses.

|

|

| 2. |

Detach the air hose from the intake manifold. Bend it to one side and plug it.

|

|

| 3. |

Unplug the timing sensor, temperature sensor and EGR valve. Cut the cable tie.

|

|

| 4. |

Remove the cable duct from the camshaft cover and throttle body. Place the cable duct over the engine.

|

|

| 5. |

Remove the throttle body.

|

|

| 6. |

Remove the engine wiring harness from the oil filter housing.

|

|

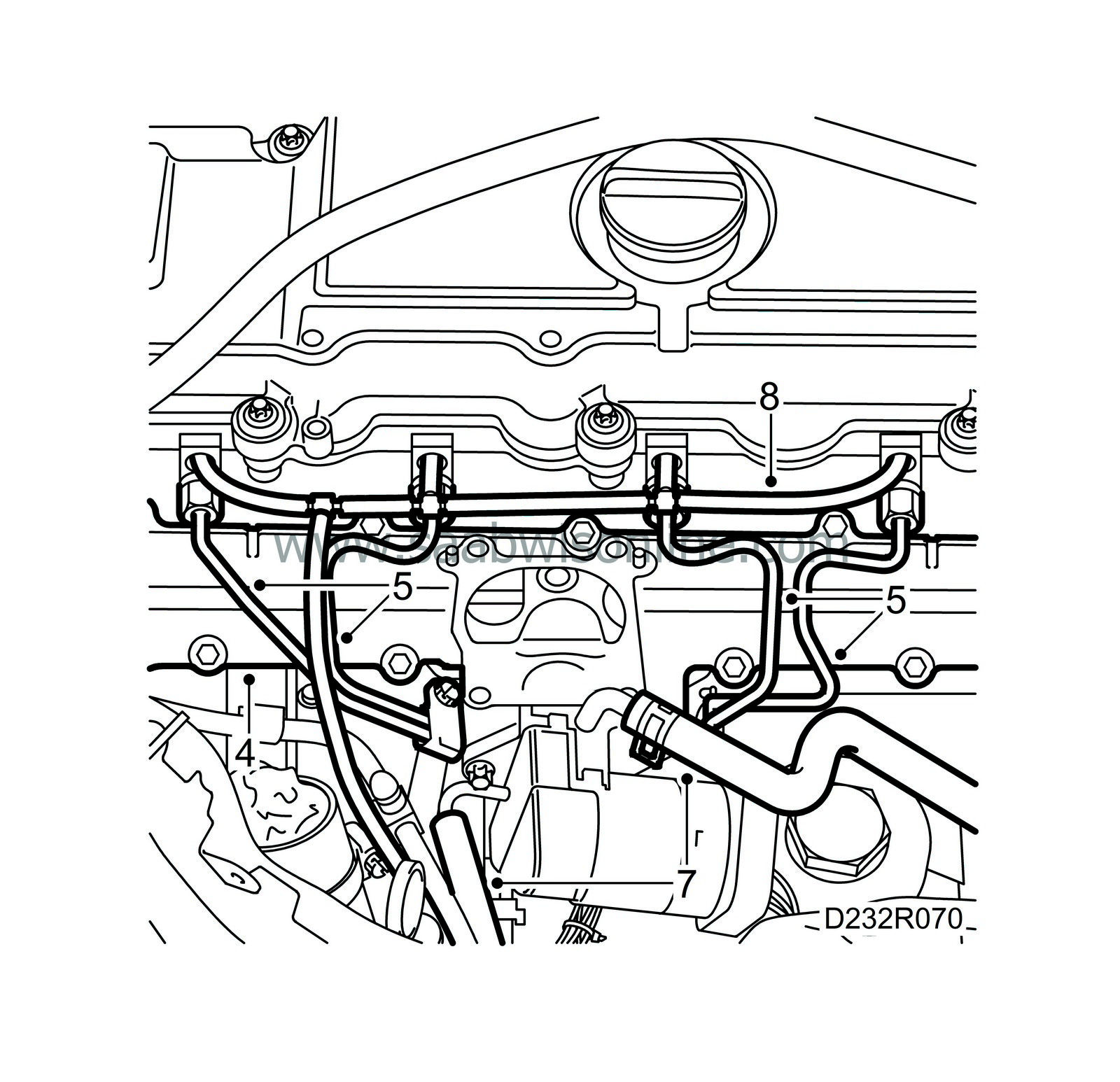

| 7. |

Note the position of the fuel rails and their clips and mark the pipes.

|

|

| 8. |

Remove the fuel return hoses from the fuel bridges.

|

|

| 9. |

Remove the fuel rails and clamps. Remove in the order of the cylinders.

|

|

| 10. |

Release any pressure in the cooling system by undo the expansion tank cap.

|

|

| 11. |

Clamp the coolant hoses to the EGR valve with

30 07 739 Pinch-off pliers

. Disconnect the hoses from the valve.

|

|

| 12. |

Remove the upper part of the intake manifold.

|

|

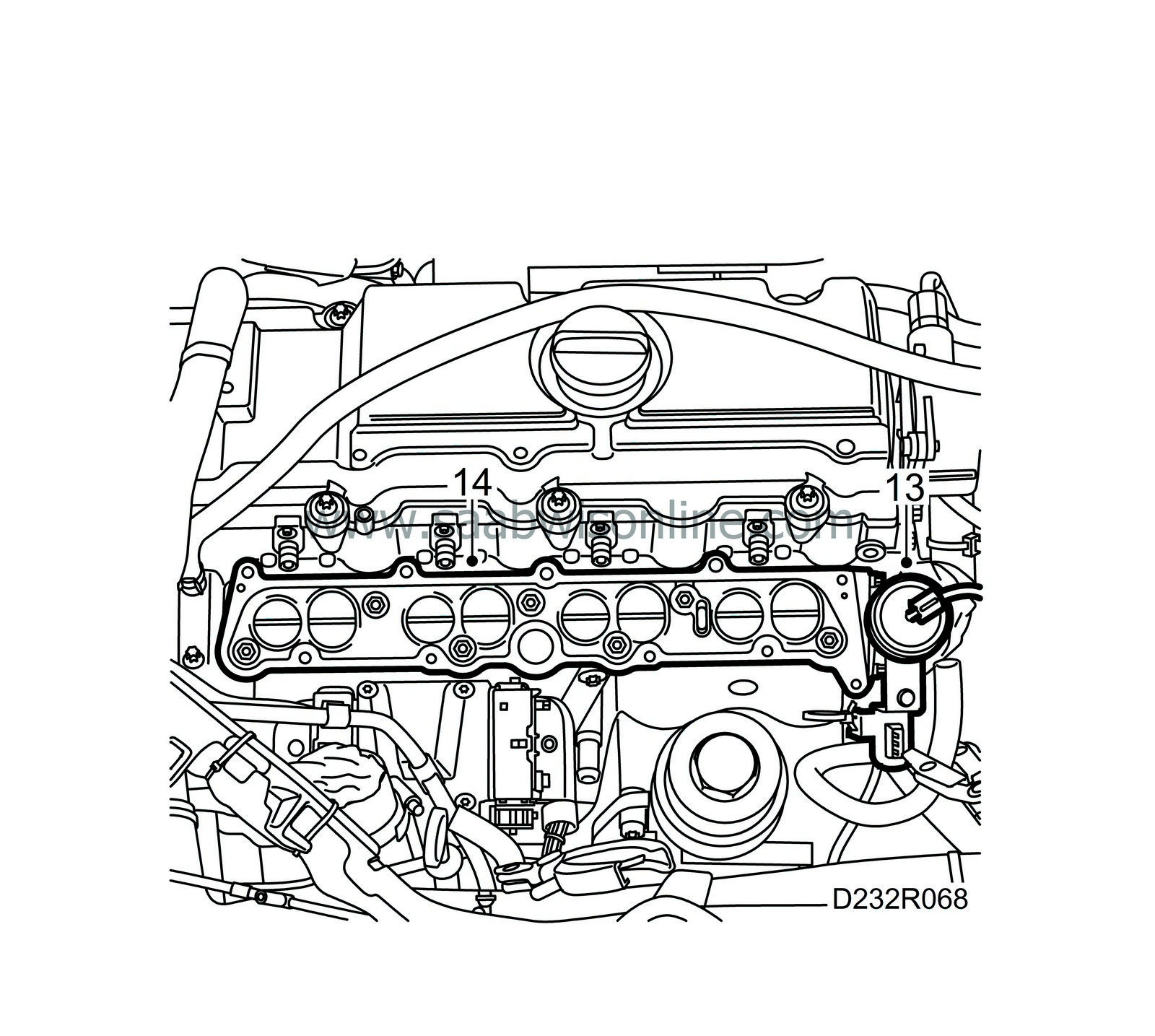

| 13. |

Remove the swirl throttle vacuum unit.

|

|

| 14. |

Remove the lower intake manifold.

|

|

| To fit |

| 1. |

Clean the sealing surfaces.

|

|

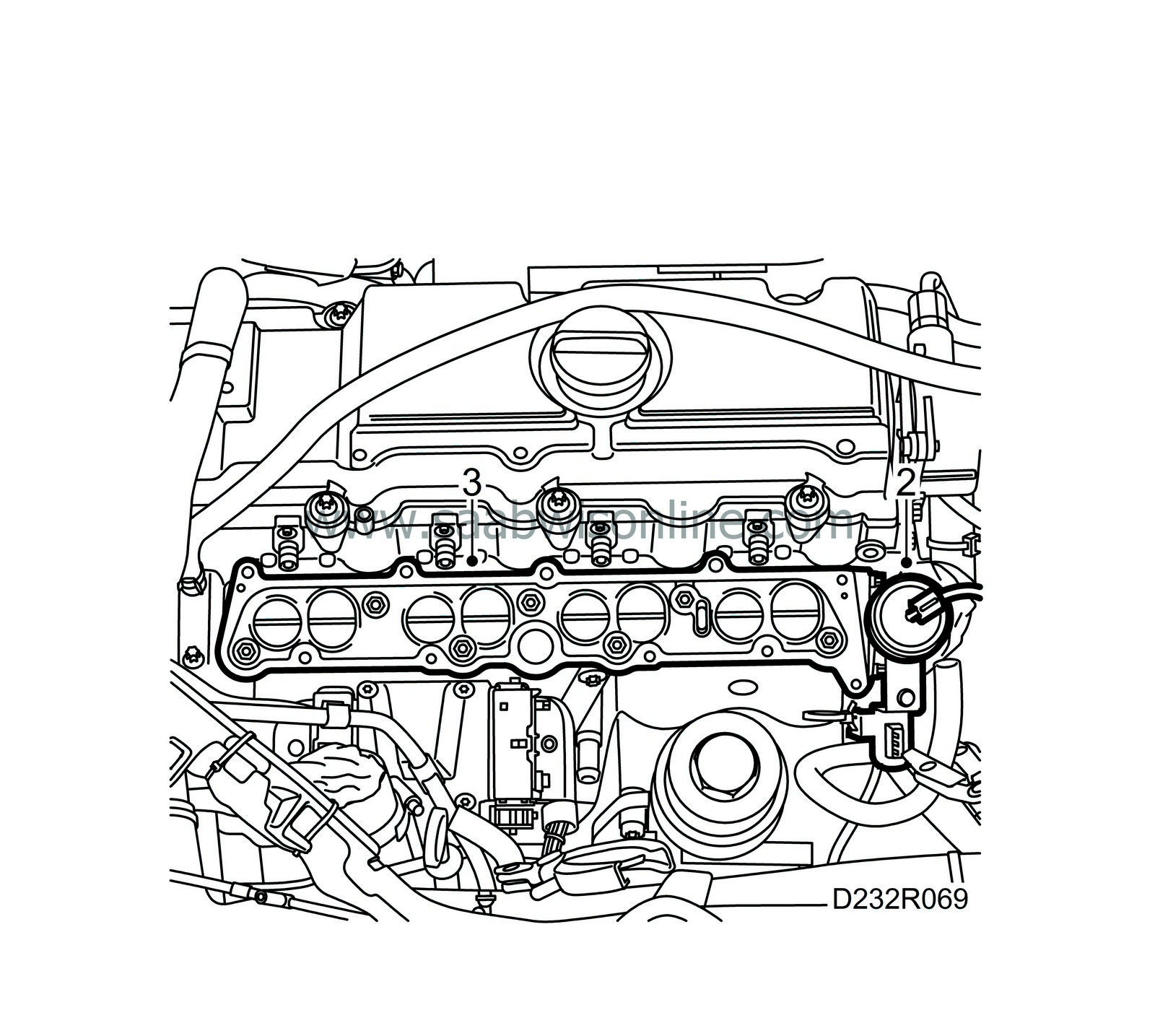

| 2. |

Refit the swirl throttle vacuum unit.

|

|

| 3. |

Fit a new gasket and fit the lower section of the intake manifold.

Tightening torque: 20 Nm (15 lbf ft) Tighten the bolts securing the vacuum unit. |

|

| 4. |

Fit a new gasket to the lower part of the intake manifold and fit the upper part of the intake manifold.

Tightening torque 10 Nm (7 lbf ft).

|

|

| 5. |

Fit the fuel lines with clips to the cylinder head and fuel pump. Check the fuel rail connecting cones and replace if necessary.

Tightening torque 25 Nm (19 lbf ft) |

|

| 6. |

Check the fuel rail connecting cones and replace as necessary.

|

|

| 7. |

Connect the coolant hoses to the EGR valve.

|

|

| 8. |

Fit new fuel return hoses. Check the condition of the T-pieces and change if necessary.

|

|

| 9. |

Fit the lower clip that secures the wiring harness to the oil filter housing.

|

|

| 10. |

Fit the throttle body.

|

|

| 11. |

Plug in the timing sensor, temperature sensor and EGR valve.

|

|

| 12. |

Secure the wiring harness as it was previously and tighten the bolts.

|

|

| 13. |

Fit the hose to the intake manifold.

|

|

| 14. |

Fit the charge air pipe and secure the engine wiring harness with a cable tie.

|

|

| 15. |

Press the cable duct into place.

|

|

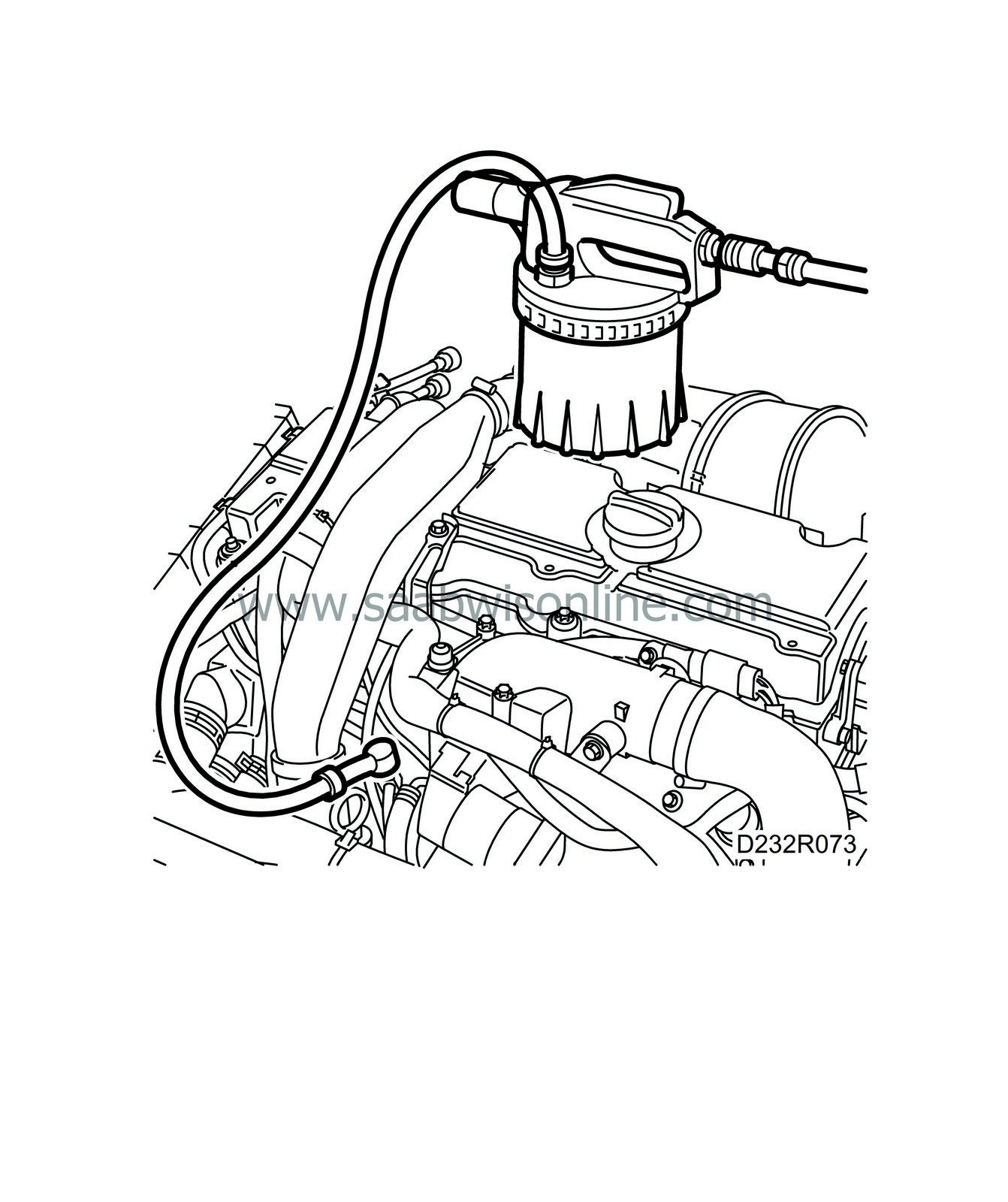

| 16. |

Connect

30 31 069 Nipple, bleeding equipment

to

88 19 096 Bleeding equipment

or equivalent and start the suction device.

|

|

| 17. |

Remove the end cap and connect the nipple to the service outlet on the fuel pump feed line.

|

|

| 18. |

Suck until a constant flow of fuel is seen in the suction line to the brake bleeding tool.

|

|

| 19. |

Remove the bleed nipple from the service outlet while it is still sucking (to avoid fuel spillage and air entering the system).

|

|

| 20. |

Put on the end cap for the service outlet.

|

|

| 21. |

Fit the upper engine cover.

|

|

Warning

Warning