(311-2145) Maintenance program for starting battery

| SERVICE INFORMATION | |

| Bulletin Nbr: | 311-2145 |

| Date: ........... | MAJ 1999 |

| Market: | SE |

| Maintenance program for starting battery |

| Cars affected |

9-3, 9-3CV and 9-5 from M1999.

| Background |

This SI replaces SI 311-1773, SI 100-1482 as well as the sections concerning battery maintenance in Service Manual 1 Service and 3.1 Electrical system.

If a battery is left without maintenance for long periods, its charge level will successively drop. What principally determines the speed of the drop is the size of the current being consumed by the car's electrical system. Even if the battery is disconnected, a certain discharge will take place. This will increase with temperature.

If the battery is left standing at a low charge level for long periods, a chemical process will be initiated in which the battery acid gradually converts to water and the battery plates start to corrode. This corrosion process will start to be critical if the battery is left standing for about 2 weeks at a charge level below 65-75 % (corresponding to a battery voltage less than 12.4 volts without a load). A battery with low charge level can freeze even at 0ºC, which will also damage the battery plates.

The damage this causes is permanent and can not be remedied by charging the battery in the normal way. This means that the deterioration in the battery's capacity and service life is permanent.

The objective with this maintenance program is to prevent this kind of damage to the battery from ever occurring and therefore increase the service life of the battery, and above all to ensure that the customer always receives a battery that is in good condition.

| Parts required |

Saab Battery Analyser 311.

The analyser is available in two language versions:

|

86 12 533

|

Swedish, Finnish, German, Dutch, French, English (UK)

|

|

86 12 525

|

English (US), French (CA), Spanish, Portuguese, Italian, German

|

| Brief summary of the battery maintenance program |

This program is a procedure to document the battery's condition from factory to end-user.

Each car is issued with a battery card at the factory. The battery is checked during the delivery approval and the results registered on the battery card. The battery is tested with a new type of battery analyser, which, besides measuring the voltage, is able to measure and assess the battery's current capacity.

A similar analyser (Battery Analyser 311) is to be available at each dealership. This analyser provides test results in writing and a test code that contains all the test values.

When the car is standing in storage at the dealership and the battery is not disconnected, the battery must be checked monthly and the result entered onto the battery card.

Demonstration cars (in showrooms, etc.) are checked weekly if the battery has not been disconnected.

Battery Analyser 311 will indicate whether the battery is in need of recharging. After charging, the battery card is updated with a new test.

When the car is delivered to the customer (pre-delivery service), the battery status in the form of a test code together with the mileage and the date is entered into the customer's “Saab Service” book.

The test code from Battery Analyser 311 must accompany warranty claims if the claim is to be approved.

| Battery Analyser 311 |

Battery Analyser 311 is manufactured by Midtronics Inc. in the USA and uses a patented measuring method (conductance), which is able to measure not only the battery voltage but also the battery's current capacity. Saab Automobile AB judges this analyser to be the most suitable test instrument on the market for this kind of maintenance program. Using this analyser makes it possible to obtain a uniform battery test method on all Saab's markets around the world.

Handling is simple as there are only four buttons to use:

| • |

two arrow buttons for making selections in menus

|

|

| • |

one ← button to confirm selections

|

|

| • |

one “ i “ button to read the test code

|

|

A special Saab adapted test program enable the analyser to provide test results in writing as well as in the form of an 8-character test code.

The analyser does not require a separate power source as it is supplied by the battery to which it is connected during the test.

Only 12 V starting batteries can be tested. The analyser can also be used to check batteries from Saab 900 and 9000.

Saab Automobile AB offers a one year warranty on the analyser. During the warranty period, a defective instrument can be reclaimed to Parts Testing, Saab Automobile AB, Trollhättan. A new analyser can be ordered through normal spare parts procedures.

| Important | ||

|

Test cables must never be repaired or replaced with others as the instrument and its test cables have been calibrated as one unit. |

||

|

If test cables from another battery analyser are used, for example, incorrect test values will be obtained. |

||

|

For repair of test cables or instrument, both items must be sent in together. |

||

| Battery card |

The objective of the battery card is to chart and document the condition of the battery from the factory to the end-user. The car's VIN is entered onto the card and the card placed in the glove compartment when the car leaves the assembly line. The first test is registered on the card when the car is delivery approved at the factory and the card then accompanies the car all the way to the final dealer. The battery card is of no use once the car has been delivered to the customer.

The battery card must be updated as described below. The numbers refer to the respective zone on the battery card, see illustration.

| 1. |

Vehicle (Dealer Reference No)

Used by the dealer as necessary (stock no., coordinate, etc.) to help identify and locate the car and respective key. |

|

| 2. |

VIN

The car's vehicle identification number as specified at the factory. FactoryThis section is completed at the factory after the battery has been approved for delivery. |

|

| 3. |

Battery OK Date

The date the battery was checked and approved for delivery at the factory (Customer Care). |

|

| 4. |

Code

Battery test code according to battery test at factory. |

|

| 5. |

Battery type — CCA(SAE)

The marked box specifies the size of the factory-fitted battery in CCA (“Cold Cranking Amps”) according to SAE standard. |

|

Dealer

The result of every battery test carried out while the dealer is responsible for battery maintenance, i.e. up until the day the car is delivered to the customer is registered in this section.12 Date

The date the battery is checked is noted here. Normally, the battery is checked monthly. Demonstration cars in showrooms, etc., are tested weekly. This applies if the battery has not been disconnected.

13 Code

The test code obtained from Battery Analyser 311 is noted here.

| Note | ||

|

The test code is required for possible warranty claims on the battery. |

14 Message - Action

The test message given by Battery Analyser 311 is noted here together with any measures taken where appropriate.

| Note | ||

|

If charging is needed - Check the battery and update the battery card after charging. |

| Monitoring system |

Besides Battery Analyser 311 and the battery card, each dealer should have a system for keeping track of cars requiring test or recharging respectively. We recommend a simple PC register program or a binder system where cars in storage, showroom cars and cars being made ready for delivery can be identified.

| Test procedure |

Select the relevant alternative in each menu with the arrow buttons.

Use the ← button to confirm a selection. The selections that are made now will remain as default selections the next time the analyser is turned on.

| 1. |

Check the acid level in the battery and top up if necessary (especially on warm markets). If the battery has been used for a time with low acid level, it should be charged after topping up before the battery test is carried out.

|

|||||||

| 2. |

Clean the battery terminals.

|

|

| 3. |

Connect the red cable clamp to the positive terminal (+). (Incorrect polarity will not harm the analyser.)

|

|

| 4. |

Connect the black cable clamp to the negative terminal (-). Once both clamps are connected, the analyser will be activated automatically and initiate a self-test. In case of a fault in the analyser, the message “INTERNAL FAULT SERV. REQUIRED” will be displayed.

|

|

| 5. |

Make sure the cable clamps make as good contact as possible.

|

|||||||

| 6. |

At “SELECT TEST”, select whether the battery is connected to the car's electrical system (“IN-VEHICLE”) or not (“OUT-OF-VEHICLE”).

|

|

| 7. |

At “BATTERY TYPE”, select whether the battery is factory-fitted (“SAAB BATTERY”) or a replacement battery of another make (“NON SAAB”).

|

|

| 8. |

Confirm “SELECT TEST BY SAE(A)” if the battery's cold starting current is specified to CCA(SAE) standard. For batteries specified to DIN standard, select and confirm “SELECT TEST BY DIN (A)”.

DIN standard can be selected when the analyser is used to check replacement batteries that are not specified to SAE standard. |

|||||||

| 9. |

Enter the battery's rated cold starting current.

On Saab factory-fitted batteries, this value can be found with large text on the label on top of the battery from model year 1999. The following table specifies the CCA (SAE) values for factory-fitted batteries from model year 1994 and onwards that should be used when testing the relevant battery with Battery Analyser 311. |

|

| Manufacturer | Part No. | Car model | Ah | CCA (SAE) |

|

Varta

|

4231775

|

900/9000

|

60

|

520 A

|

|

Varta

|

4813804

|

900/9000

|

60

|

520 A

|

|

Varta

|

4947065

|

900/9000/9-5

|

60

|

520 A

|

|

Varta

|

4812921

|

900/9000/9-3/9-5

|

60

|

580 A

|

|

Varta

|

5106661

|

9-3/9-5

|

60

|

580 A

|

|

Jungfer

|

4354908

|

900/9000

|

60

|

520 A

|

|

Bären

|

4231783

|

900 V6

9000 |

70

|

570 A

|

|

Bären

FIAMM |

4813820

|

900 V6

9000/9-5 |

70

|

650 A

|

|

FIAMM

|

5107354

|

900 V6

9000/9-5 |

70

|

650 A

|

|

FIAMM

|

4584108

|

9-3 diesel

|

85

|

760 A

|

|

FIAMM

|

5107370

|

9-3 diesel

|

85

|

760 A

|

| Note | ||

|

If the battery's cold starting current can not be identified, the following standard values can be used. |

|

900, 9-3 (not diesel)

|

570 CCA (SAE)

|

|

9-3 diesel

|

750 CCA (SAE)

|

|

9000 and 9-5 with A/C

|

640 CCA (SAE)

|

|

9000 and 9-5 without A/C

|

570 CCA (SAE)

|

Once the value has been selected and confirmed, the actual battery test will start automatically.

The analyser may then require further information before the result can be presented.

| A. |

“BATTERY TEMP”

Under certain circumstances, the analyser may need to know whether the temperature of the battery is above or below 0º(32°F) in order to make a correct assessment of the battery. This can happen even if the battery is tested at room temperature. By selecting and confirming the correct value, a new test will be started. |

|

| B. |

“SURFACE CHARGE DETECTED”

Under certain circumstances, the charge may be present only on the surface of the battery plates. This provides a relatively high voltage reading but does not contain any practical starting energy. In order to obtain a correct assessment of the battery in this case, the analyser will request that the operator turn the ignition key to ON and turn on the headlights for a few seconds by displaying the message "TURN KEY ON HEADLAMPS ON". The analyser then indicates when the load should be disconnected with "IGNITION OFF HEADLAMPS OFF". A new battery test will start automatically when this has been done. If the analyser does not detect that the load has been connected or disconnected the message “WARNING” will first be displayed, followed by "LOAD ON NOT DETECTED" or "LOAD OFF NOT DETECTED" respectively. |

|

| C. |

“SELECT MODE BEFORE CHARGE”

“SELECT MODE AFTER CHARGE” Under certain voltage and conductance conditions, the analyser will need to know whether the test is being carried out before or after the battery has been charged in order to make a correct assessment of the battery.

|

|||||||

After answering the question/s, the analyser will display the results in one of the following ways:

| Message | Signification |

|

GOOD BATTERY

|

Fully charged. No action needed.

|

|

GOOD - RECHARGE

|

Recharge the battery, connect and put in operation.

|

|

CHARGE & RETEST

|

Charge the battery and repeat the test (see further under the heading ”Battery charging”). If the message remains after charging - replace the battery.

|

|

REPLACE BATTERY

|

Replace the battery.

|

|

BAD CELL REPLACE

|

Replace the battery.

|

When the messages “GOOD BATTERY” and “GOOD - RECHARGE” are shown, the display will alternate between displaying the message and showing the degree of charge in steps of 25%, e.g. “STATE OF CHARGE: 0-25%”. This value gives a clear indication of the current state of the battery.

When the analyser indicates that the battery should be replaced under warranty, we recommend performing an extra test with the battery out of the car. The test code from this test should be attached to the warranty claim (see further under Warranty Policy).

| Note | ||

|

Check a replacement battery with Battery Analyser 311 as well before fitting it in the car. If the cold starting current of the replacement battery is not specified to SAE standard, select the DIN standard test in step 7 above. |

| Fault diagnosis |

| 1. |

If the display does not come on:

|

|

| • |

Check connections to the battery and that polarity is correct.

|

| • |

If the battery voltage is below 5.5 volts, the battery analyser will not start. Charge the battery and test again.

|

| 2. |

If the message "CHECK CONNECTION” is displayed:

Check that both halves of each connecting clamp have good contact with the respective battery terminal. |

|

| Note | ||

|

The same test message can be obtained when testing Saab 900 batteries and then mainly when the ICE control module is active. |

||

|

The ICE control module has a run-on time of 20 minutes after the ignition has been turned off and is activated when a door is opened. |

||

|

By removing maxi fuse 2 in the maxi fuse board, the ICE control module can be de-energized. |

| Test code |

The Saab battery test code can be read at any time by pressing the "i" button.

The test code consists of 8 characters and contains all the information from the battery test in coded form and is required for all warranty claims. The code is interpreted during warranty and quality reviewing by special software.

This test code (together with the VIN and test date) will also be used to track the condition of the battery from the factory to the end-user and determine how the distribution chain can be optimized in the future.

Press the "i" button once more to return to reading the test results.

| Note | ||

|

The test code can only be obtained when the "SAAB BATTERY" test type has been selected. Otherwise, the message “NON SAAB BATTERY TEST”. |

| Note | ||

|

For continuous trickle charging of batteries in demonstration cars, an especially adapted charger will lower voltage should be used. Too high a voltage from the charger will damage the battery due to overcharging. |

| Charging code |

At any time during the reading of test results, the ← button can be pressed to display a charging code. This code is for future use and will then be entered into an especially intelligent battery charger for automatic and adapted battery charging.

| Charging |

|

|||||||

The battery must be charged if the battery analyser displays any of the following test messages:

“GOOD - RECHARGE"

"CHARGE & RETEST"

A battery charger with charging current approx. 10-20 % of the battery's rated capacity, i.e. 7-14 amperes for a 70 Ah battery, should be used. Normal charging time is 4-12 hours depending on the condition of the battery and the charging current.

| Important | ||

|

So-called quick-chargers with high charging currents must not be used! |

||

Always check battery acid level before and after charging and top up if necessary.

The battery terminals need not be disconnected and the covers can remain on provided the charging value above are adhered to.

Perform a new test after charging and enter the results onto the battery card.

| Note | ||

|

The test should not be performed directly after charging, as the charge gases that arise form a layer on the battery plates, giving an incorrect indication of the capacity. The layer can be removed in the following way: |

||

| • |

Allow the battery to rest for approx. 2 hours before conducting the test.

|

|

| • |

When testing a disconnected battery:

Shake the battery by alternately lifting both ends of the battery max. 2 centimetres from the surface it is standing on and then releasing it. |

|

| • |

When testing a connected battery:

Apply a load on the battery, e.g. turn on the headlamps, for approx. 10 seconds. |

|

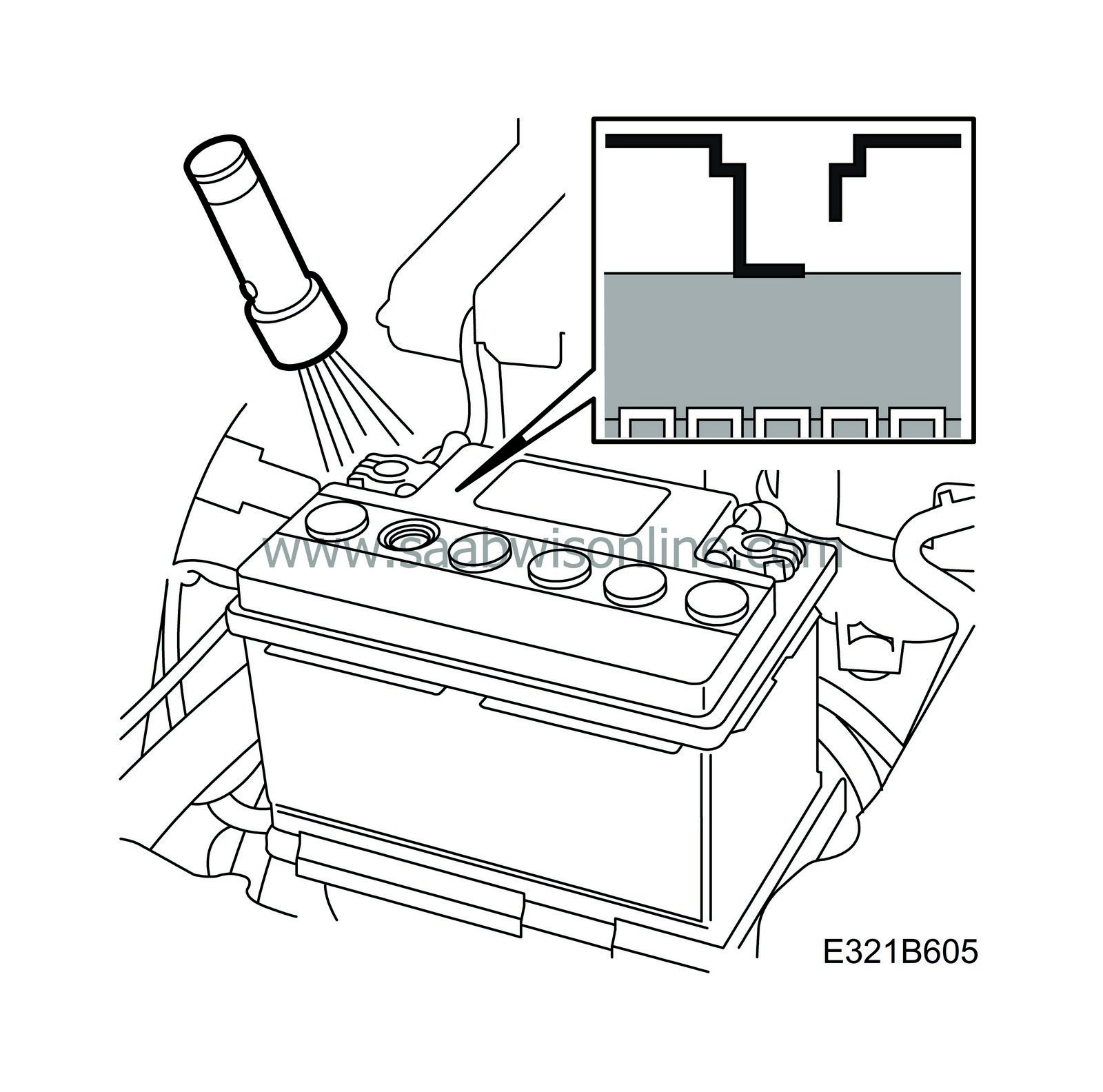

| Checking battery acid level |

Always check the level of battery acid in all the cells before and after charging the battery by removing the battery plugs with a suitable screwdriver. Use a torch to make it easier to see the level of battery acid.

If necessary, top up with distilled or de-ionized water to the max. mark. Each cell has its own max. level marking.

| Important | ||

|

Never use tap water. |

||

Normal tap water contains salts and minerals that accelerate corrosion of the battery plates, which can severely shorten the service life of the battery.

Fit the covers and tighten them after completing the procedure.

| Important | ||

|

Never fill above the max. level markings. This can cause the battery acid to leak. |

||

| Measuring standing current |

If the capacity of the battery is severely diminished after leaving the car parked for a few days, it is possible that the current consumption from the car's electrical system is abnormally high when the car is turned off. At the slightest suspicion of this being the cause of deficient battery performance, the standing current must be measured.

| Note | ||

|

Always check that the customer is in possession of the code for the radio or any other equipment that may be relevant before disconnecting the battery. |

| 2. |

Turn the ignition to ON but

do not start the engine

- the meter will be ruined.

|

|

| 3. |

Turn the ignition key to OFF after 10 seconds, remove the key and close all the doors.

|

|

| 4. |

Wait for 25 min. (due to the run-on time of certain electrical components) and then disconnect the jumper lead across the milliammeter and read off the standing current. The standing current should normally not exceed the following values (provided that no accessories, e.g. a telephone, have been fitted):

|

|

| Car model | Transport mode | Customer mode |

|

9-3/9-5

|

5 mA

|

16 mA

|

|

900

|

7 mA

|

20 mA

|

|

9000

|

10 mA

|

30 mA

|

Transport mode: Maxi fuse 1 in the maxi fuse board removed and TWICE control module programmed to transport mode.

If these values are exceeded, the source must be localized by removing fuses one at a time.

As the table shows, it is essential to the service life of the battery that the car is left in transport mode for as long as possible.

| Manufacturing date of battery |

A manufacturing codes is stamped on the negative terminal on factory-fitted batteries and Saab original spare part batteries. This code specifies the week the battery was activated at the manufacturer's. The code specifies the year and week as follows:

25 98, alternatively 8 25 = year 1998, week 25.

| Pre-delivery inspection (PDI) |

This SI replaces the directions for pre-delivery inspection of batteries in Service Manual 1 Service. No battery service action is required during pre-delivery inspection on the Swedish market.

| Storage care |

This SI replaces the directions for storage care of batteries in Service Manual 1 Service.

When the car is in storage, the battery must be checked with Battery Analyser 311 monthly if the battery has not been disconnected.

Check also the battery acid level on each occasion (see “Checking battery acid level”). This is especially important on warm markets.

Charge the battery if required. (See “Charging”).

| Important | ||

|

So-called quick-chargers with high charging currents must not be used! |

||

| Note | ||

|

If the car is to be in storage for longer than a month, the negative battery cable can be disconnected. In this way, the maintenance interval can be extended to 3 months provided the battery is approved with Battery Analyser 311. Note this action on the battery card. |

||

|

The correct time and language must be set in SID when connecting the battery. |

| Delivery service |

This SI replaces the directions for delivery inspection of batteries in Service Manual 1 Service.

Check the battery with Battery Analyser 311 as the first step in the delivery service before fitting the transport fuse and programming the TWICE control module to customer mode.

| Note | ||

|

In case of warranty claims, it is essential that the test code from the delivery service is made available. |

The test code is to be entered into the customer's Saab Service book together with the mileage and date under the heading “Note” next to the space for the stamp.

| Note | ||

|

It is only in connection with the delivery service that the transport fuse (maxi fuse 1) is fitted and the TWICE control module is programmed to customer mode. This may not apply to demonstration cars, etc. |

| Maintenance service (Saab Original Service) |

The condition of the battery is to be checked with Battery Analyser 311 on each service occasion and the test code and date entered in the “Note” box in the “Saab Service” book next to the space for the stamp. From model year 2000, the Saab Service book will have a special box with the heading “Battery test code”. The battery acid level is also to be checked on each service occasion (see “Checking battery acid level”).

| Warranty conditions |

See separate information in the Warranty Manual.

| Warranty/Time Information |

The procedures in this SI are included in Pre Delivery Service, Delivery Service and Maintenance Service.

Time differences are included in STM, edition 99-1.

The new times will be available in the dealer's DMS in May.

Warning

Warning