Windscreen member

| Windscreen member |

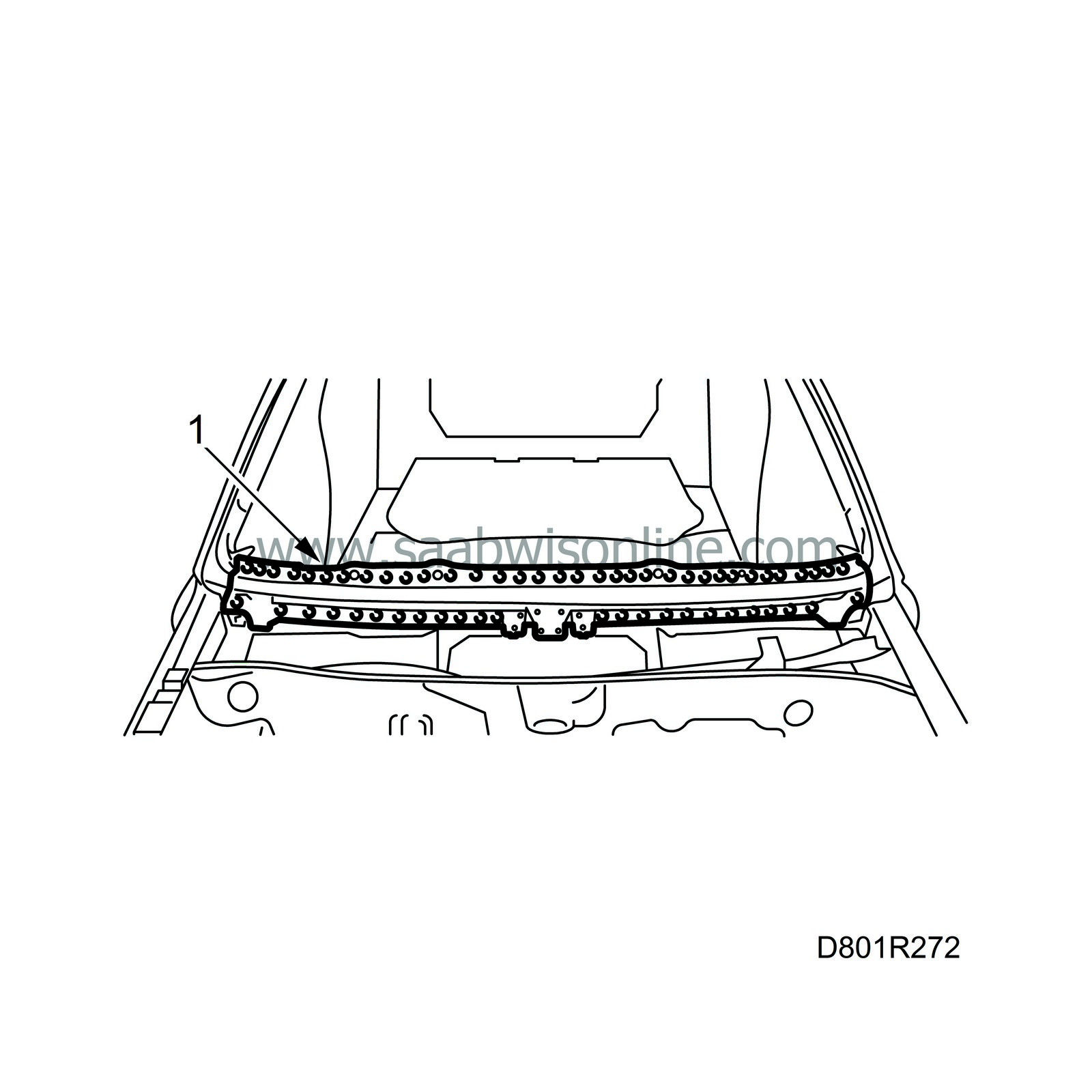

| 1. |

Drill out the spot-welds.

|

|

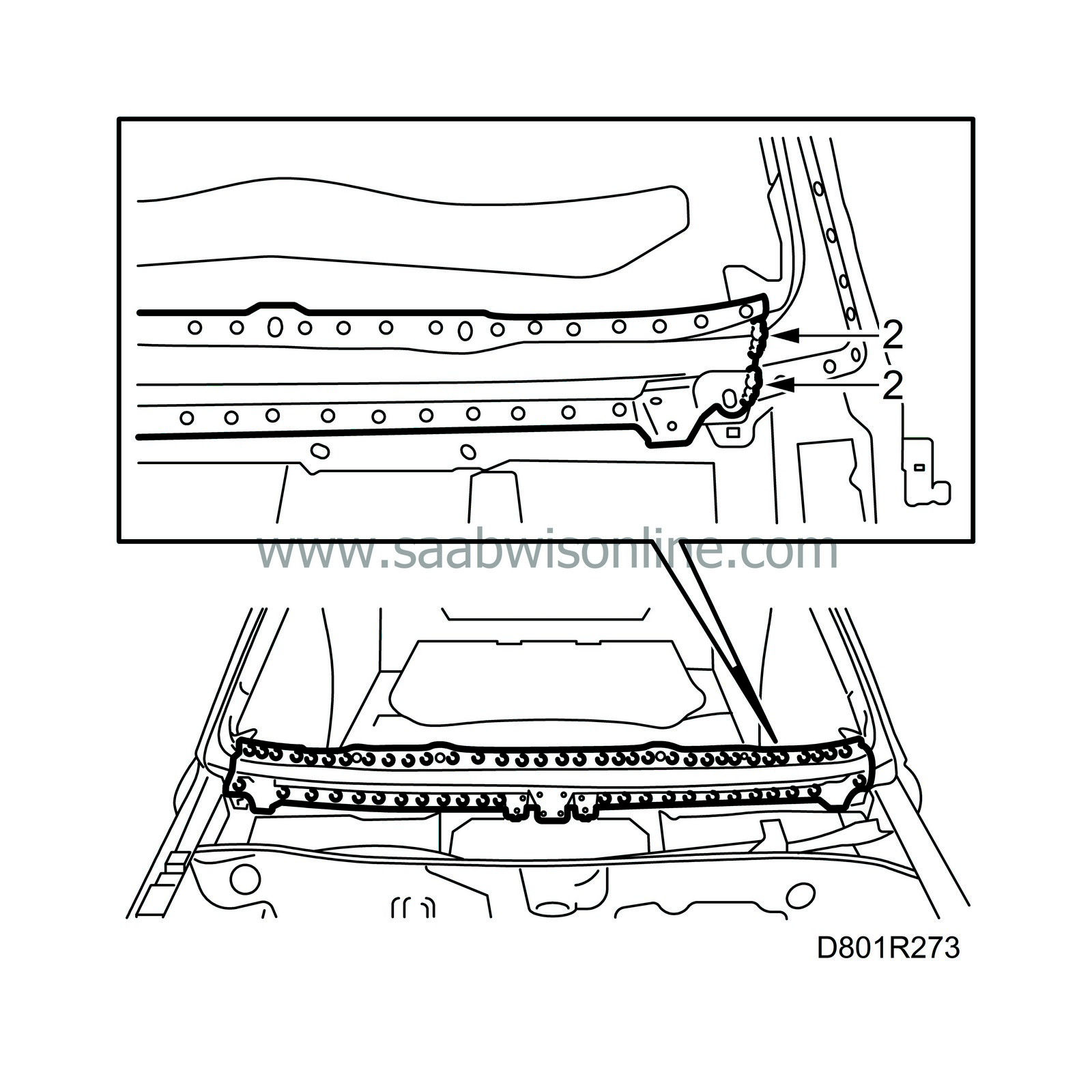

| 2. |

Grind down the welds securing the windscreen member to the bottom of the A-pillars and cut the windscreen member.

|

|

| 3. |

Tap loose the windscreen member and align any damaged panels.

|

|

| 4. |

Grind the surfaces to be welded on the body and spare part.

|

|

| 5. |

Apply welding primer on the surfaces to be spot-welded. Use Teroson Zinkspray.

|

|

| 6. |

Fit the spare part and fixate with a couple of welding clamps.

|

|

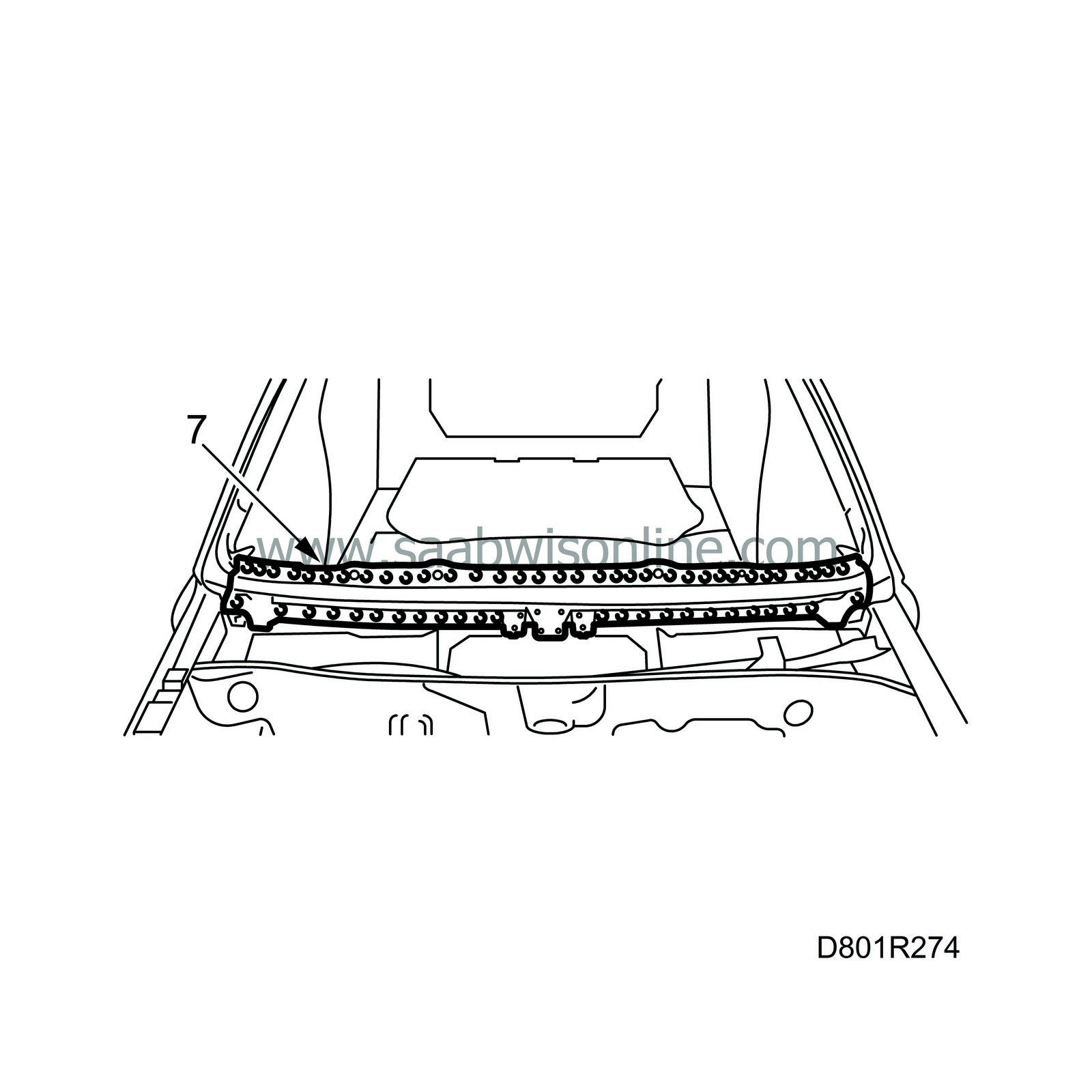

| 7. |

Spot-weld the new windscreen member.

|

|

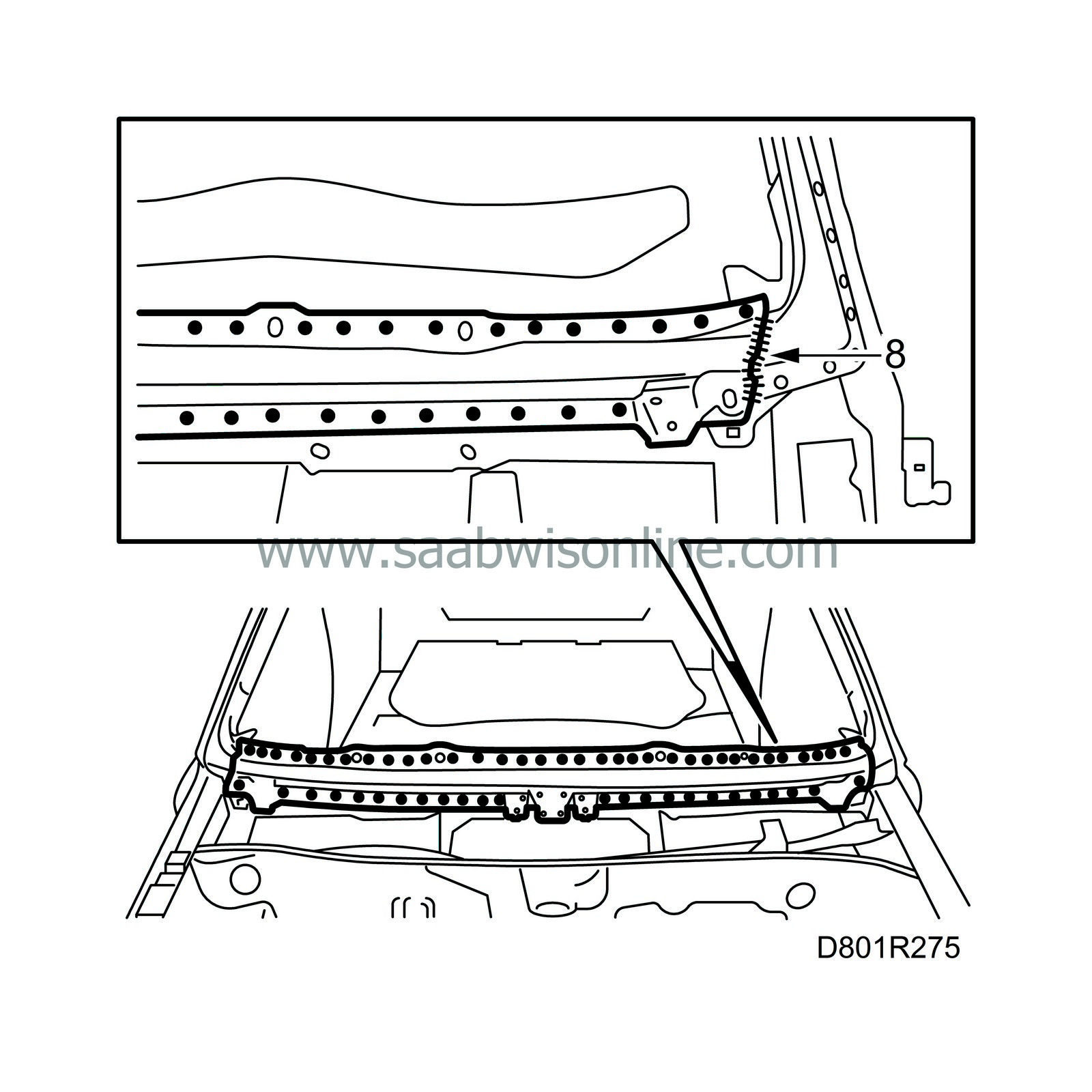

| 8. |

All-weld the joints between the windscreen member and the lower ends of the A-pillars.

|

|

| 9. |

Grind the welds.

|

|

| 10. |

Remove any remaining welding primer. Welding primer reduces adhesion of paint, filler and sealant.

|

|

| 11. |

Apply primer to all ground surfaces. Use Standox 1K Primer.

|

|

| 12. |

Seal joints and sheet metal flanges with sealant. Use Terostat 1K-PUR.

|

|