Checking crankshaft values

|

|

Checking crankshaft values

|

|

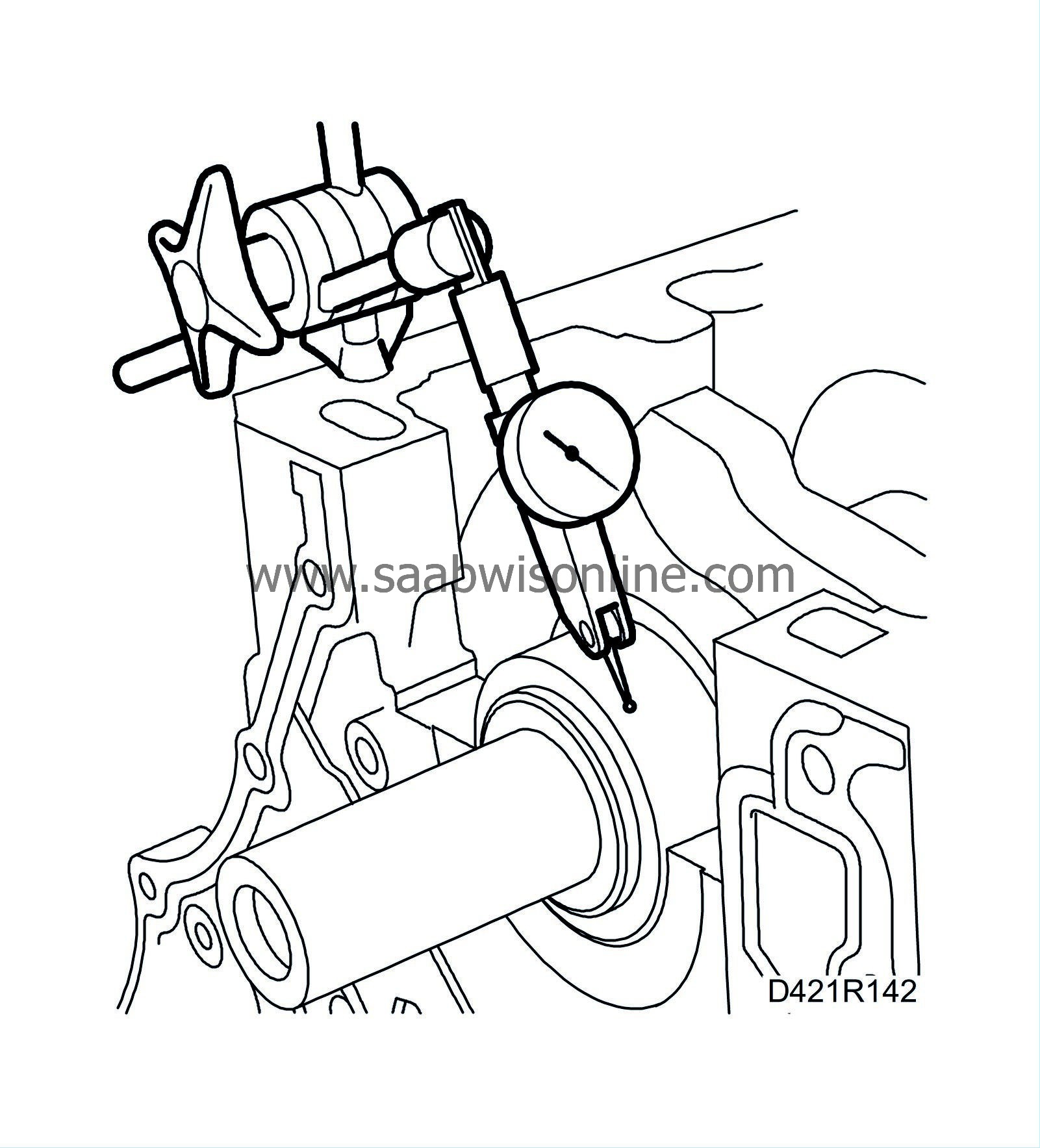

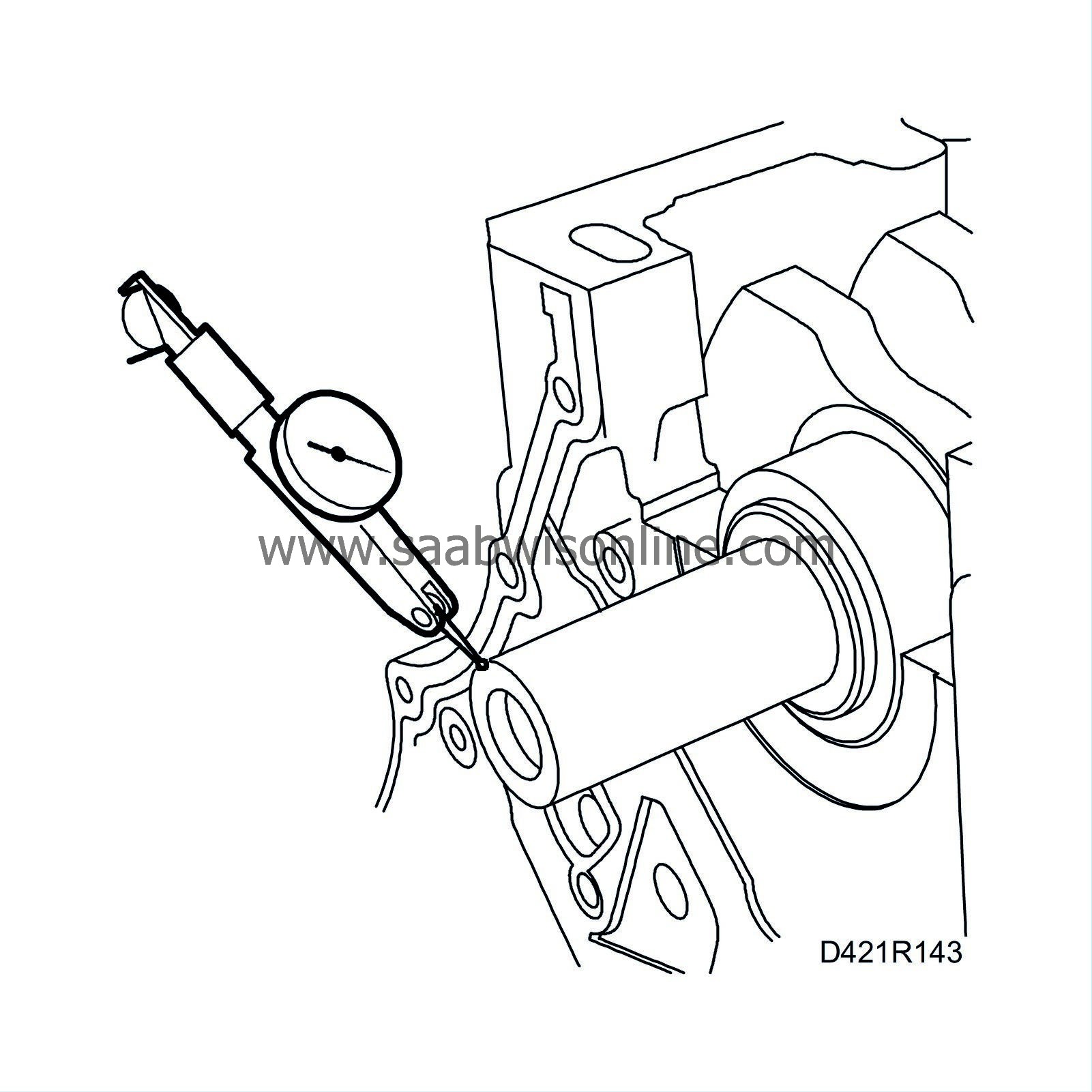

2.

|

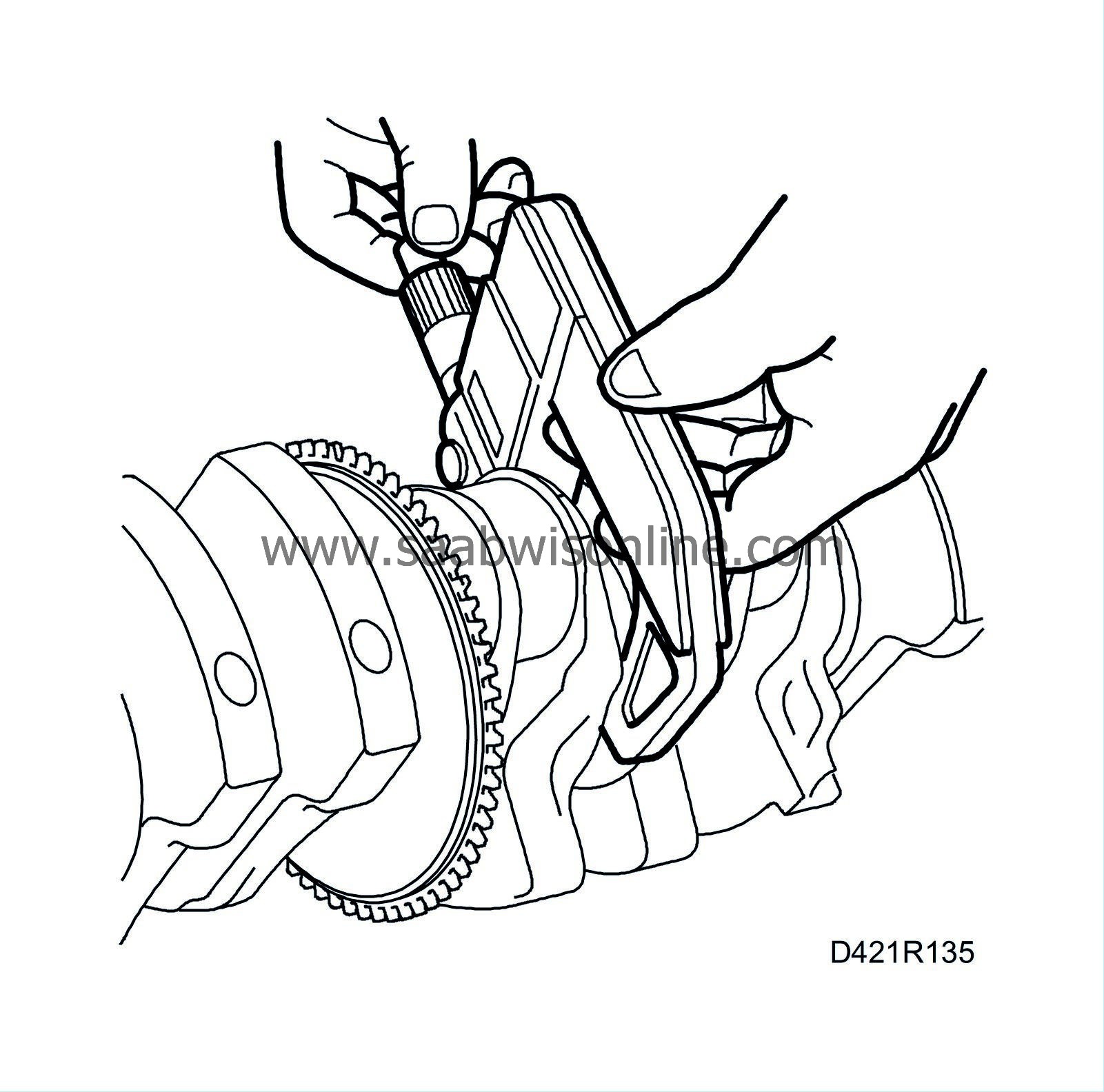

Move the crankshaft axially and measure the play.

|

|

3.

|

Compare the reading with the specifications, see

Crankshaft

.

|

|

4.

|

Remove the dial gauge.

|

|

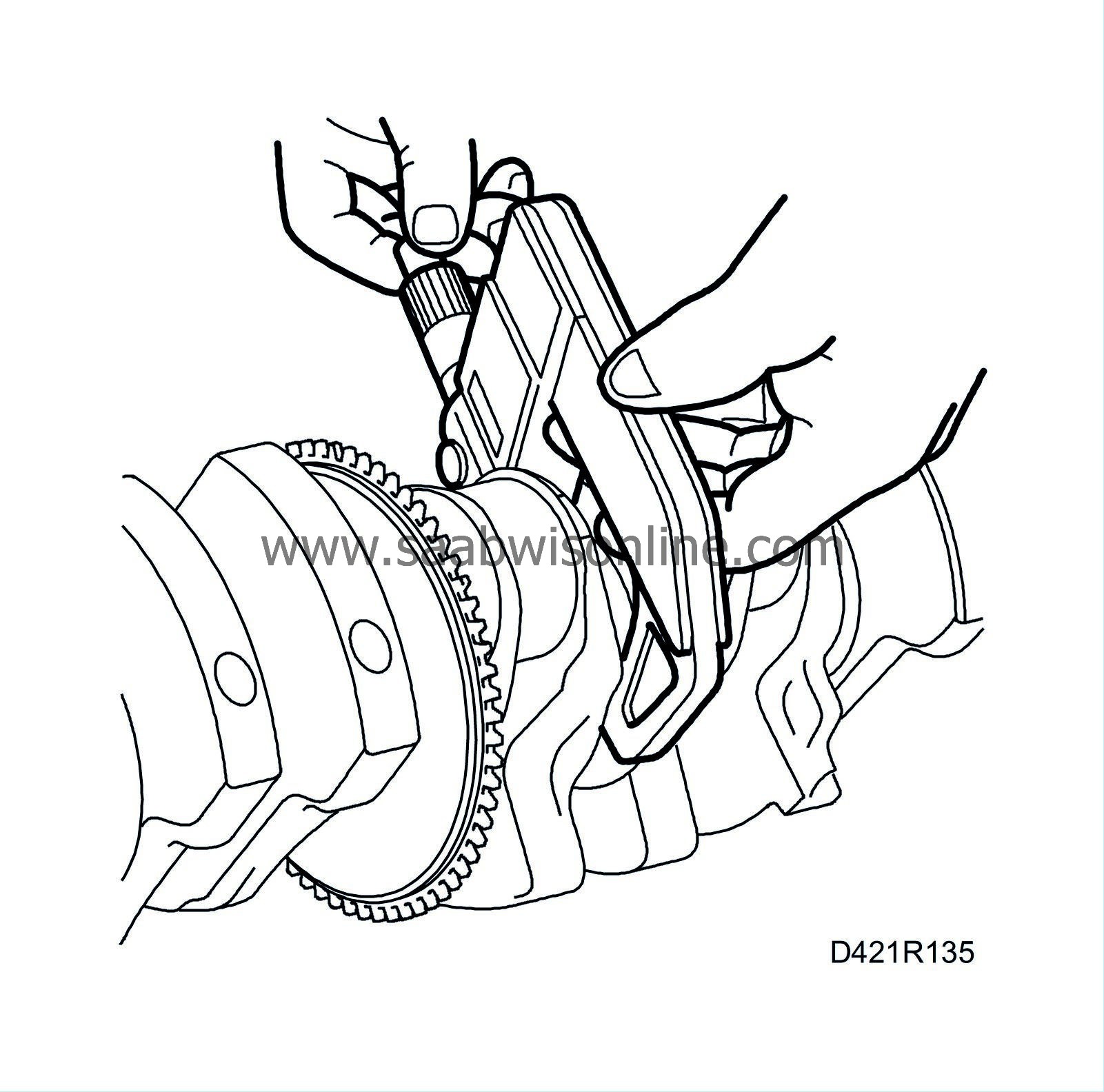

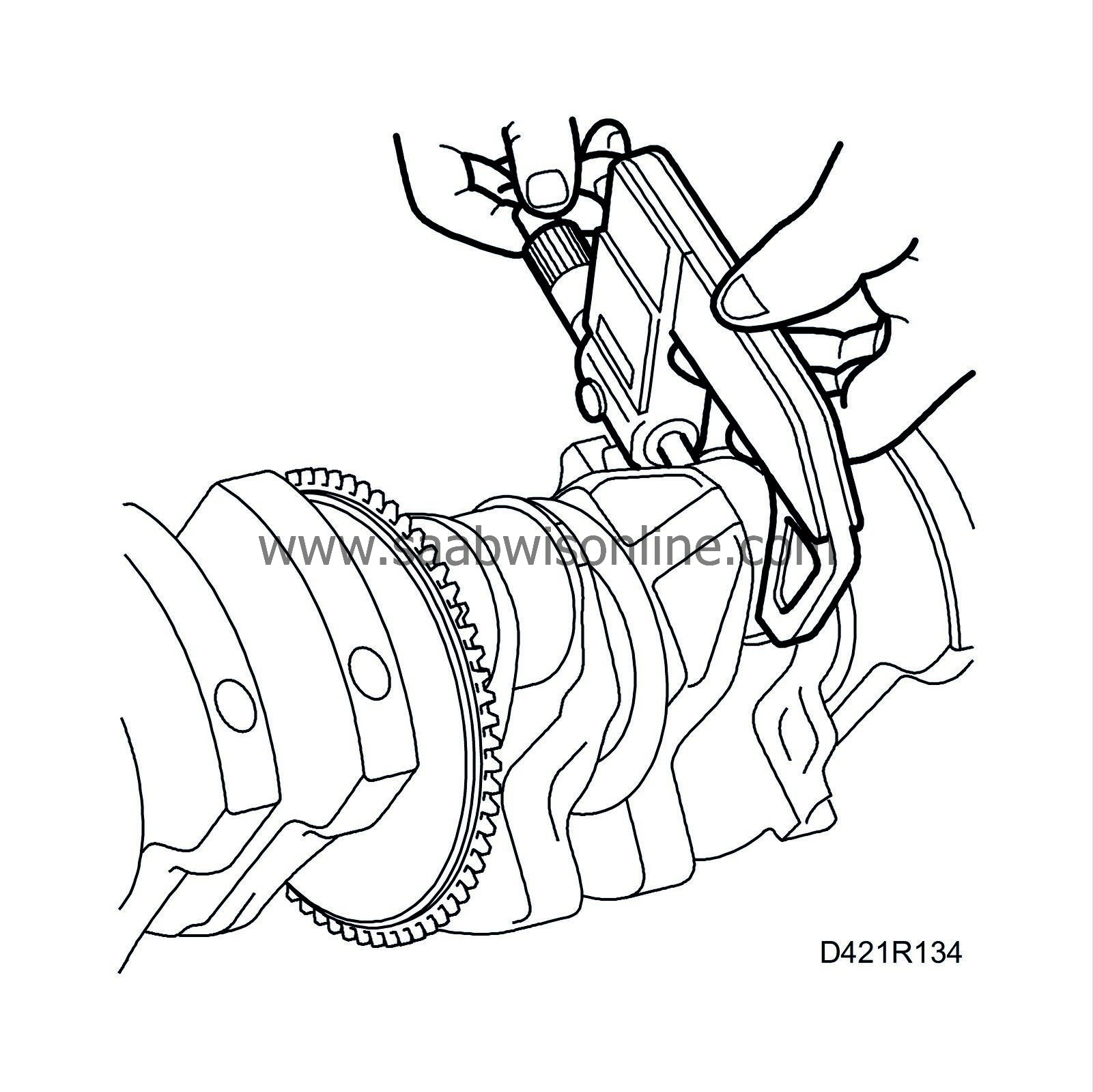

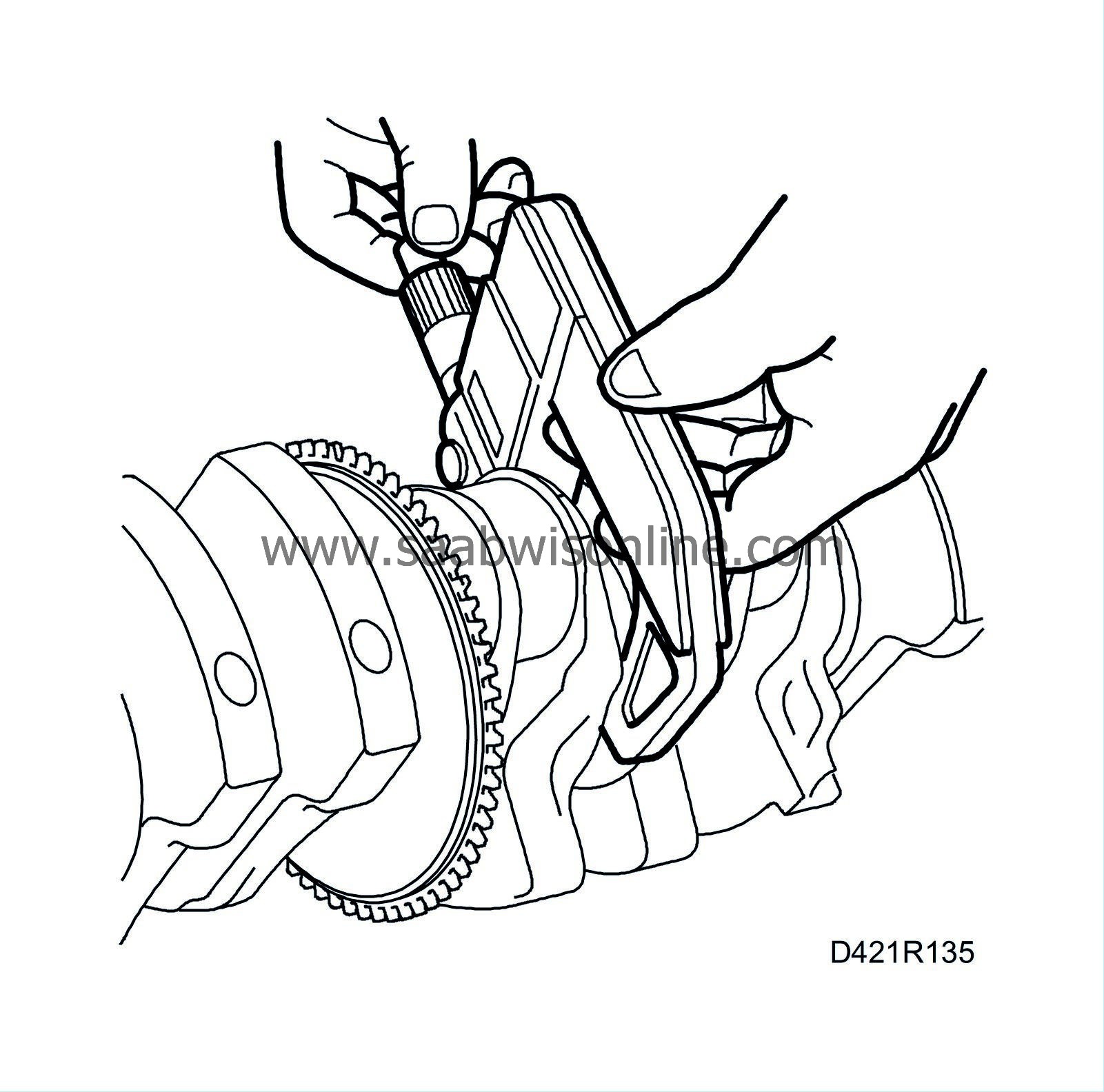

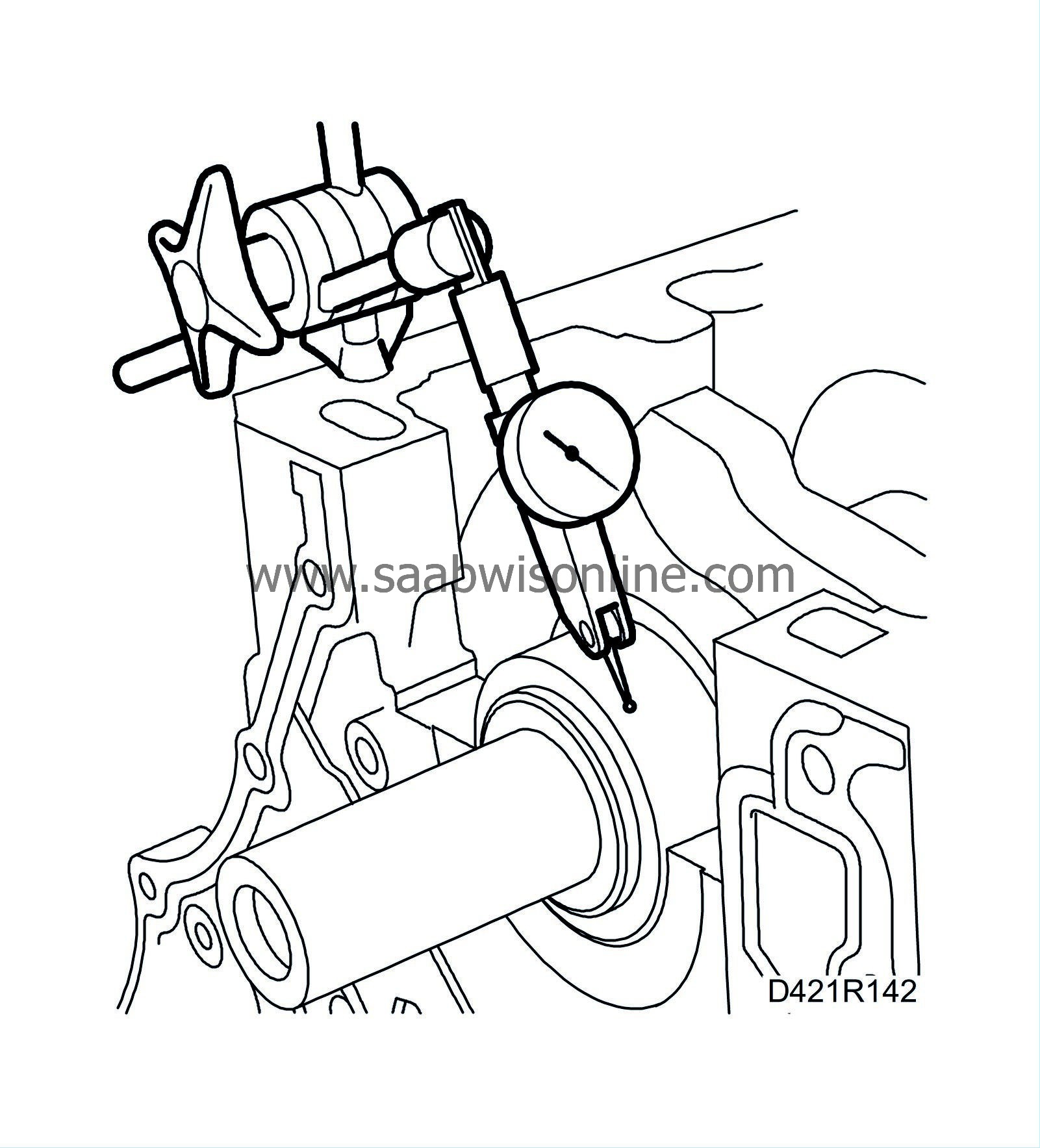

2.

|

Hold up the balancer shaft chain and rotate the crankshaft at an even speed.

|

|

3.

|

Compare the reading with the specifications, see

Crankshaft

.

|

|

4.

|

Remove the dial gauge.

|

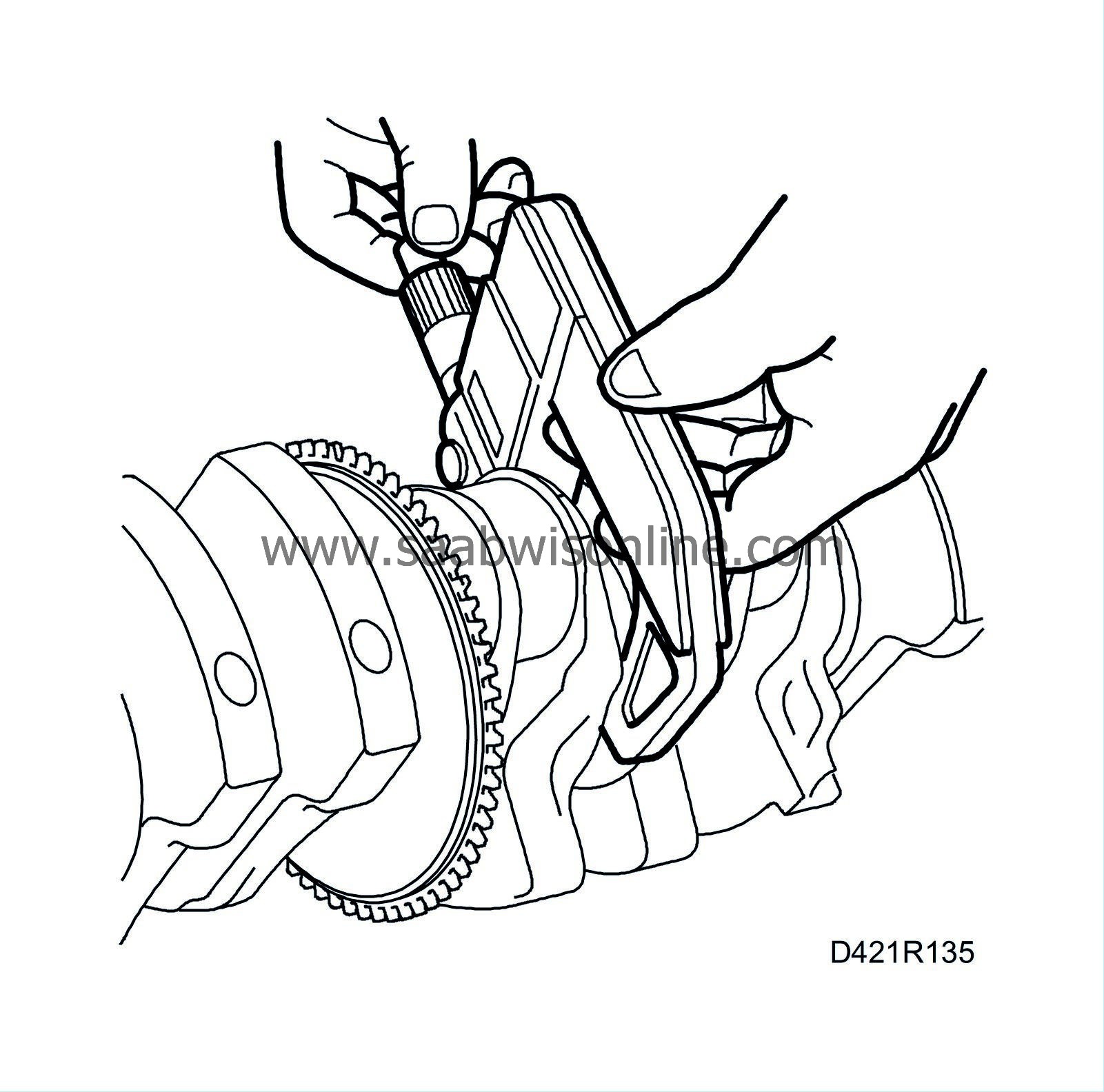

Clean the crankshaft and measure its journals with a micrometer. This should be done at several points around the circumference. Main journal out-of-round must not exceed 0.03 mm. If the reading is close to or above the specified wear, the crankshaft should be reground to a specified undersize, see Crankshaft.

|

1.

|

Clean the crankshaft and measure its journals with a micrometer. This should be done at several points around the circumference.

|

|

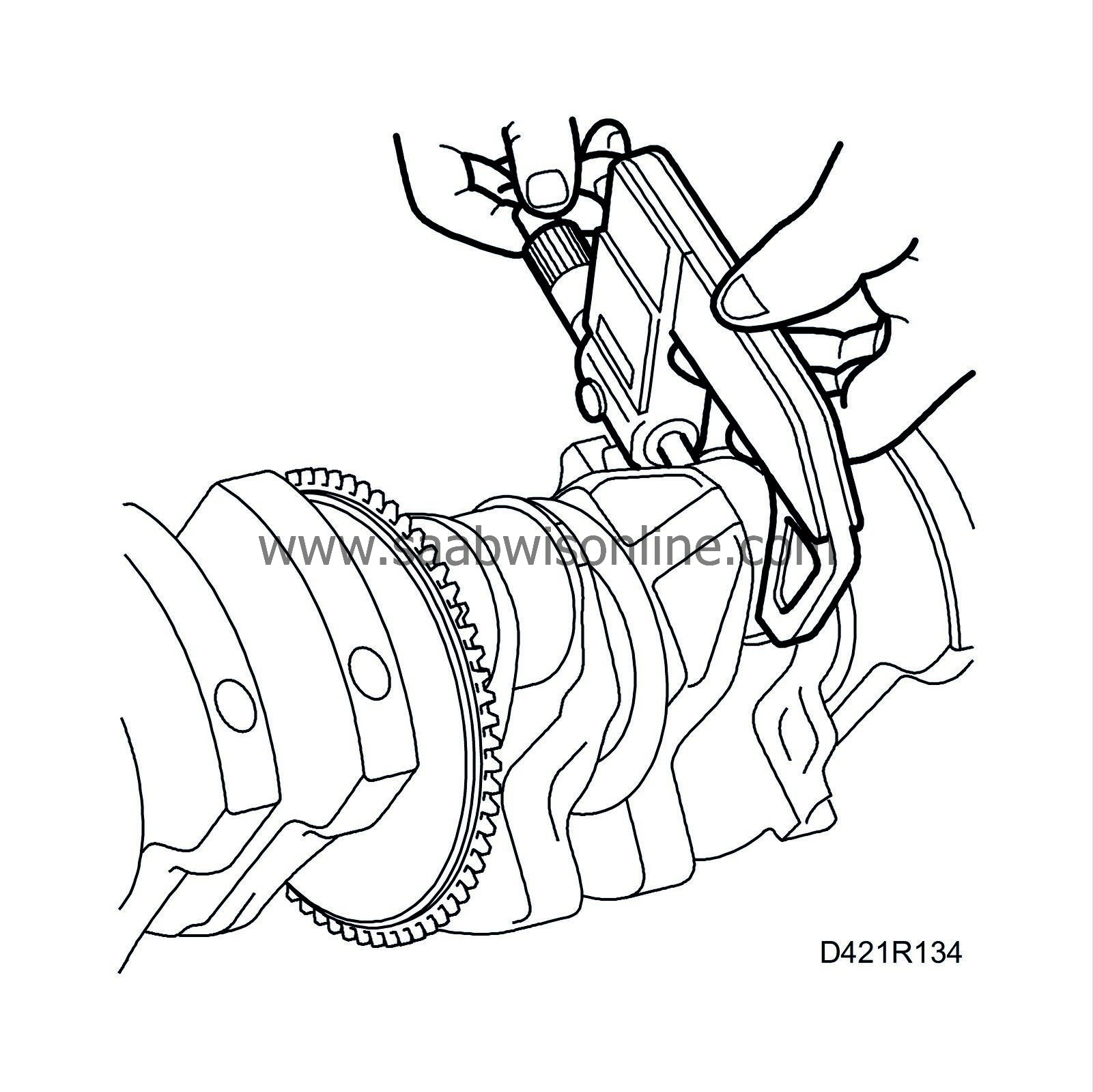

2.

|

Calculate a mean value for the journal.

|

|

3.

|

Clean the connecting rod and its cap and assemble them.

Tightening torque 35 Nm 45° (26 lbf ft + 45°)

|

|

4.

|

Measure the hole with a micrometer. This should be performed at several points around the circumference.

|

|

5.

|

Calculate a mean value for the connecting rod.

|

|

6.

|

Subtract the mean value for the journal from the mean value for the connecting rod and its caps. The result is the mean clearance between the connecting rod and the crankshaft.

|

|

7.

|

Compare the reading with the specifications, see

Crankshaft

.

|

|

1.

|

Clean the crankshaft and measure its journals with a micrometer. This should be done at several points around the circumference.

|

|

2.

|

Calculate a mean value for the journal.

|

|

3.

|

Clean the cylinder block and main bearing cap and assemble them.

Tightening torque 90 Nm + 60° (66 lbf ft + 60°)

|

|

4.

|

Measure the hole with a micrometer. This should be performed at several points around the circumference.

|

|

5.

|

Calculate a mean value for the main bearing.

|

|

6.

|

Subtract the mean value for the journal from the mean value for the main bearing and its cap. The result is the mean clearance between the main bearing and the crankshaft.

|

|

7.

|

Compare the reading with the specifications, see

Crankshaft

.

|