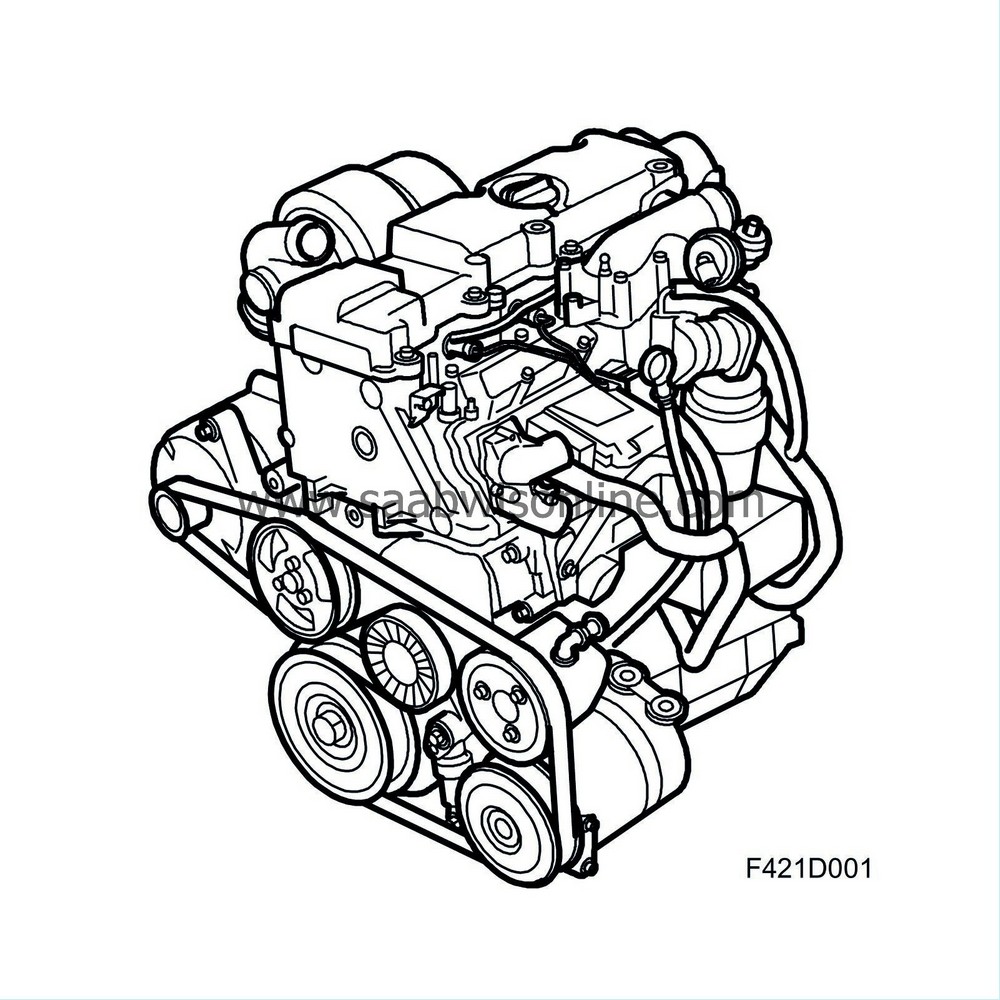

Brief description of D223L

| Brief description of D223L |

The total swept volume of 2.2 litres delivers, together with the turbocharger, a high torque even at low engine speeds, which is advantageous when driving in normal traffic conditions.

The balancer shafts suppress vibration and the forces from moving parts in the engine, and lower the level of engine noise.

| Principles of operation, diesel engine |

The diesel engine has four strokes, intake, compression, power and exhaust, but does not have spark plugs to start the combustion of the fuel/air mixture. Instead, the engine is designed with high compression and specially shaped combustion chambers.

The principle is that air enters into the cylinder and is compressed. During the compression stroke, the air reaches such a high temperature that the fuel mixture self-ignites when injected and expands to give the power stroke. The exhaust stroke takes place as normal.

The engine works by air and fuel being mixed when the fuel is injected into the compressed air. The air is free to flow continuously. The throttle does not regulate the air flow but is simply to ensure that the engine does not continue to run after having been switched off. Instead, the engine speed is regulated by a high-pressure distribution pump that delivers the correct amount of fuel to be injected into the cylinder at the right moment. This pump is controlled by the engine control module, which, in turn, is informed of the accelerator position and then makes a calculation. After the calculation, the control module sends a request to the pump control module for a certain amount of fuel. The amount of fuel determines the engine torque.

A diesel engine is normally about 30% more efficient than a petrol engine. This means that fuel consumption is lower than for an equivalent petrol engine.

Mechanically, a diesel engine is constructed in much the same way as a petrol engine, with crankshaft, connecting rods, pistons, camshafts and valves, but lacks an ignition system and throttle body. The engine's throttle is fully open while the engine is running and there is no way of connecting hoses for a vacuum servo, etc. to a throttle body. This means that a separate vacuum pump is required.