Short description

| Short description |

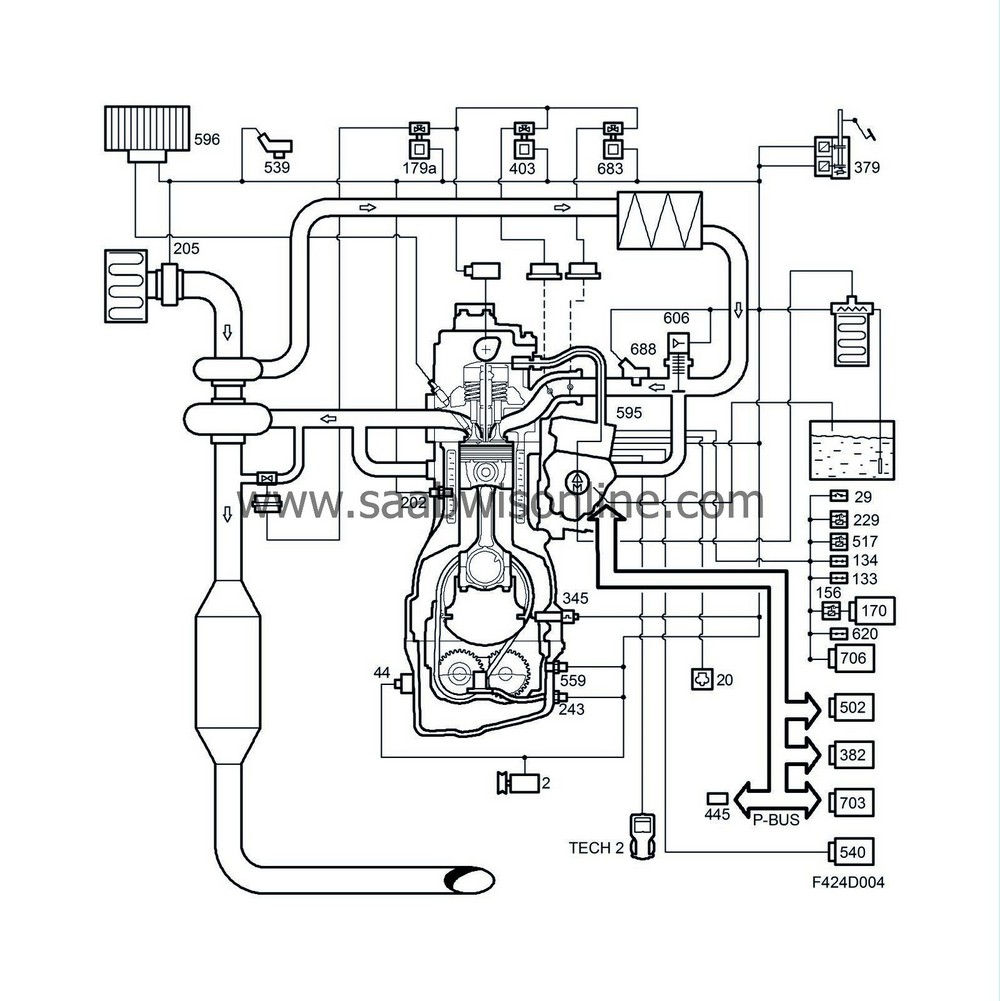

| Overview |

| • |

PSG 16 control module (595)

|

|

| • |

Generator (2)

|

|

| • |

Ignition lock (20)

|

|

| • |

Brake light switch (29)

|

|

| • |

Pressure monitor, engine oil (44)

|

|

| • |

Level sensor, fuel (46)

|

|

| • |

Clutch switch, cruise control (133)

|

|

| • |

Brake switch, cruise control (134)

|

|

| • |

Switch, cruise control (141)

|

|

| • |

A/C pressure sensor (620)

|

|

| • |

Boost pressure control valve (179a)

|

|

| • |

Coolant temperature sensor (202)

|

|

| • |

Mass air flow sensor (205)

|

|

| • |

Main relay, engine management system (229)

|

|

| • |

Level sensor, engine oil (243)

|

|

| • |

Crankshaft position sensor (345)

|

|

| • |

Accelerator pedal position sensor (379)

|

|

| • |

Glow plug, cylinders 1-4 (398a-d)

|

|

| • |

Solenoid valve, swirl throttle (403)

|

|

| • |

Data link connector 16-pin, CARB (445)

|

|

| • |

Atmospheric pressure sensor (539)

|

|

| • |

Engine oil temperature sensor (559)

|

|

| • |

Control module, glow plug (596)

|

|

| • |

Relay, A/C compressor (156)

|

|

| • |

Relay, starter relay (517)

|

|

| • |

EGR solenoid valve (606)

|

|

| • |

Intake air temperature sensor (688)

|

|

| • |

Cut-off valve (683)

|

|

| • |

CIM (703)

|

|

The PSG 16 engine management system with VP44 diesel pump is a fuel management system for diesel engines. Its primary task is to deliver the correct amount of diesel fuel to the combustion chambers at the right point in time.

The pedal position sensor is read by the engine control module to find out the magnitude of the power output desired by the driver. The amount of fuel injected controls the power output of the engine and it is up to the control module to convert the desired power output from the driver or cruise control into the amount of fuel injected per combustion.

The control module calculates the optimum injection amount per combustion for all driving conditions based on emissions, engine durability, driveability and fuel consumption.

The PSG 16 diesel injection system with VP44 diesel pump is manufactured by Robert Bosch GmbH.

The PSG 16 with VP44 diesel pump has the following advantages compared with older diesel injection systems:

| • |

It is possible to control the injected amount of fuel individually for each cylinder.

|

|

| • |

The system compensates for mechanical wear in the drive between the diesel pump and the crankshaft. Consequently, the correct moment for pressure build-up in the diesel pump is ensured during the whole service life of the engine.

|

|

| • |

Load compensation is possible throughout the entire load and speed register.

|

|

| • |

Effective torque limitation as necessary.

|

|

| • |

Cruise control can easily be integrated.

|

|

| Description |

Control module and diesel pump, PSG 16 (595)

The engine control module is integrated with the diesel pump. The control module detects the request from the driver for power (request for torque) with the help of a number of sensors. The control module calculates the permitted fuel quantity in mg/combustion and with the help of the diesel pump's electrohydraulics regulates the amount of fuel injected per combustion, as well as the start time for pressure build-up in the high-pressure pump.The pump has a feed pump that draws diesel fuel from the tank through a fuel filter to the high-pressure section of the fuel pump.

The control module has internal diagnostics, the results of which can be read with the diagnostic tool.

It reads the digital information from the cruise control switches and, if so desired by the driver, the engine control module controls vehicle speed.

Accelerator pedal position sensor (379)

The position sensor contains two potentiometers that inform the PSG 16 control module of the driver's request for torque.Temperature sensor, coolant, engine management system (202)

The temperature sensor informs the engine control module of the temperature of the engine. This information is used amongst other things to supply the engine with extra fuel during cold starting. It can also protect the engine against harmful overheating, as the control module limits the fuel quantity when there is risk of overheating.Engine oil temperature sensor (559)

The temperature sensor informs the engine control module of the temperature of the engine oil. This information can also be used to carry out feasibility diagnosis on the engine coolant temperature sensor. It can also protect the engine against harmful overheating, as the control module limits the fuel quantity when there is risk of overheating.Mass air flow sensor (205)

The mass air flow sensor sends a voltage-modulated signal about the mass air flow to the engine control module. The control module calculates the intake air mass per combustion based on the mass air flow.Temperature and pressure sensor, intake air (688)

The combined temperature and pressure sensor measures the temperature and pressure of the intake air. The sensor informs the engine control module of the intake air pressure for the control of the turbocharger boost pressure. The sensor informs the engine control module of the intake air temperature so that the control module can request the correct air mass per combustion (greater volume is required if air is warm).Crankshaft position sensor (345)

The position sensor sends an alternating current, which is dependent on the crankshaft speed, to the control module. Each pulse is used to determine when the engine has reached top dead centre.Control module, glow plugs (596)

The control module supplies power to the glow plugs on request from the engine control module. It also reduces the power to the glow plugs once the engine has started. The glow plug control module is self-diagnosing, the result of which is sent through a lead to the engine control module where any diagnostic trouble codes can be read.Switch, cruise control (141)

The driver can request that the engine control module retains the set vehicle speed or, alternatively, reduces or increases the set vehicle speed.Clutch switch, cruise control (133)

The switch informs the engine control module of the position of the clutch pedal. This is used to turn off the cruise control.Brake switch, cruise control (134)

The switch is used to carry out a feasibility assessment of the brake light switch. It is also used to turn off the cruise control.Brake light switch (29)

The switch informs the engine control module of the position of the brake pedal. This is used to turn off the cruise control.Main relay, engine management system (229)

The relay controls the electrical power supply to the diesel engine management system.Relay, A/C compressor (156)

The relay turns the A/C compressor on and off after receiving a command from the engine control module.Boost pressure control valve (179a)

The control valve controls the boost pressure with a vacuum from the vacuum pump.Solenoid valve, swirl throttle (403)

The control valve controls the swirl throttle with a vacuum from the vacuum pump.EGR solenoid valve (606)

The EGR valve is a solenoid valve with its own control module. The EGR function means that the engine control module orders the EGR valve to release a certain amount of exhaust gas to achieve the calculated mg/combustion. The EGR valve has a processor and is self-diagnosing.Pressure monitor, engine oil (44)

Pressure monitor with closing function if there is no oil pressure. Known as an On-Off switch. If there is no oil pressure, the switch closes and makes a ground to the control module ECM which in turn sends out the bus message "no oil pressure" to the MIU and SID.Level sensor, fuel (46)

Informs the PSG 16 control module of how much fuel there is in the tank. The PSG 16 then broadcasts this information on the bus.Compressor, A/C (170)

The purpose of the A/C compressor is to increase the pressure of the refrigerant, which is necessary for the operation of the A/C system.Level sensor, engine oil (243)

The sensor sends a message to the control unit which confirms that the level is low by evaluating the time for which it was low.The control module then sends out bus message "Oil level low" to SID. The information from the oil level sensor is a filtered value depending on temperature, engine speed, acceleration, vehicle speed, to give a mean value for the oil level.

Atmospheric pressure sensor (539)

The sensor informs the control module of the current atmospheric pressure. Atmospheric pressure is used in calculations for smoke limitation. The greater the car's altitude, the less oxygen there is in the air. The fuel supply must therefore be reduced. Atmospheric pressure also controls the boost pressure, which must be reduced at high altitudes to prevent the turbocharger from overrevving.A/C pressure sensor (620)

Informs the ECM of the pressure on the high pressure side of the A/C system.Used for load compensation, cooling fan function and sent as a bus message for use by the ACC.

Cut-off valve (683)

The solenoid valve converts an electrical signal to control a negative pressure that in turn closes the damper in the cut-off valve in the intake manifold.CIM (703)

If the transponder code is approved, a signal is sent to the ISM to allow the key to turn. Once this has been done, the engine can be started.Generator (2)

The ECM controls when the generator should charge or not.Once the ECM has registered that the engine has started, by calculating the engine speed, the generator is started.