Detailed description

| Detailed description |

| • |

The engine produces more torque at low engine speeds.

|

|

| • |

Since the working temperature of the turbocharger can be kept low, compression is improved increasing power output.

|

|

| • |

The turbocharger responds more quickly to requests for torque, improving driveability.

|

|

| • |

Fuel consumption is reduced and exhaust emissions are purer.

|

|

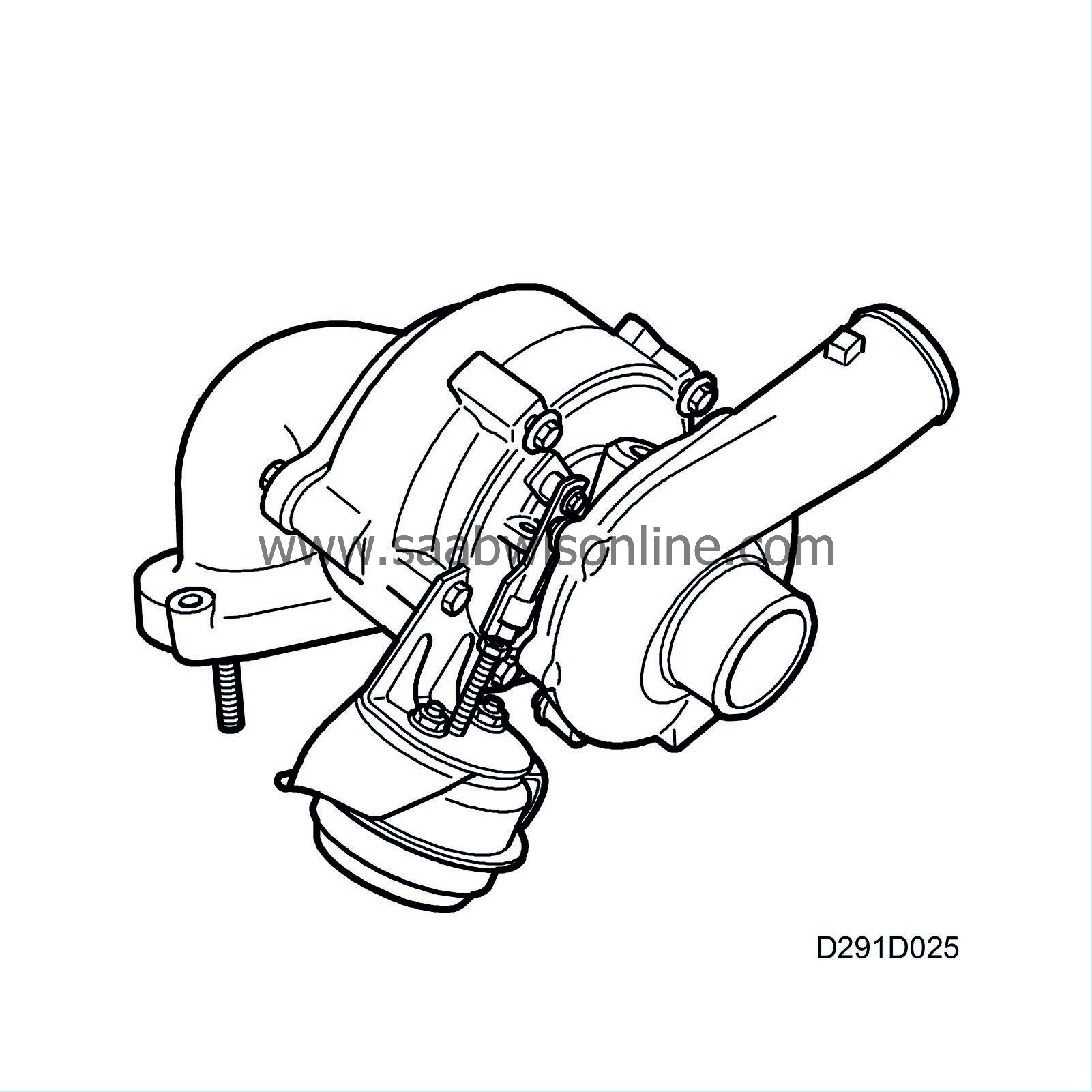

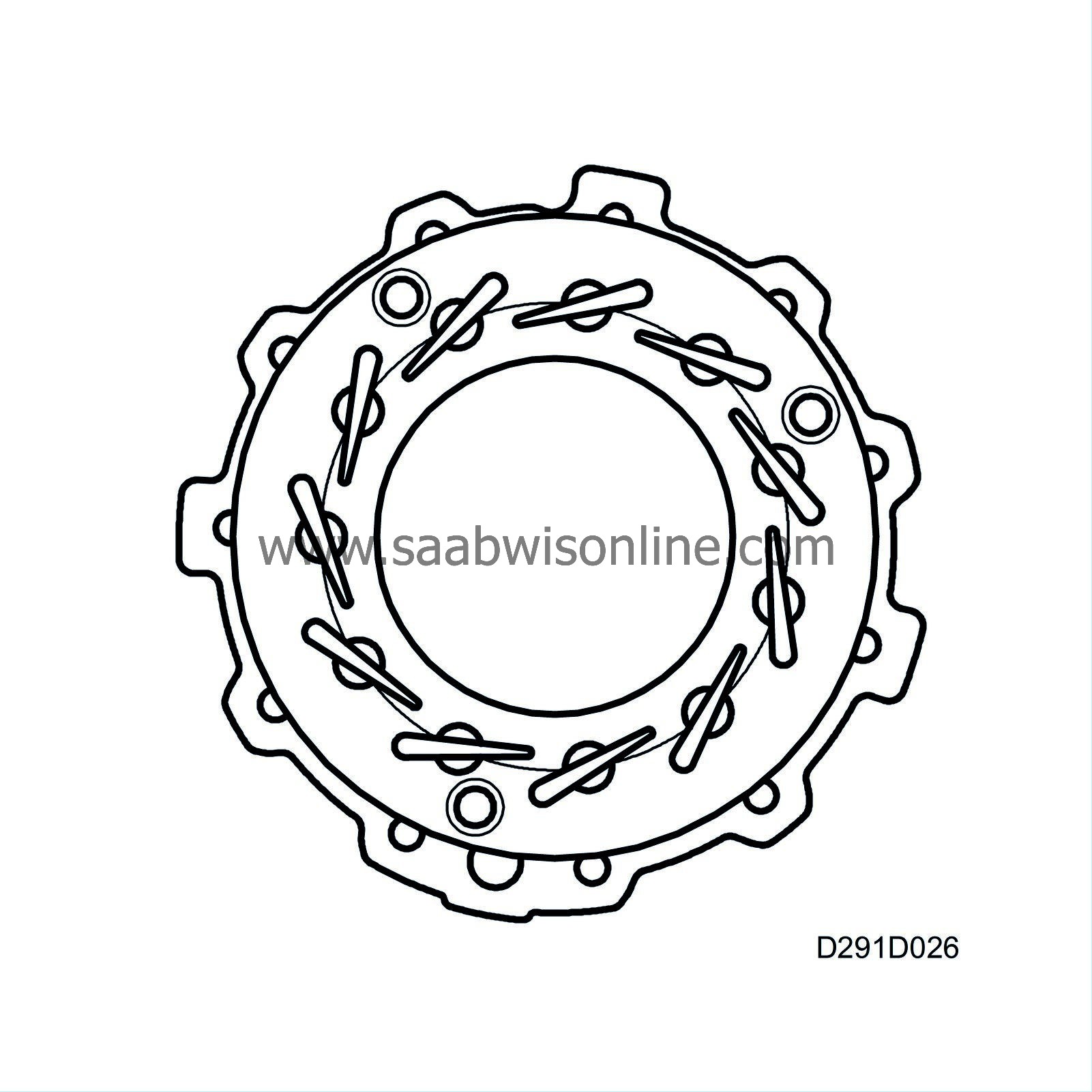

The Garret GT15VNT does not have a wastegate, but instead has a set of vanes on the exhaust side of the turbocharger.

These vanes control the turbocharger. At low exhaust flows, the vanes are positioned to increase the turbo speed and consequently the boost pressure. This provides more engine torque at low engine speeds. At high exhaust flows, the speed of the turbocharger is reduced to prevent the turbocharger overrevving while continuing to provide the requested boost pressure.

The boost pressure, which is dependent on the engine speed and load, is continually monitored by a pressure sensor in the intake manifold. The vacuum box, which regulates the position of the vanes, is larger than on previous turbochargers. The connection to the vacuum pump is larger than on previous models to ensure that the vacuum box receives the necessary underpressure.

| Lubrication |

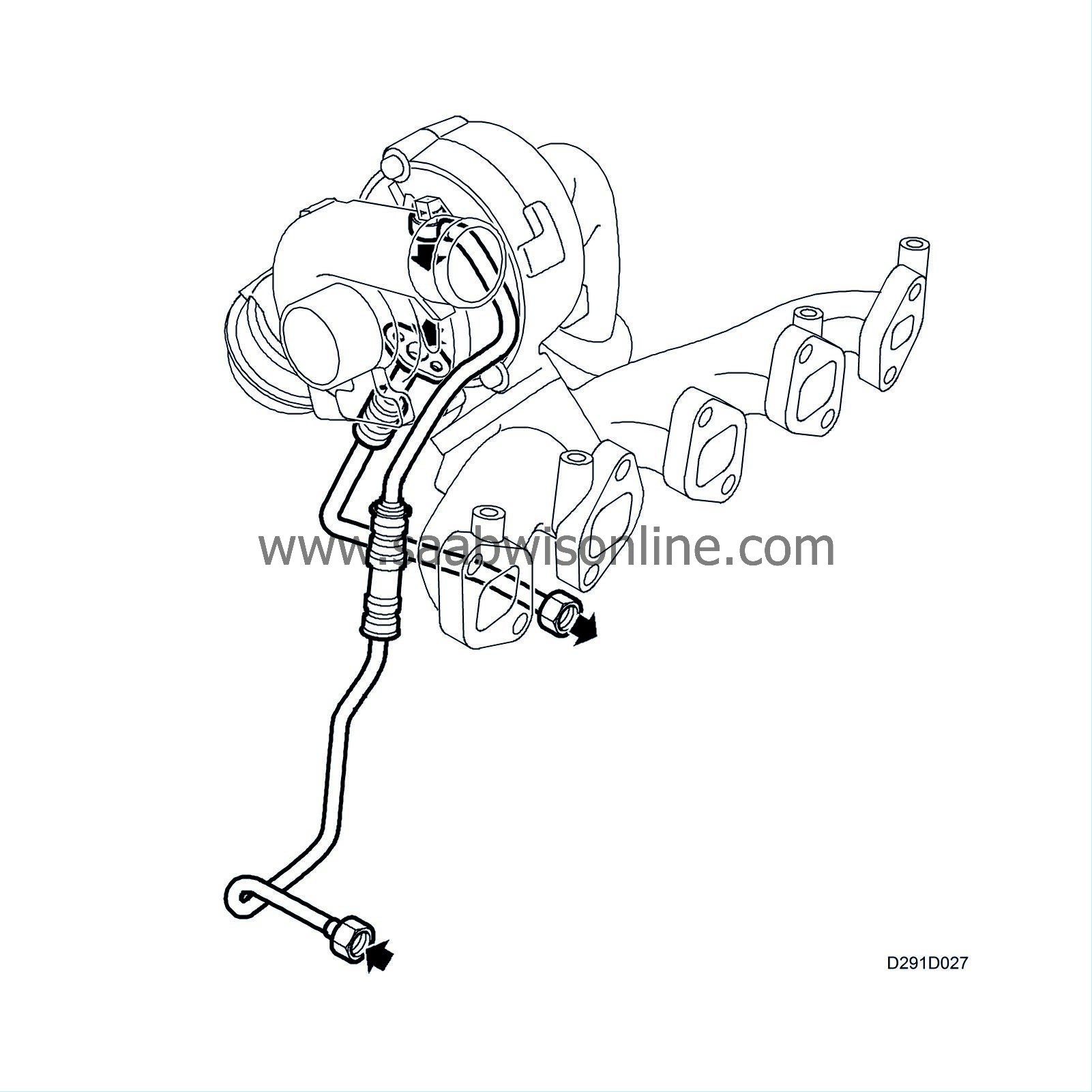

The turbo shaft, which rotates at very high speeds, is carefully balanced and journalled in so called floating plain bearing bushings. This means that there is a considerable flow of oil through the bearings with the result that, while it is rotating, the shaft floats on a film of oil. The lubrication oil is received from the engine lubrication system through an oil pipe that leads from a connection beside the pressure sensor, engine oil in the cylinder block to the turbo compressor side. The return oil flows from the underside of the turbo compressor to the engine oil sump via an oilway in the cylinder block. The seal between the shaft and the bearing housing consists of rings (similar to piston rings) which are positioned in grooves on the shaft.