Power train removal

| Power train removal |

| To remove |

|

||||||||||

| 1. |

Place the car on a lift and apply wing covers.

|

|

| 2. |

Open the cap on the expansion tank.

|

|

| 3. |

Raise the car slightly and remove the front wheels.

|

|

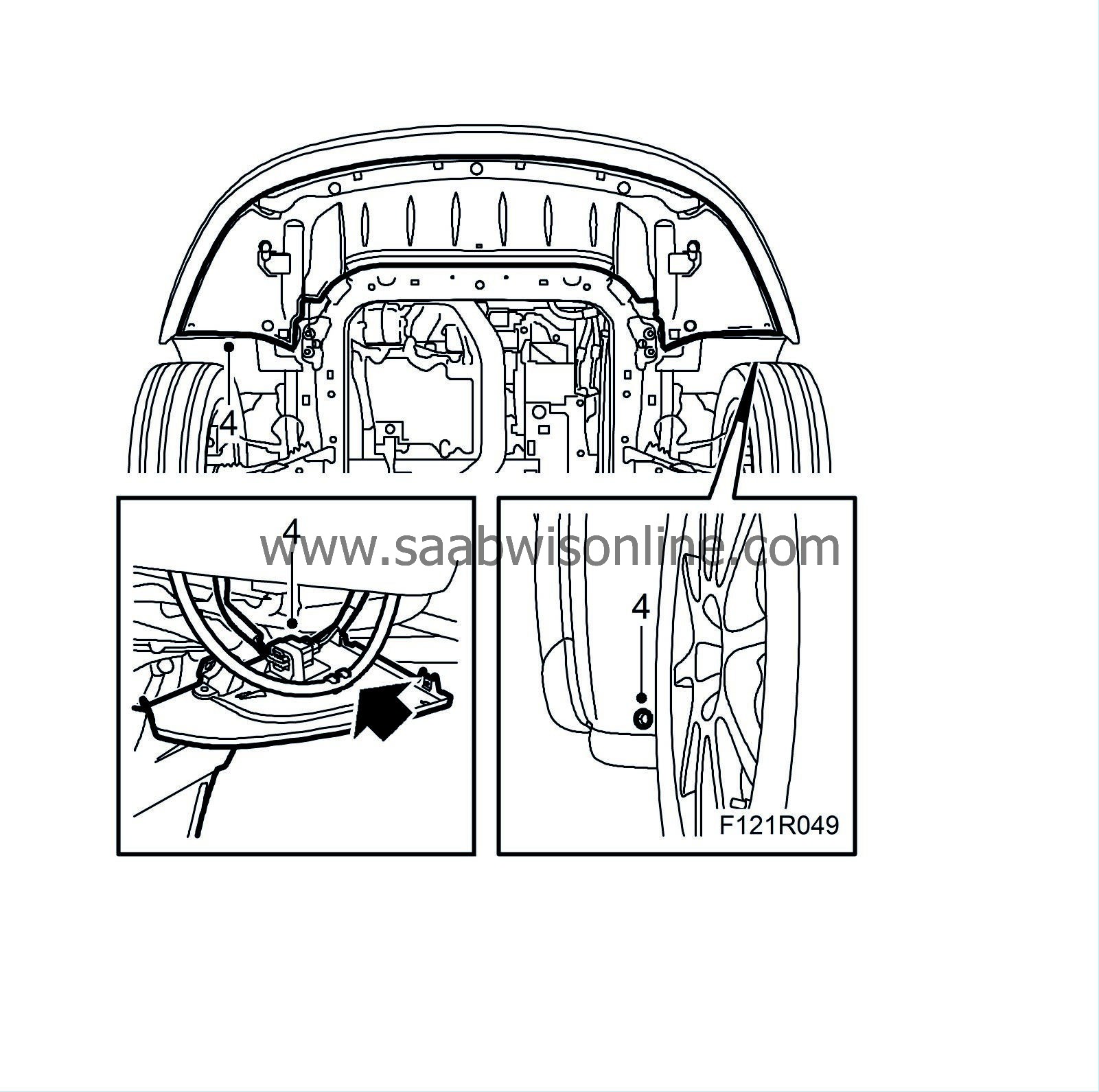

| 4. |

Remove the lower spoiler shield. Detach the hose to the headlamp washers, unplug the connector and remove it.

|

|

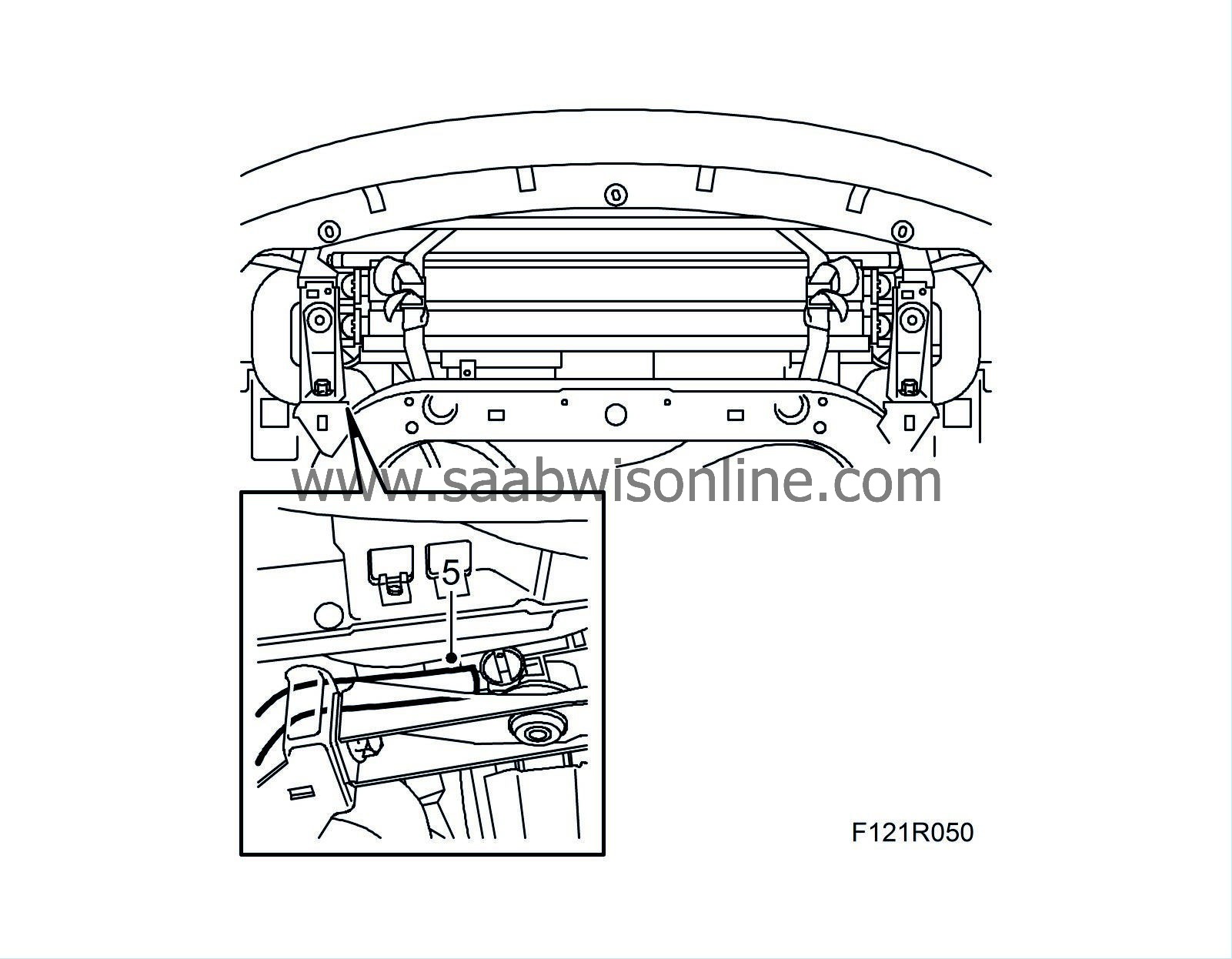

| 5. |

Place a receptacle under the car, connect a hose to the radiator and drain the coolant.

|

|

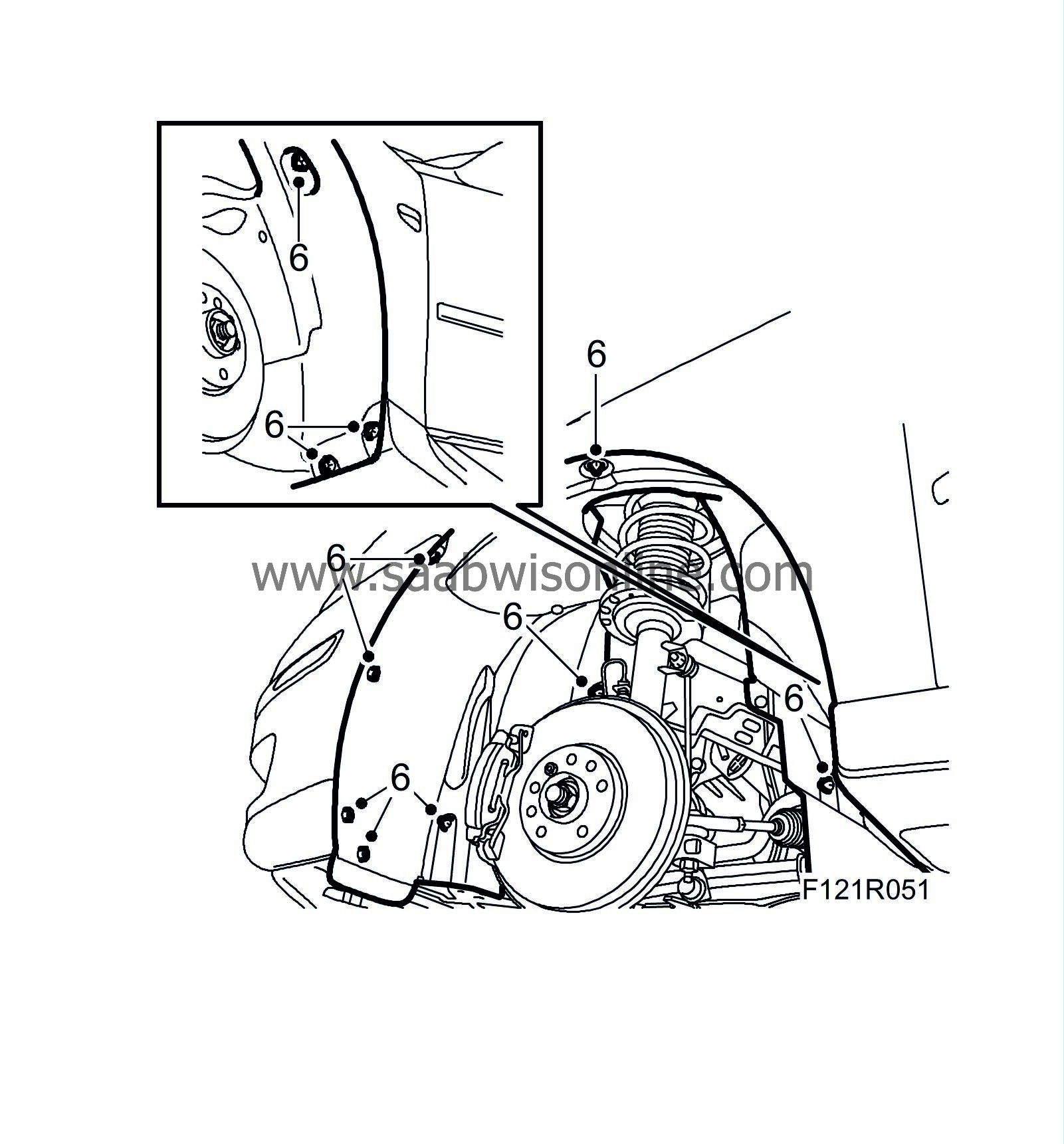

| 6. |

Remove the wing liners from both front wheel housings and the cover by the gearbox.

|

|

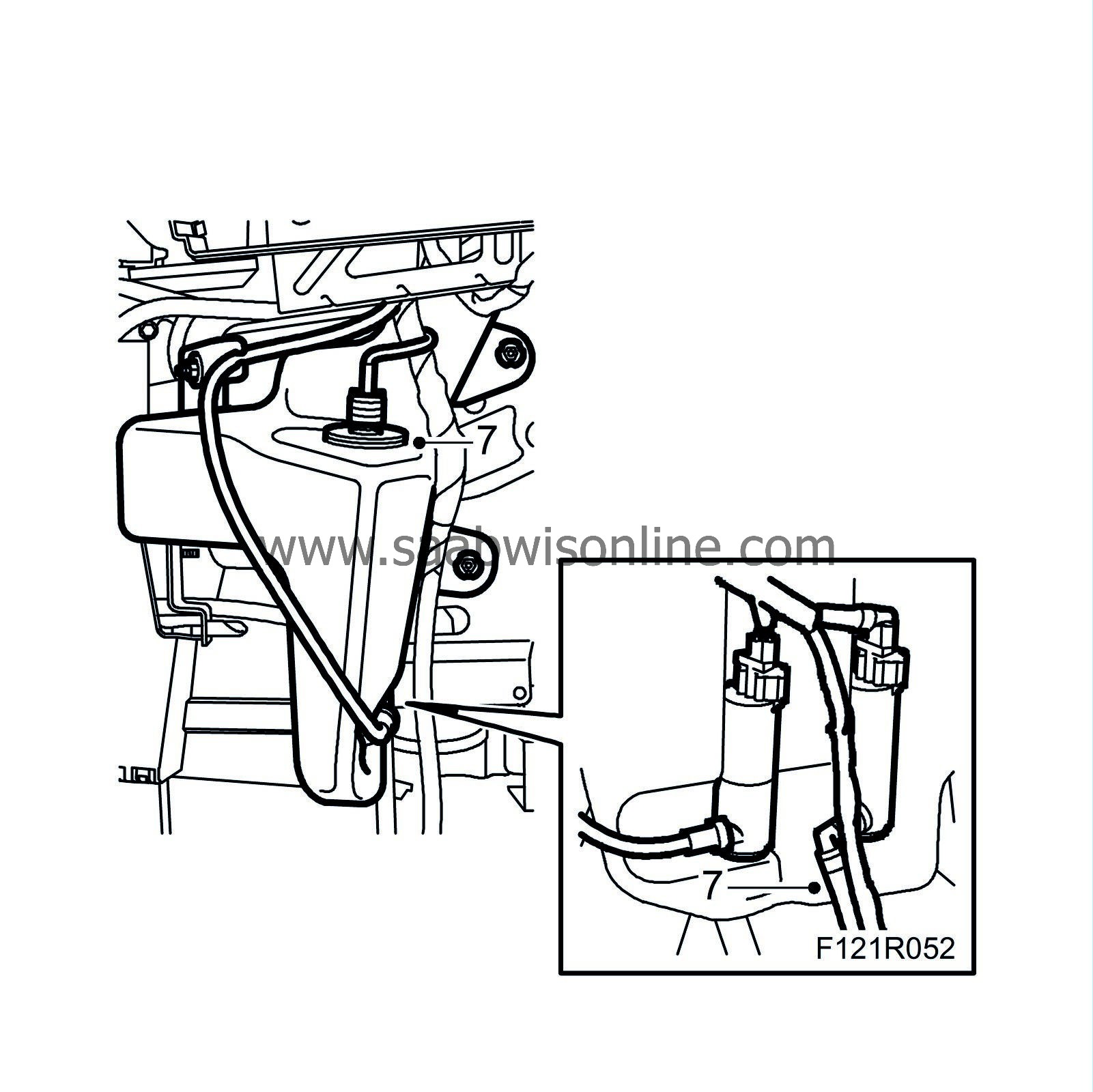

| 7. |

Detach the hose for the headlamp washers and drain the washer fluid reservoir.

|

|

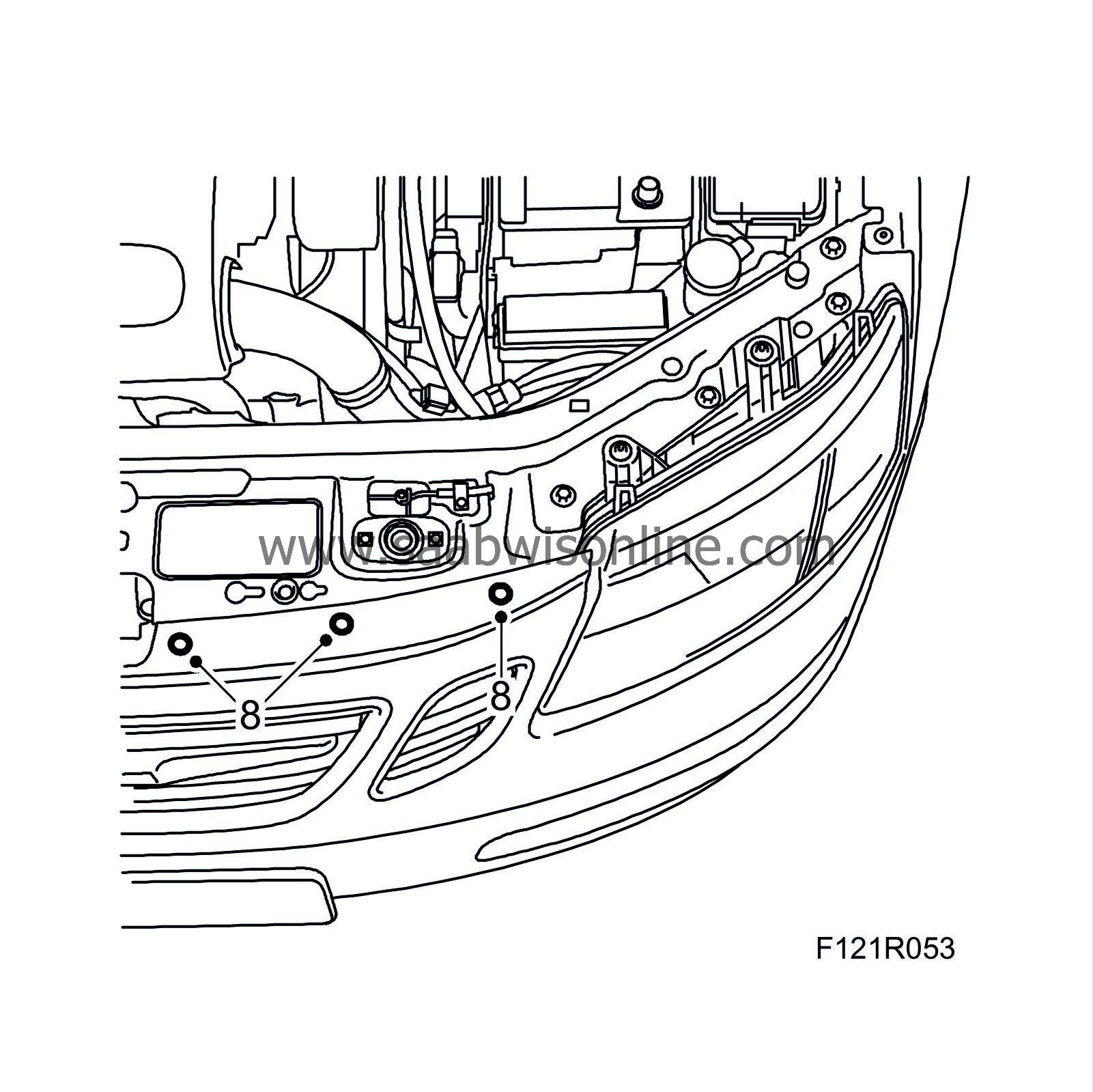

| 8. |

Lower the car slightly and remove the bumper.

|

|

| 9. |

Remove the cover on the left-hand side and the charge air hose between the charge air pipe and the charge air cooler.

|

|

| 10. |

Remove the lower charge air pipe bracket from the fan cowling.

|

|

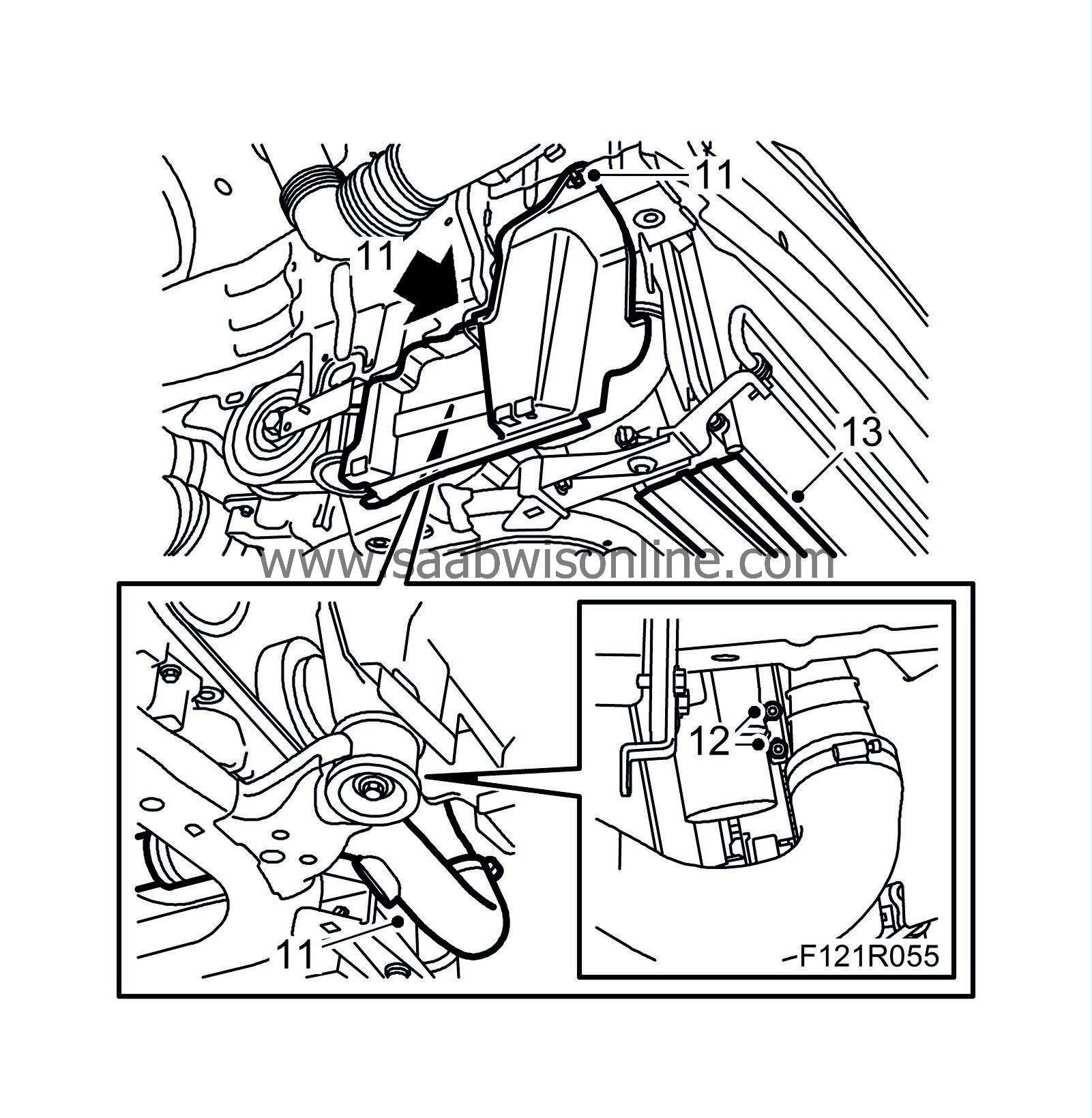

| 11. |

Remove the cover on the right-hand side and the hose between the charge air cooler and the charge air pipe.

|

|

| 12. |

Remove the dryer filter bolts from the radiator.

|

|

| 13. |

Remove the lower seal between the charge air cooler and the radiator.

|

|

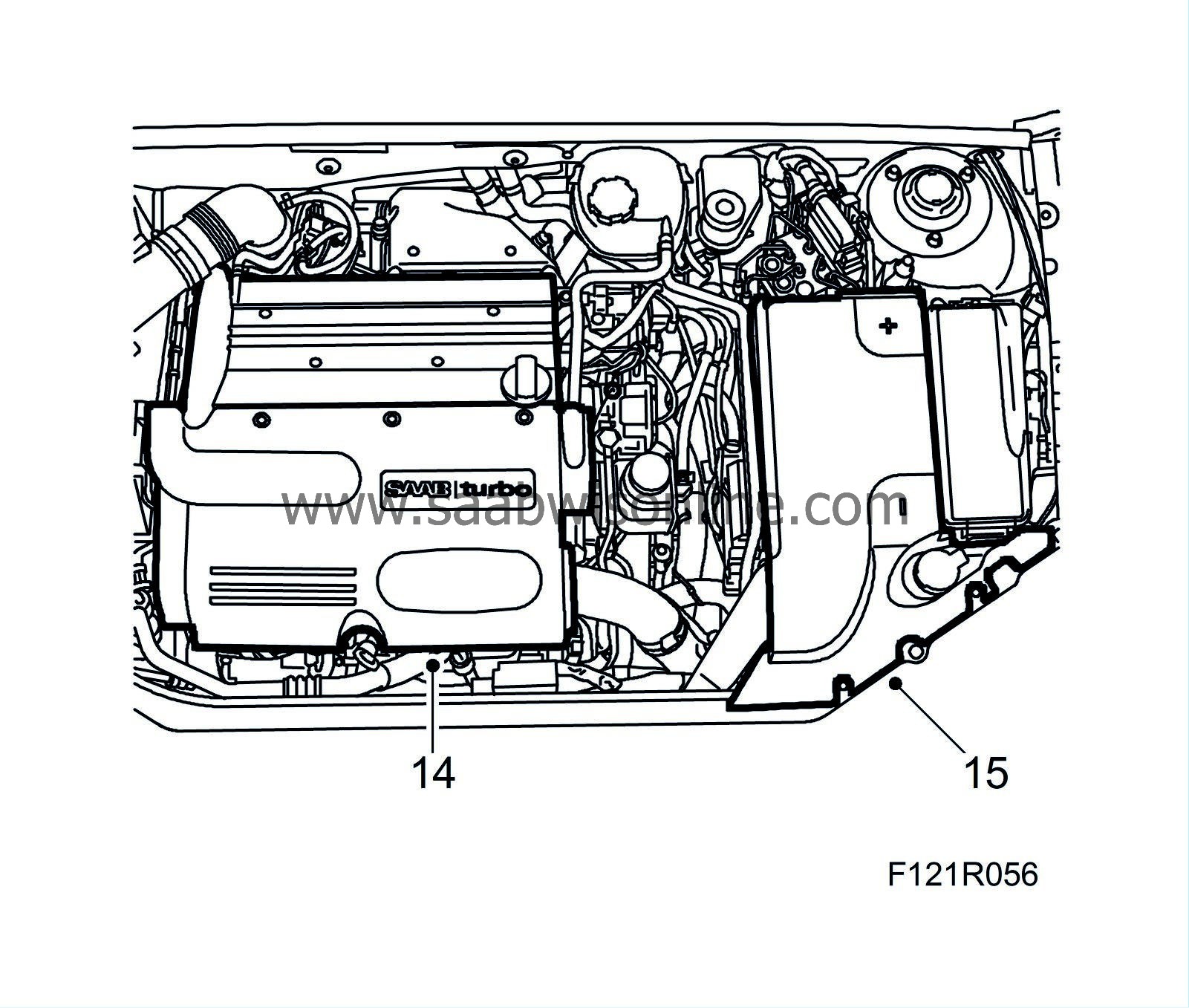

| 14. |

Lower the car and remove the upper engine cover.

|

|

| 15. |

Remove the battery cover and the battery cooler pipe.

|

|

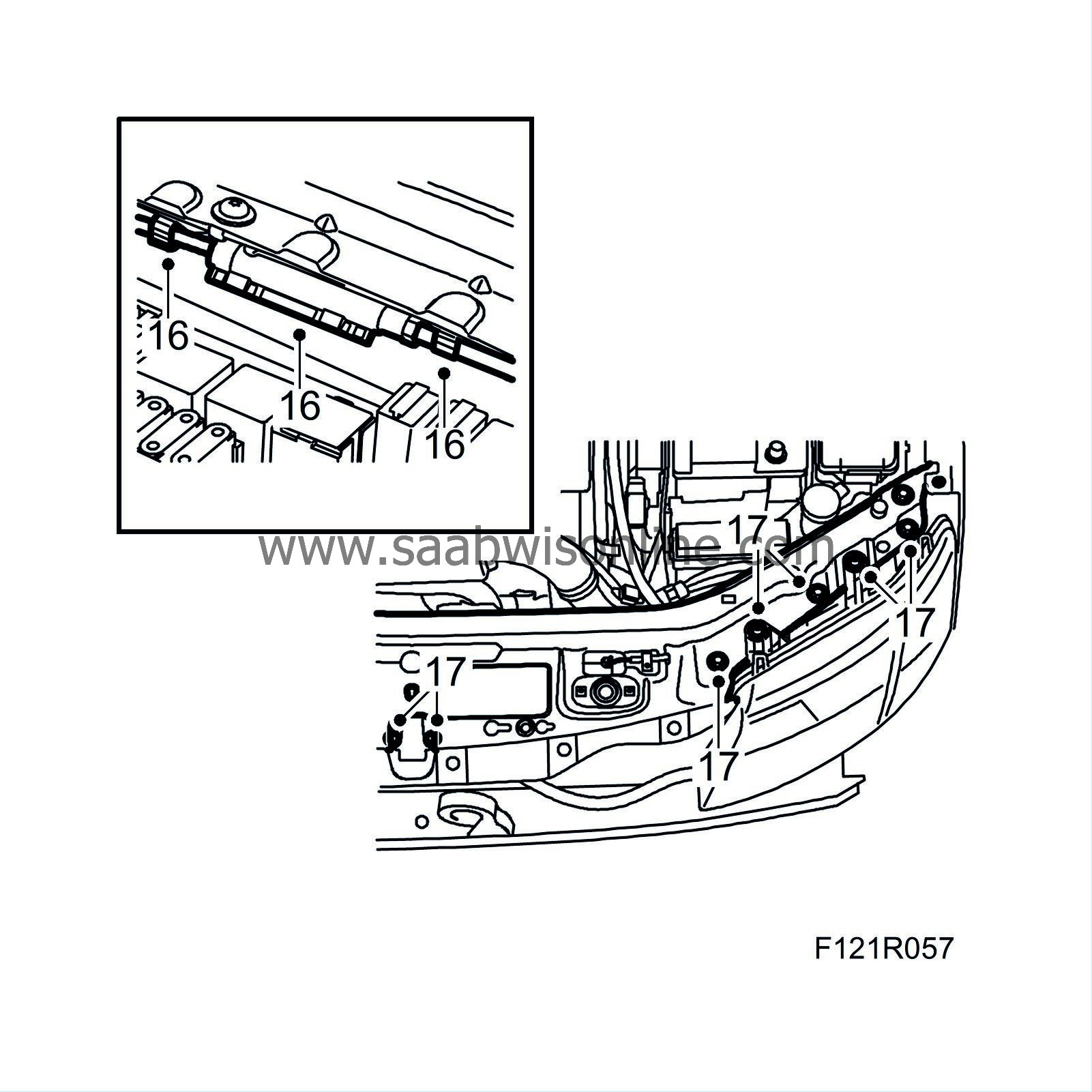

| 16. |

Undo the bonnet cable quick-release coupling by first undoing the clip in the body and then separating the quick-release coupling. Use a screwdriver.

|

|

| 17. |

Remove the upper radiator member.

|

|

| 18. |

Unplug the connector to the pressure/temperature sensor and disconnect the bypass valve hose.

|

|

| 19. |

Detach the charge air hose from the throttle body and undo the upper charge air pipe bracket from the fan cowling. Remove the pipe with hose.

|

|

| 20. |

Remove the battery.

|

|

| 21. |

Detach the ventilation hose from the radiator.

|

|

| 22. |

Detach the vacuum hose quick-release coupling form the vacuum pump.

|

|

| 23. |

Aut:

Unplug the connector to the TCM. Remove the cover with the control module. Unplug the connector under the control module.

|

|

| 24. |

Undo the main fuse box in front of the battery tray and move it aside.

|

|

| 25. |

Unplug the bonnet switch connector, undo the cable clip and remove the battery tray.

|

|

| 26. |

Unplug the connector and undo the clip securing the cables on the fan cowling.

|

|

| 27. |

Unplug the reversing light switch connector.

|

|

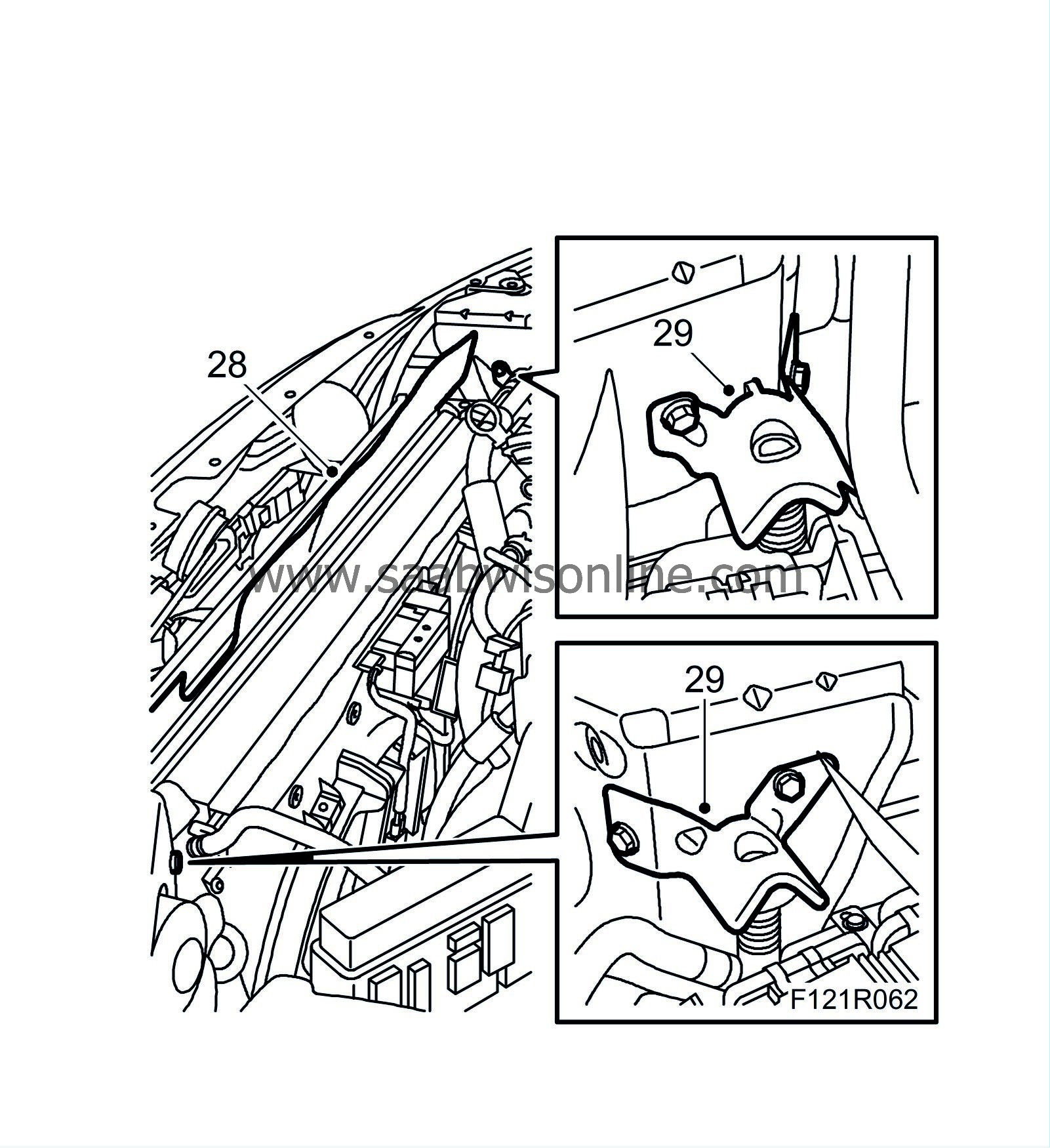

| 28. |

Remove the seal over the radiator core.

|

|

| 29. |

Remove the upper radiator brackets from the body.

|

|

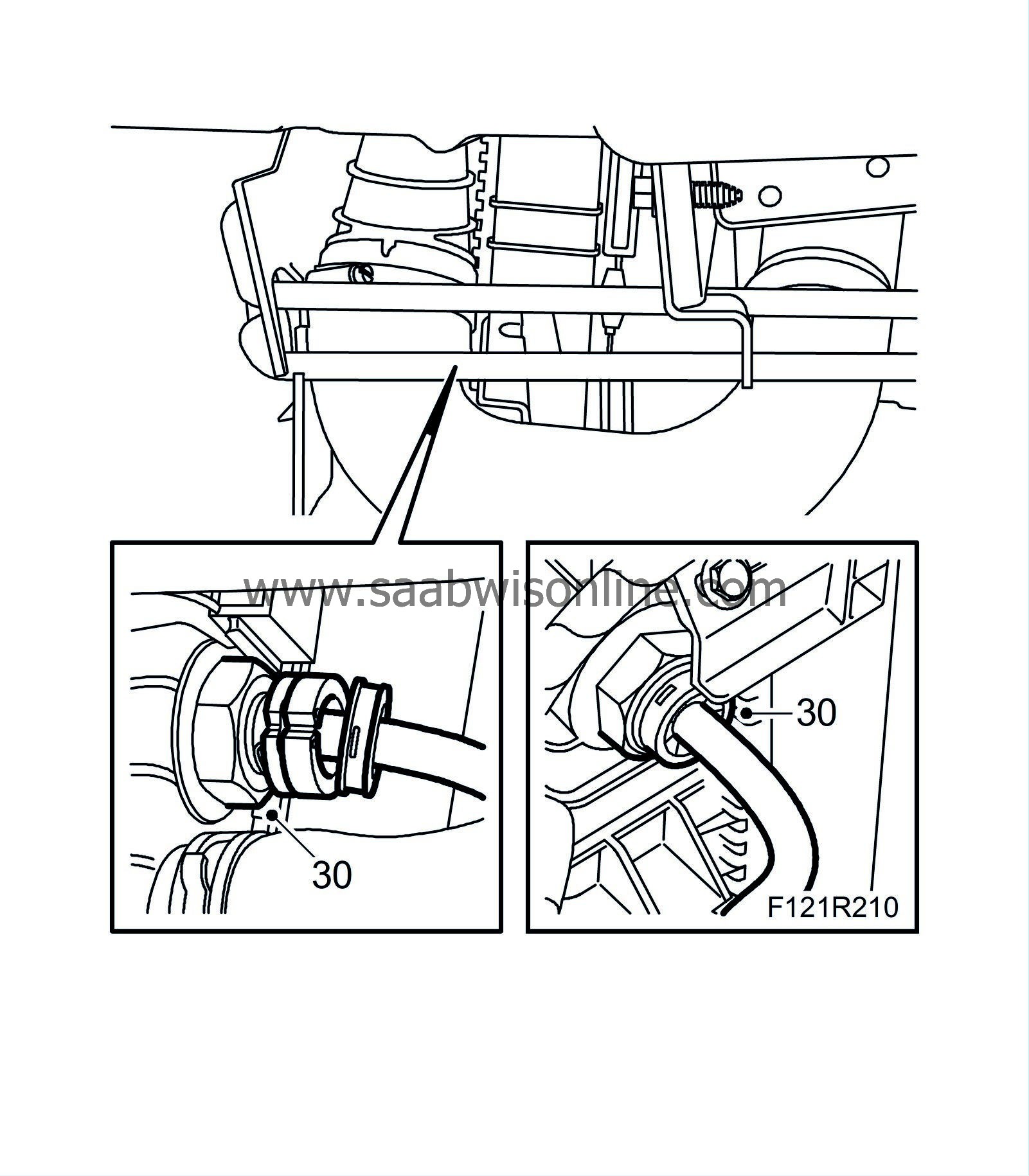

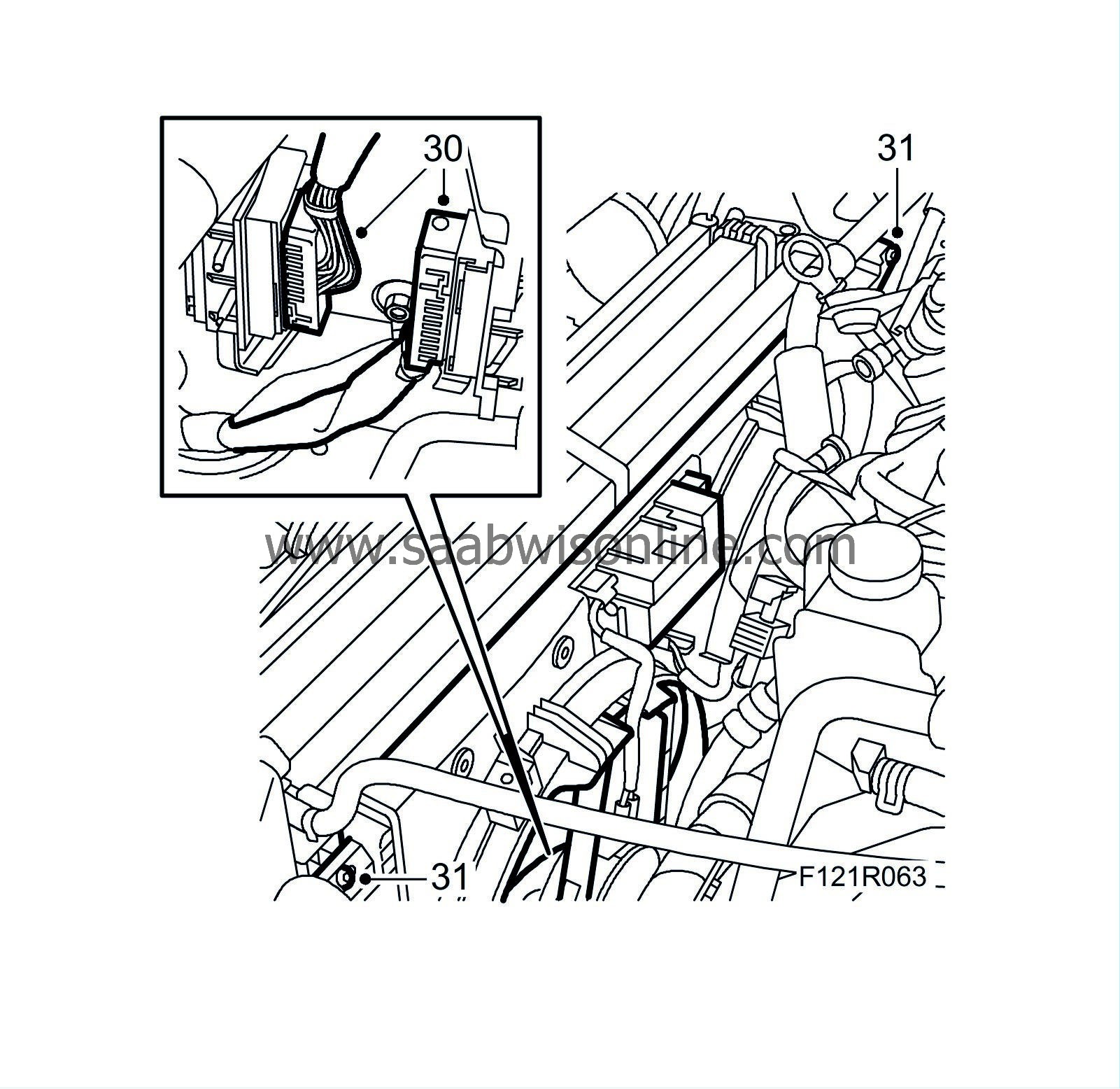

| 30. |

Unplug both connectors from the left-hand structural member.

Auto:

Detach the oil pipes from the fluid cooler. Use

87 92 806 Removal tool, automatic transmission oil pipes

.

|

|

| 31. |

Remove the fan cowling retaining bolts and loosen the cowling slightly.

|

|

| 32. |

Secure the condenser and the charge air cooler to the body with cable ties.

|

|

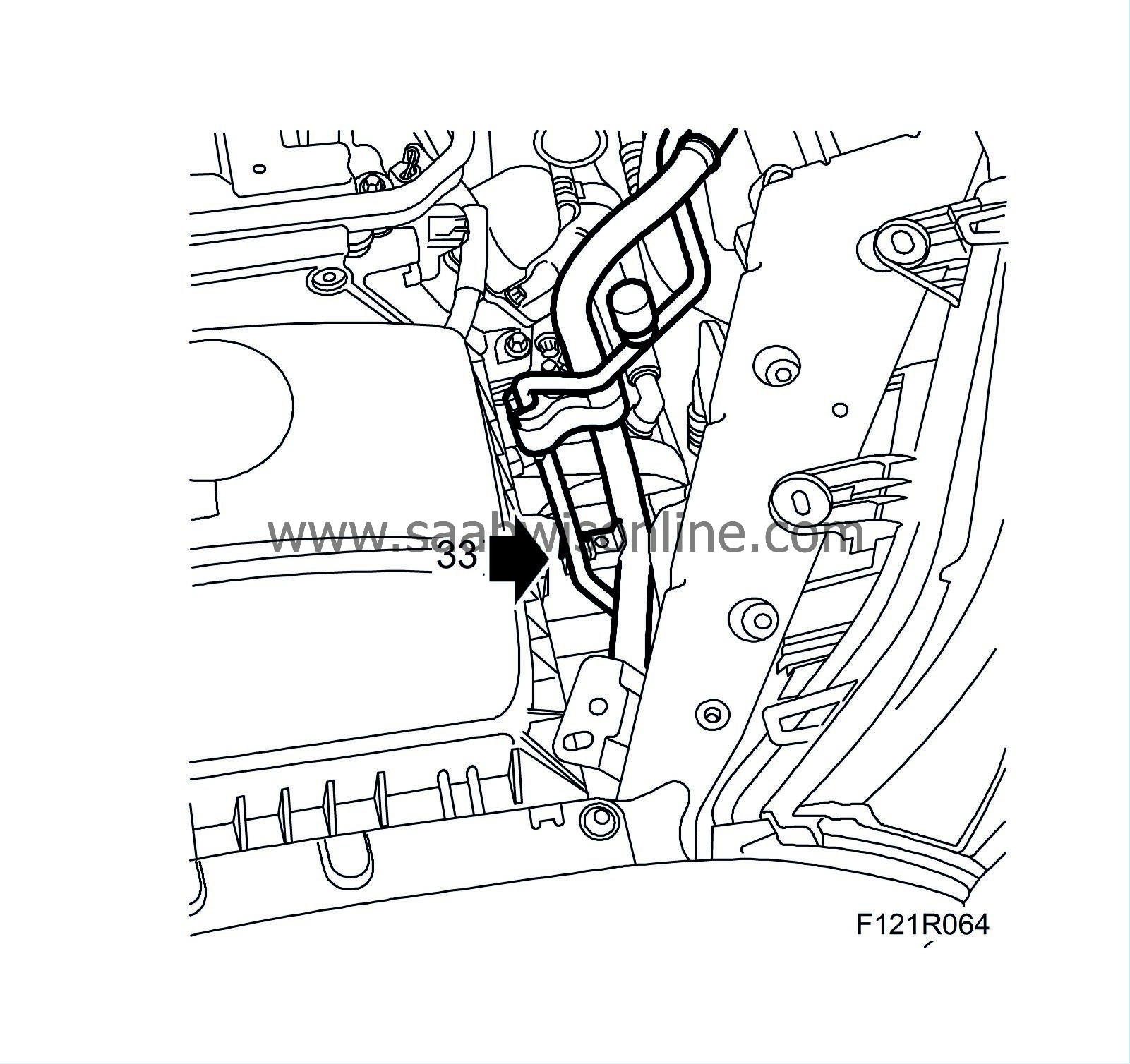

| 33. |

Remove the fan cowling. Carefully detach the A/C pipes from their retaining clips on the right structural member.

|

|

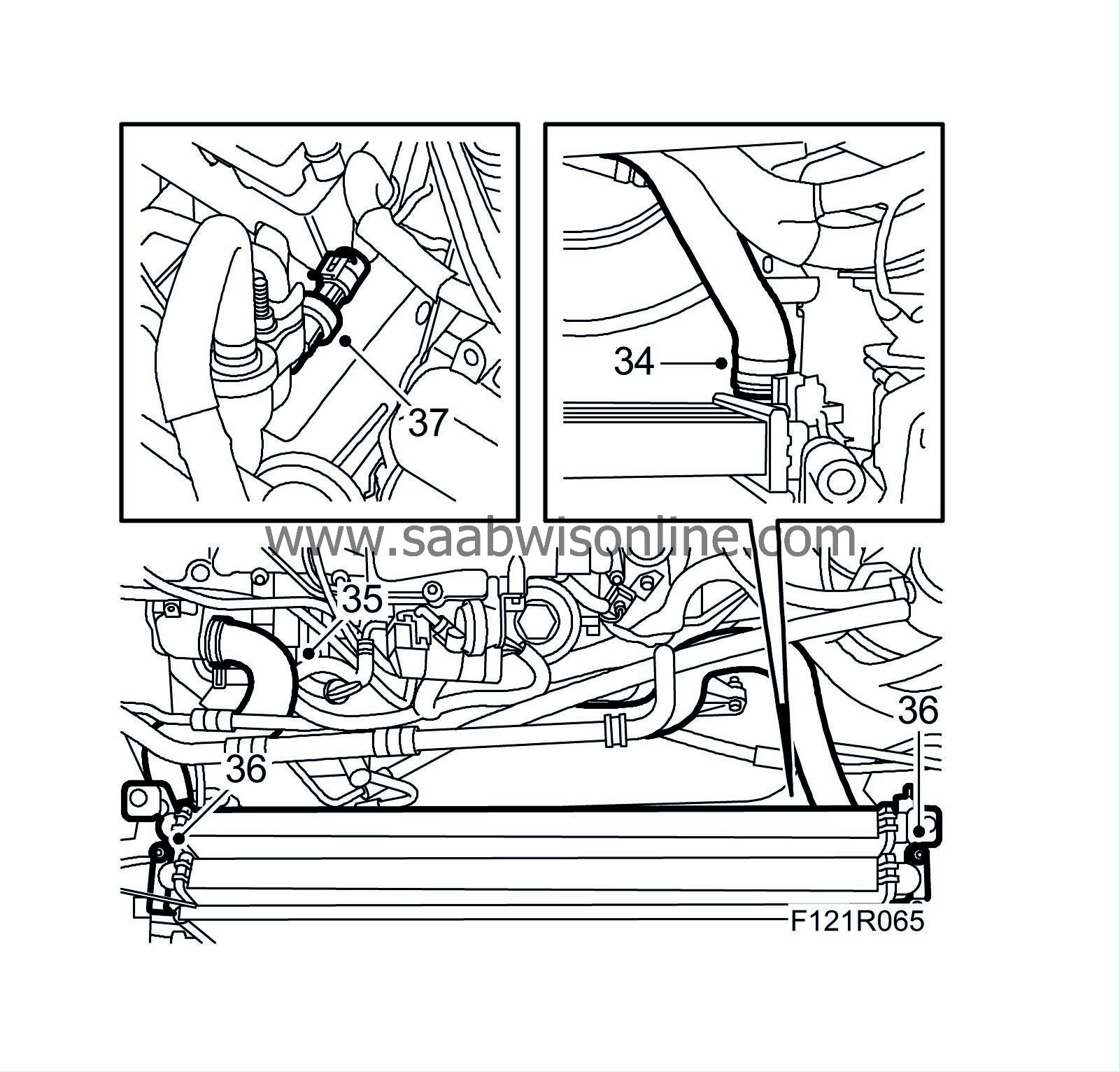

| 34. |

Place a receptacle under the radiator and remove the lower radiator hose.

|

|

| 35. |

Remove the upper radiator hose.

|

|

| 36. |

Remove the radiator.

|

|

| 37. |

Unplug the connector for the A/C pressure sensor.

|

|

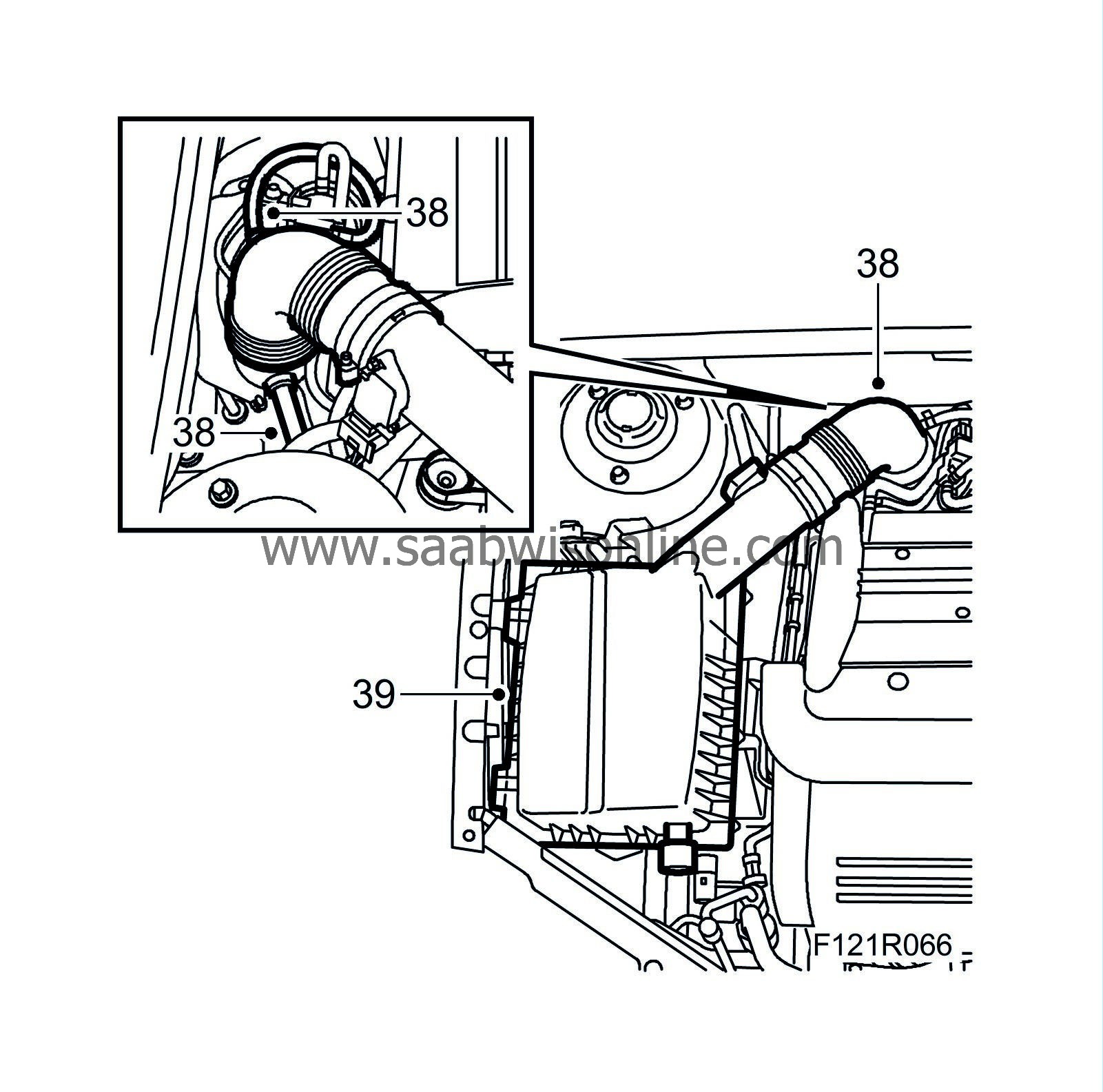

| 38. |

Detach the hoses from the turbo inlet pipe and remove the turbo inlet pipe. Unplug the mass air flow sensor connector. Plug the turbo inlet.

|

|

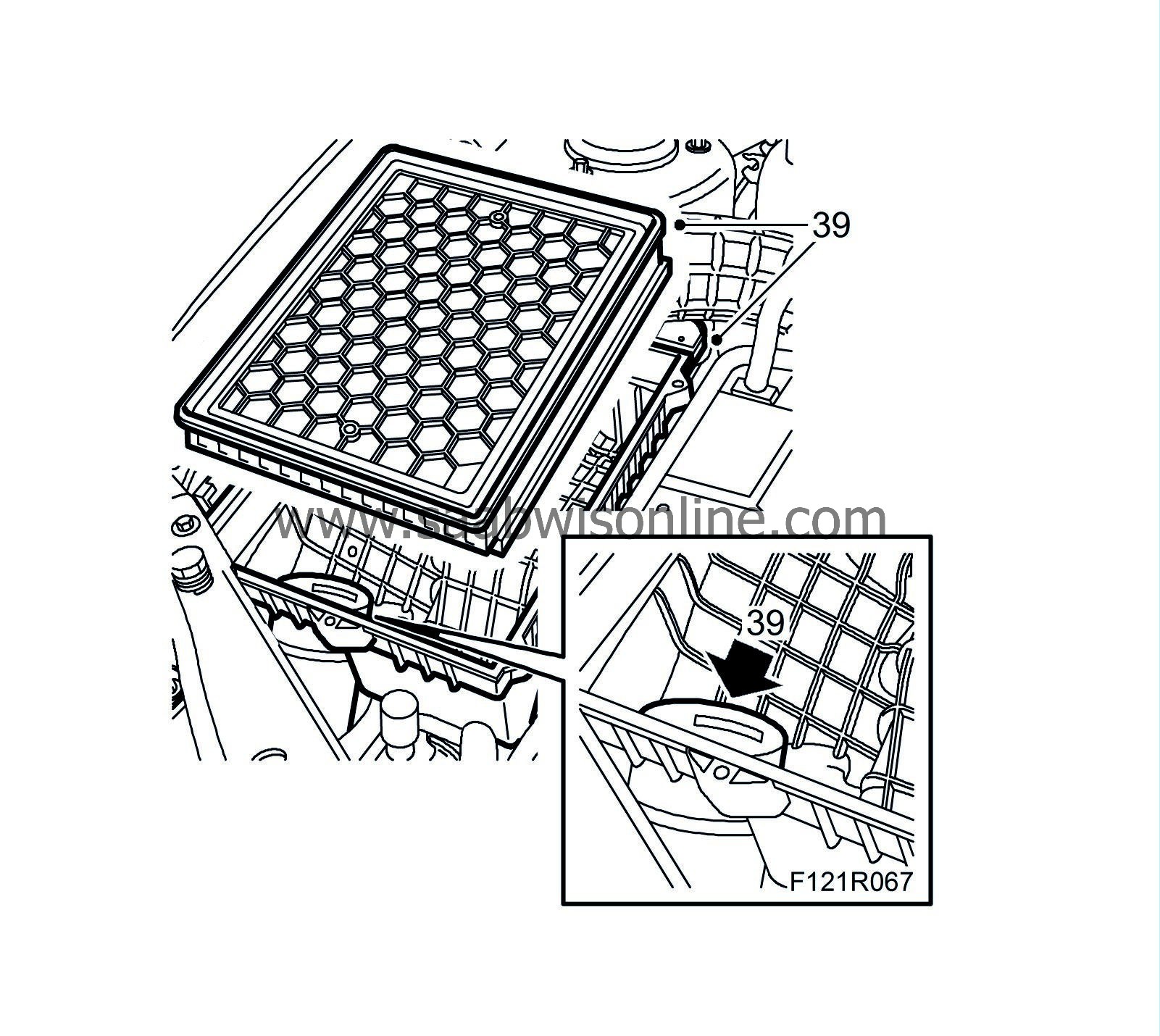

| 39. |

Remove the air cleaner cover and the air cleaner. Detach the inlet hose and remove the air cleaner casing.

|

|

| 40. |

Remove the windscreen washer filler pipe.

|

|

| 41. |

Remove the cover on the main fuse box and undo the two retaining screws.

|

|

| 42. |

Disconnect the positive cable from the battery.

|

|

| 43. |

Undo the retaining screw on the engine harness connector in the main fuse box.

|

|

| 44. |

Remove the engine harness clamp from the body and the ground cables.

|

|

| 45. |

Bend up the engine harness and secure it to the engine with e.g.

83 95 212 Strap

.

|

|

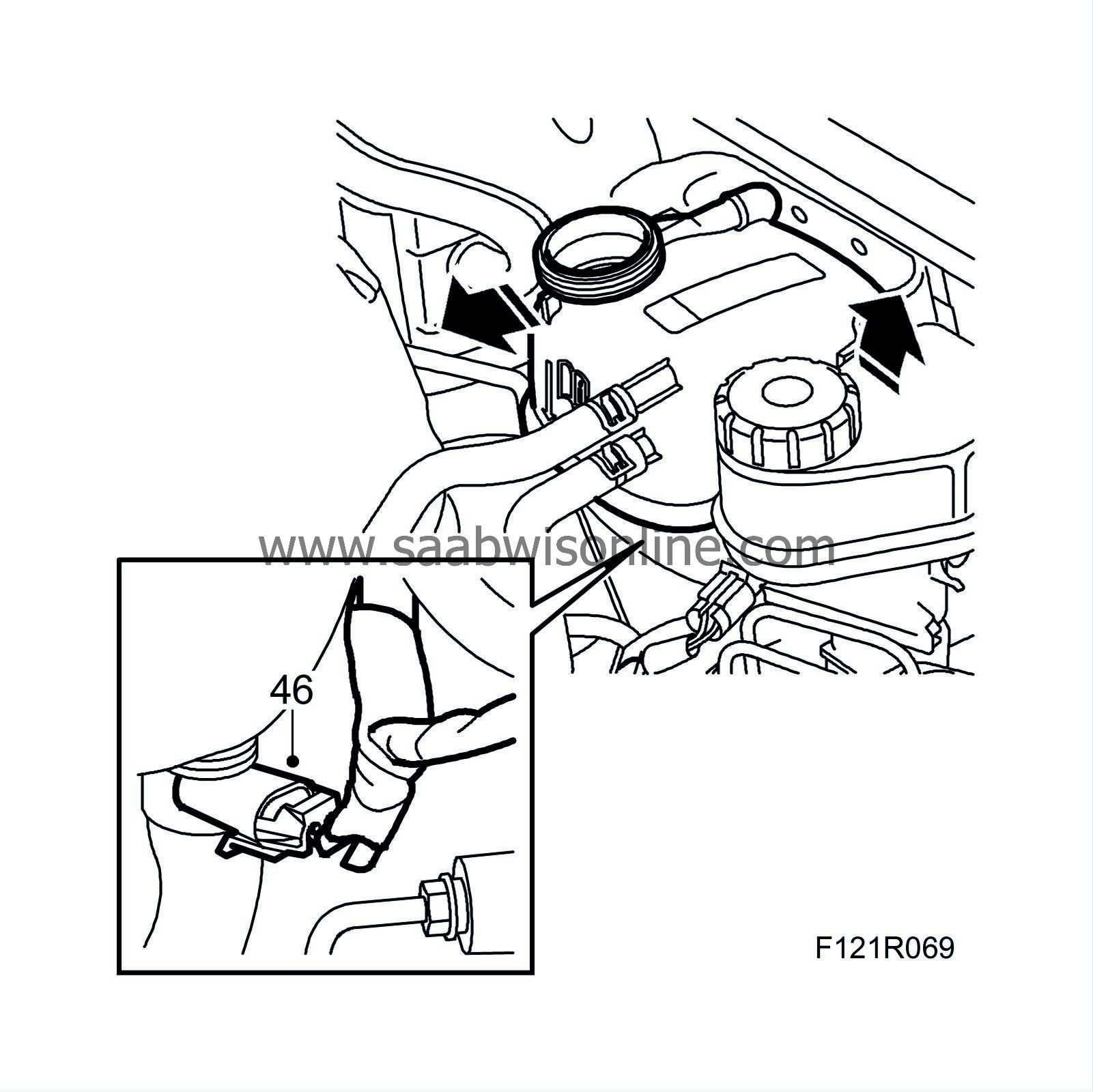

| 46. |

Unplug the coolant level connector. Detach the expansion tank from the body and secure it to the engine. Use

83 95 212 Strap

.

|

|

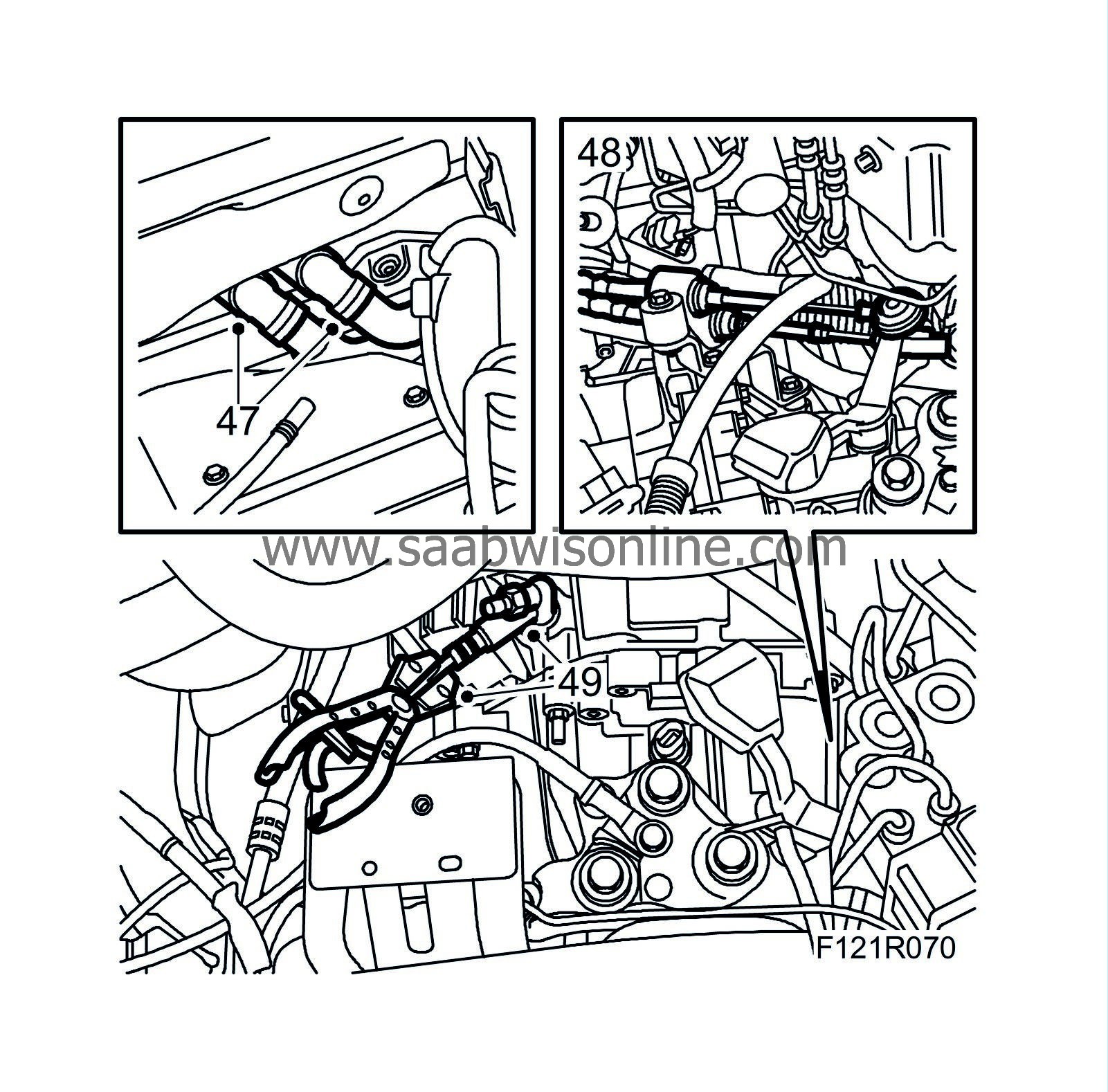

| 47. |

Undo the coolant hose quick-release couplings while trapping any coolant spill, bend aside and secure the hoses to the engine.

|

|

| 48. |

Detach the gear cables from the gearbox, carefully bend them aside and secure them to the expansion tank bracket on the body with cable ties.

|

|

| 49. |

Fit

30 07 739 Hose pinch-off pliers

to the clutch hose and disconnect the quick-release coupling from the clutch slave cylinder.

|

||||||||||||||||||||||||

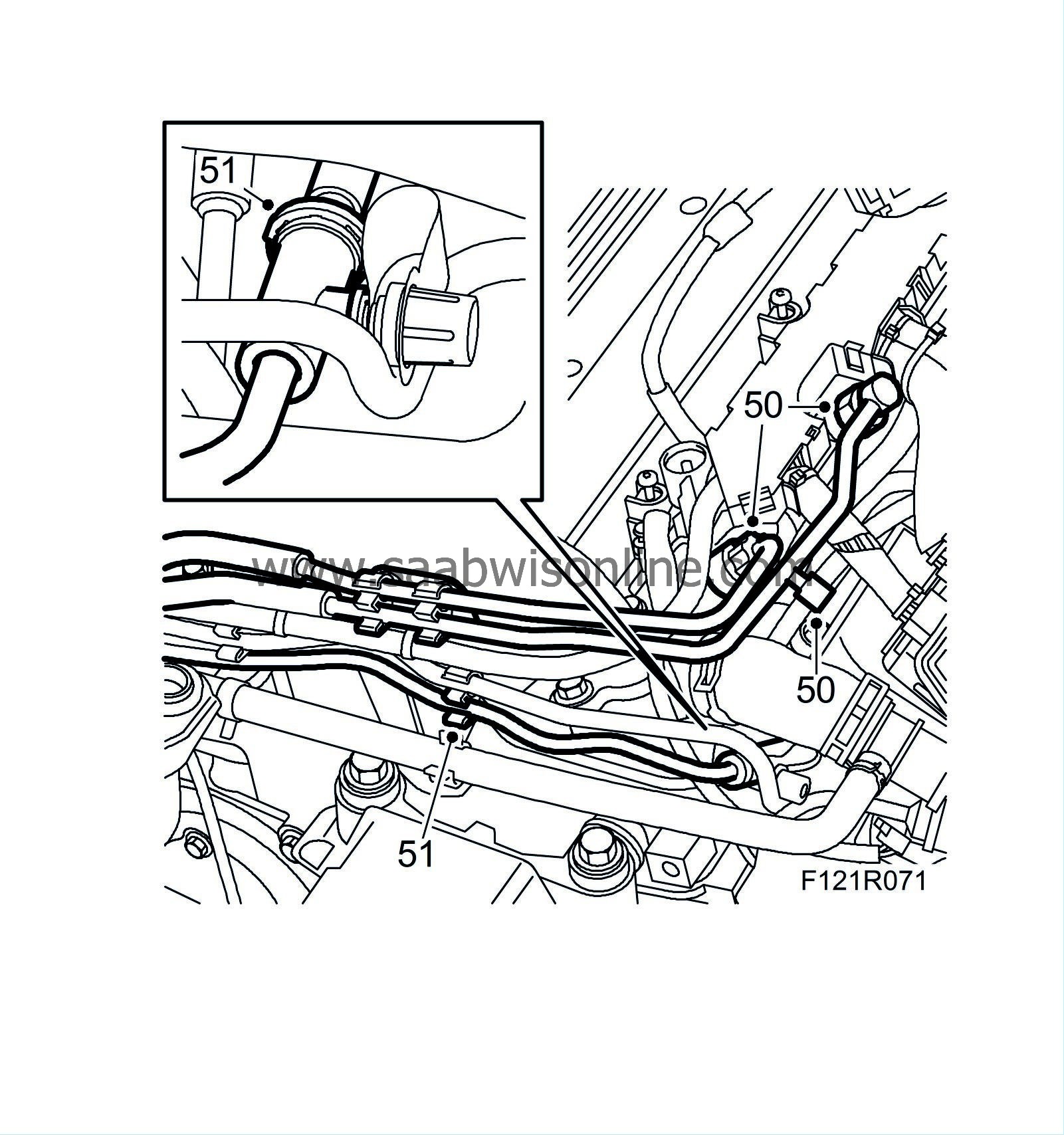

| 50. |

Release any pressure in the fuel system by carefully pressing the service valve needle. Collect any fuel spill. Detach both fuel lines from the fuel rail while gripping the lower nut. Plug the fuel lines. Use

82 92 948 Plugs, A/C system, kit

.

|

|

| 51. |

Disconnect the quick-release coupling for the ventilation line and detach the fuel lines and ventilation lines from the clips on the camshaft cover. Bend up the ventilation hose from the intake manifold and place it on the camshaft cover.

|

|

| 52. |

Check and adjust the steering wheel and the steering assembly so that they are pointing straight ahead.

|

|||||||||

| 53. |

Detach the steering shaft from the steering gear.

|

|

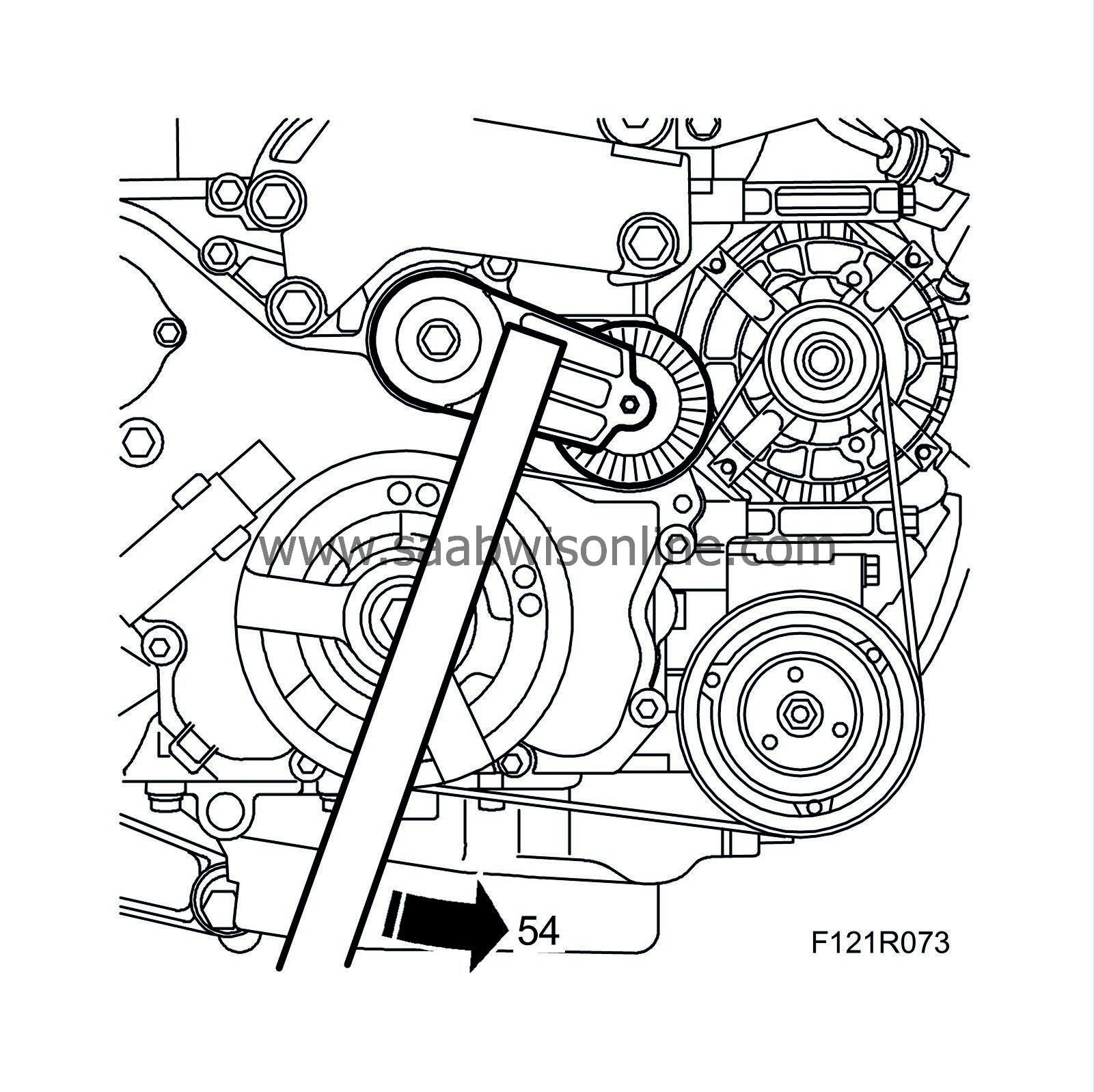

| 54. |

Raise the car, loosen the multigroove belt and remove it. Mark the direction of rotation of the belt. Use

83 96 095 Belt circuit relieving tool B207

.

|

|

| 55. |

Unplug the A/C compressor connector and remove the A/C compressor retaining bolts.

|

|

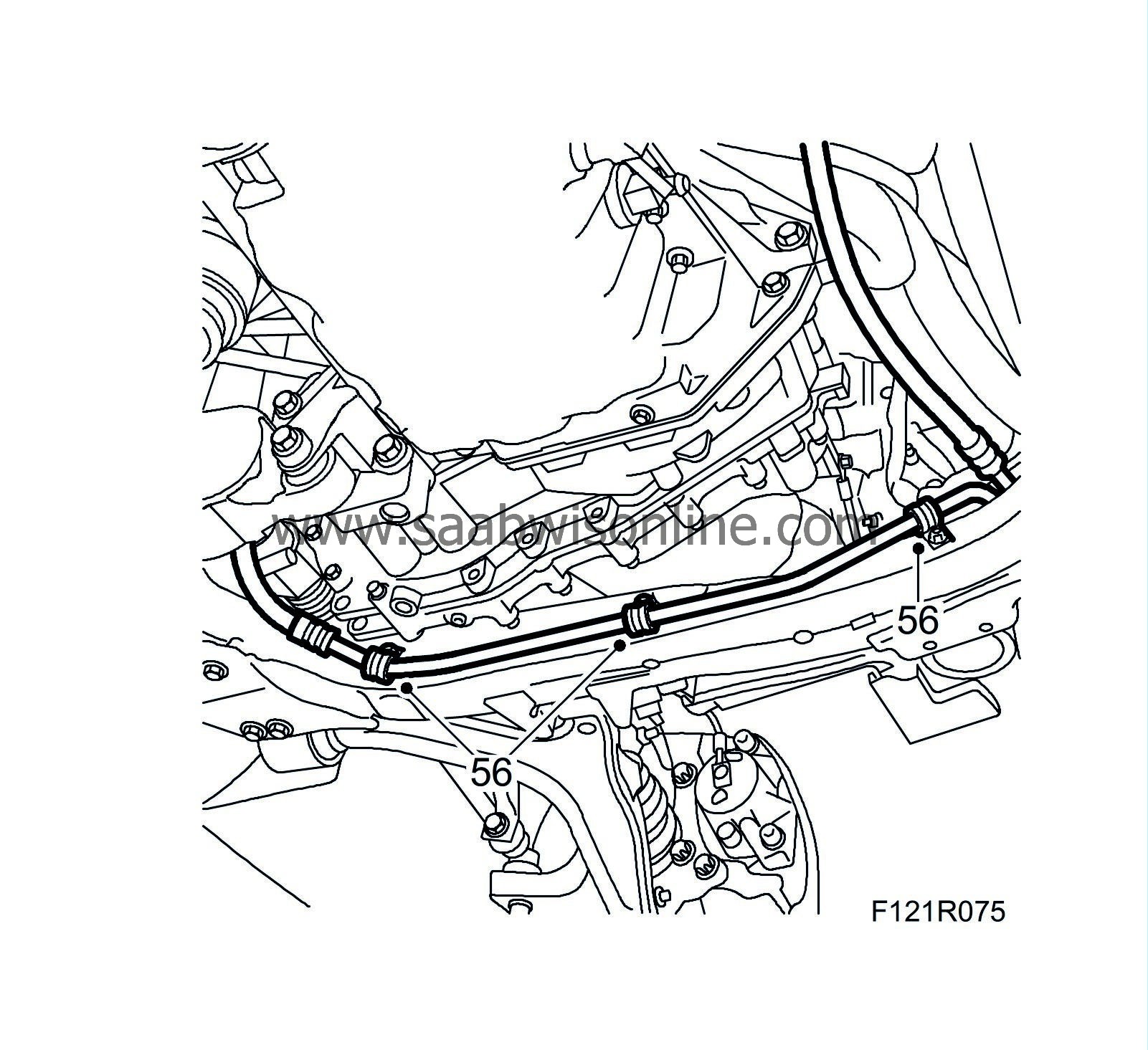

| 56. |

Undo the bolts on the power steering pipe clamps on the subframe.

|

|

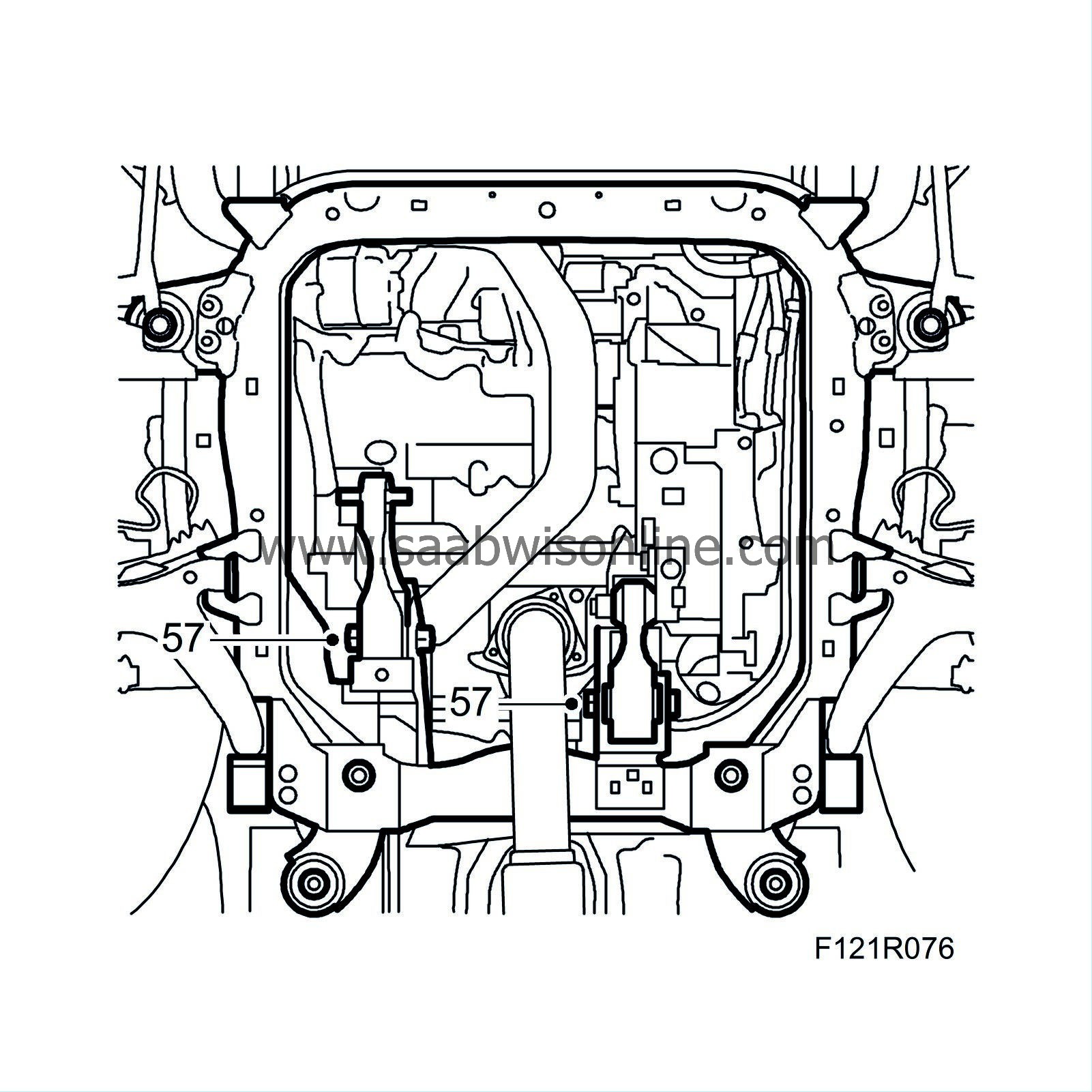

| 57. |

Undo the rear torque arm bolts slightly.

|

|

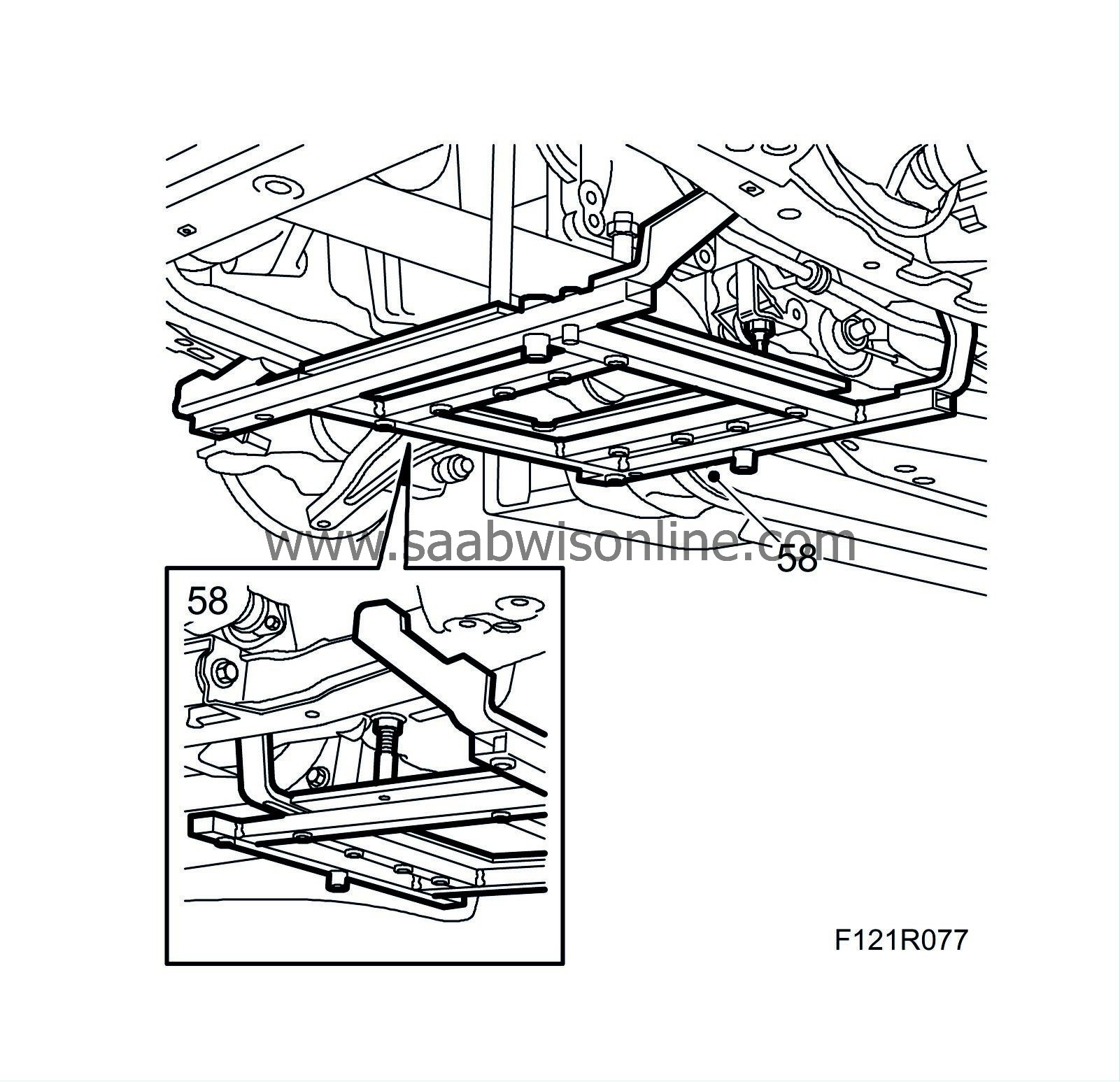

| 58. |

Fit

83 96 152 Engine centring tool kit

to the subframe. Due to narrow tolerances on the drive shafts, the centring tool must be used to carefully fit the powertrain to the subframe and body during refitting. Adjust the centring tool bolts so that the adjuster screw slots are completely visible. See

Centring tool, engine and subframe

.

|

|

| 59. |

Lower the car and refit the radiator member.

|

|

| 60. |

Attach

83 95 212 Strap

to the radiator member, lower the strap and wind it an extra turn round the A/C compressor to relieve it.

|

|

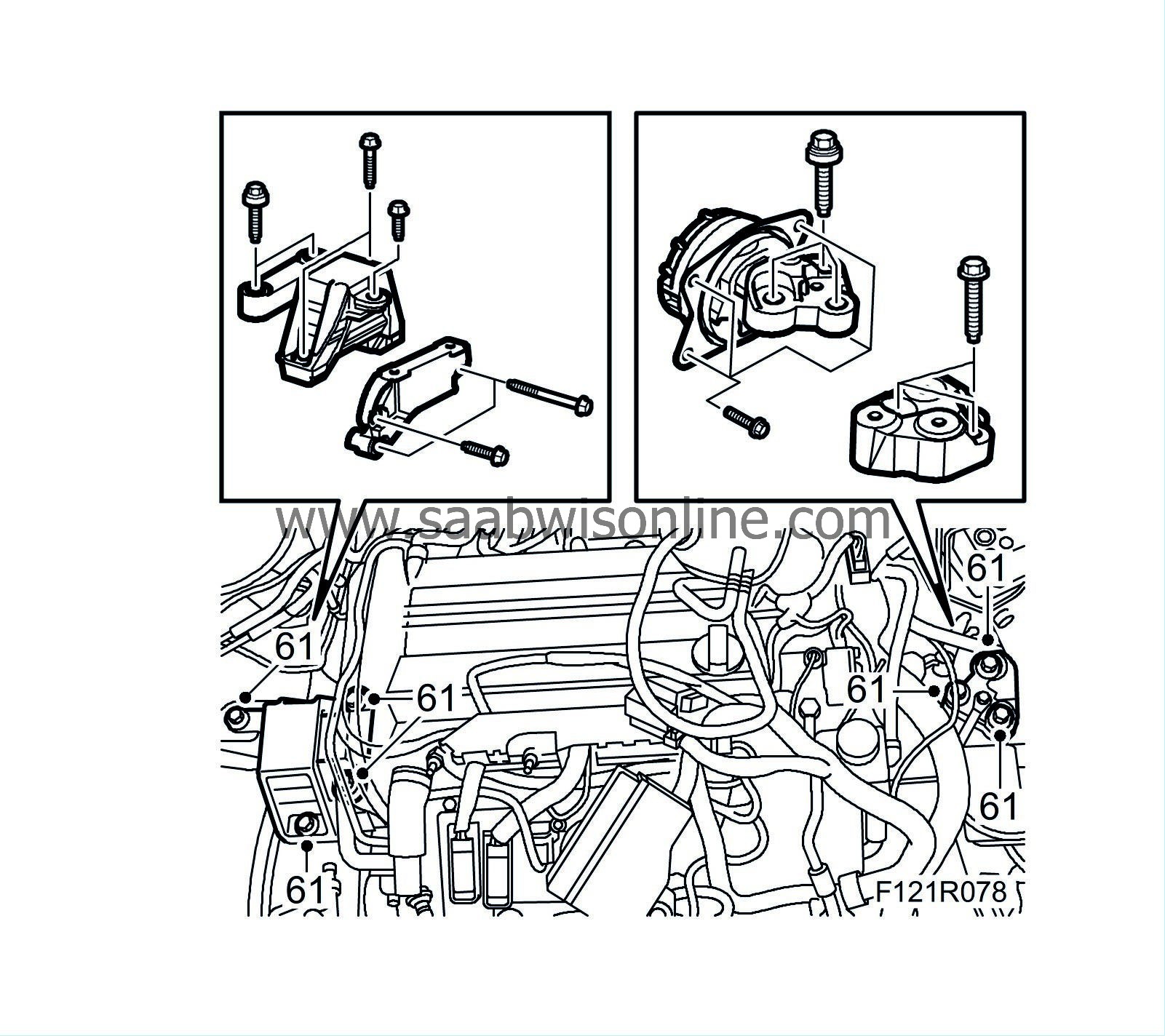

| 61. |

Remove the right and left engine mountings.

|

|

| 62. |

Raise the car and undo the drive shaft centre nuts. Detach the drive shafts from the hub. Use

89 96 951 Drive shaft hub puller

or a brass drift and mallet.

|

|||||||||

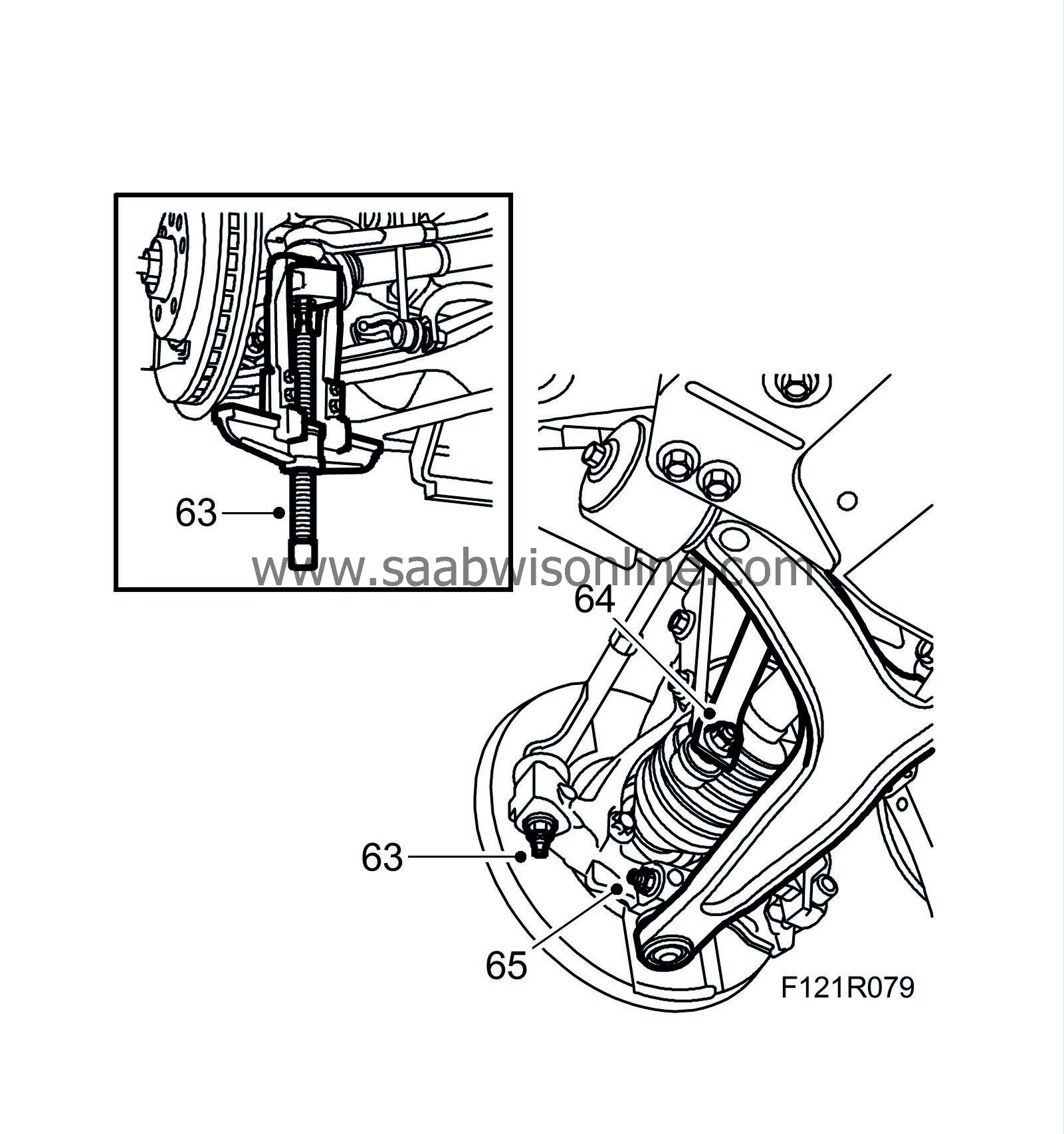

| 63. |

Undo the nuts and the outboard steering links from the steering swivel member with

87 91 287 Puller, 150 mm

.

|

|

| 64. |

Undo the lower anti-roll bar links while gripping the flats with a thin spanner.

|

|

| 65. |

Undo the lower swivel joints from the steering swivel members and lower the suspension arms.

|

|

| 66. |

Undo the drive shafts and move them away.

|

|

| 67. |

Measure a distance of 87 mm from the front end of the silencer and cut the exhaust pipe between the silencer and the flexipipe with a

83 95 667 Pipe cutter/exhaust system

.

|

|

| 68. |

Detach the front pipe from the catalytic converter.

|

|

| 69. |

Disconnect the ground cable from the gearbox and the connector for the angle sensor (option).

|

|

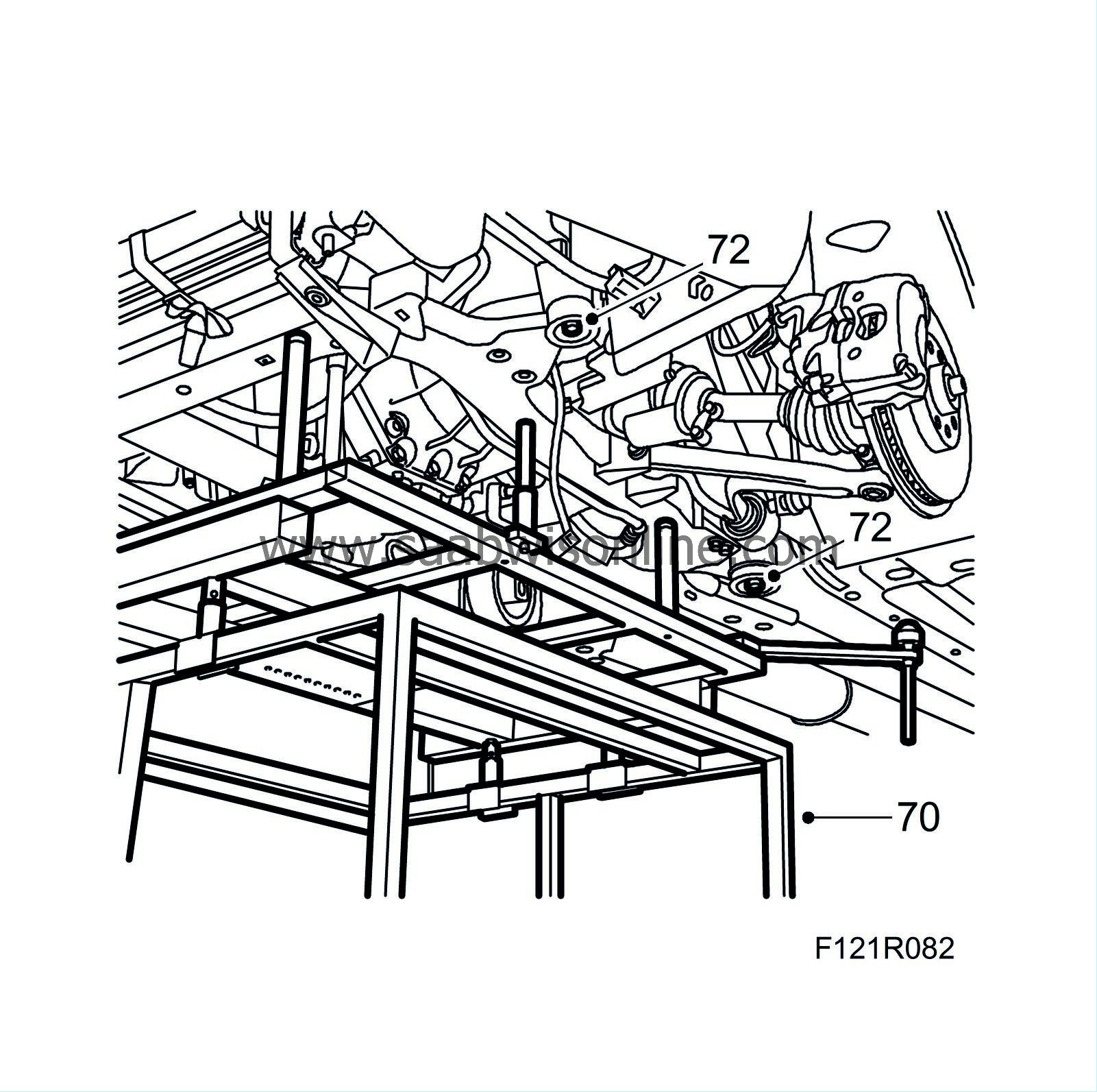

| 70. |

Place

83 96 145 Centring tool, subframe - engine

on the trolley lift. Make sure adjuster screws on the height adjusters, part no. 83 95 170, are in their lowest position. See

Centring tool, engine and subframe

.

|

|

| 71. |

Position the trolley lift; raise and insert the guide pins in the subframe reference holes. Adjust the lifting pillars with the height adjusters, part no. 83 95 170, so that they rest evenly on the subframe. Check with the body guide pins that the subframe is positioned correctly in relation to the body. See

Centring tool, engine and subframe

.

|

|

| 72. |

Raise the trolley lift slightly for stable contact and undo the subframe bolts in the body.

|

|

| 73. |

Carefully lower the power train on the trolley lift, making sure nothing gets caught or damaged.

|

|

Warning

Warning