Centring tool, engine and subframe

| Centring tool, engine and subframe |

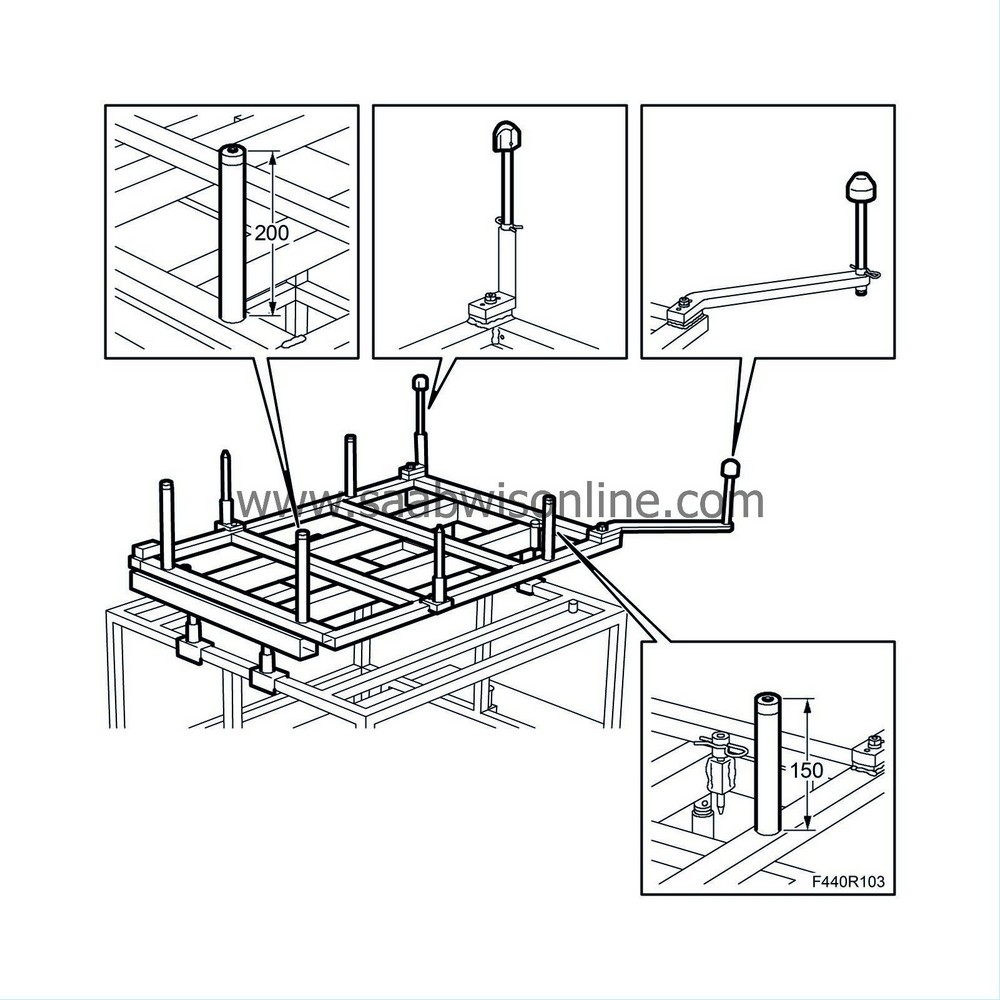

| Fitting removal and fitting tools, subframe |

| 1. |

Fit the tool on the trolley lift as illustrated. Pay attention to the location of the columns and guide pins.

|

|

| 2. |

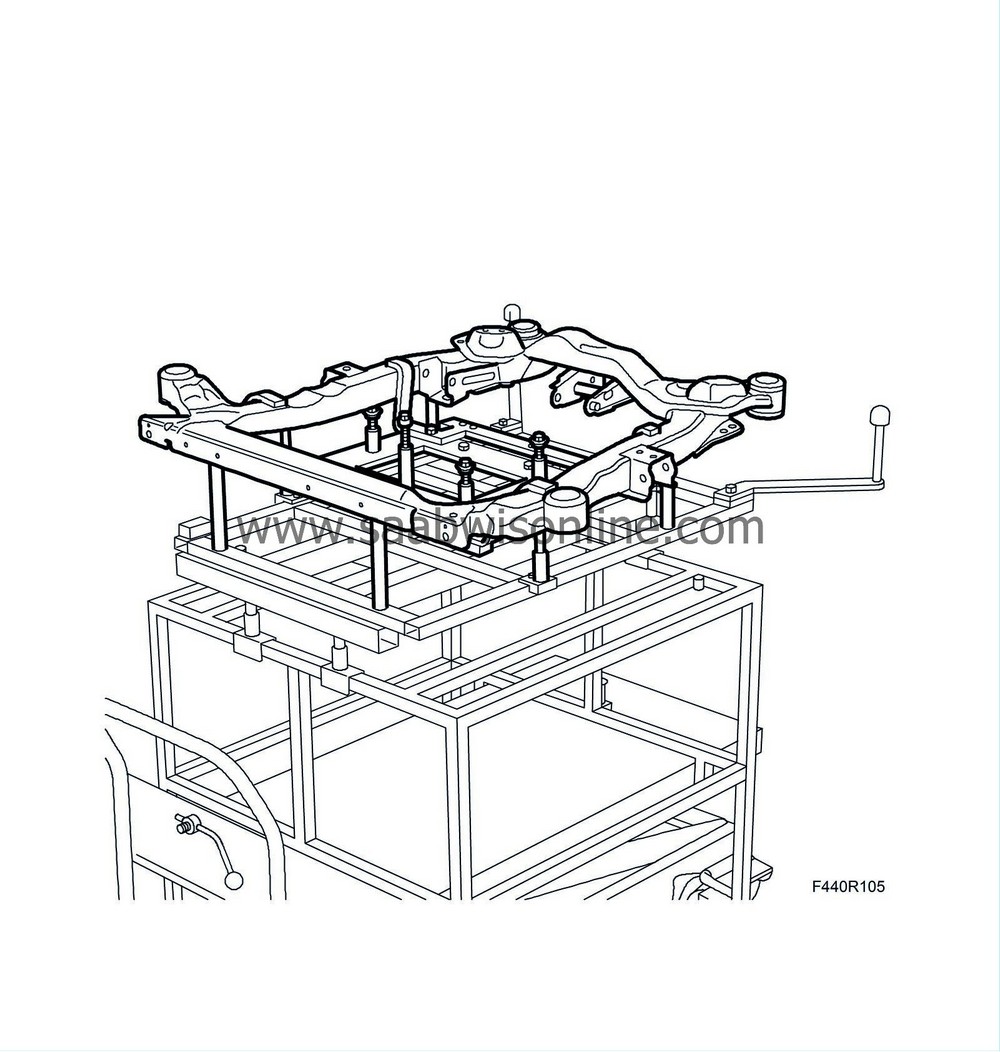

Position the tool under the vehicle subframe as illustrated.

|

|

| Fitting centring tool, subframe - engine |

| 1. |

Fit

83 96 152 Engine centring tool kit

to

83 96 145 Centring tool, subframe - engine

. Make note of the location of the bolts. The distance from the bolt head to the slit in the threads is different on the two short sleeves. Fit the sleeves as illustrated. Use

Thread locking adhesive, Loctite 270

on the sleeves.

|

|

| 2. |

Fit the tool for centring the engine and subframe as illustrated. Sleeve C is intended for automatic transmission while sleeve D is for manual.

|

|

| 3. |

Adjust each adjuster screw to the reference holes on the oil sump, torque rod bracket and the machined plane on the transmission casing. The screws should be adjusted so that the groove on the screw thread are completely visible.

|

|

| 4. |

Continue with the other points of the method in question.

|

|

| Adjustment (after the subframe has been fitted to the body) |

| 2. |

Tighten the screws to the specified tightening torque.

|

|