Checking for lateral run-out and variation in thickness, front wheels

| Checking for lateral run-out and variation in thickness, front wheels |

| 1. |

Raise the car and remove the front wheels.

|

|

| 2. |

Start by control measuring on one side.

|

|

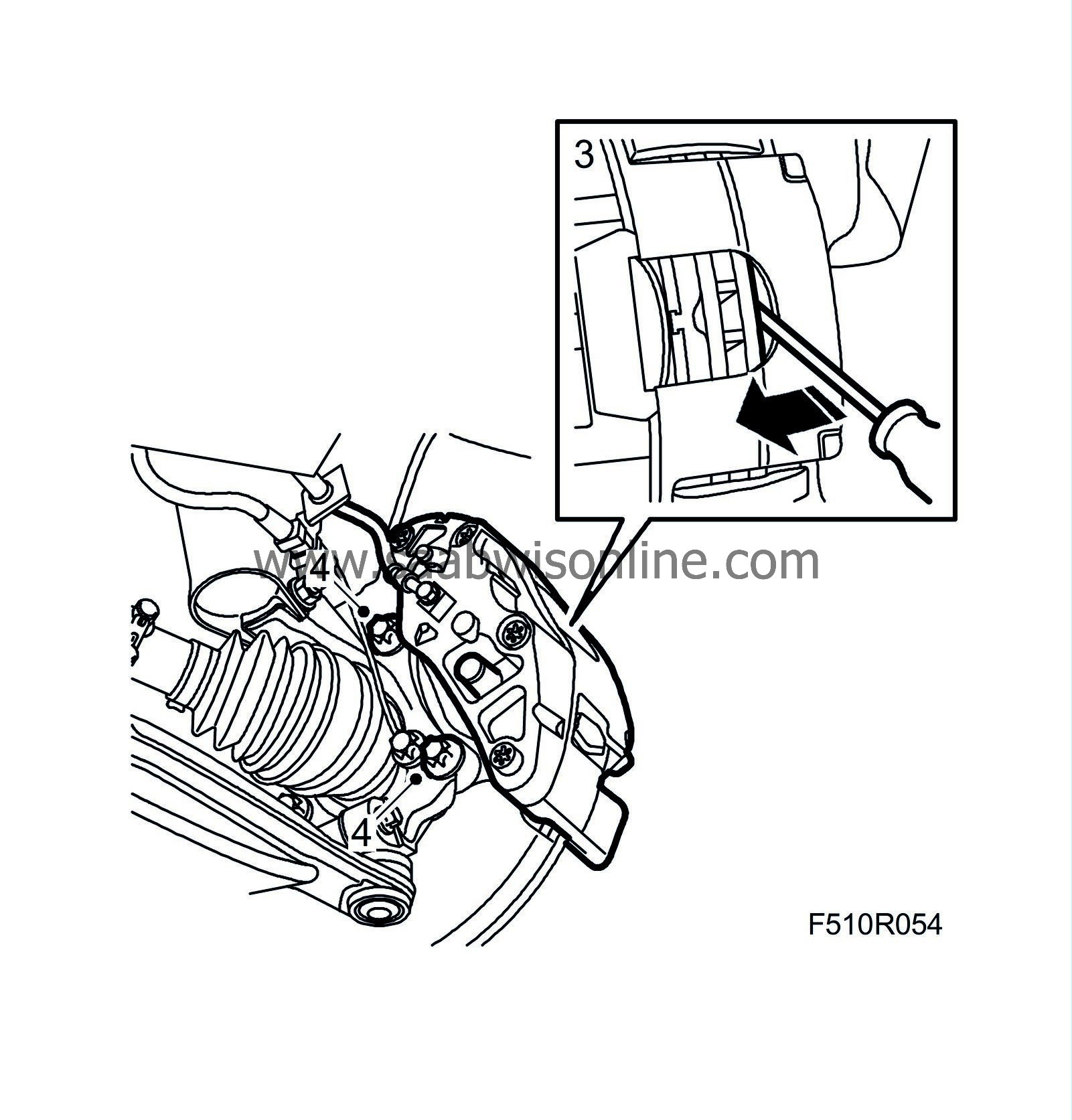

| 3. |

Press in the piston

|

|

| - |

Level 1 and 2:

Press in the brake pad by prising with a screwdriver.

|

| - |

Level 3:

Prise between the brake disc and the brake caliper using a screwdriver.

|

| 4. |

Remove the brake caliper retaining bolts and lift of the caliper.

|

|||||||

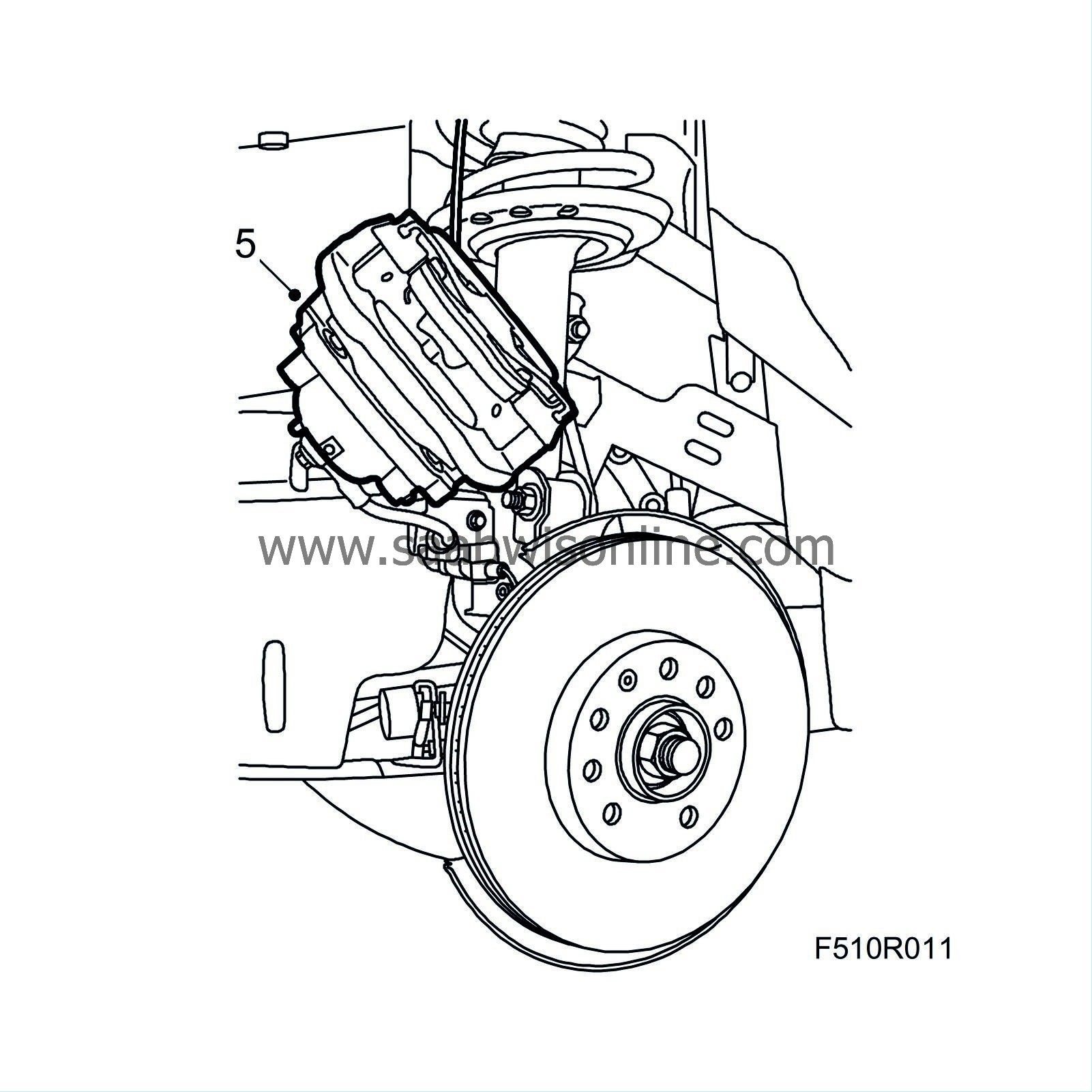

| 5. |

Suspend the caliper with cable ties.

|

|

| 6. |

Fit the five wheel bolts with one washer, part no. 80 73 124, on each.

|

|

| 7. |

Fit

89 96 639 Gauge, brake disc

to the upper mounting lug for the brake caliper with an M10 bolt and nut. Fit a

78 40 622 Dial gauge

on either side.

|

|

| 8. |

Rotate the brake disc while observing the outboard dial gauge. Zero both gauges when the negative reading obtained on the outboard one is at maximum.

|

|

| 9. |

Rotate the disc and read the gauges. Note the runout (A) and variation in thickness (B).

|

|

| 10. |

Check that the readings are within the tolerance limits, see

Brake discs

.

|

|

| 11. |

Remove the dial gauges, brake disc measuring tool and wheel studs with washers.

|

|

| 12. |

If runout and thickness variation exceeds specified tolerances, the discs must be machined or replaced. see

Brake disc, front

.

|

|

| 13. |

Fit the brake caliper. Secure the bolts with

74 96 268 Thread locking adhesive

.

Tightening torque: 210 Nm +30° (155 lbf ft +30°)

|

|

| 14. |

Fit the wheel

|

|

| 15. |

Repeat this method of measurement on the other brake disc.

|

|

| 16. |

Lower the car and depress the brake pedal to press out the brake pads.

|

|