(641-2468) Noise with steering wheel turning

Symptom: A loud snapping noise arises with steering wheel turning which appears to originate from the area around the CIM.

| TECHNICAL SERVICE BULLETIN | |

| Bulletin Nbr: | 641-2468 |

| Date: ........... | Maj 2004 |

| Market: | US, CA |

| Noise with steering wheel turning |

| Cars affected |

Saab 9-3 (9440) within Vehicle Identification Number range:

Upper joint

4D M03 - M04: 31000001 - 41027672

CV M04: 46000001 - 46010241

Lower joint

4D M03 - M04: 31000001 - 41049361

CV M04: 46000001 - 46015427

| Background |

The play between the steering shaft and joint can, in some cases, give rise to a movement in the joint when the steering wheel is turned. In connection with this, a loud snapping noise can be heard which appears to originate from the area around the steering wheel/CIM.

In the case of customer complaint, the following procedure must be carried out.

Symptom description

A loud snapping noise arises with steering wheel turning which appears to originate from the area around the CIM.| Parts required |

74 96 268 (CA: 10953489) Thread locking adhesive

The fluid is sufficient for approx. 100 cars/bottle.

| Procedure |

Always start by working on the upper joint in the passenger compartment.

Upper joint

| 1. |

Remove the sound insulating baffle on the driver's side, see WIS Group 8 - Interior equipment - Adjustment/Replacement - Sound insulating baffle, driver's side.

|

|

| 2. |

Remove the bolt in the joint on the intermediate shaft.

|

|

| 3. |

Brush clean the bolt using a wire brush and blow clean with compressed air.

|

|

| 4. |

Clean out the threads in the joint with a thread tap M8 x 1.25. Blow clean with compressed air.

|

|

| 5. |

Apply 74 96 268 Thread locking adhesive to the bolt.

|

|

| 6. |

Fit the bolt.

Tightening torque 30 Nm (22 lbf ft) |

|

| 7. |

Fit the sound insulating baffle on the driver's side, see WIS Group 8 - Interior equipment - Adjustment/Replacement - Sound insulating baffle, driver's side.

|

|

| 8. |

Check that the noise has ceased. If the noise remains then the lower joint in the engine bay must also be rectified in accordance with the following description.

|

|

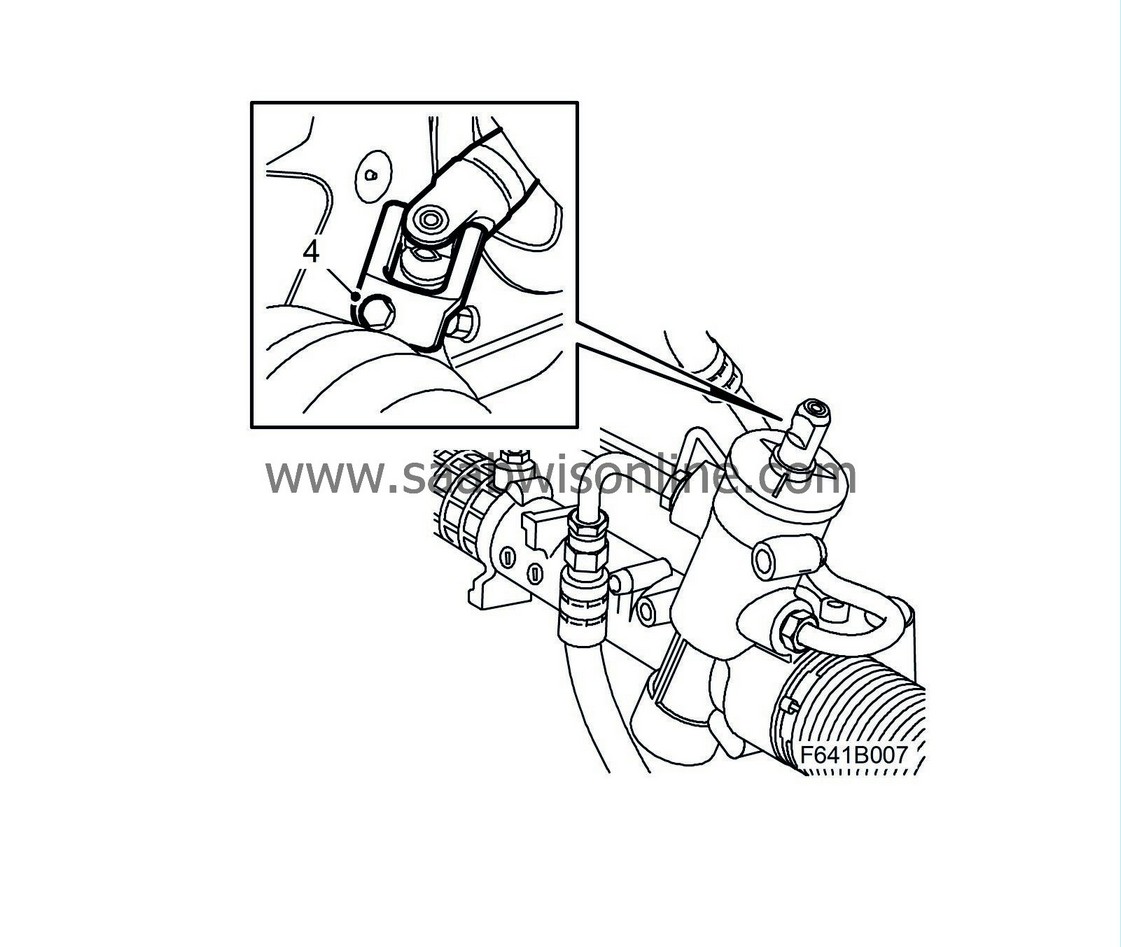

Lower joint

| 1. |

Set the wheels straight ahead.

|

|

| 2. |

Raise the car.

|

|

| 3. |

Remove the wheel on the driver's side.

|

|

| 4. |

Remove the bolt in the lower joint. It is accessible through the wheel housing.

|

|||||||

| 5. |

Brush clean the bolt using a wire brush and blow clean with compressed air.

|

|

| 6. |

Clean out the threads in the joint with a thread tap M8 x 1.25. Blow clean with compressed air.

|

|||||||

| 7. |

Apply 74 96 268 Thread locking adhesive to the bolt.

|

|

| 8. |

Fit the bolt.

Tightening torque 30 Nm (22 lbf ft) |

|

| 9. |

Fit the wheel in accordance with WIS Group 7 Suspension, wheels - Wheels and tyres - Adjustment/Replacement - Wheels.

|

|

| 10. |

Lower the car.

|

|

| Warranty/Time Information |

In the case of customer complaint and if the car is within the warranty period , use the following information to fill out the claim:

Failed Object: 64135

Fault/Reason code: 40

Location code: 05, 06, 08 and 09 (US=9)

Warranty Type (US): 01

Repair/Action code: 05

Labour Operation (US):

6413503 Adjustment of intermediate shaft upper bolt in passenger compartment

6413504 Adjustment of intermediate shaft bolt in engine bay

6413505 Adjustment of both intermediate shaft bolts

Labour Operation (CA): E7700

Time:

Adjustment of intermediate shaft upper bolt in passenger compartment: 0.2 hr

Adjustment of intermediate shaft bolt in engine bay: 0.3 hr

Adjustment of both intermediate shaft bolts: 0.5 hr

Add $1.00 as compensation for locking fluid