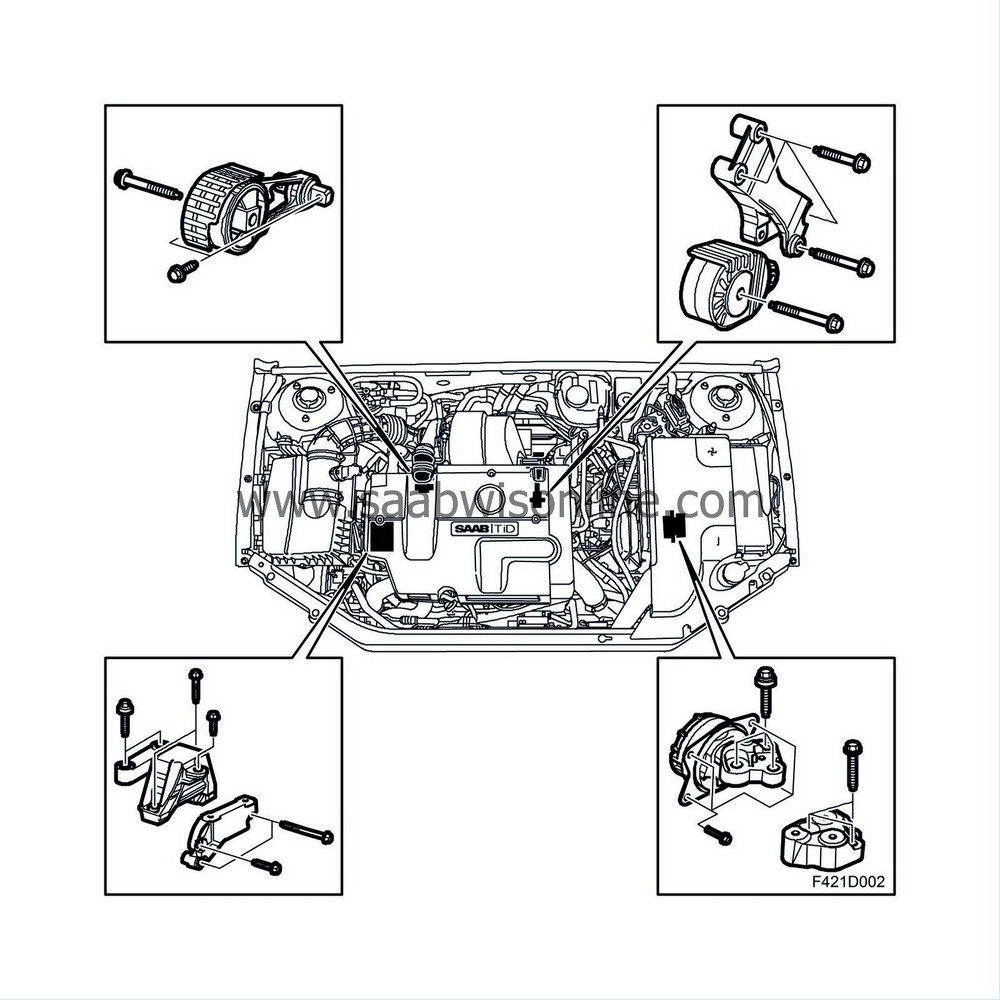

Engine mountings

| Engine mountings |

| Background |

The power unit is suspended from two points: one on the left-hand side between the top of the gearbox and the body, and the other between the top right of the engine and the body.

The left-hand suspension point is made of rubber, while the right-hand point employs a combination of rubber and hydraulics. The hydraulic right-hand mounting reduces power train oscillations that are due to a poor road surface. Engine vibrations are absorbed by the rubber part of the mounting while the hydraulic part is active when the amplitude of the oscillations is too great. Two torque arms supplement the engine mountings. These arms, one attached between the oil sump and subframe, and the other between the joint between the engine and gearbox and the subframe, absorb the torsion produced during acceleration and deceleration.

| Description |

The hydraulic mounting consists of two chambers filled with a special glycol-based damping fluid. There is a diaphragm and a passage between the two chambers where the length and cross-sectional area of the passage determines the damping characteristics of the mounting.

The affect of the diaphragm is not sufficient to dampen more pronounced engine movement. Fluid is forced from the upper chamber to the lower chamber, equalizing the pressure. This gives the hydraulic mounting a progressive damping action, resulting in increased resistance with increased load.