Injectors (206)

| Injectors (206) |

| To remove |

|

||||||||||||||||||||||

| Important | ||

|

Be particulary observant regardning cleanliness when working on the fuel system. Loss of function may occur due to very small particles. Prevent dirt and grime from entering the fuel system by cleaning the connections and plugging pipes and lines during disassembly. Use 82 92 948 Plugs, A/C system assembly. Keep components free from contaminants during storage. |

||

| 1. |

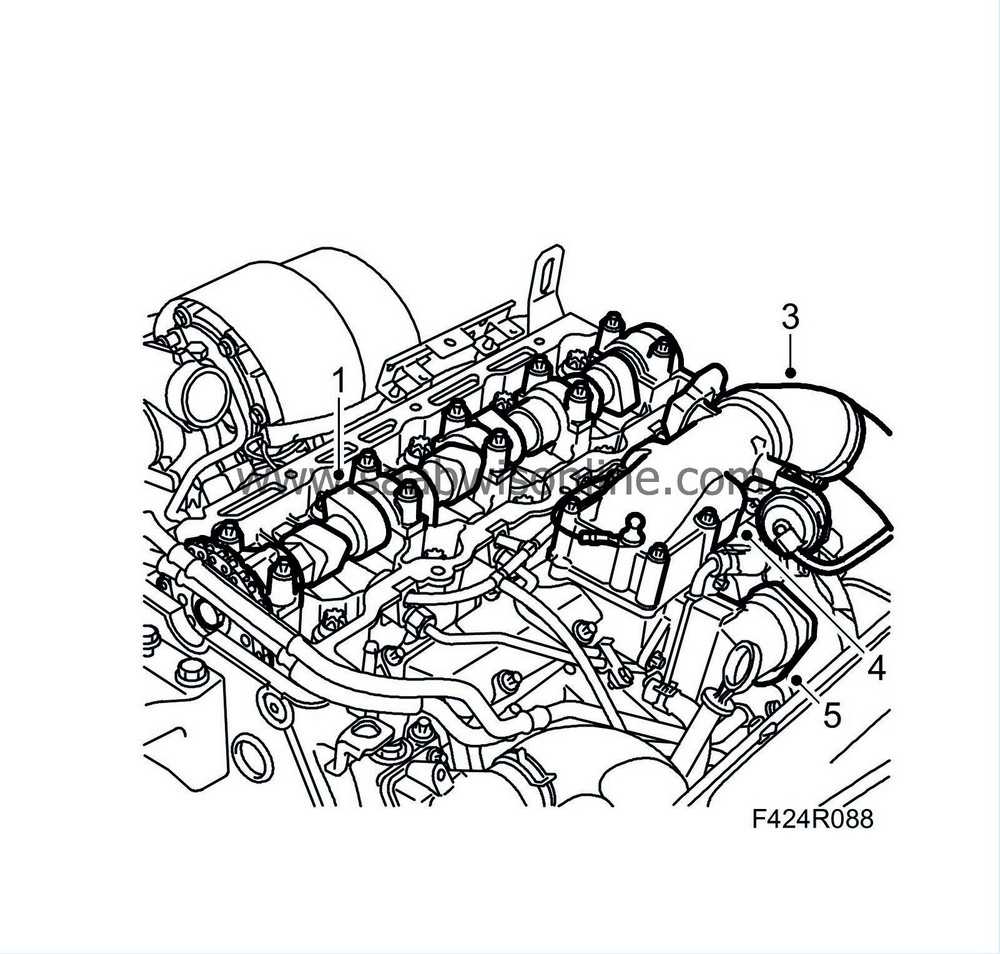

Remove the camshaft. Refer to

Camshaft

.

|

|

| 2. |

Mop up the oil from the cylinder head.

|

|

| 3. |

Remove the turbo delivery pipe and hose from the throttle body and move them aside. Plug the pipe and the inlet.

|

|

| 4. |

Remove the cut-off valve vacuum hose. Remove the throttle body.

|

|

| 5. |

Unplug and remove the EGR valve from the intake manifold and move it to one side.

|

|

| 6. |

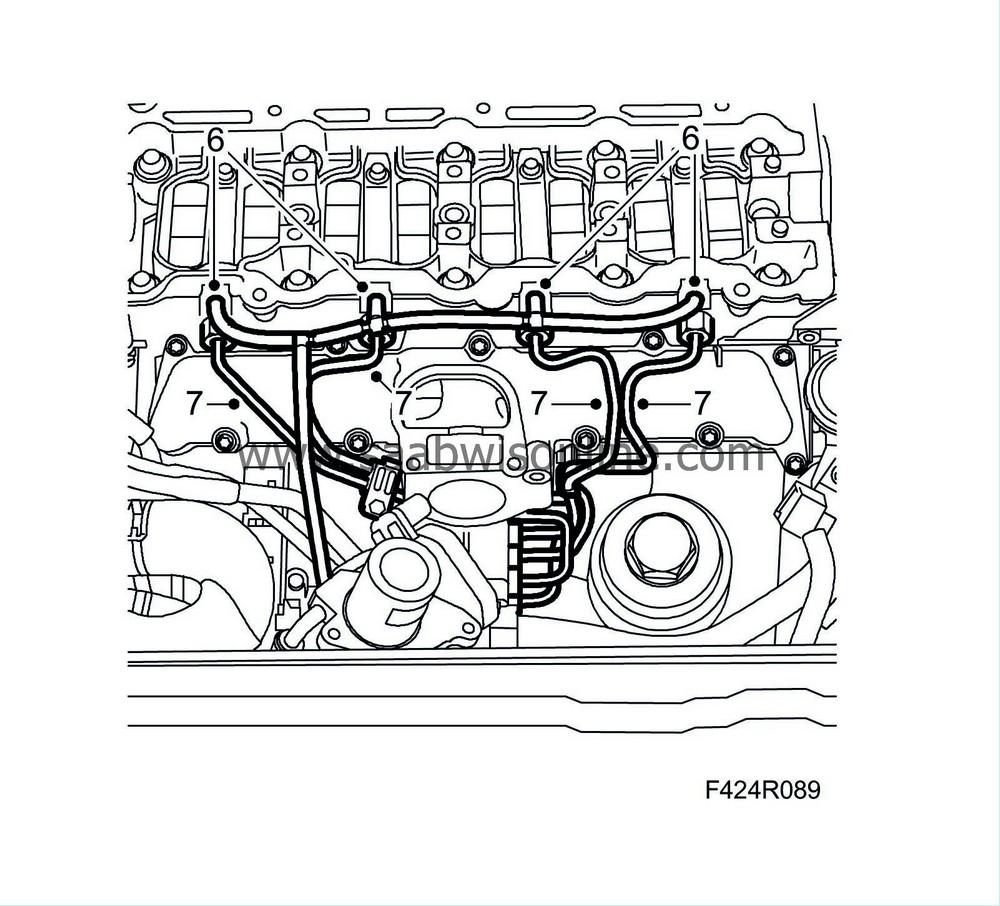

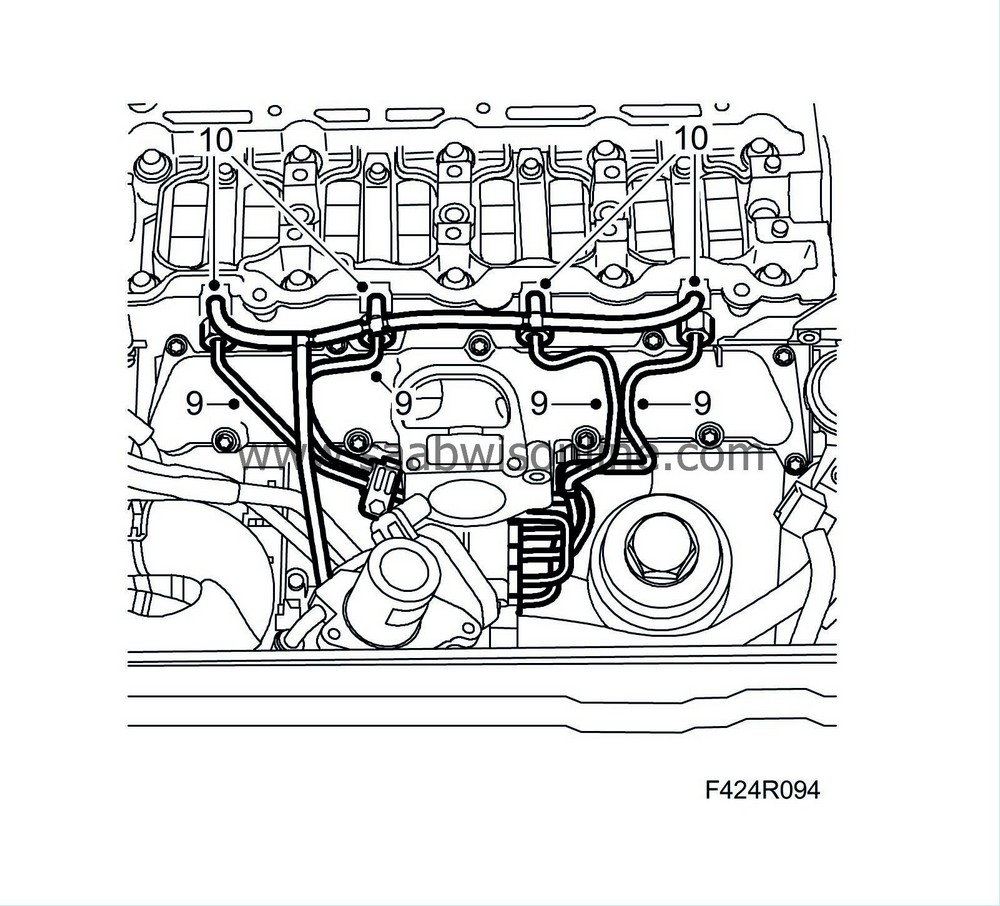

Remove the fuel return hoses from the fuel bridges.

|

|

| 7. |

Mark the position of the fuel distribution pipes and clamps and remove the pipes.

|

|

| 8. |

Remove the upper part of the intake manifold and seal the intakes.

|

|

| 9. |

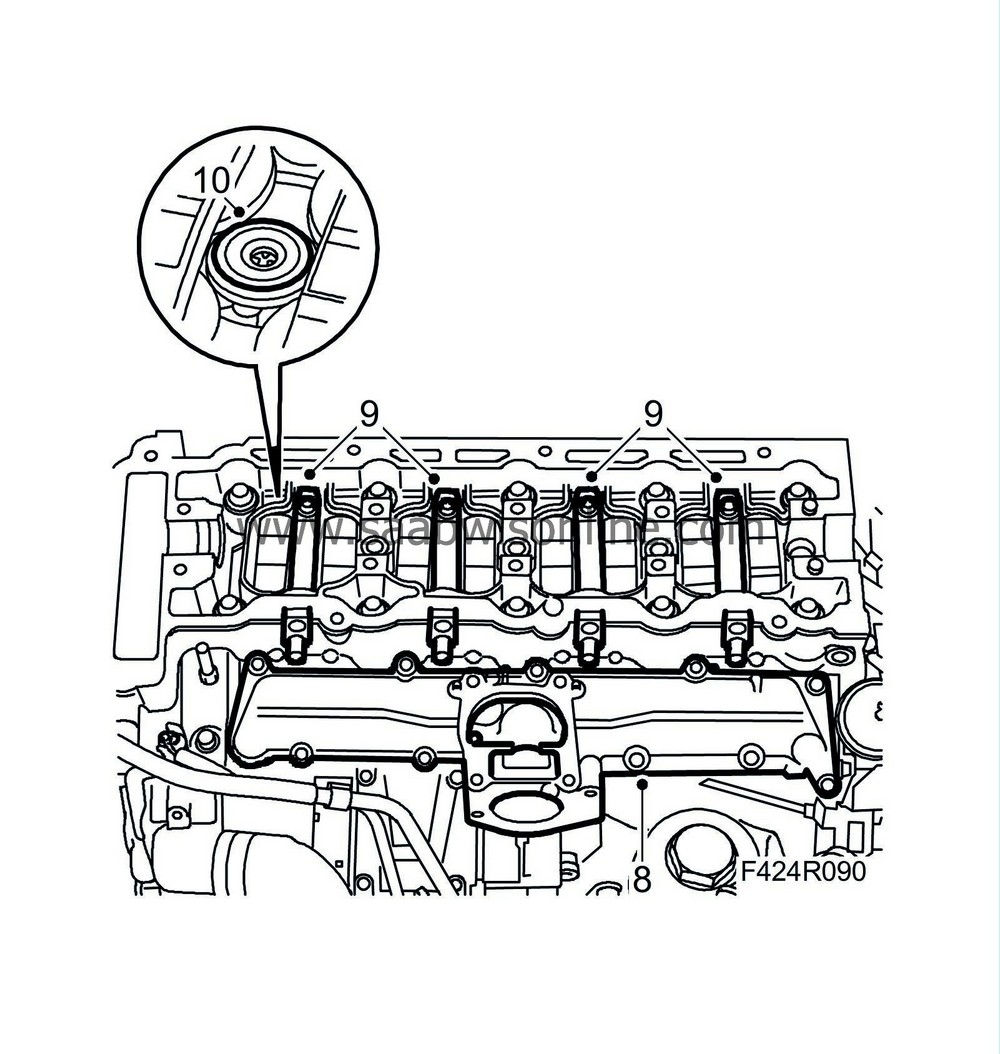

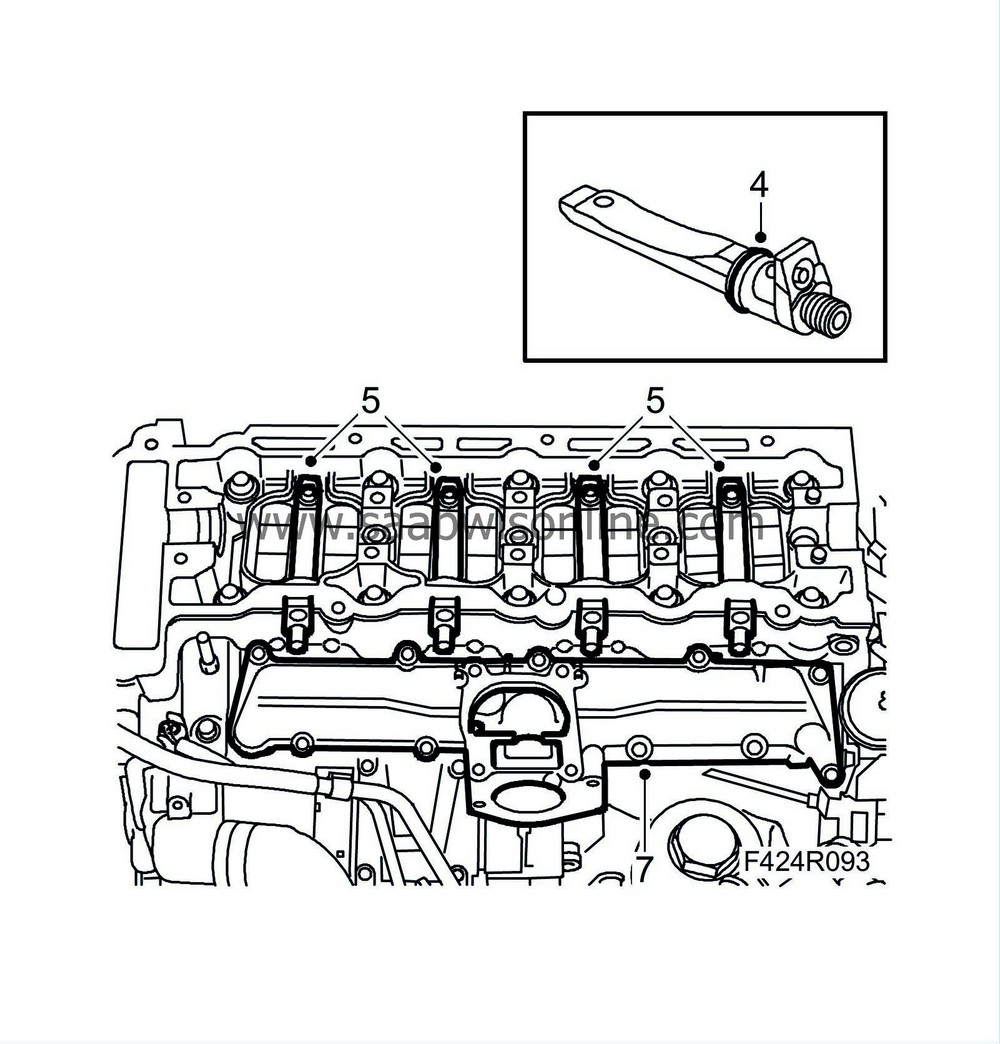

Remove the bolts securing the fuel bridges. Lift and withdraw the fuel bridges from the cylinder head.

|

|

| 10. |

Remove the rubber seals from the injectors.

|

|

| 11. |

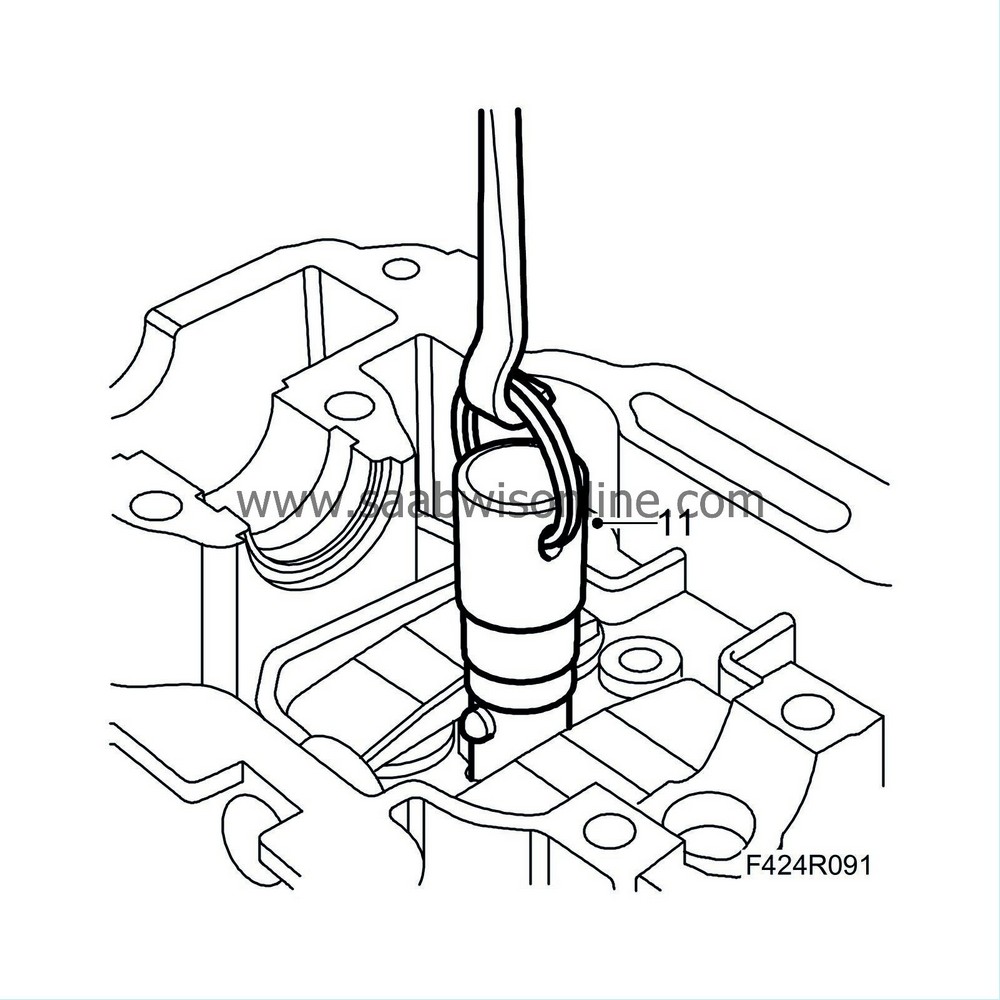

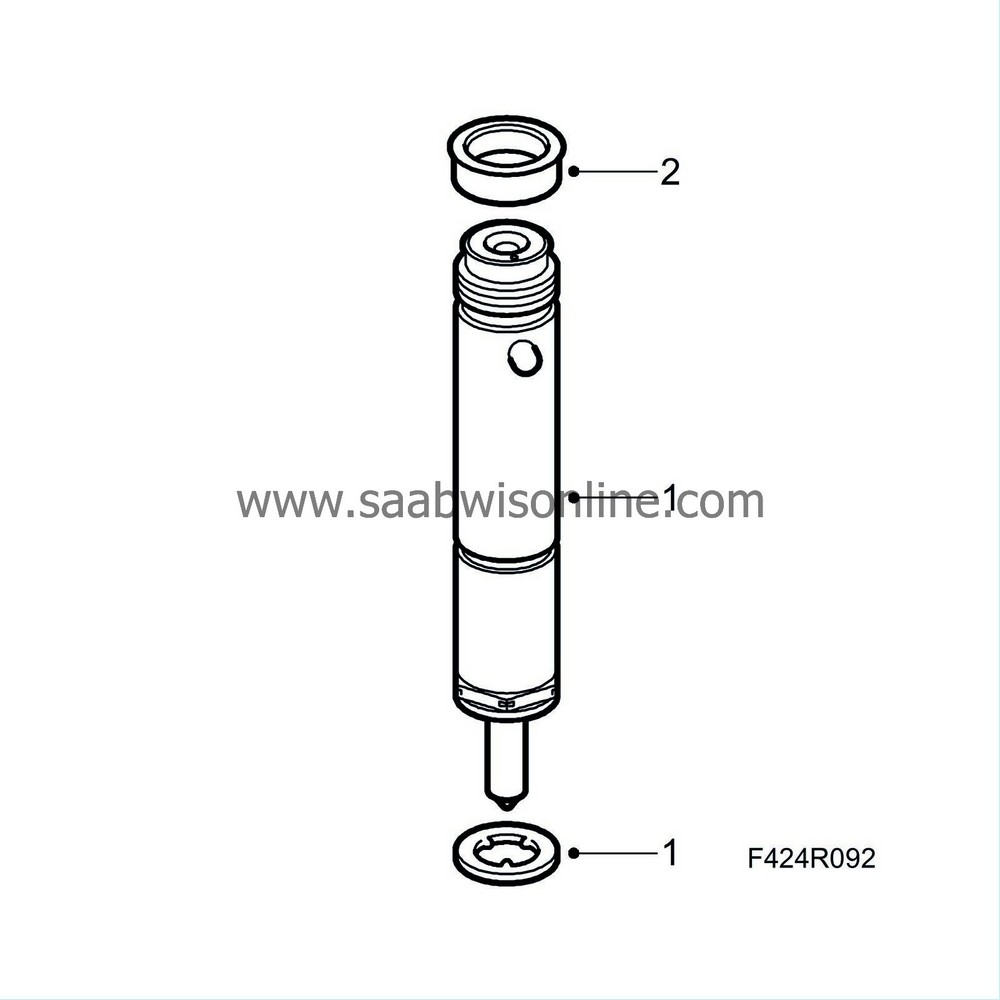

Bolt

83 95 378 Removal tool, injectors

onto the injectors and remove them.

|

|

| 12. |

Remove the seals from the injectors.

|

|

| To fit |

| 1. |

Fit new seal washers to the injectors and fit the injectors.

|

|

| 2. |

Fit new seals to the connections between the injectors and fuel bridges. Remove any remains of old seals.

|

|

| 3. |

Blow the bolt holes for the fuel bridges clean.

|

|

| 4. |

Fit new O-rings to the fuel bridges. Lubricate the O-rings with acid-free vaseline and carefully insert the fuel bridges into the cylinder head.

|

|

| 5. |

Tighten the fuel bridge bolts.

Tightening torque 5 Nm + 360° (4 lbf ft + 360°) |

|

| 6. |

Clean the sealing surfaces.

|

|

| 7. |

Place a new gasket on the lower part of the intake manifold and fit the upper part of the intake manifold.

Tightening torque 10 Nm (7 lbf ft) |

|

| 8. |

Check the fuel distribution pipes' connecting cones and replace if necessary.

|

|

| 9. |

Fit the fuel distribution pipes to their original positions with the clamps.

Tightening torque 25 Nm (18 lbf ft). |

|

| 10. |

Fit new fuel return hoses. Check the condition of the T-pieces and change if necessary.

|

|

| 11. |

Connect the fuel return hoses to the fuel bridges. Disconnect the fuel return hose from the fuel pump and connect

83 93 514 Boost pressure gauge

to the hose. Create a negative pressure of 750 mbar and wait 1 minute. Check that the indicator on the tool has not moved.

If you detect a leak, check each fuel bridge in turn. Connect the pressure/vacuum pump in turn to the fuel return connection on each fuel bridge, not the return hose. If the fuel bridges are OK, check the fuel return hoses and the T-piece. The hoses should be supple and not cracked or damaged in any way. If there are indications of a leak, change all the fuel return hoses and T-pieces. If the leak originates in a fuel bridge, remove the bridge, change the seal and refit the bridge. Recheck the system for leaks. |

|

| 12. |

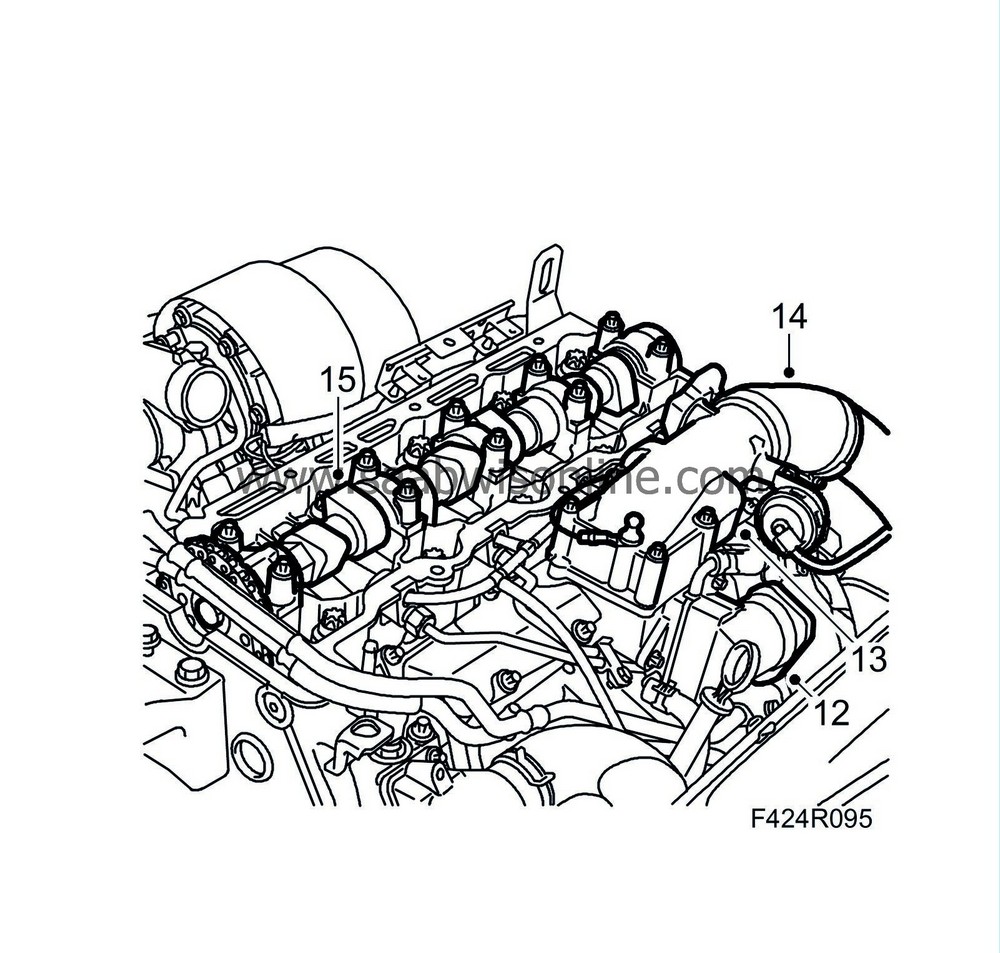

Fit the EGR valve with a new O-ring. Plug in the EGR valve's connector.

|

|

| 13. |

Fit the throttle body with a new seal. Connect the vacuum hose to the cut-off valve.

Tightening torque 10 Nm (7 lbf ft) |

|

| 14. |

Fit the turbo delivery pipe and hose to the throttle body.

|

|

| 15. |

Fit the camshaft, see

Camshaft

.

|

|

Warning

Warning