Checking and adjusting basic charge pressure, B207

|

|

Checking and adjusting basic charge pressure, B207

|

|

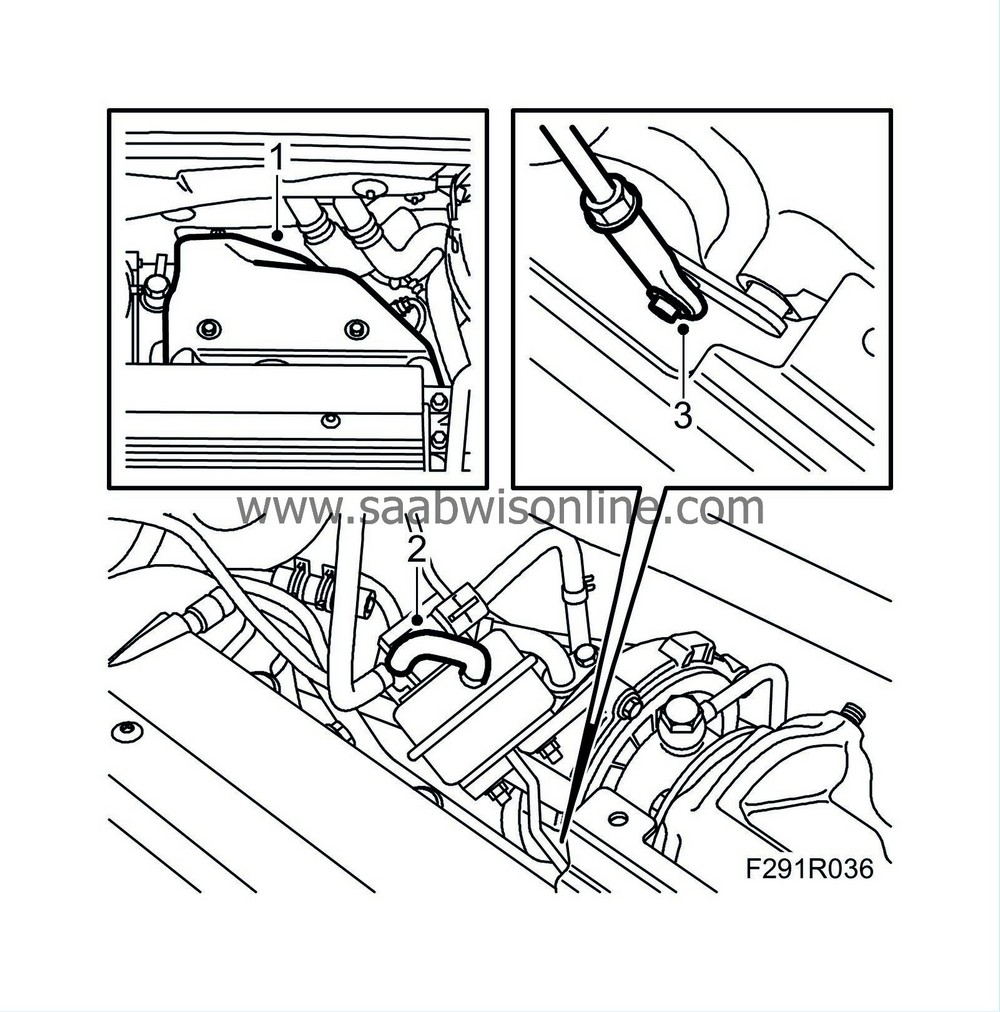

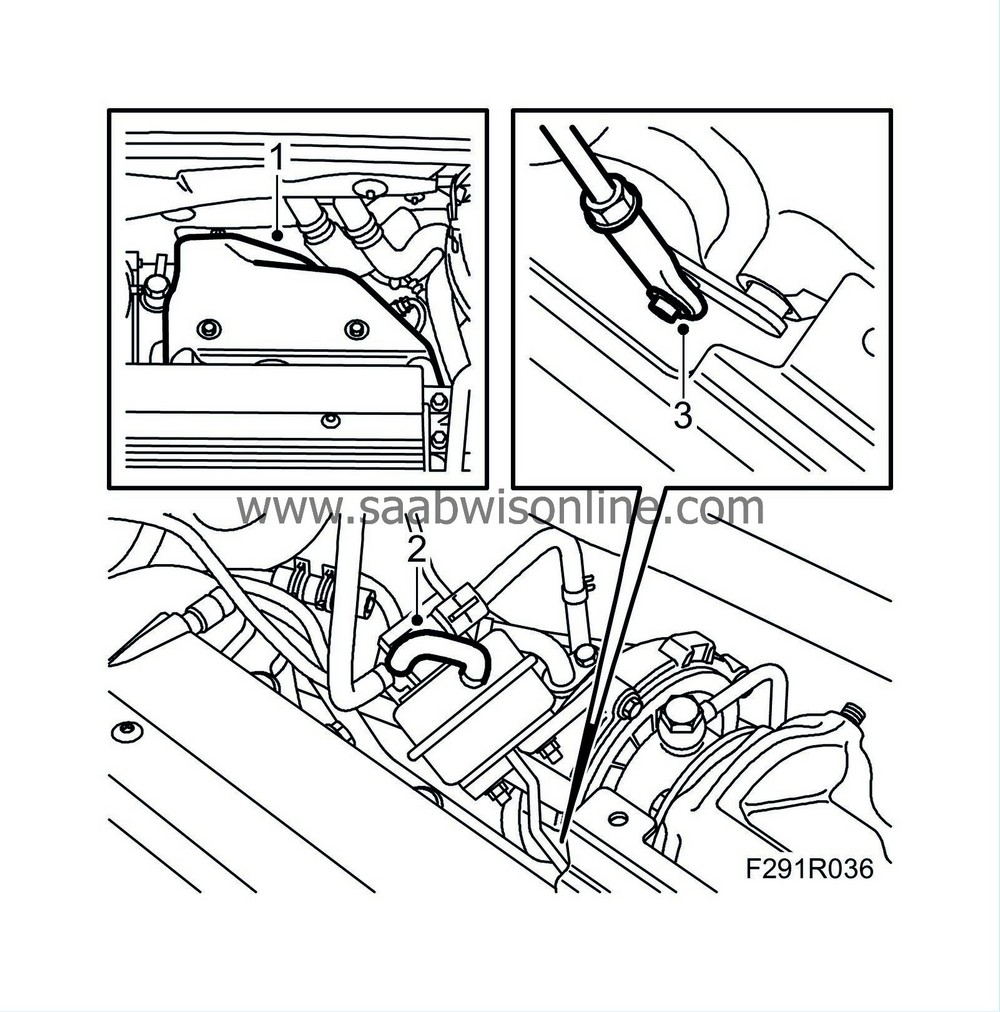

1.

|

Remove the turbo heat shield by undoing the bolts and pulling the shield straight up out of the clip on the back.

|

|

2.

|

Detach the hose from the diaphragm box.

|

|

3.

|

Remove the control arm retaining clip with 83 94 538 Circlip tool.

|

|

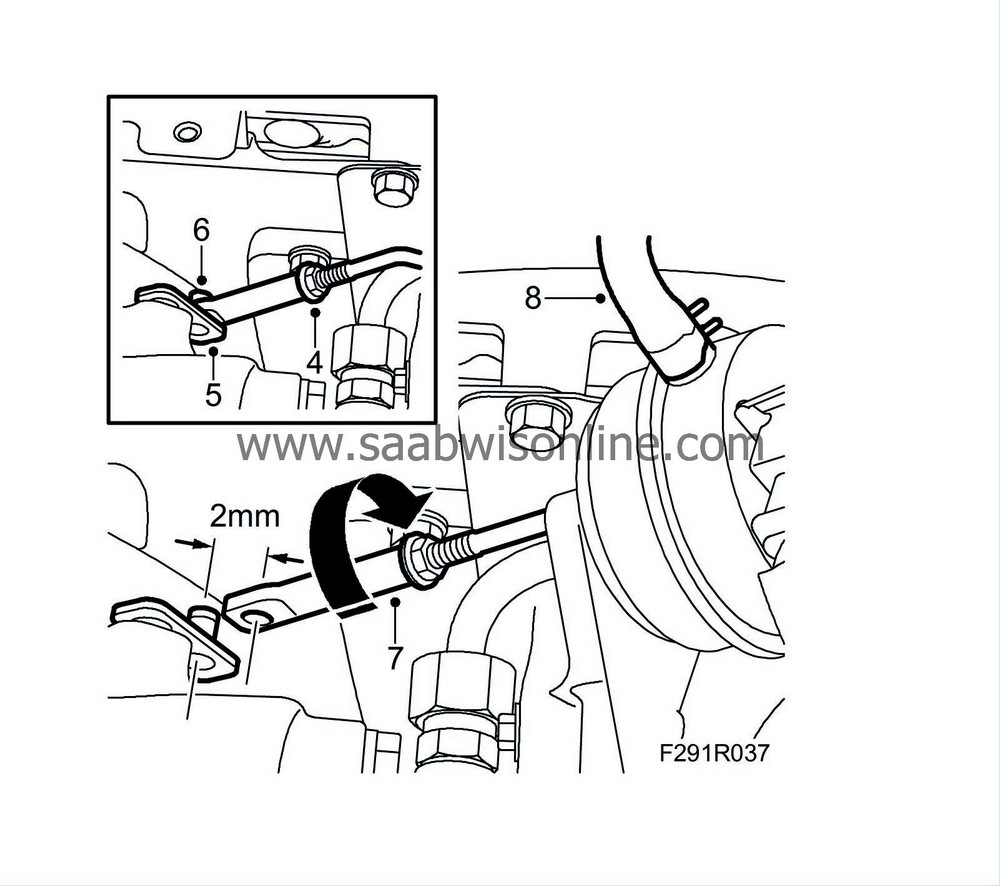

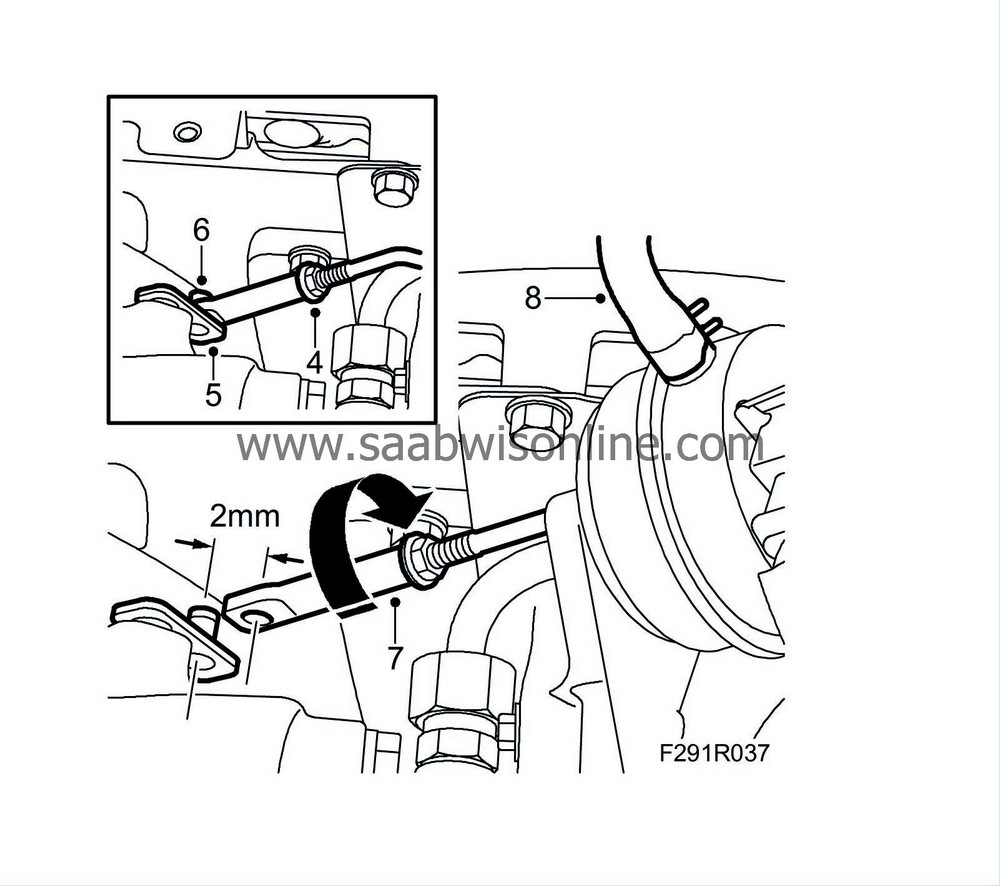

4.

|

Grip the pushrod with

83 94 066 Pliers

or similar tool and undo the nut.

B207R:

Use a pair of flat nose pliers and a screwdriver.

|

|

5.

|

Hold the operating arm and remove the pushrod from it. Secure the operating arm as it might otherwise "overcentre".

|

|

6.

|

Move the control arm on the wastegate to the "Closed" position and adjust the end piece so that the pushrod can easily be fitted on the control arm pin.

|

|

7.

|

Detach the pushrod from the control arm pin. Turn the end piece clockwise about 2 turns to attain a tension of 2 mm. Hook the pushrod to the control arm pin.

|

|

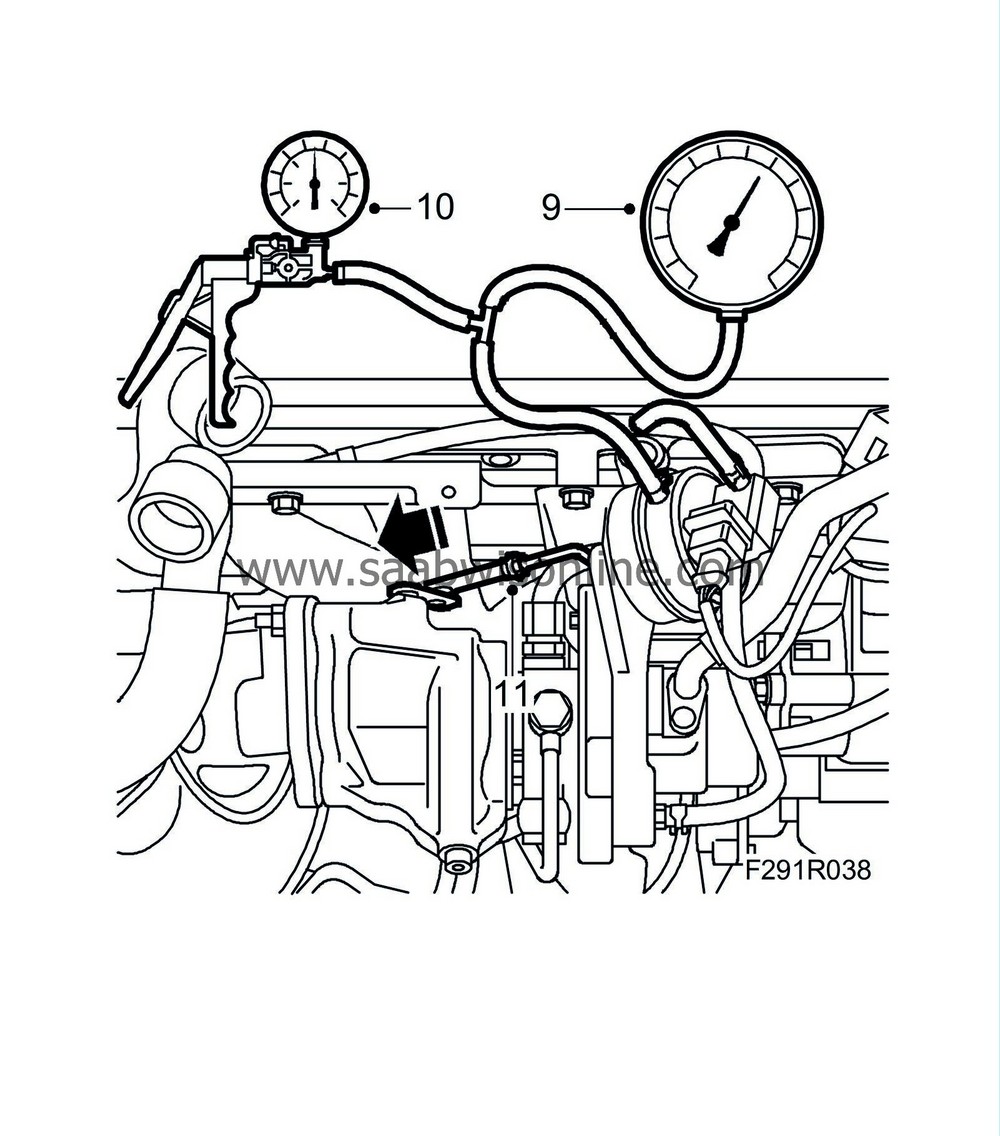

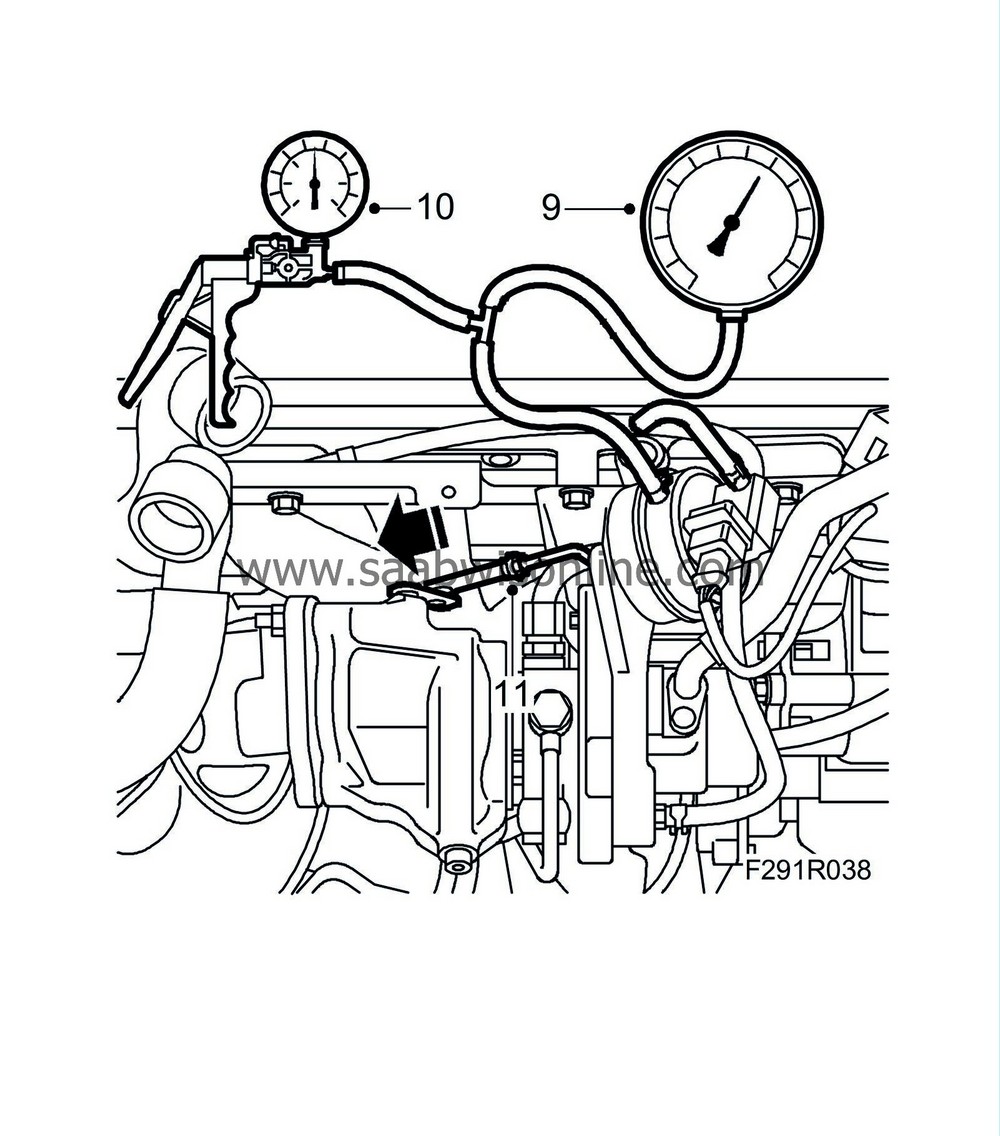

9.

|

Pump up the pressure carefully and read off the pressure on the pressure gauge just as the control rod starts to move (approx. 1 mm). The pressure should be 0.25 - 0.27 bar.

|

|

10.

|

If the pressure is too low, shorten the rod until the correct pressure is obtained.

|

|

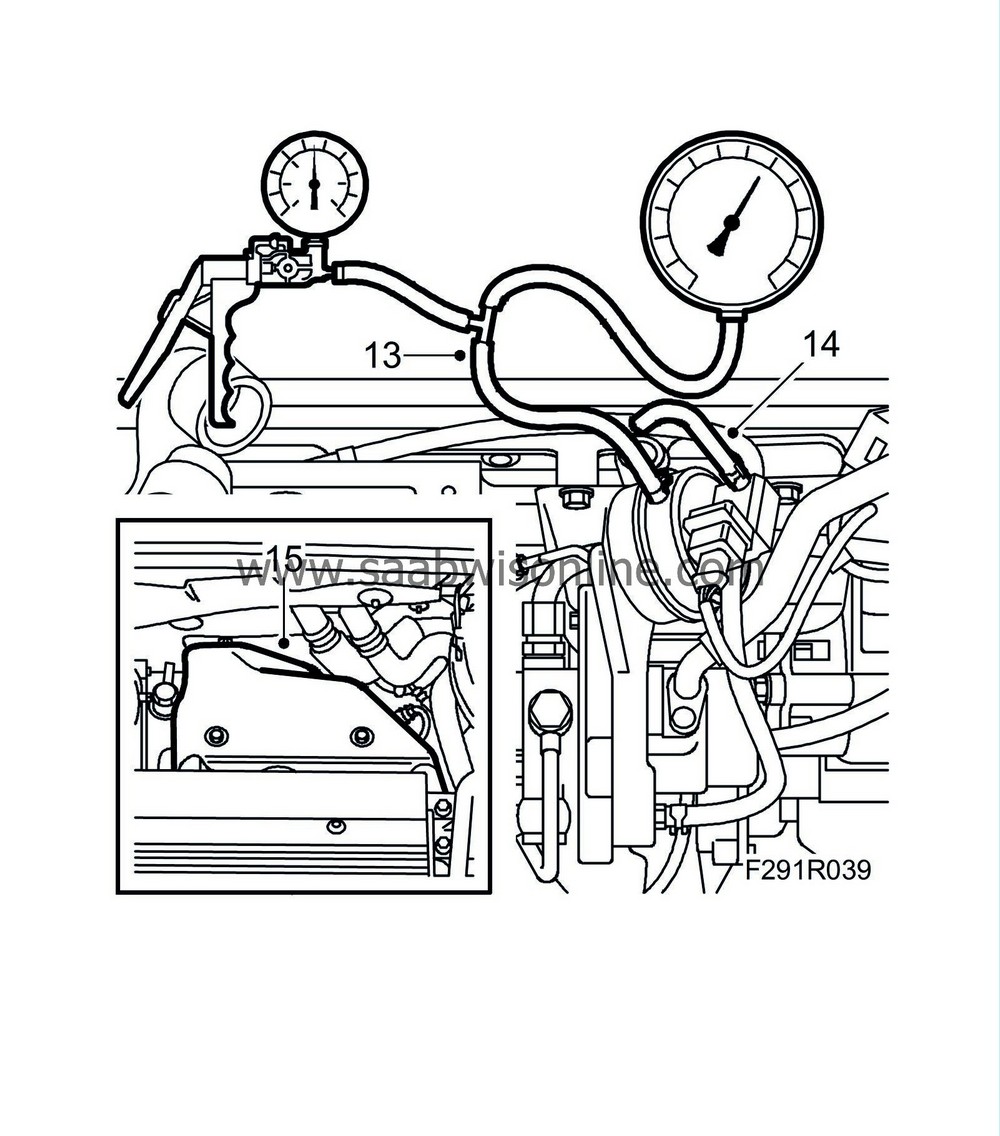

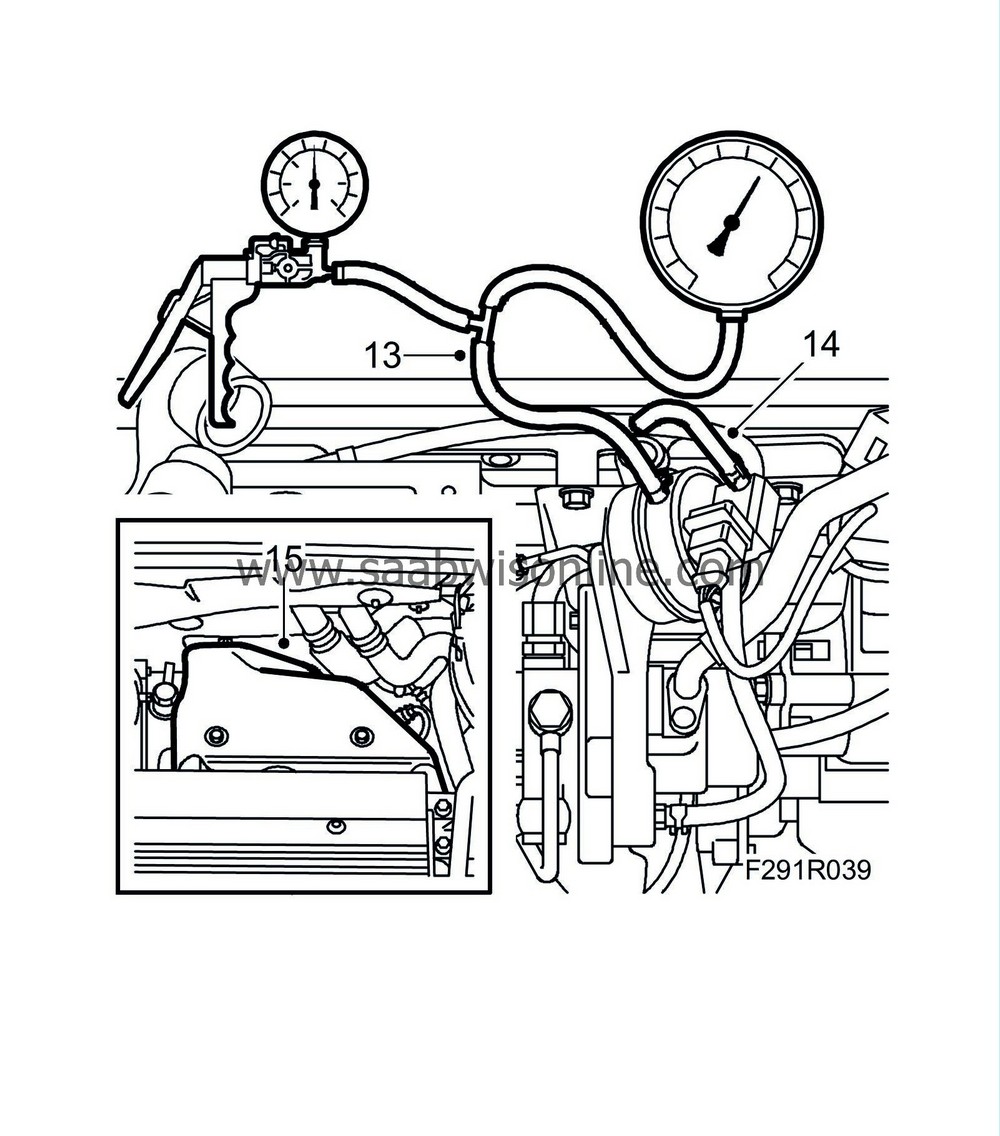

12.

|

Fit the control rod and clip, grip the control rod and lock the nut.

|

|

13.

|

Remove the pressure gauge and pump.

|

|

14.

|

Refit the hose to the diaphragm box.

|

|

15.

|

Fit the turbocharger heat shield.

|

|

16.

|

Carry out charge air adaptation:

16 a. Run the car to heat up the engine.

16 b. Accelerate full throttle at 2000 rpm a few times. The time the engine speed is in the range 2000-4000 rpm must exceed 2 seconds.

|

Note

|

|

Charge air adaptation must be carried out in as high a gear as possible. If charge air adaptation is not carried out, the customer must be made aware that engine torque may fluctuate slightly the first few times during hard acceleration.

|

|