Subframe

| Subframe |

| To remove |

| 1. |

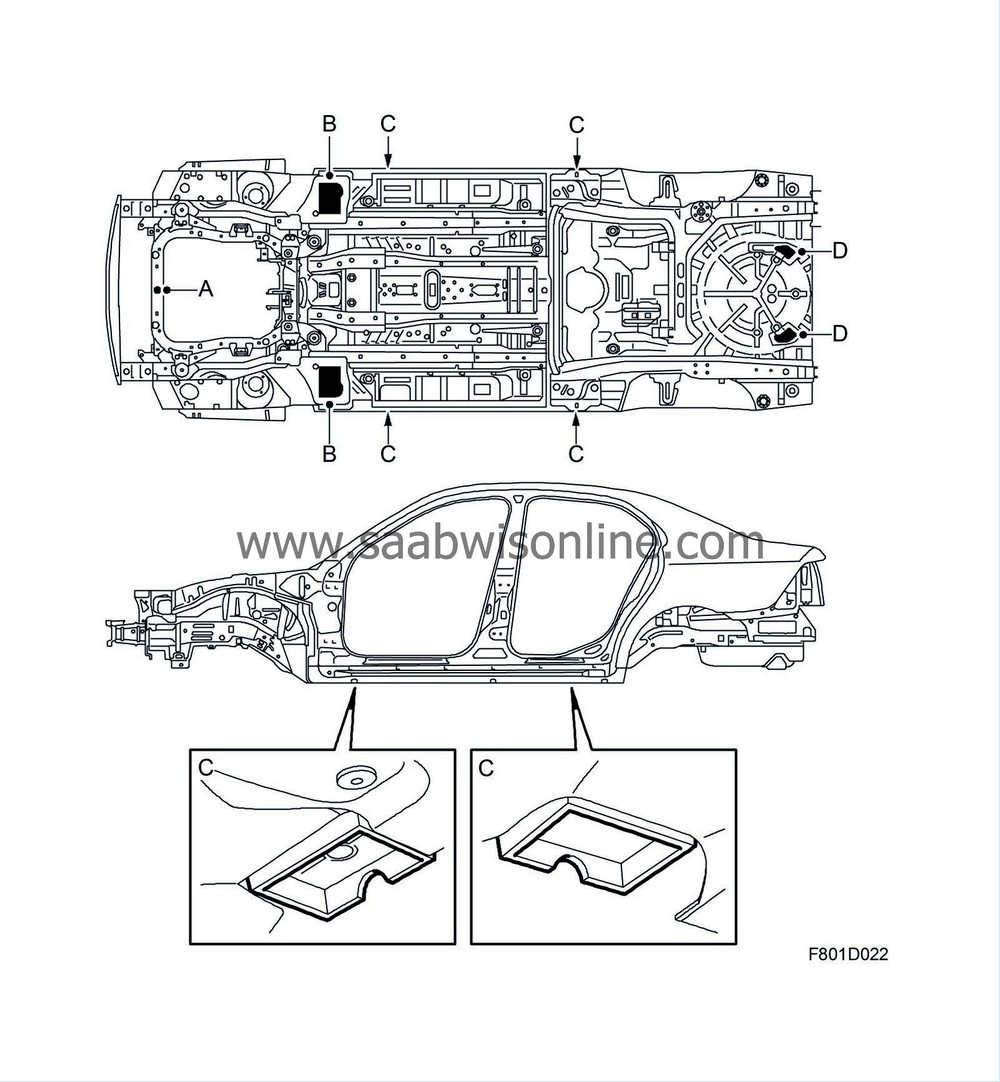

Raise the car. use the rear jacking points C and the front jacking points B, see

Jacking and attaching points

.

|

|

| 2. |

Remove the rear wheels.

|

|

| 3. |

Cars with tyre pressure monitoring:

Remove the rear RH wing liner

.

|

|

| 4. |

Remove the spring and the hydraulic bodies, remove the brake pads and suspend the hydraulic bodies on a hook in the brake hose holder on both sides.

|

|||||||

| 5. |

Remove the parking brake cables from the clamps on the longitudinal links on both sides.

|

|

| 6. |

Open the protective case and unplug the connection for the electrical circuit. Remove the wiring harness from the clip set and suspend it out of the way.

|

|

| 7. |

For cars with tyre pressure monitoring:

Remove the connector from the signal detector. Remove and twist away the wiring harness.

|

|

| 8. |

Cut the exhaust pipe 87 mm in front of the front silencer using

83 95 667 Pipe cutter/exhaust system

. Remove the exhaust system. Clean the cut section of burrs and dirt.

|

|

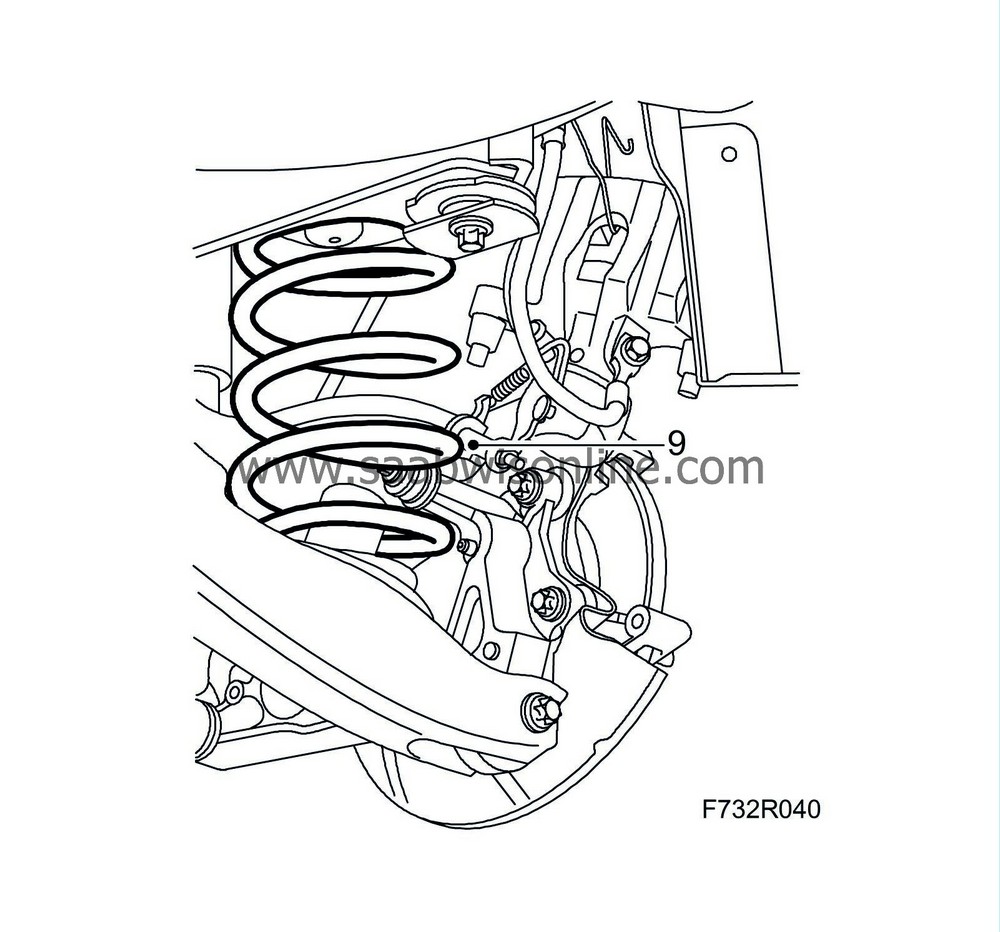

| 9. |

Compress the spring with a

88 18 791 Spring compressor

and the small jaws on one side and lift away the spring.

Change the 88 18 791 Spring compressor over to the other spring and remove it.

|

|

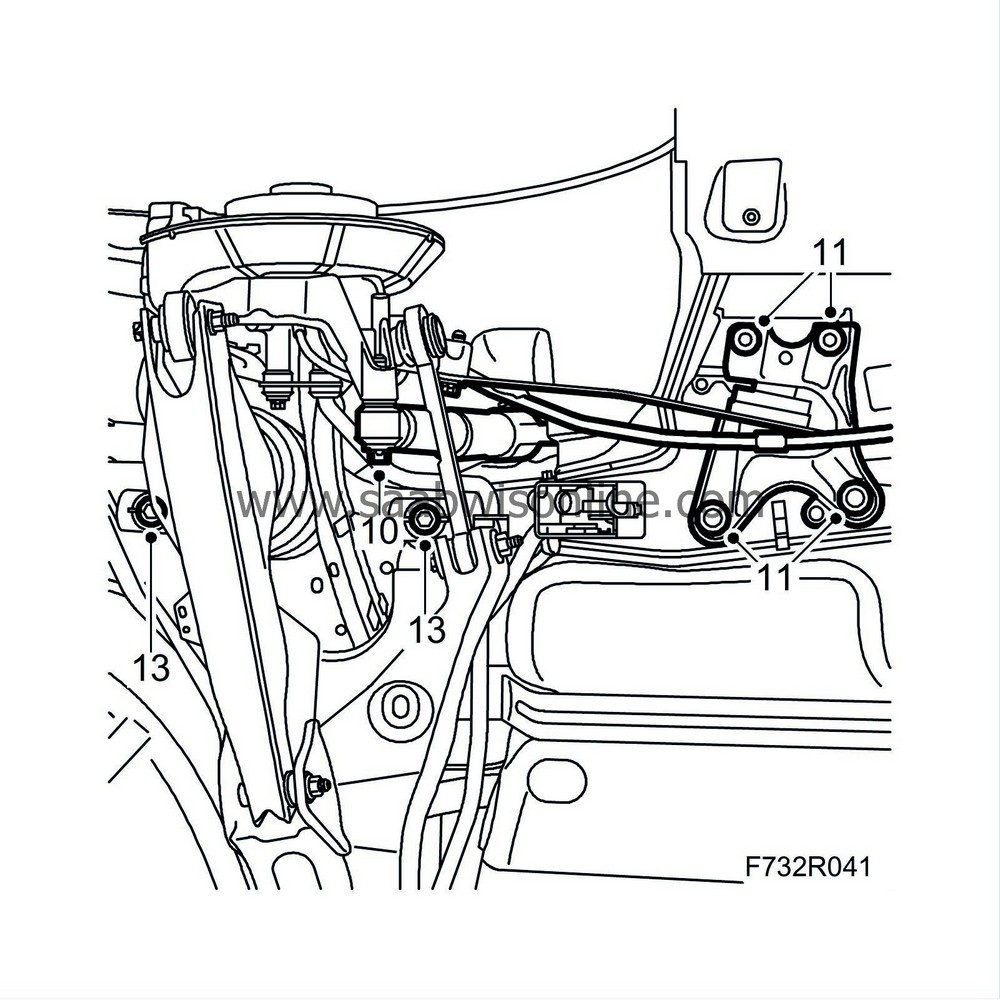

| 10. |

Clean, lubricate and remove the bolts holding the shock absorber to the steering swivel member.

|

|

| 11. |

CV:

Remove the chassis reinforcement from the rear subframe

.

Remove the front longitudinal link attachments. |

|

| 12. |

Position the

83 95 311 Trolley lift

underneath with

89 96 944 Jig, rear subframe

.

|

|

| 13. |

Remove the bolts holding the subframe to the body.

|

|

| 14. |

Remove the parking brake cables from their brackets in the body.

|

|

| 15. |

Make sure that the parking brake cables and the cable network allow the longitudinal link to move freely and lower the trolley lift with the subframe.

|

|

| To fit |

| 1. |

Lift the subframe with the

83 95 311 Trolley lift

and

89 96 944 Jig, rear subframe

.

|

|

| 2. |

Lift the subframe so that the inner sections of the bushes are pressing against the body. Fit the subframe bolts on both sides.

Tightening torque 75 Nm +135° (55 lbf ft +135°)

|

|

| 3. |

Fit the longitudinal links and brackets for the parking brake cables to the body.

Tightening torque 70 Nm +90° (52 lbf ft +90°) |

|

| 4. |

Lower and pull away the trolley lift.

|

|

| 5. |

Fit the parking brake cables into their brackets.

|

|

| 6. |

Cars with tyre pressure monitoring:

Fit the wiring harness and plug in the connector for the signal detector.

|

|

| 7. |

Connect and fit the wiring harness into the protective case and close the lid.

|

|

| 8. |

Fit the shock absorbers to the steering swivel members.

Tightening torque 150 Nm (110 lbf ft)

|

|||||||

| 9. |

Fit the spring supports to the spring.

|

|

| 11. |

Fit the exhaust system and fit a splice (see EPC).

Tightening torque 40 Nm (30 lbf ft) |

|

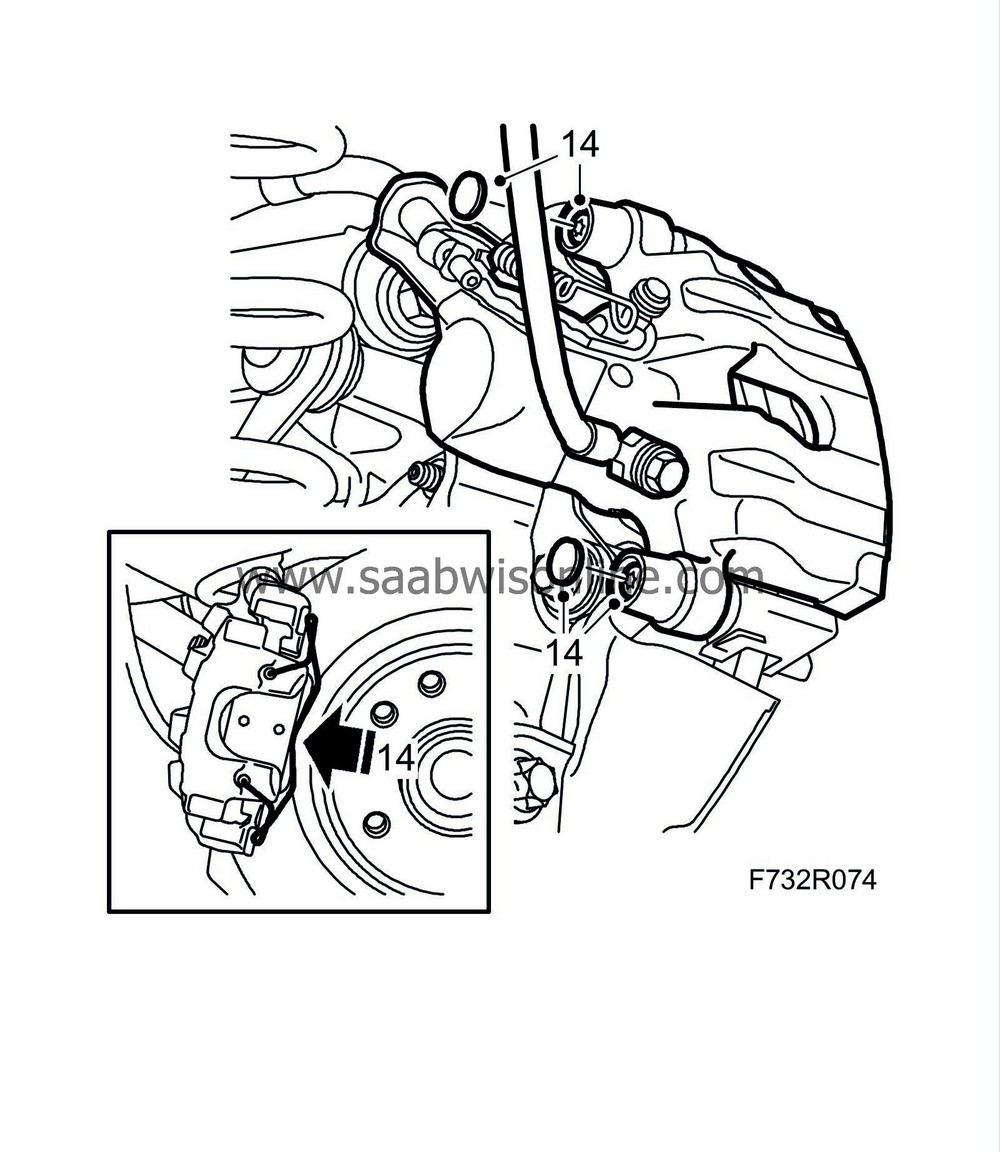

| 12. |

Remove the inner brake pad and screw in the brake piston using

89 96 969 Resetting tool

and

89 96 977 Adapter

.

|

|

| 13. |

Fit the brake pads.

|

|||||||

| 14. |

Fit the hydraulic body.

Tightening torque 28 Nm (21 lbf ft) Fit the protective covers. Fit the spring to the brake caliper.

|

|

| 15. |

Repeat steps 12-14 on the other side.

|

|

| 16. |

Cars with tyre pressure monitoring:

Fit the wing liner

.

|

|

| 17. |

Fit the wheels

.

|

|

| 18. |

Repeat the steps 11-15 for the other side of the car.

|

|

| 19. |

Lower the car to the floor.

|

|

| 20. |

Depress the brake pedal several times to press out the self adjustment of the brake pistons and the parking brake.

|

|