Tyre pressure monitoring, TPMS, detailed description

| Tyre pressure monitoring, TPMS, detailed description |

| General |

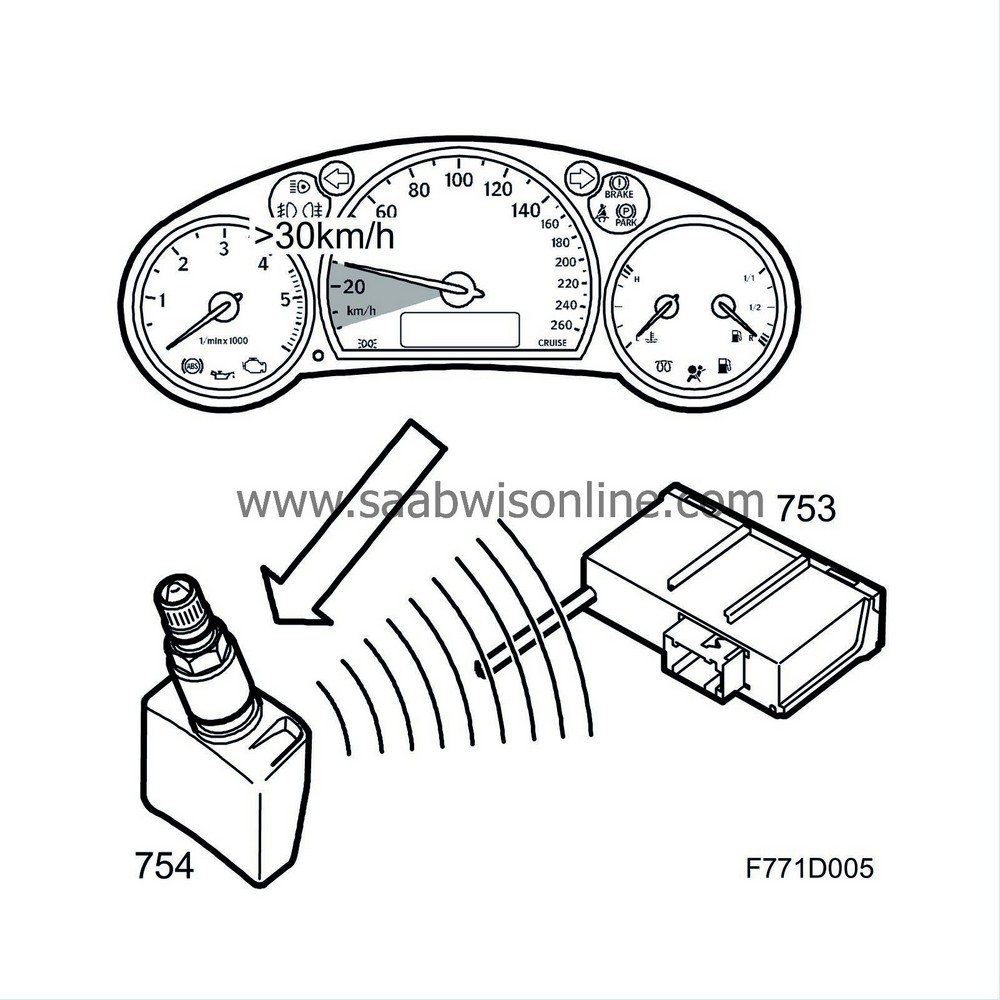

Automatic tyre monitoring informs the driver if the tyre pressure in one of the tyres falls when the speed of the car is above 30 km/h. The control module uses bus information on the vehicle speed and outside temperature. The control module is calibrated for a nominal tyre pressure and warns the driver with a warning message in SID if the pressure falls 0.3 bar below the nominal pressure.

| Condition |

The system operates in three main conditions:

| • |

Active condition

The system becomes active when the speed of the car rises above 30 km/h. This means that the tyre pressure is monitored. If a value deviates from the tyre pressure limits the control module outputs a warning or alarm message. The information is sent on the I-bus and is used by ICM. |

|

| • |

Resting condition.

The system runs to resting condition if the speed of the car falls below 30 km/h. All units are active under resting condition, which lasts for 30 seconds. The tyre pressure sensors transmit despite the centrifugal switches not being activated. The tyre pressure information is updated during this period. |

|

| • |

Closed condition

The system runs to closed condition if the speed of the car is lower than 30 km/h for 30 seconds. The control module is supplied with current and the signal detectors communicate. The tyre pressure sensors do not transmit and information on tyre pressure is not updated. |

|

| Messages |

Tyre pressure monitoring can display a warning message or an alarm message for each tyre. The message indicates how serious the fault is and the tyre in question. A system fault message can also be displayed.

The warning messages are cleared and removed from SID using the Clear button on the instrument panel. The message will be displayed at the next ignition activation, if the fault remains. With an alarm message only the message text can be deleted while the fault symbol is displayed until the fault is dealt with.

| Text in SID | Type | Conditions |

| Tyre pressure low, left rear. Check the tyre. | Warning message. Displayed for each wheel. | If the pressure in one of the tyres is 0.3 bar below the nominal pressure. |

| Puncture left rear. Stop. | Alarm message. Displayed for each wheel. | If the pressure in one of the tyres is 0.6 bar below the nominal pressure or if the pressure falls by more than 0.3 bar per minute. |

| System fault. Contact the workshop. | Warning message | If a fault arises on a component or if a sensor is missing. |

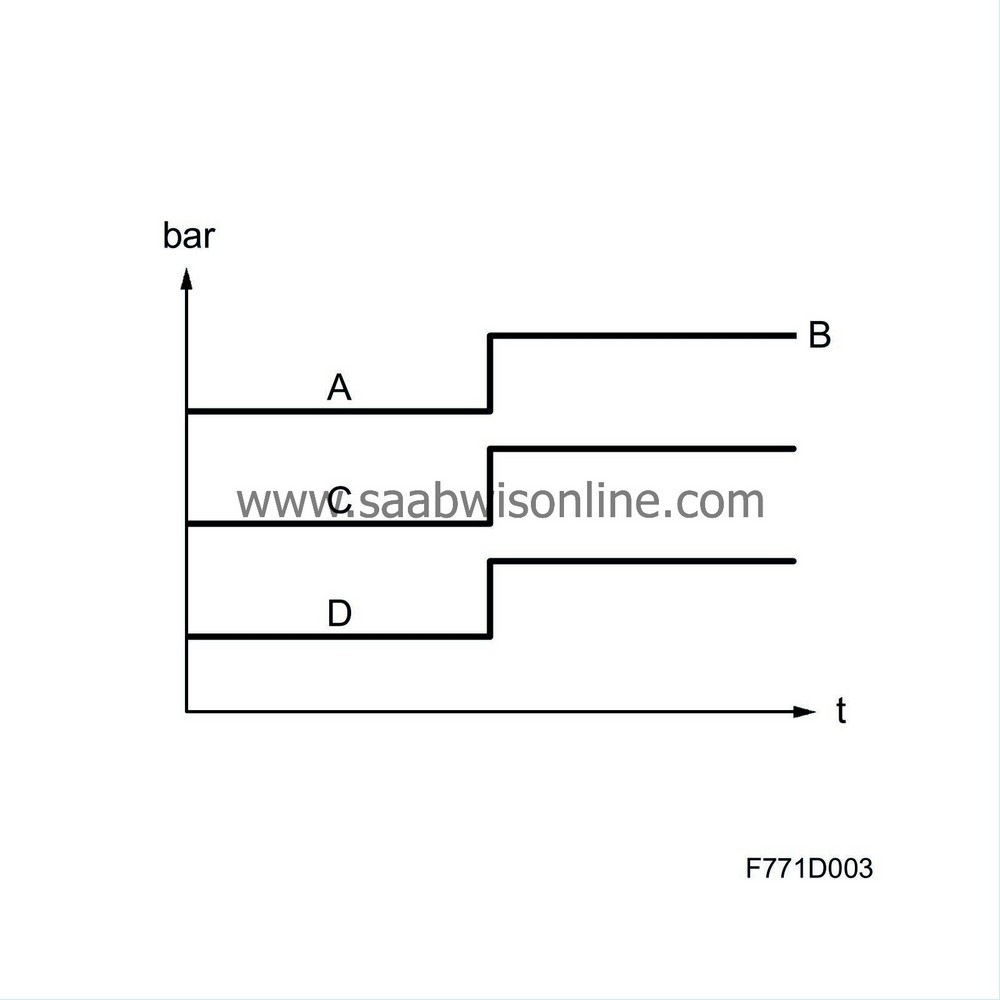

| Tyre pressure limits |

A Nominal pressure value

B Changed nominal value

C Warning level

D Alarm level

The system is programmed with a nominal tyre pressure limit, depending on which wheel and what equipment the car has. The control module corrects the nominal value by using the bus message: outside temperature from panel control module. The system is adaptive, which means that the nominal value per axle can be changed. This takes place if the pressure in the tyres is changed for driving with a heavy load or at high speed for example.

| Control module |

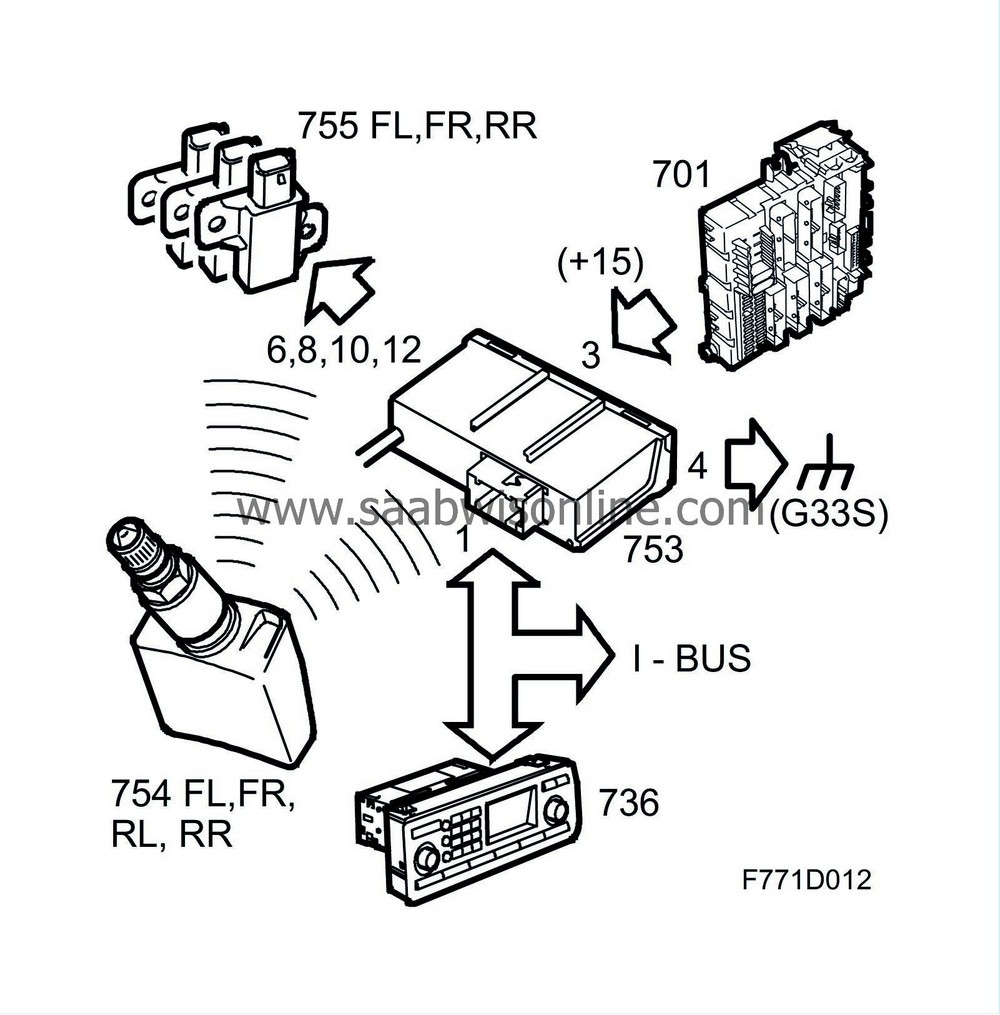

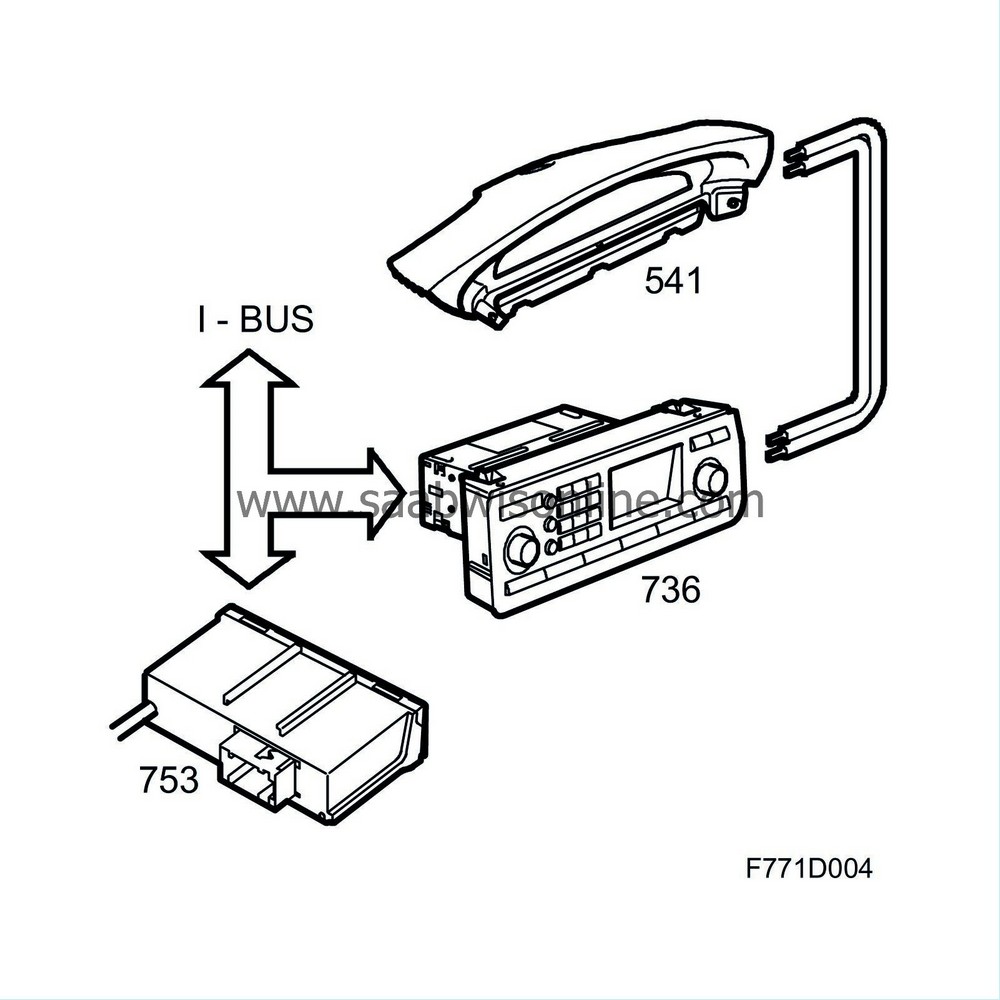

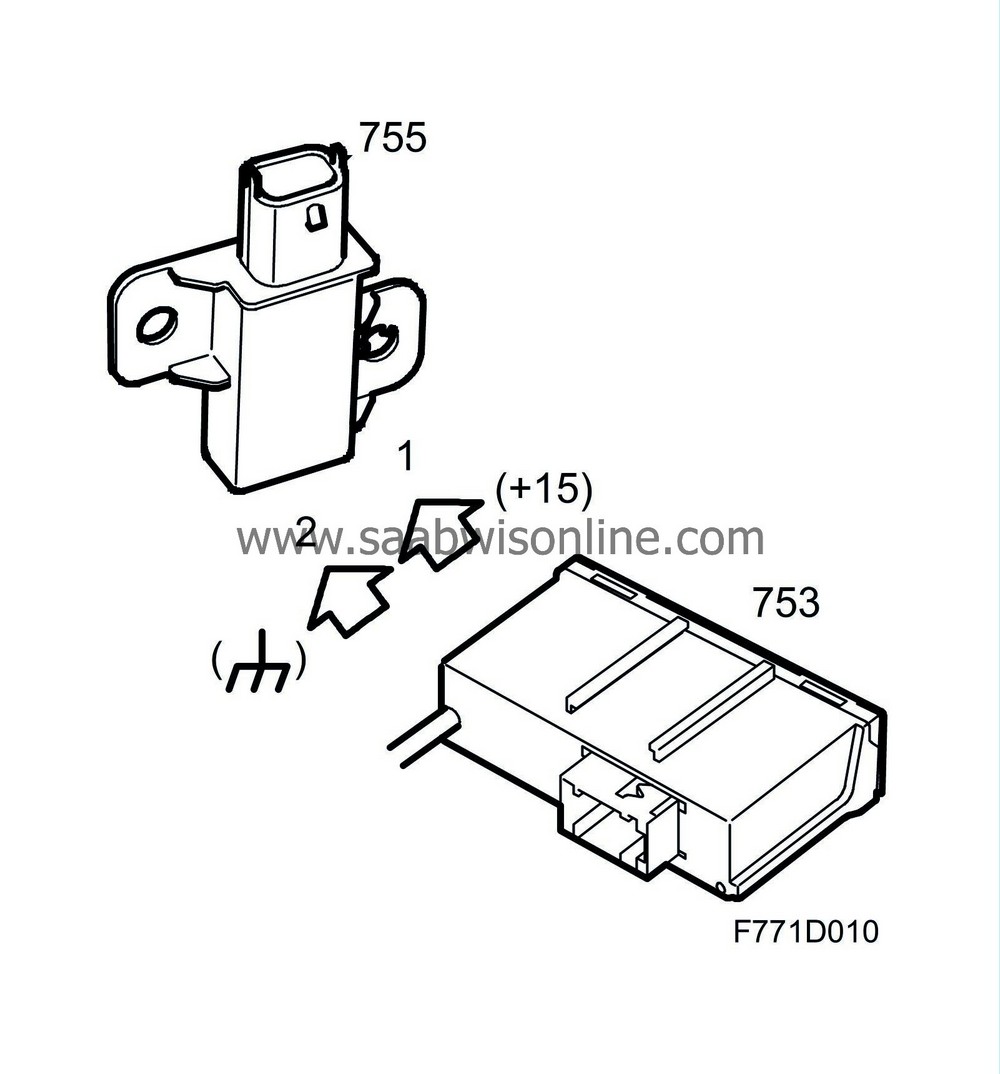

The control module is a receiver which takes in information on tyre pressure and which tyre the information applies to via radio waves from the four tyre pressure sensors, see technical data Tyre Pressure Monitoring Module (753) . It communicates with the signal detectors by cable in order to identify which tyre pressure sensor it is which is communicating.

With identified warning or alarm, the control module communicates on the I-bus. ICM loads all messages and uses this bus information to activate SID, which displays the current message.

Learning

The first period of the active condition is a programming procedure which lasts until the four wheel positions are identified. This means that the control module notices the signal detectors which register when the different tyre pressure sensors transmit. By means of this communication the control module "teaches itself" which pressure sensor applies to which wheel.The control module has saved five information blocks from each tyre pressure sensor from the latest active period and takes in fives new information blocks, of which three must be approved. This procedure normally takes approx. one minute.

A clock in the control module is activated by the bus message, vehicle speed, when the speed rises above 30 km/h, in order to guarantee that it has communication with all tyre pressure sensors within a certain time. If a fault is indicated the control module moves into diagnosis mode to establish what is wrong. This can take up to ten minutes. The signal detectors are only used during the programming procedure.

When replacing the control module or changing wheel dimension the control module must be calibrated using the diagnostic instrument.

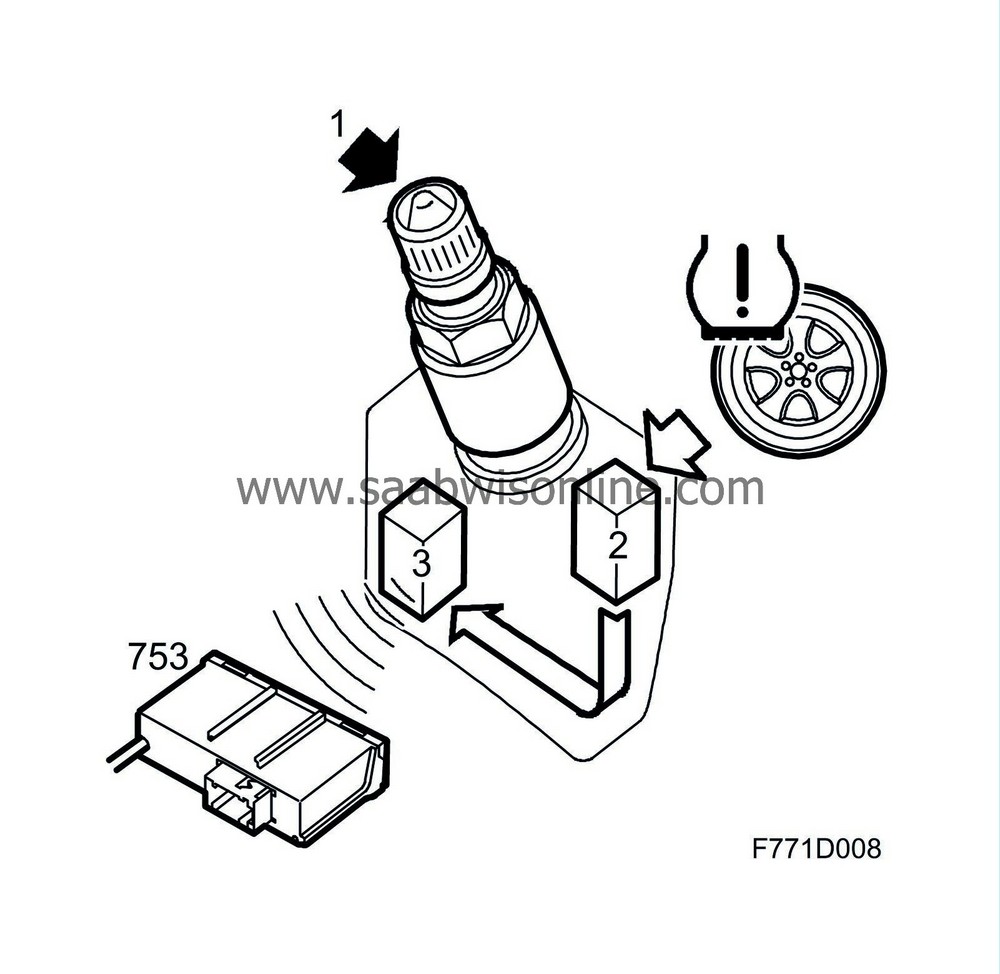

| Tyre pressure sensor |

1 Valve

2 Sensor

3 Transmitter

The tyre pressure sensor is integrated with the valve and the battery. A ball switch is activated by centrifugal force which connects the battery. This means that the wheels must turn for the system to start. In this way energy is saved and the battery's service life is around 10 years or 160,000 km.

The pressure sensor measures tyre pressure. A transponder transmits signals on a specific frequency, see technical data Pressure sensor, tyre pressure (754) . Each sensor has a unique code which is transmitted with every information block. The sensors are fitted into unique Saab wheels. During normal operation, the sensor takes a reading every 10 seconds and transmits a signal once every minute. If the pressure is reduced by more than 0.1 bar from the latest reading, a new signal is transmitted after 10 seconds.

| Signal detector |

For the signal detectors, connection with the control module is established electrically, which grounds and supplies current to the detectors. When the signal detector registers that the tyre pressure sensor transmits radio waves from the nearest wheel the signal received is amplified and filtered. The detector is supplied with 5 V current from the control module and communicates by modulating the continuous supply voltage from the control module, which means that the detectors consume more or less current. The microprocessor in the control module registers the pulse change from the detector and can determine which wheel is transmitting.