Crossmember, CV

| Crossmember, CV |

| 1. |

Position the car in an aligning bench and cross-measure if necessary.

|

|

| 2. |

Remove the

Bootlid

and

Soft top cover

.

|

|

| 3. |

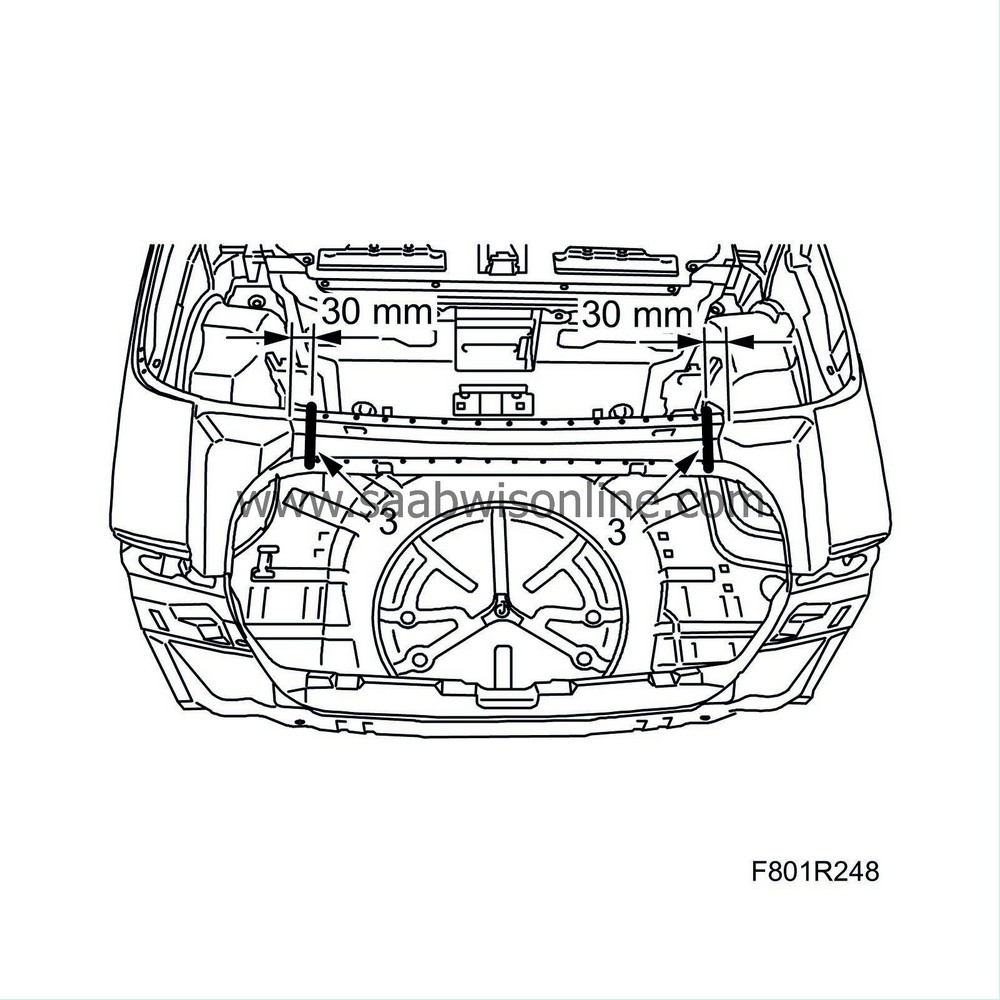

Cut the crossmember 30 mm from the outer edge of the upper panel on both sides. Lift aside the crossmember.

|

|

| 4. |

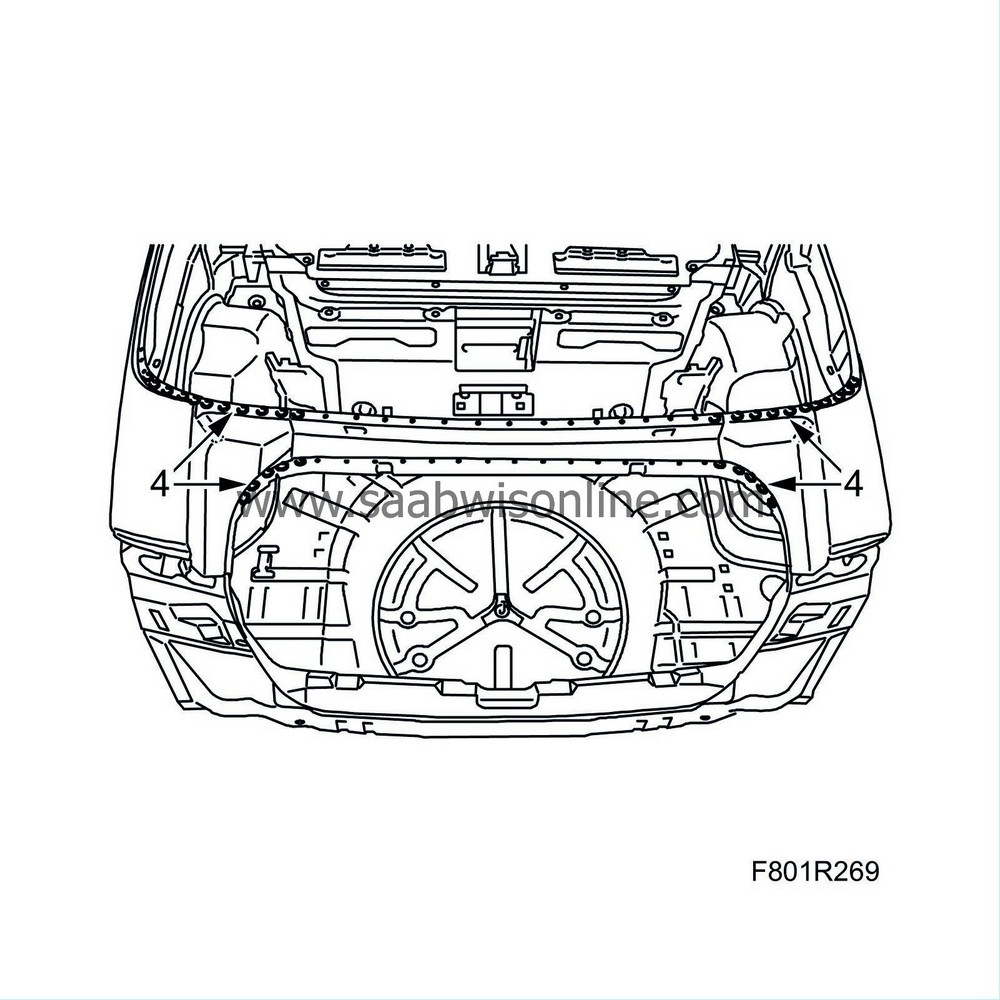

Drill out the upper spot welds to the lower crossmember panel on the relevant side.

|

|

| 5. |

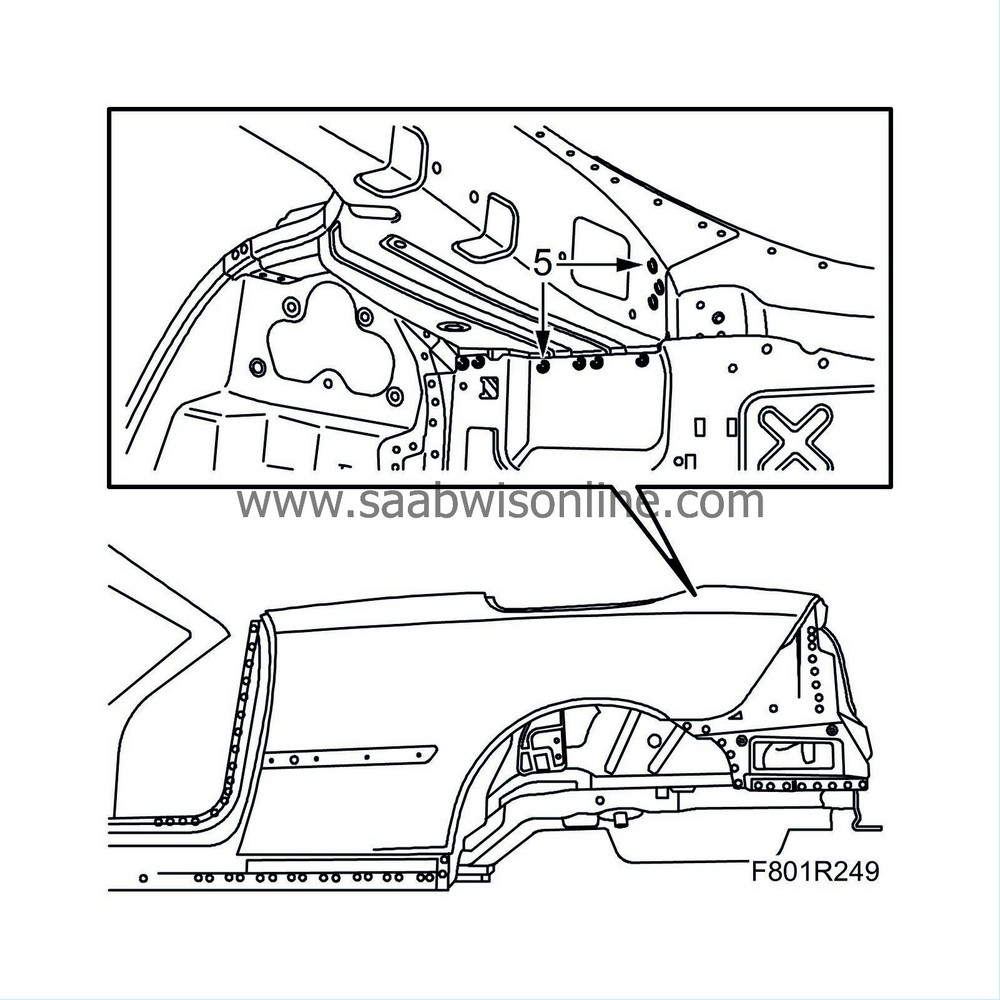

Drill out the lower spot welds to the lower crossmember panel on the relevant side.

|

|

| 6. |

Tap the lower crossmember panel loose. Align any damaged sheet metal or panels.

|

|

| 7. |

Tap both remaining sections of the upper crossmember panel loose. Align any damaged sheet metal or panels.

|

|

| 8. |

Cut the replacement panel so that it fits against the cuts previously made.

|

|

| 9. |

Apply welding primer to the surfaces to be spot and plug welded. Use Teroson Zink Spray.

|

|

| 10. |

Place the lower crossmember panel in fitting position on the body and secure it with welding clamps.

|

|

| 11. |

Position the upper section without applying adhesive. Secure with welding clamps.

|

|

| 12. |

Place some welds in the lower section to secure it. Do not weld the upper section.

|

|

| 13. |

Lift off the upper section.

|

|

| 14. |

All-weld the lower section's joint.

|

|

| 15. |

Apply welding primer to the surfaces to be spot and plug welded. Use Teroson Zink Spray.

|

|

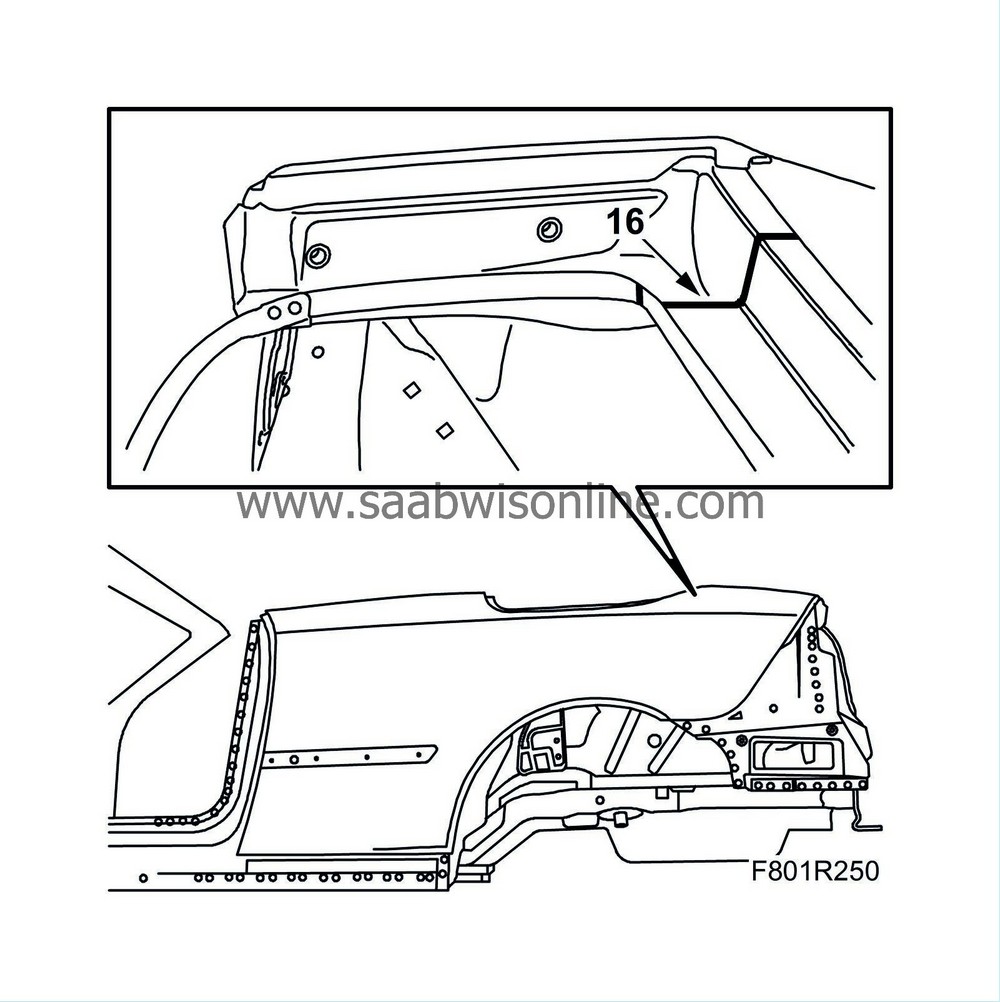

| 16. |

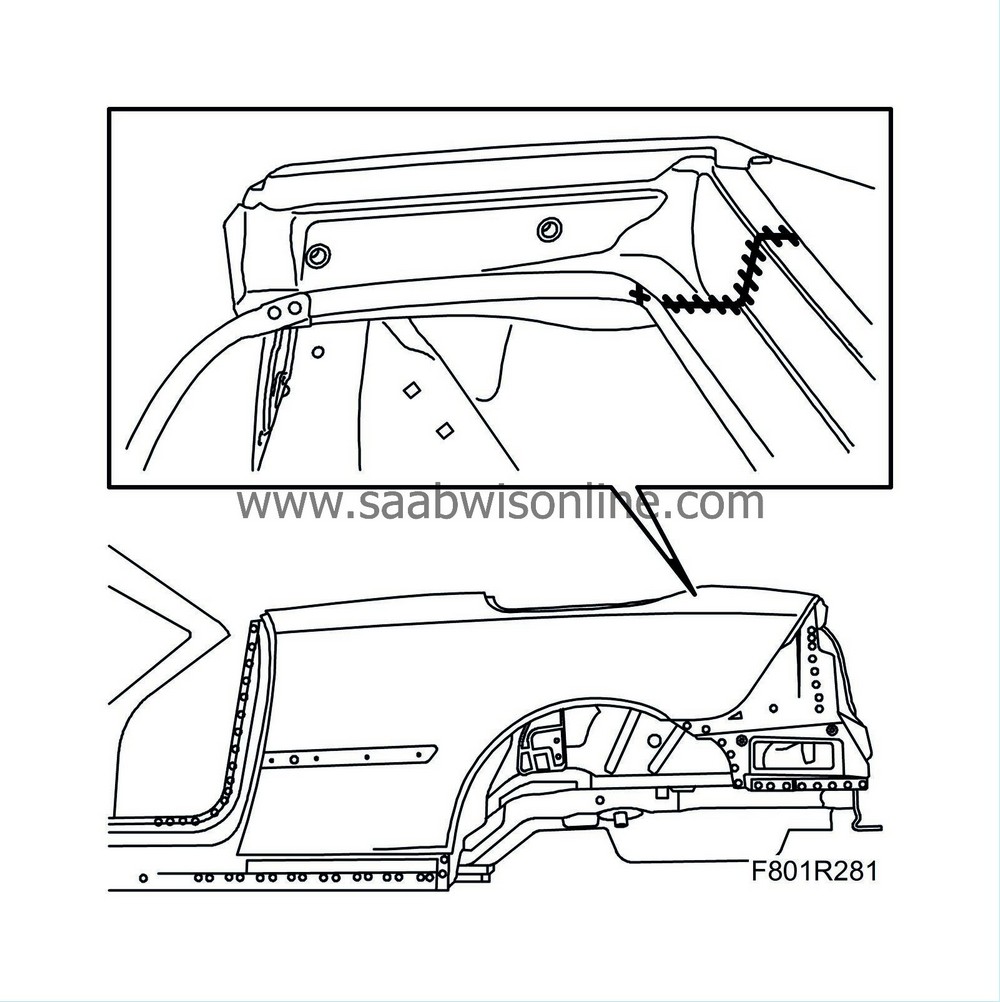

Apply body adhesive to the water ducts on both side panels. Use Teromix 6700.

|

|

| 17. |

Place the upper section in fitting position and secure it with welding clamps.

|

|

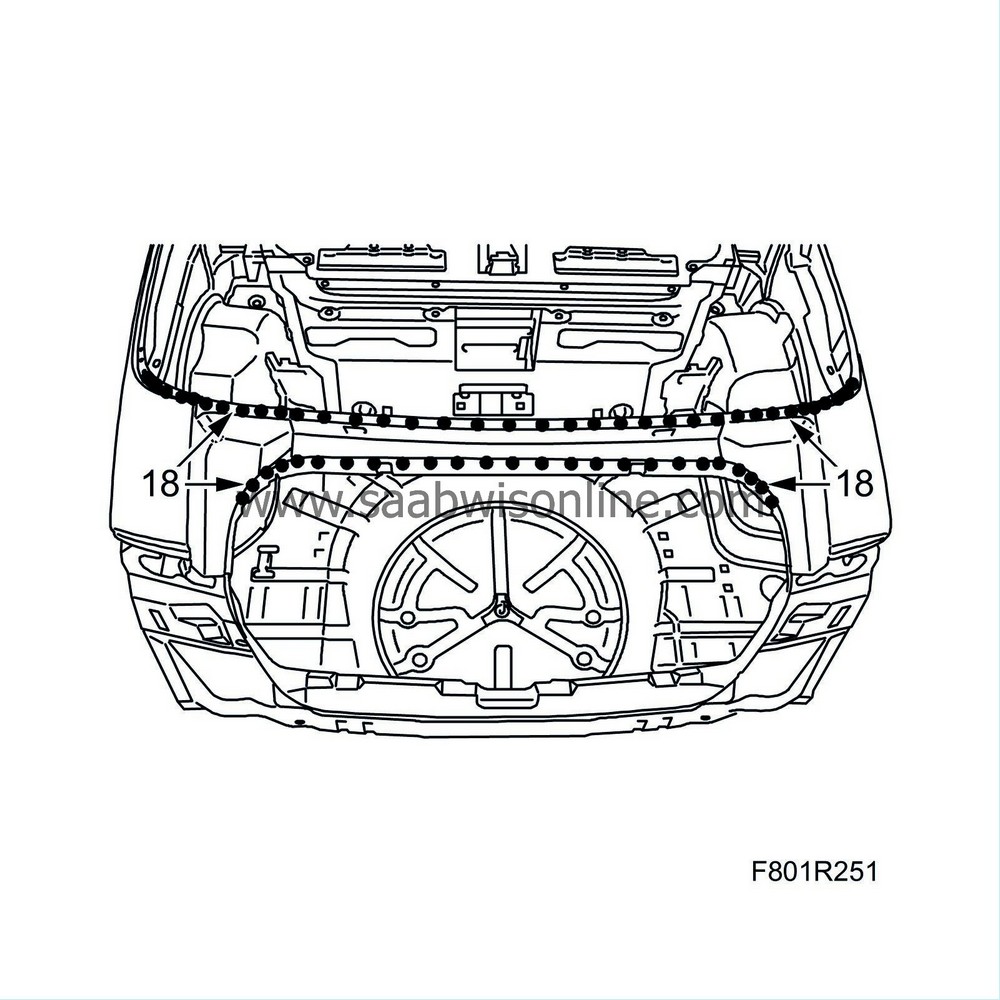

| 18. |

Spot and plug weld the upper and lower crossmember panel from the top side.

|

|

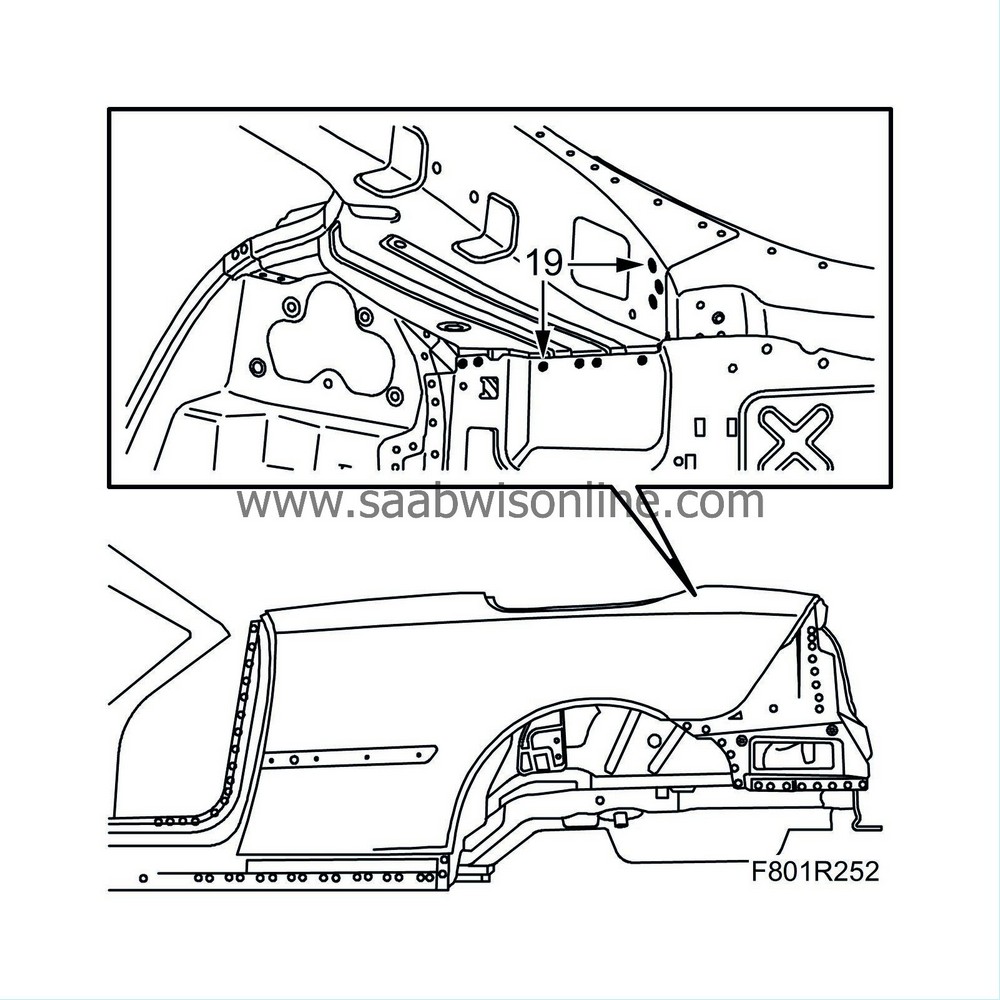

| 19. |

Spot and plug weld the lower crossmember panel on the relevant side.

|

|

| 20. |

Wash away surplus welding primer. Welding primer reduces the adhesion of paint, filler and sealant.

|

|

| 21. |

Apply primer to all bare metal surfaces. Use Standox 1K.

|

|

| 22. |

Seal joints and seams with sealant. Use 1K-PUR.

|

|

| 23. |

Apply anti-corrosion agent to internal surfaces after painting. Use Terotex HV 400.

|

|

| 24. |

Fit the

Bootlid

and

Soft top cover

.

|

|