High-pressure pump, Z19DTH

| High-pressure pump, Z19DTH |

|

||||||||||||||||||||||

|

|||||||

| Important | ||

|

Be very thorough in terms of cleanliness when working in the fuel system. Malfunctions can also occur due to very small dirt particles. Prevent dirt from entering the fuel system by cleaning the hoses and plugging the pipes and lines upon removal using 93 161 370 Plug set. Store the components so that contaminants cannot enter. |

||

| To remove |

| 1. |

Open the bonnet and place a wing cover over the right wing.

|

|

| 2. |

Remove the battery cover and the negative battery cable.

|

|

| 3. |

Remove the upper engine cover and insulation.

|

|

| 4. |

Remove

Engine pad, right

.

|

|

| 5. |

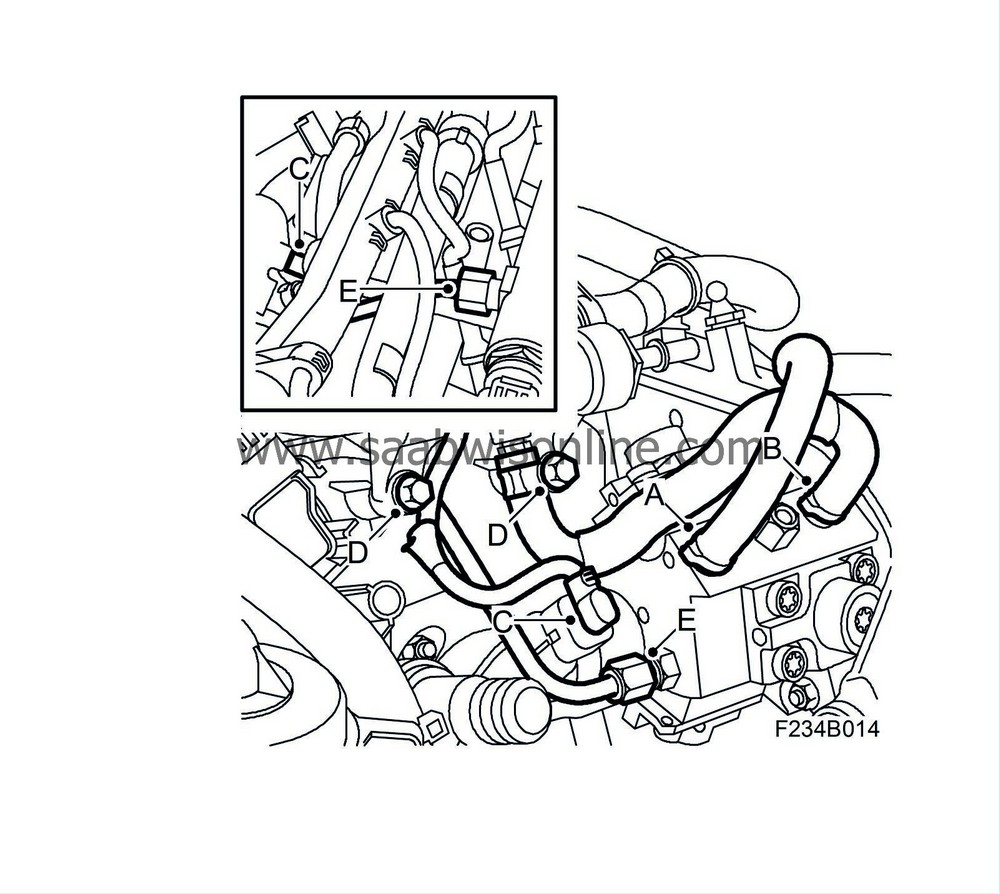

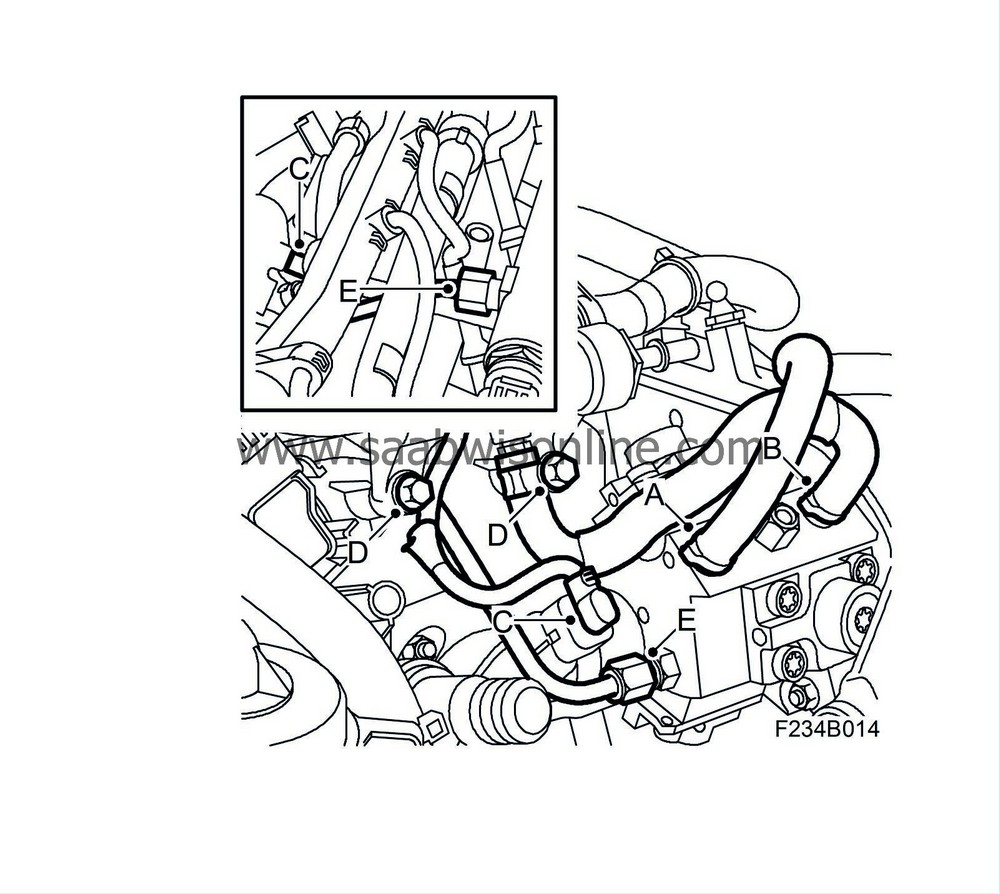

Remove the bolts of the upper timing cover (A). Open the clip (B). Lift out the wiring harness and lift away the cover.

|

|||||||

| 6. |

Remove the bolts (A) of the crankcase ventilation pipe (B) and detach the hose from the camshaft housing.

|

|

| 7. |

Certain cars:

Unplug the connector (A). Remove the bracket (B).

|

|

| 8. |

Detach the hoses on the high-pressure pump:

|

|

| • |

Plug all connections with plugs from kit 92 01 697.

Have a cloth on hand to catch any fuel spill. |

| • |

Undo the clamp and detach the fuel supply hose (A) from the high-pressure pump. Plug the hose.

|

| • |

Undo the clamp and detach the return hose (B) from the high-pressure pump. Plug the hose.

|

| • |

Unplug the fuel pressure sensor connector (C) from the high-pressure pump.

|

| • |

Remove the bolts (D) of the return fuel collector.

|

| • |

Detach the high-pressure fuel line (E). Plug the nozzle pipe.

|

| 9. |

When replacing the high-pressure pump:

Move aside the return fuel collector and secure to the nozzle pipe using a cable tie (A).

|

|

| 10. |

When replacing the intake manifold/seal:

Detach the return fuel line (A) from the return fuel collector. Use

83 95 261 Fuel line tool

. Have a cloth on hand to catch any fuel spill. Plug the connections.

|

|

| 11. |

When replacing the intake manifold/seal:

Detach the hoses from the return fuel collector (B). Remove the return fuel collector. Plug the connections.

|

|

| 12. |

Place a cloth under the pump so as not to lose the pulley wedge.

|

|

| • |

Turn the engine so it is possible to fit 2 Allen bolts (A) M6 x 40 (30 mm unthreaded and 10 mm threaded) through the holes in the pulley and to threads in the high-pressure pump bracket.

|

| • |

Remove the pulley nut (B).

|

| 14. |

Remove the high-pressure pump from the pulley by pressing the pump out with 32 025 005 Puller (A). Counterhold with a 30 mm wrench (B). Remove the puller.

|

|

| 15. |

Remove the high-pressure pump:

|

|

| • |

Remove the nuts and any washers (A). Use a magnet so as not to drop the washers.

|

| • |

Lift out the pump. Pay attention to the wedge.

|

| To fit |

| 1. |

Fit the wedge to the pump and put the pump in place. Fit any washers and nuts (A). It is important that the wedge fits into the groove on the pulley.

Tightening torque 25 Nm (18 lbf ft)

|

|

| 2. |

Fit the nut (B) to the high-pressure pump's pulley.

Tightening torque, fuel pipes 50 Nm (36 lbf ft)

|

|

| 3. |

Remove the bolts (A) holding the pulley in place.

|

|

| 4. |

When replacing the high-pressure pump:

Remove the cable tie (A).

|

|

| 5. |

Attach the hoses to the pump:

|

|

| • |

Remove all plugs from the pump connections.

|

| • |

Remove the plug and attach the high-pressure fuel line (E). If it is difficult to get the fuel pipe in place, slacken the fuel rail retaining bolts slightly.

Tightening torque, fuel pipes 25 Nm (18 lbf ft) |

| • |

Remove the plug and attach the fuel supply hose (A) and clamp to the pump.

|

| • |

Remove the plug and attach the return hose (B) and clamp to the pump.

|

| • |

Attach the fuel pressure sensor connector (C) to the pump.

|

| • |

Fit the bolts (D) of the return fuel collector.

Tightening torque 9 Nm (7 lbf ft) |

| 6. |

When replacing intake manifold/seal:

Attach the hoses (B) to the return fuel collector. Attach the return fuel line (A).

|

|||||||

| 7. |

Fit the bolts to the upper timing cover (A) and fit the wiring harness to the clip (B).

|

|

| 8. |

Certain cars:

Fit the bracket (B) and connector (A).

|

|

| 9. |

Fit the bolts (A) of the crankcase ventilation pipe (B) and attach the hose to the camshaft housing.

|

|

| 10. |

Fit

Engine pad, right

.

|

|

| 11. |

Fit the insulation and the upper engine cover.

|

|

| 12. |

Connect the negative battery cable and fit the battery cover.

|

|

| 13. |

Carry out

Procedures after reconnecting the battery

.

|

|

| 14. |

Start the engine and turn it off.

|

|

| 15. |

Remove the wing cover and close the bonnet.

|

|

Warning

Warning