Connector, handling and checks

|

|

Connector, handling and checks

|

|

1.

|

It is important when removing captive connectors to release the lock before removing the connector. Make sure the connector locks properly when connecting.

Before removing a connector you must ensure that no fluid, dirt or the like can enter the connector.

Examples of different types of connectors on some cars:

|

|

|

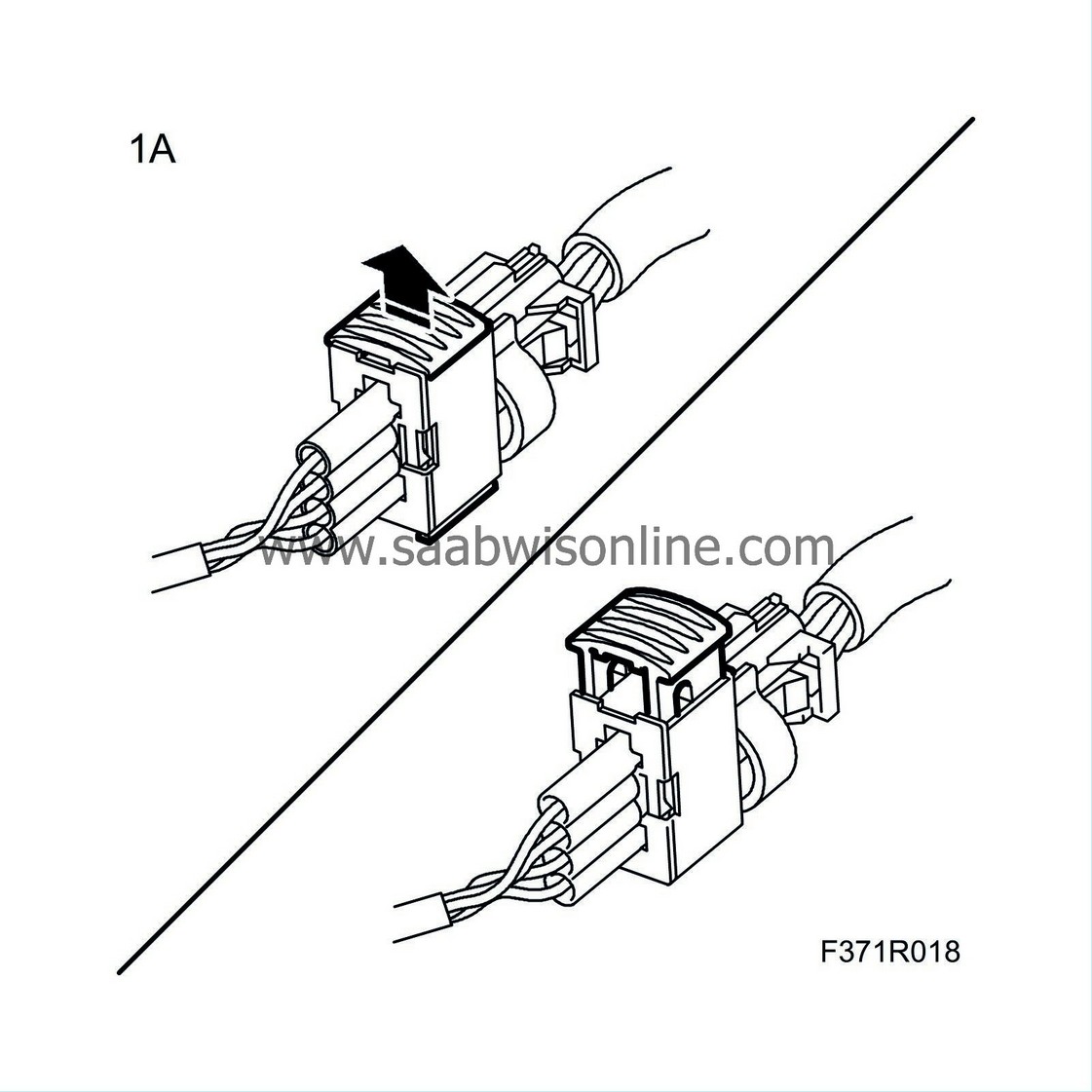

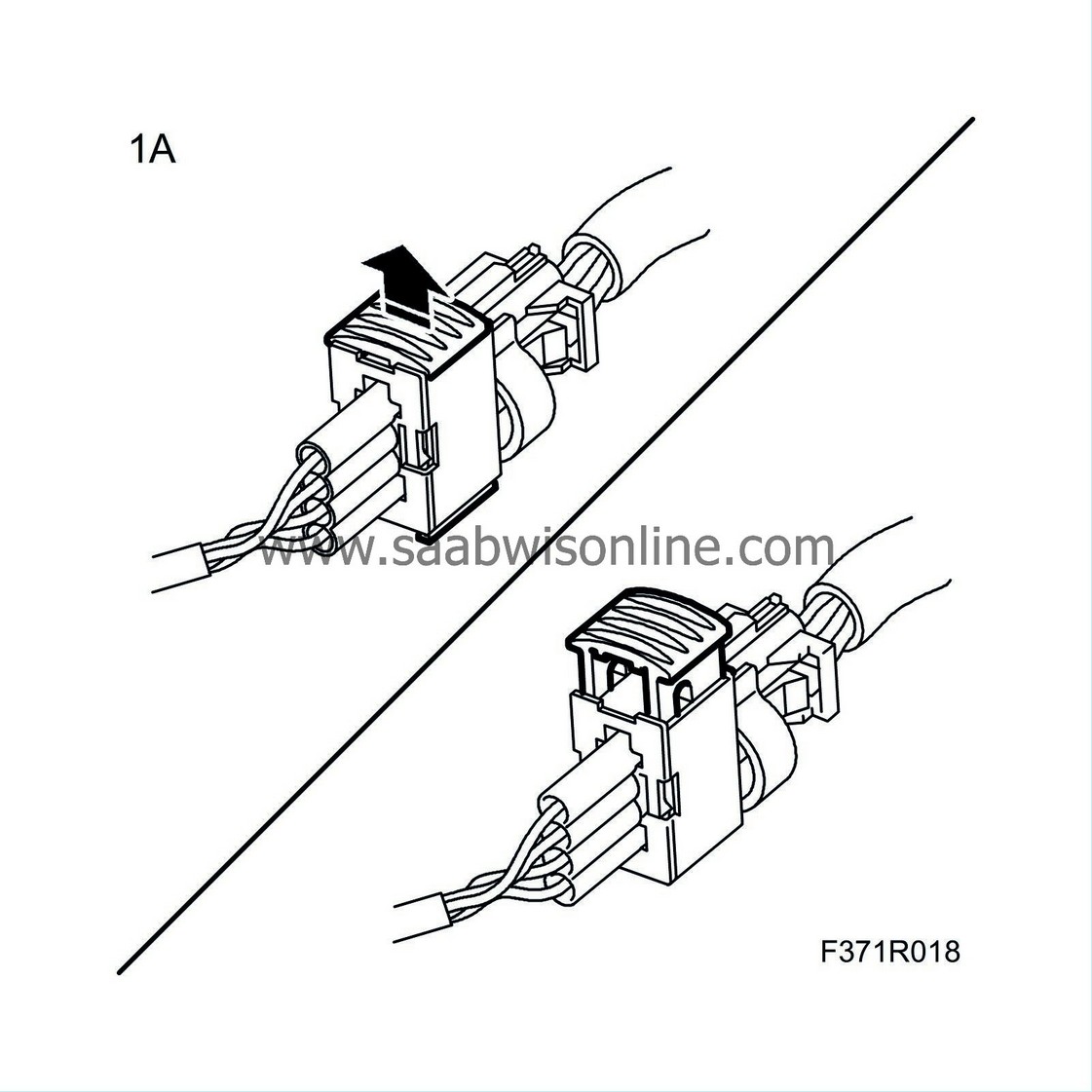

1.A.

|

Pull out the slide to release the connector's lock.

After connection the connector is locked by pushing in the slide.

|

Note

|

|

Use a small screwdriver to make it easier to loosen the lock on the connector.

|

|

|

|

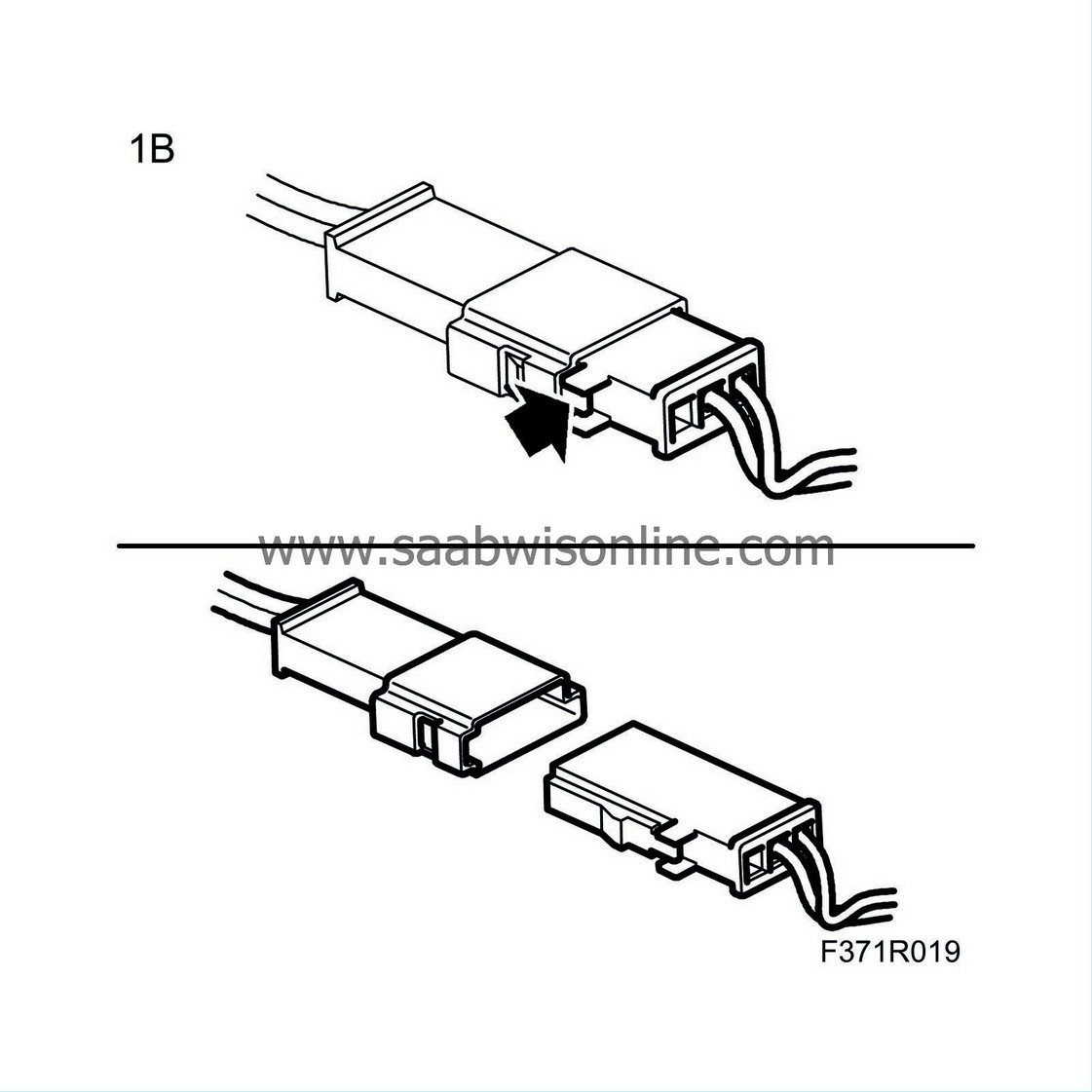

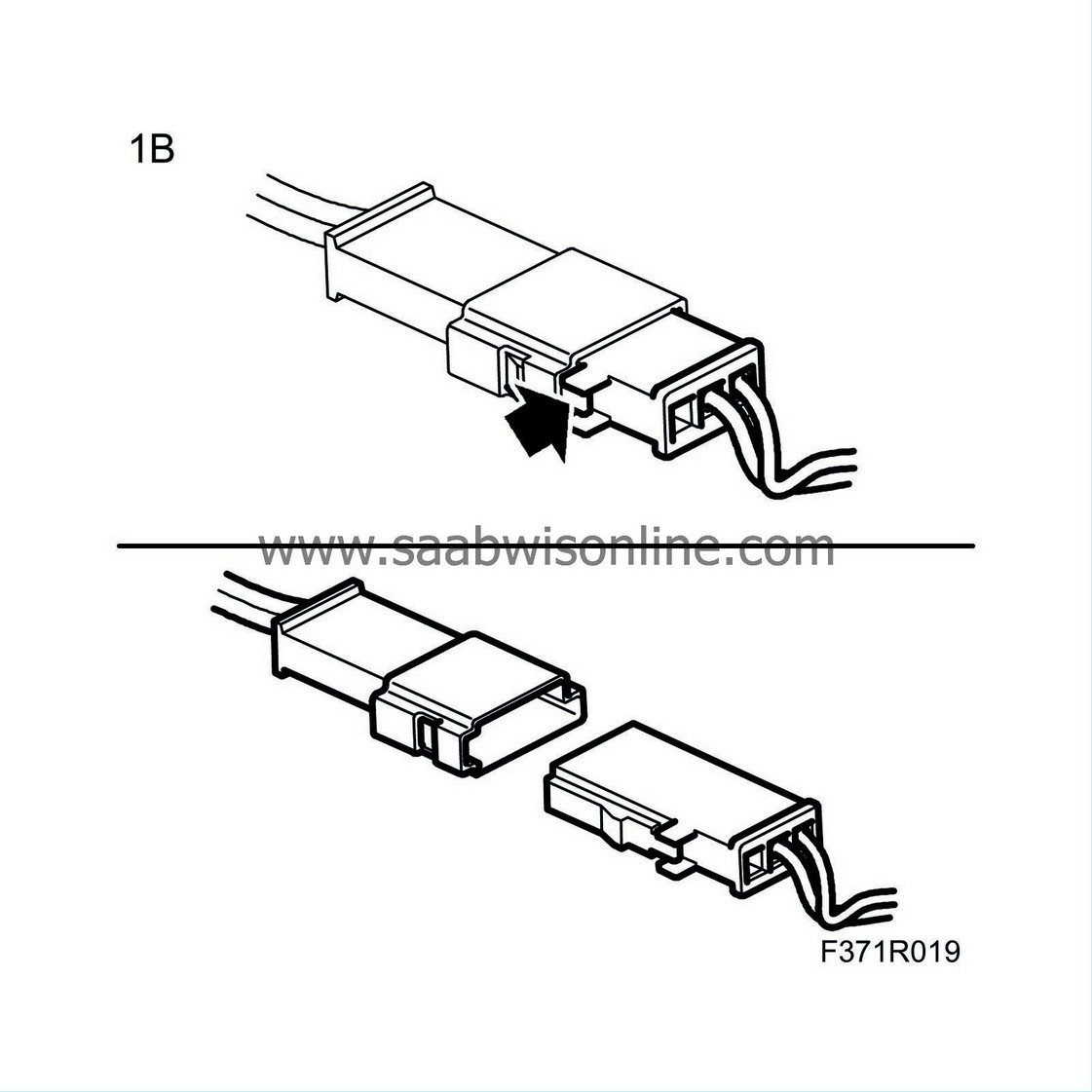

1.B.

|

Push in the locking tab to release the connector's lock.

Make sure the connector is locked properly when connecting.

|

|

|

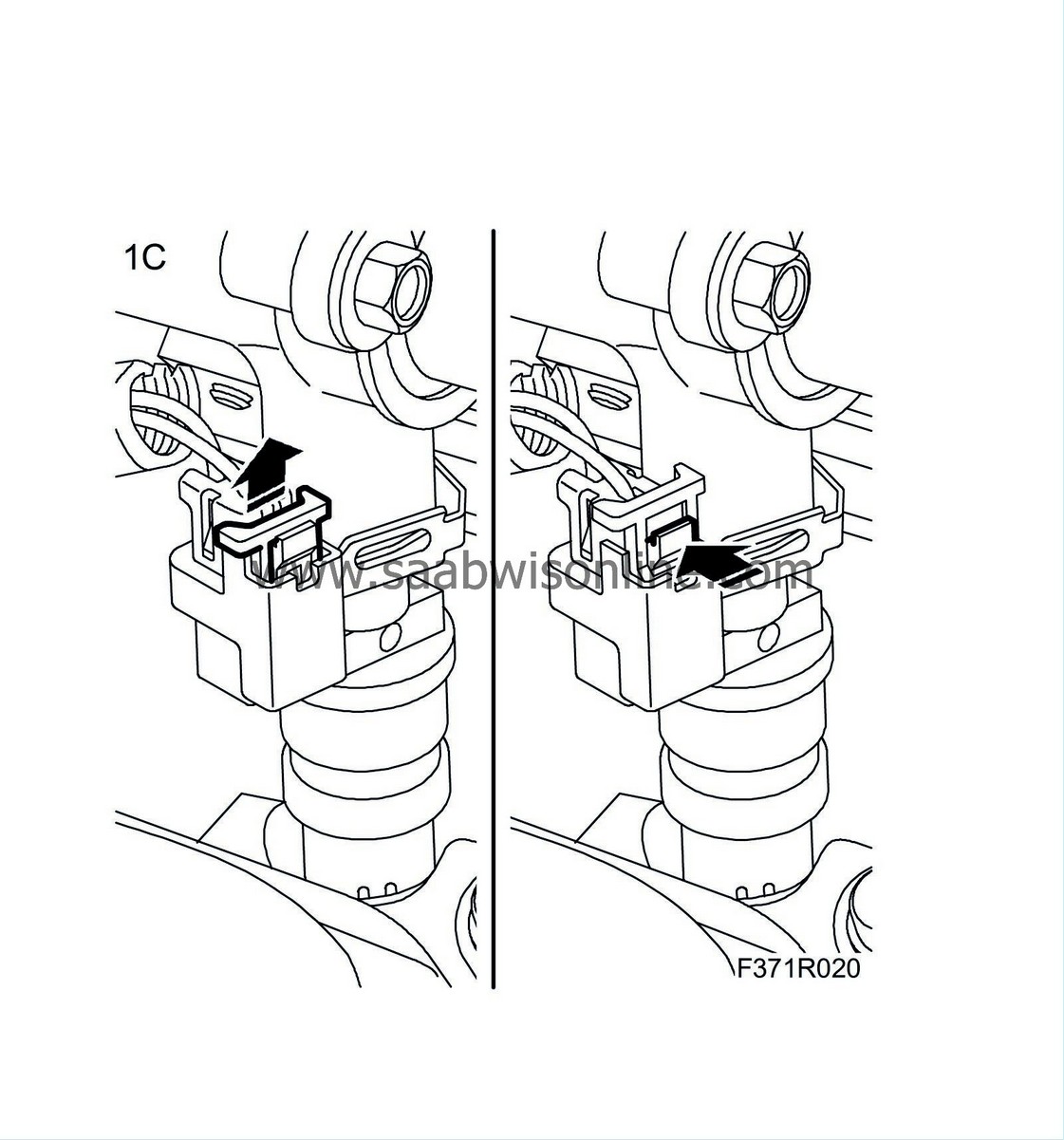

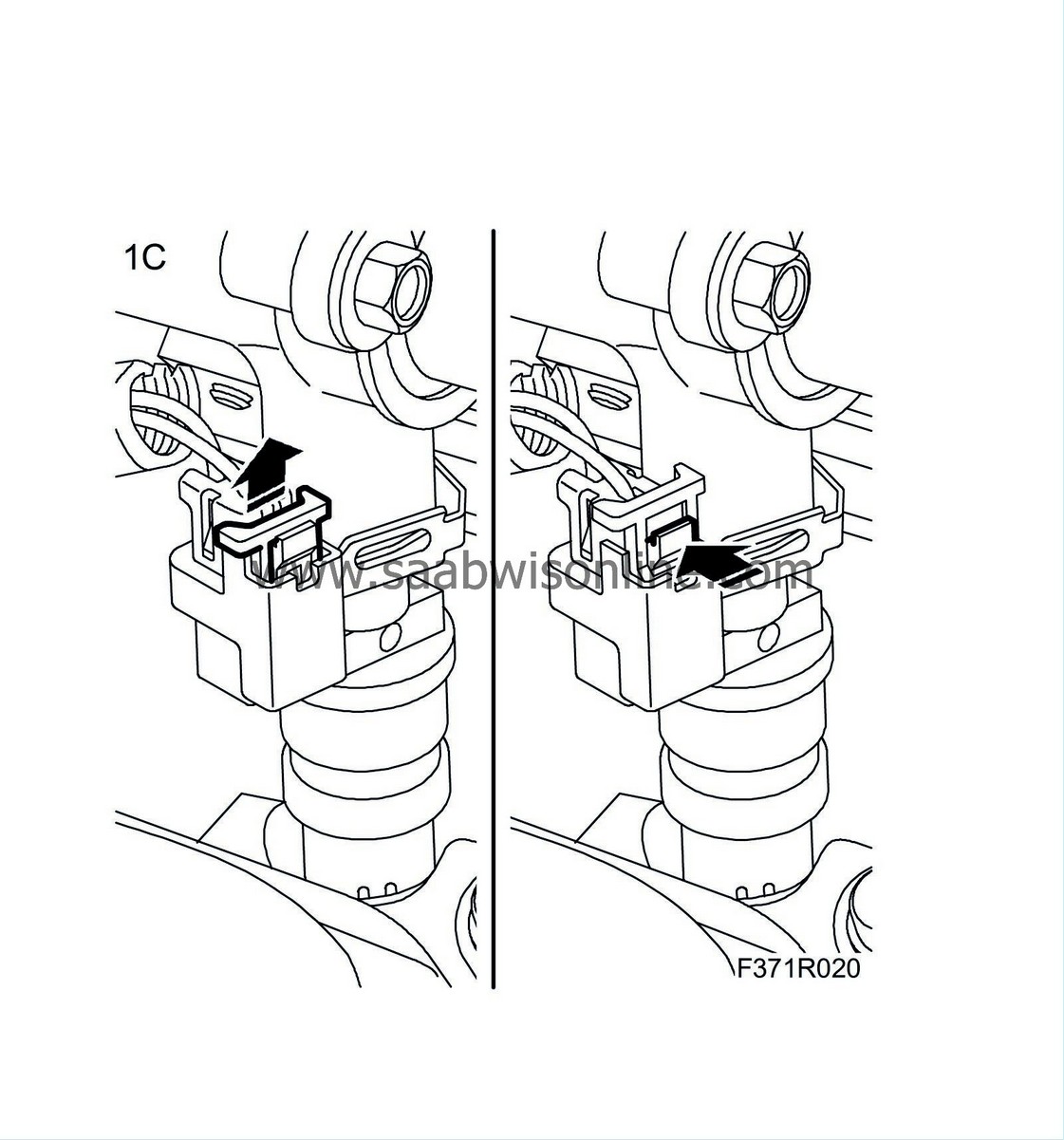

1.C.

|

Pull out the slide to release the connector's lock.

After connection the connector is locked by pushing in the slide.

|

|

|

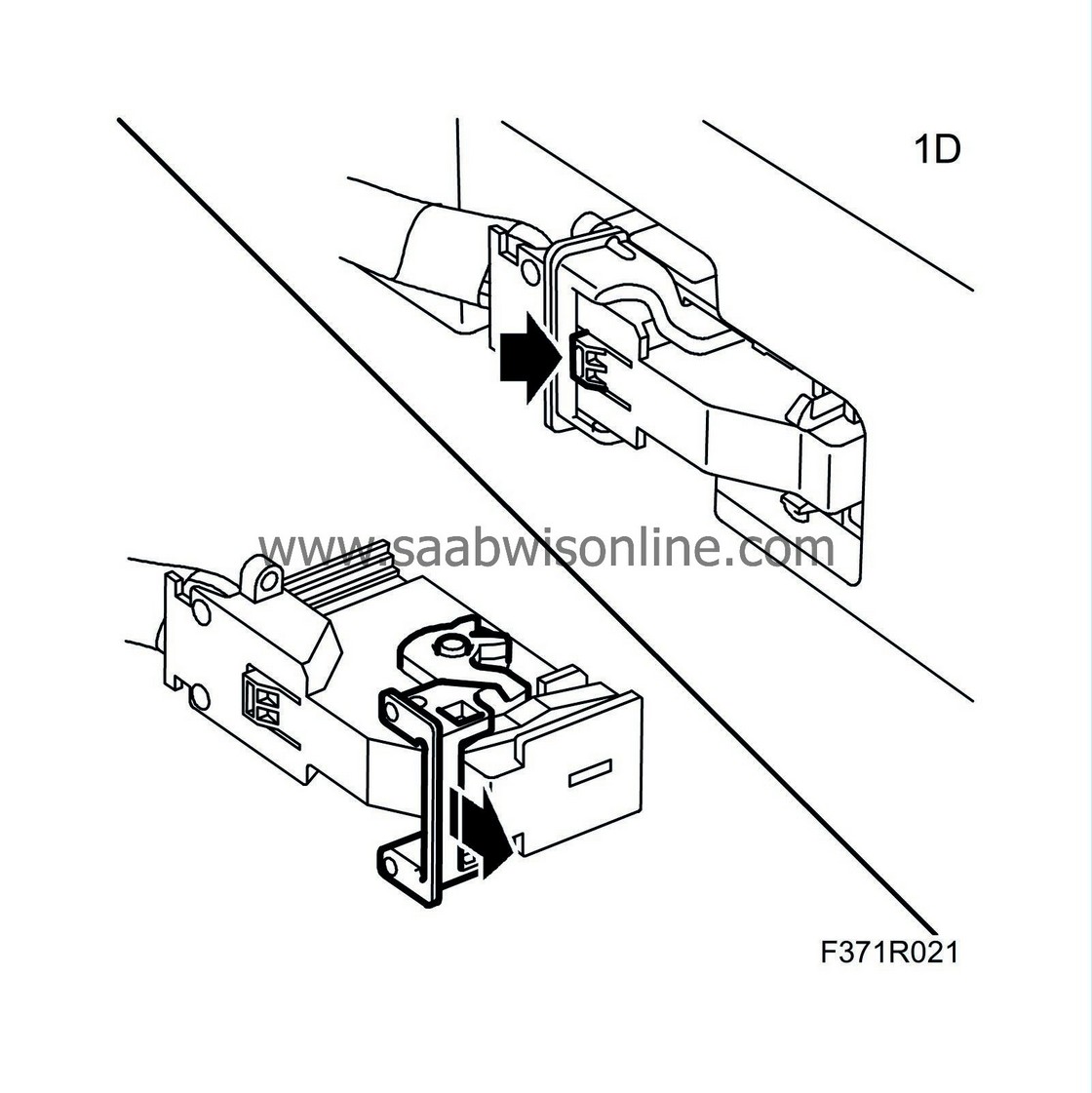

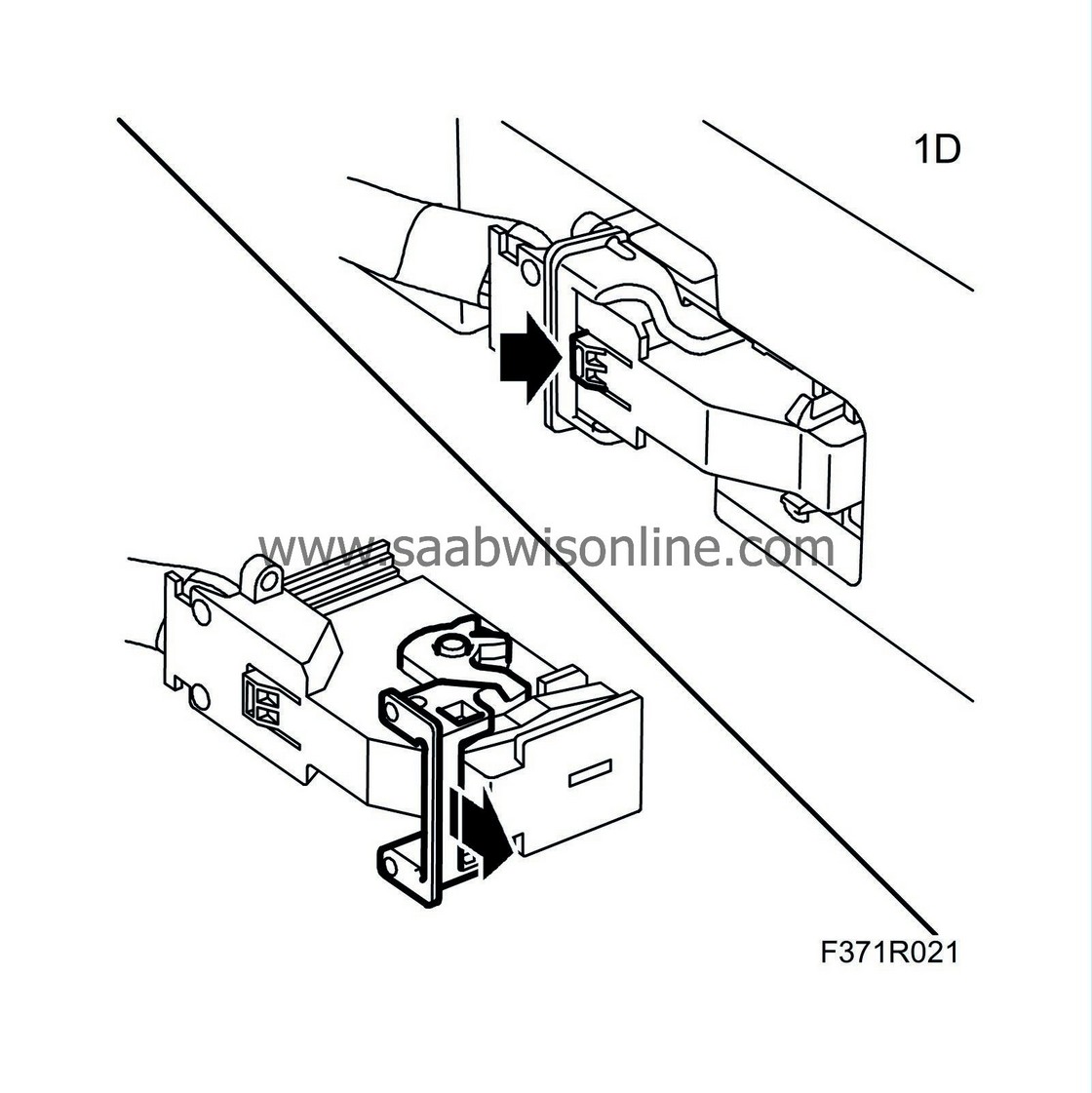

1.D.

|

Push in the clamp's locking catch and fold the clamp forward.

When connecting, fold back the clamp to lock the connector.

|

Note

|

|

Make sure that the clamp is locked in the right position to guarantee contact between the connectors.

|

|

|

|

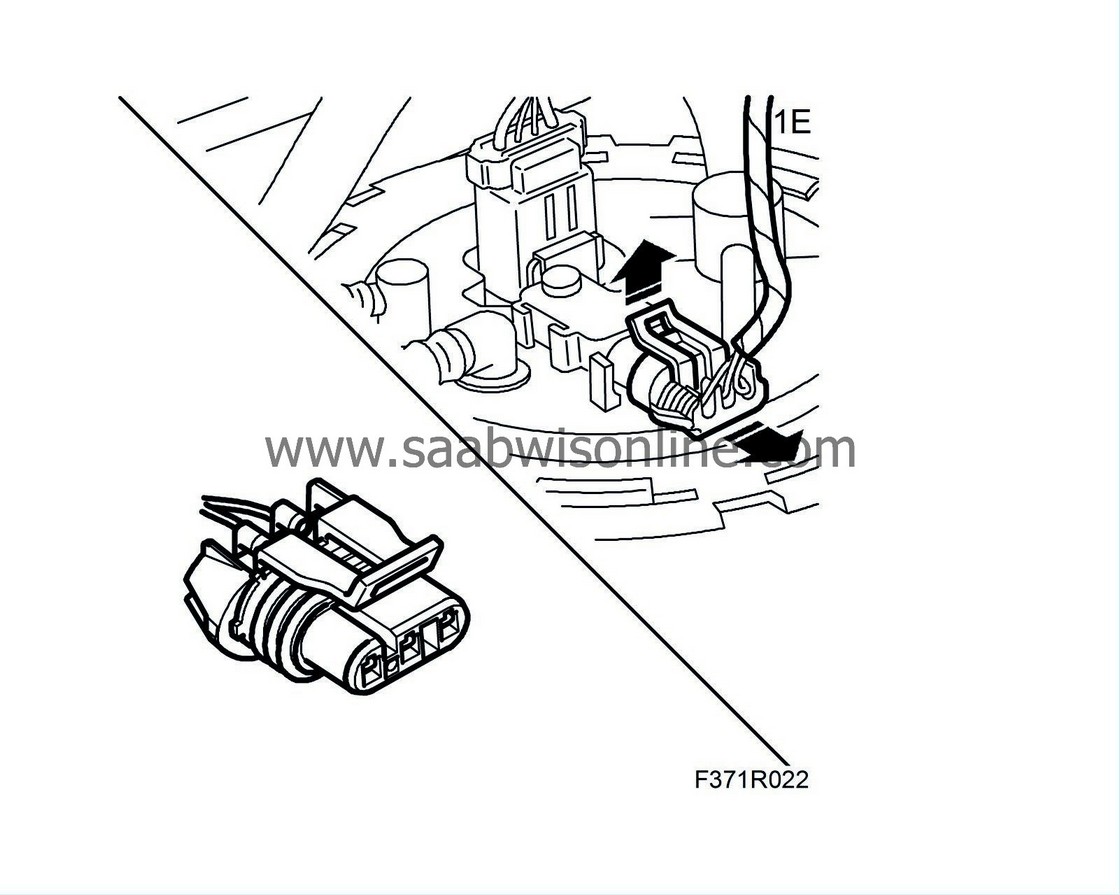

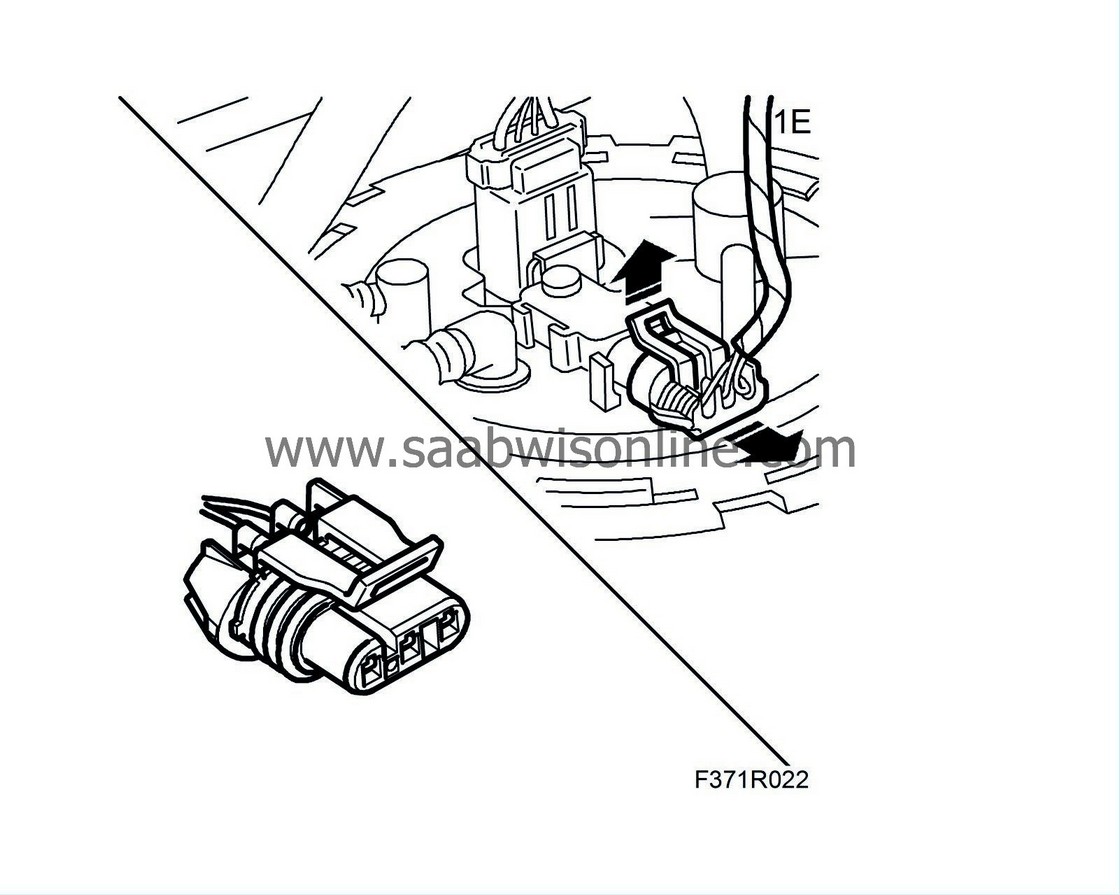

1.E.

|

Lift up the locking tab to release the connector's lock.

Make sure the connector is locked properly when connecting.

|

|

|

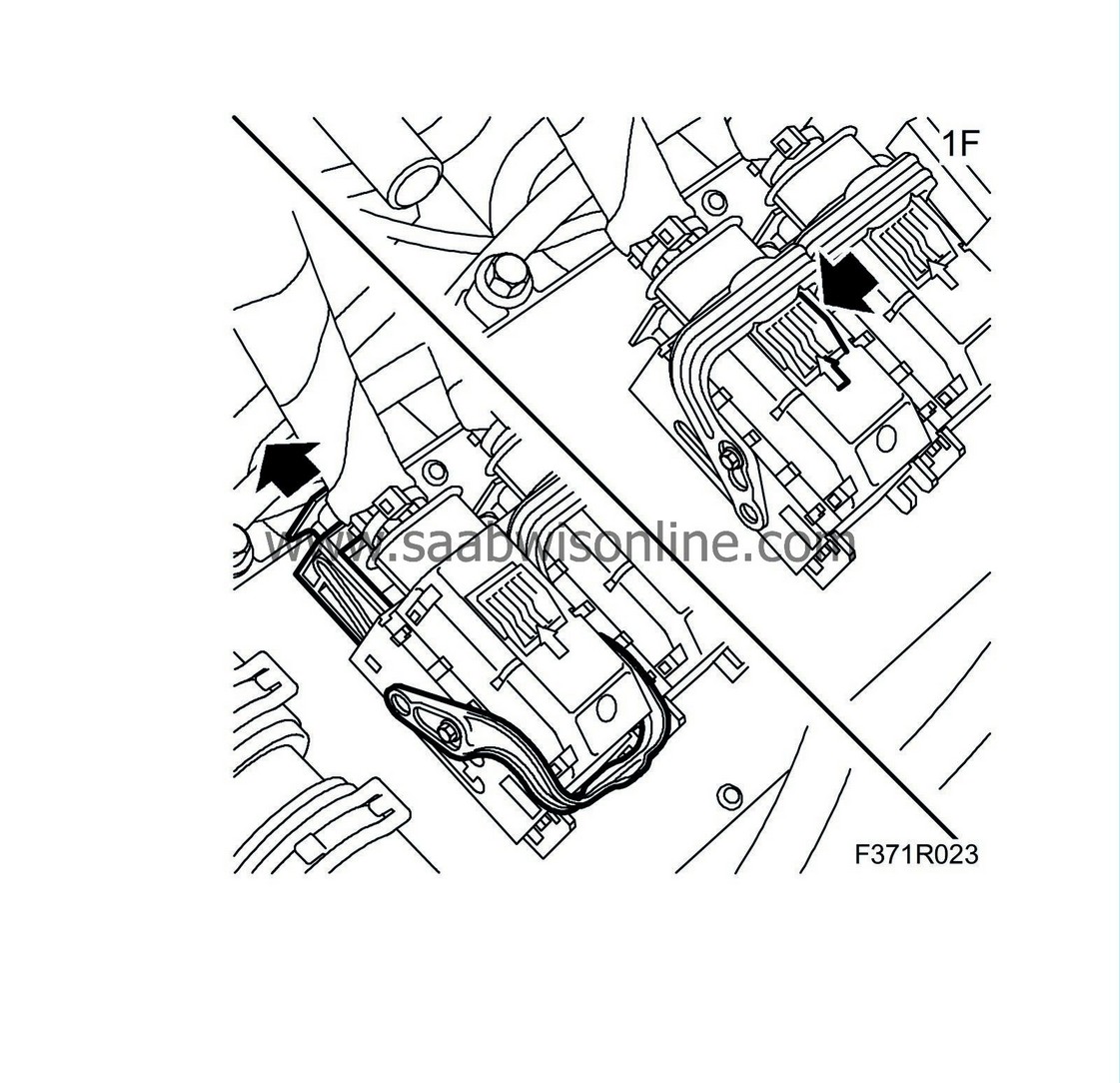

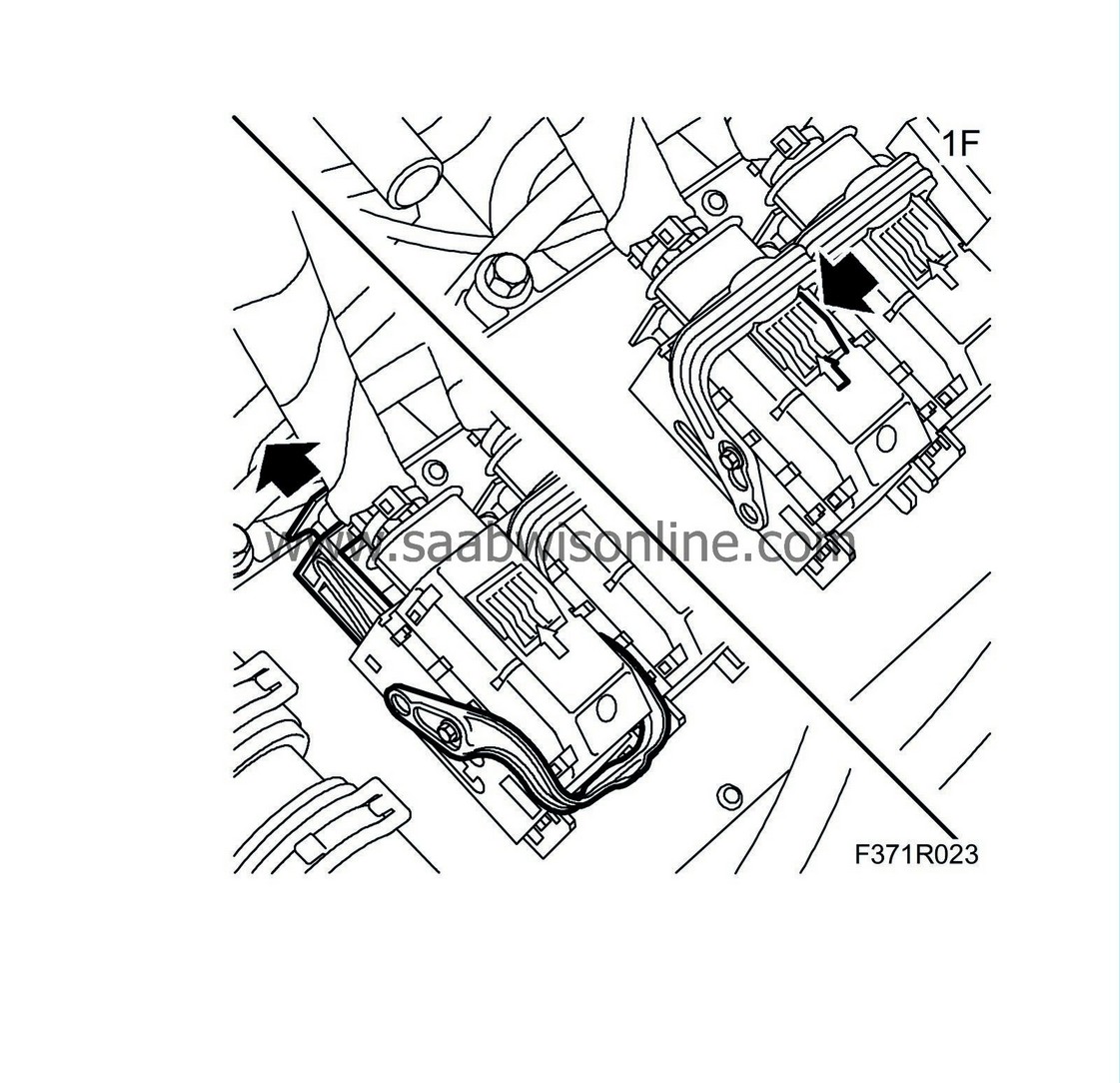

1.F.

|

Press in the connector's locking tab to release the clamp. Release the connector's slide and at the same time fold forward the clamp.

|

Note

|

|

The connector can be damaged if greater force than necessary is used to fold the clamp forward without releasing the slide.

|

When connecting, fold back the clamp to lock the connector.

|

|

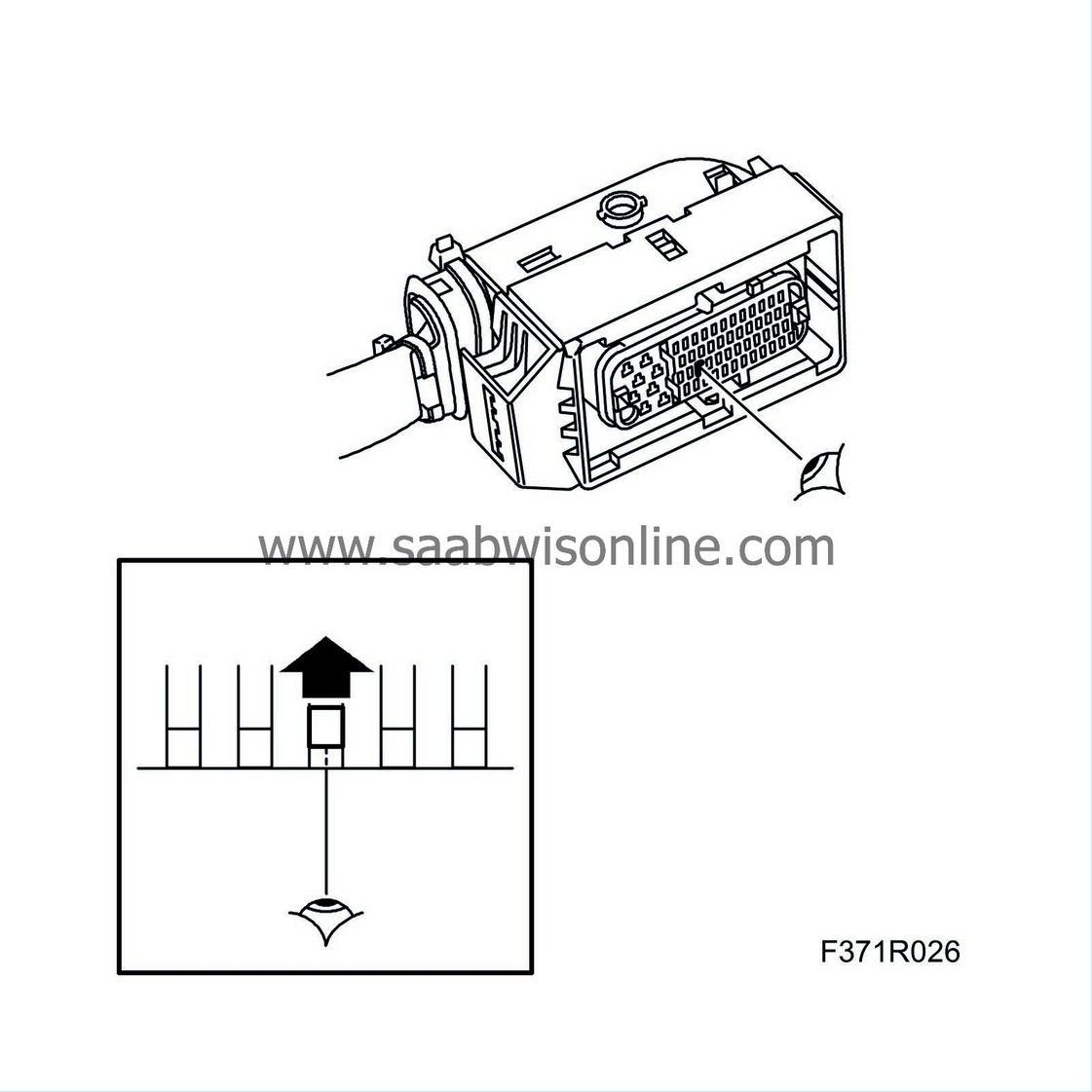

2.

|

Ground yourself, by taking hold of the car's body/engine, when removing or fitting the connector on the car's control module.

|

|

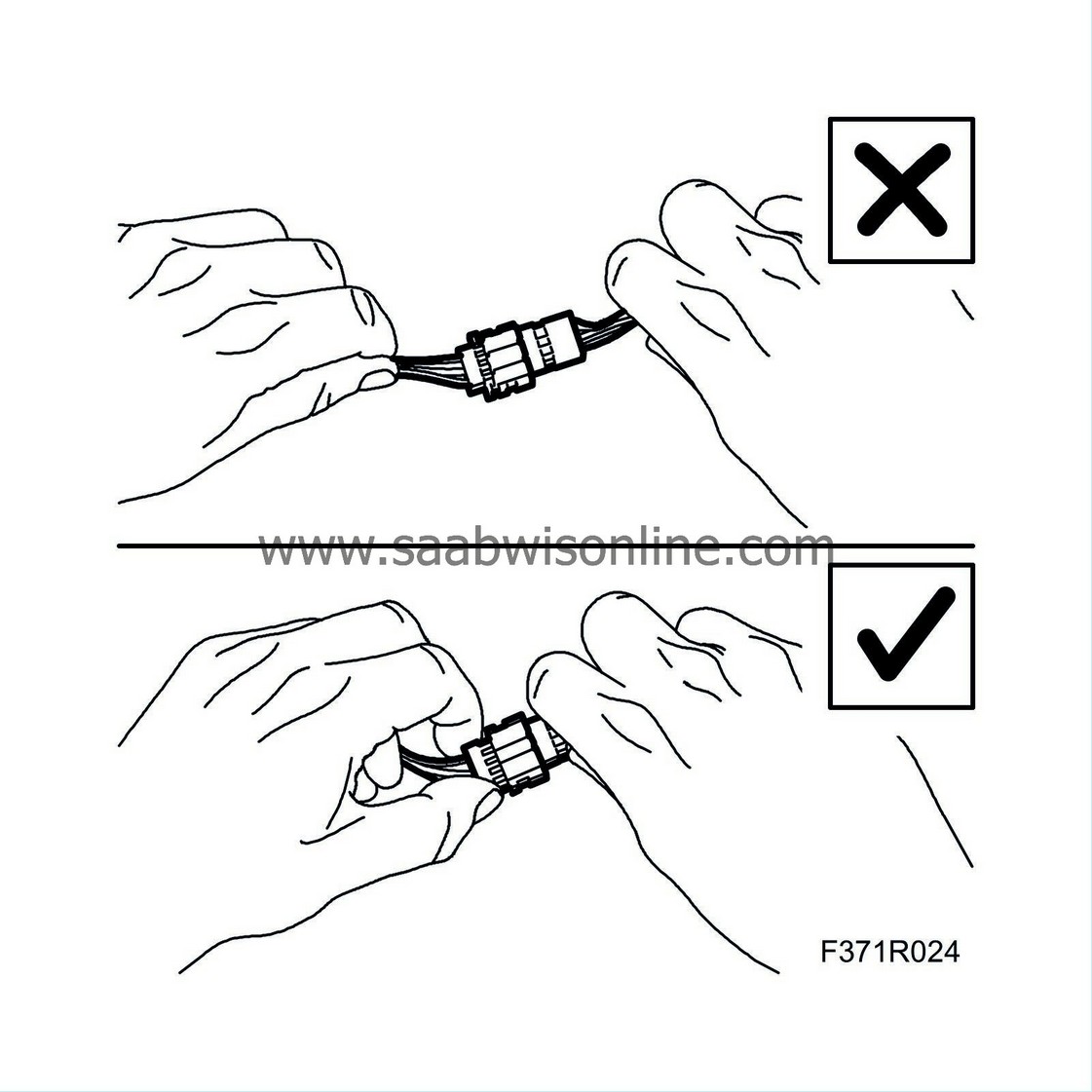

3.

|

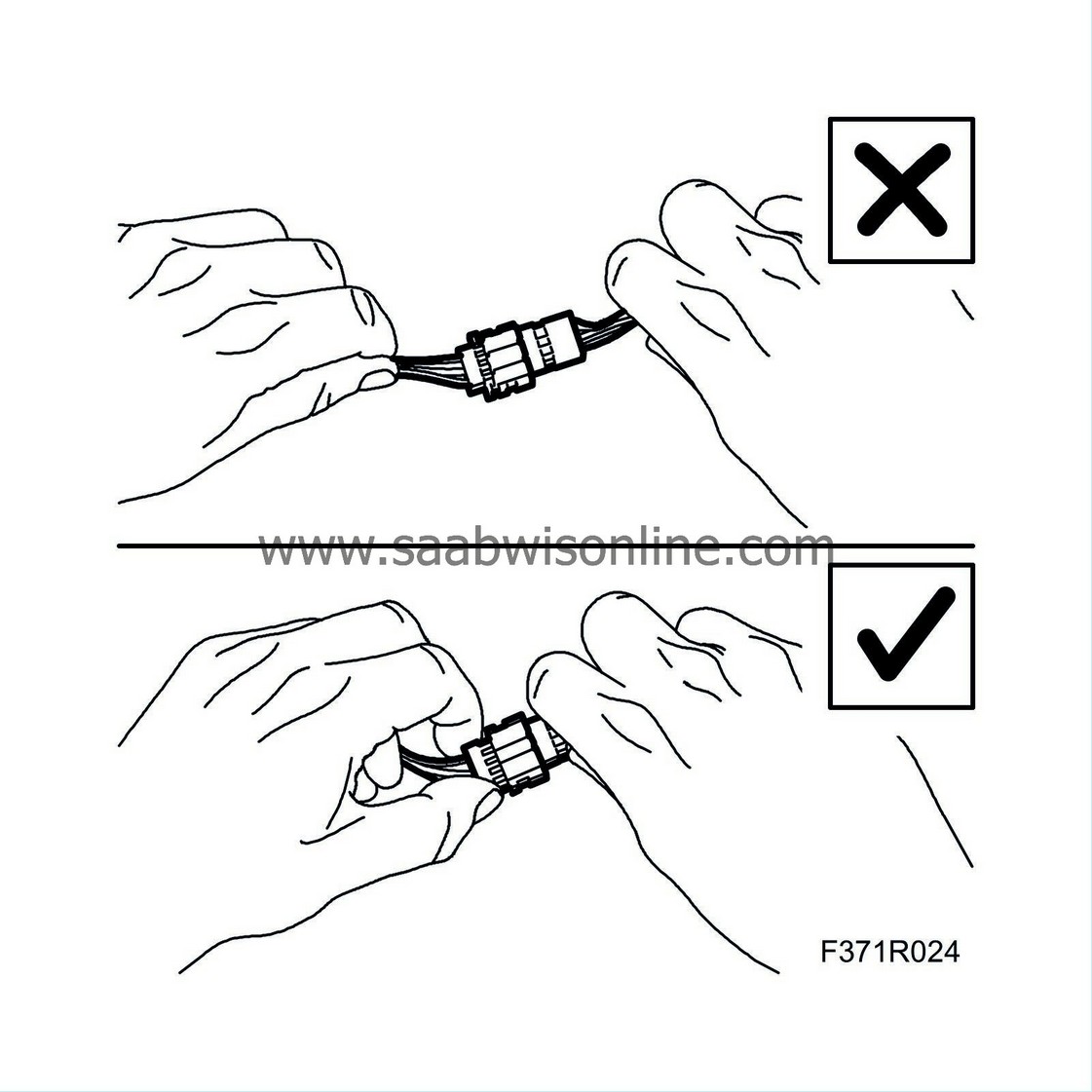

Never pull the wiring harness when removing the connector.

|

|

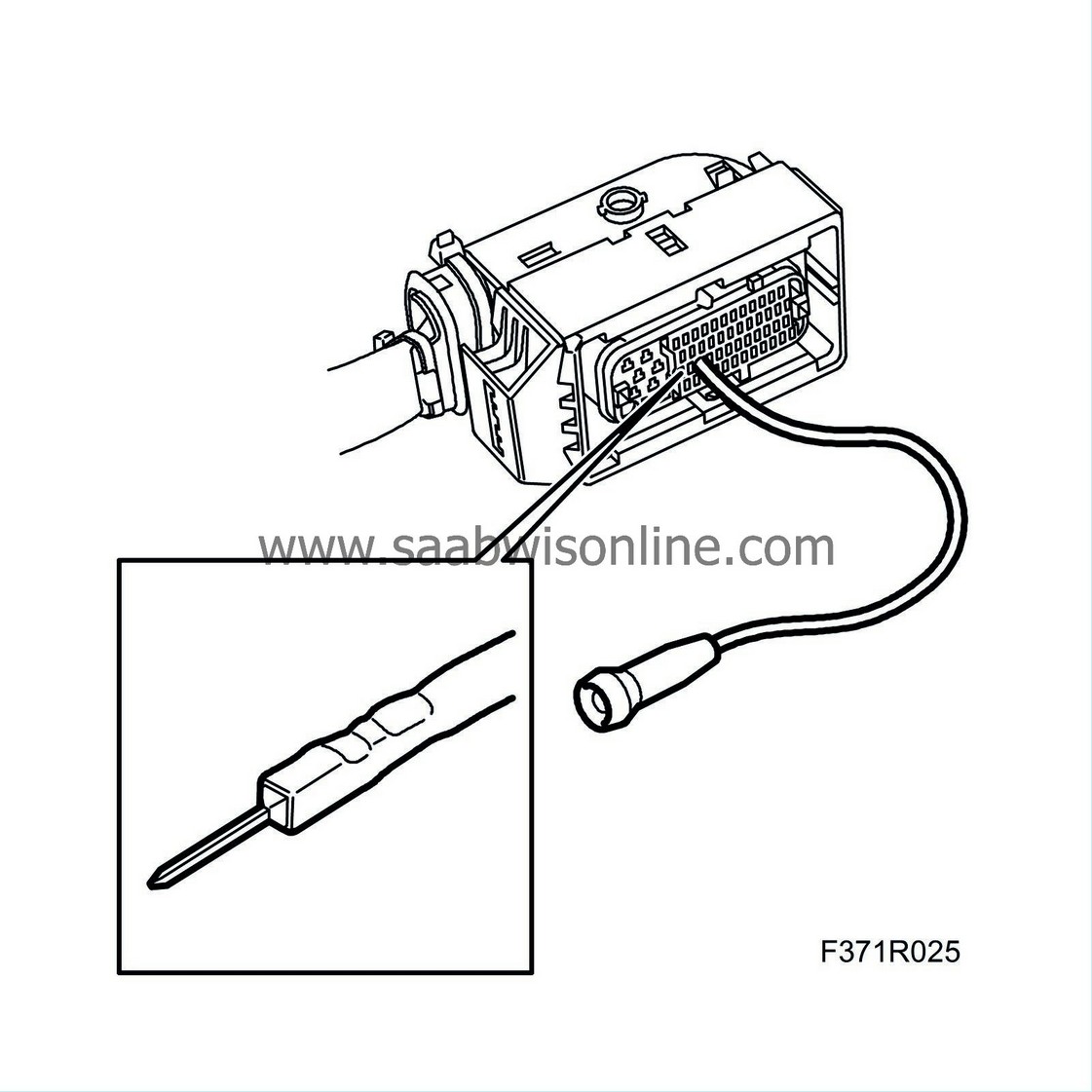

4.

|

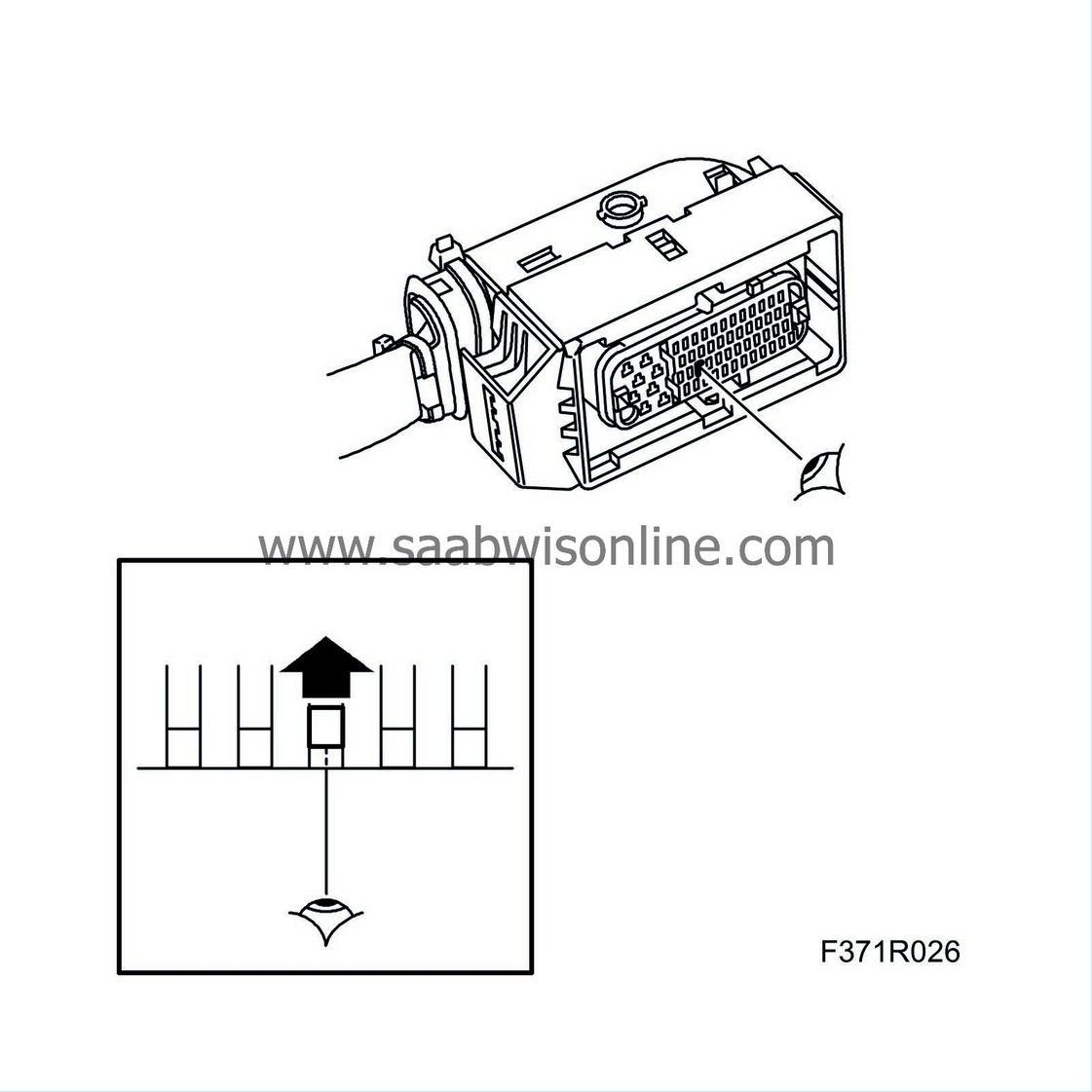

Never touch the pins on a control module with your hands or clothes.

|

Important

|

|

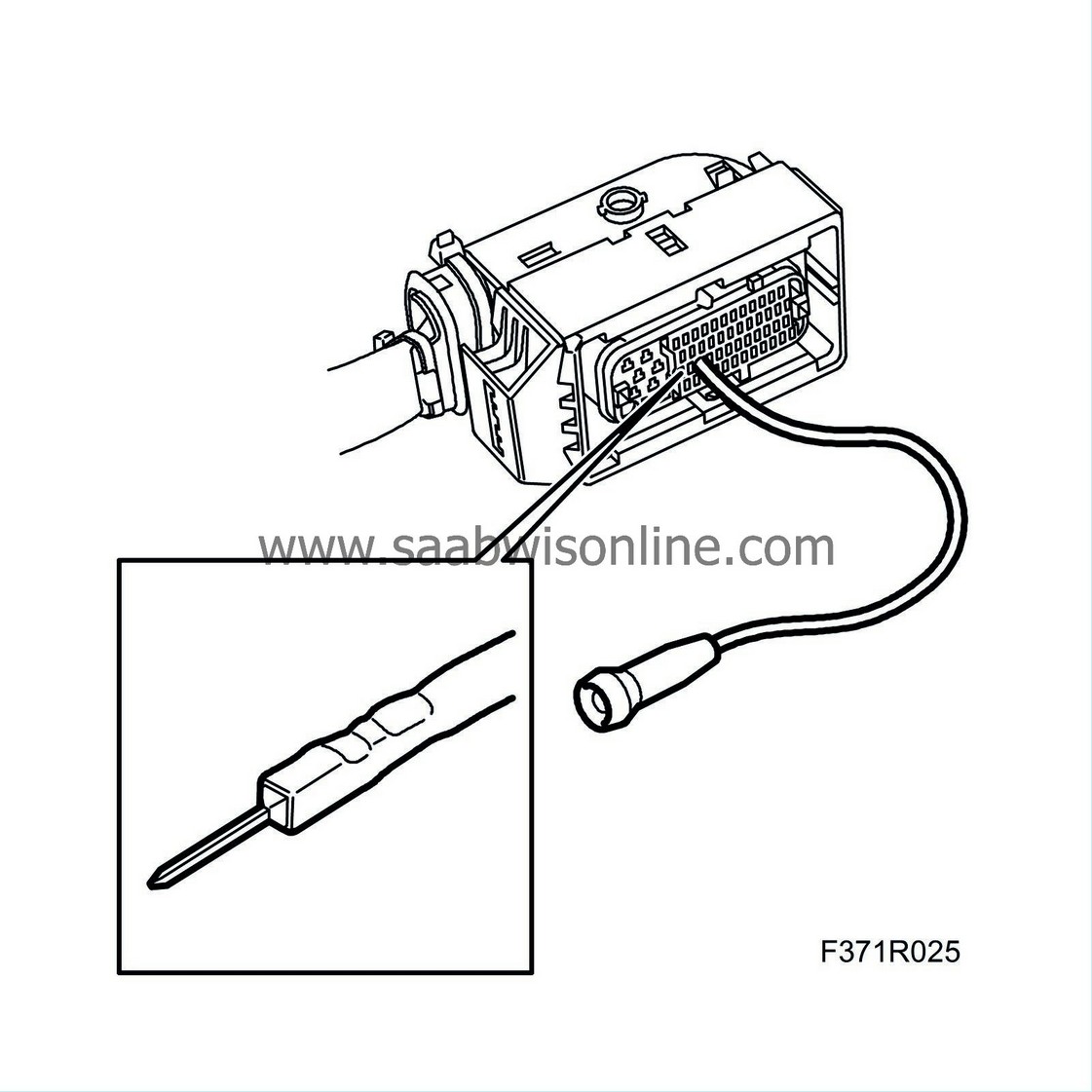

Incorrect handing or the use of the wrong tool can damage the sleeves in the connector.

|

|

Use a test cable (part no. 86 12 731) of the correct size to avoid damaging the sleeves in the connector.

|

|

|

|

|

5.

|

When performing measurements, only use measurement probes designed for this purpose to avoid damage to the connectors. Use the right size test cable (part. no. 86 12 731).

|

|

6.

|

The connector may only be repaired using the specified special tools and spare parts.

|

|

7.

|

The following connectors must not be repaired:

|

|

|

•

|

Shielded cables/coaxial cable (e.g. ESP sensor cable)

|

|

|

•

|

Airbag system and pyrotechnic seat belt tensioner system

|

|

|

•

|

High voltage cable (e.g. ignition system, xenon lamp).

|

|

Note

|

|

Before fitting a connector you must ensure that no fluid, dirt or the like can enter the connector.

|

|

1.

|

Check that there are no contact problems on the connection.

|

|

2.

|

Check the connectors, splicing sleeves and crimps with regard to oxidation, dislodged pins and the pin's clamping force.

|

Important

|

|

Incorrect handing or the use of the wrong tool can damage the sleeves in the connector.

|

|

Use a test cable (part no. 86 12 731) of the correct size to avoid damaging the sleeves in the connector.

|

|

|

|

|

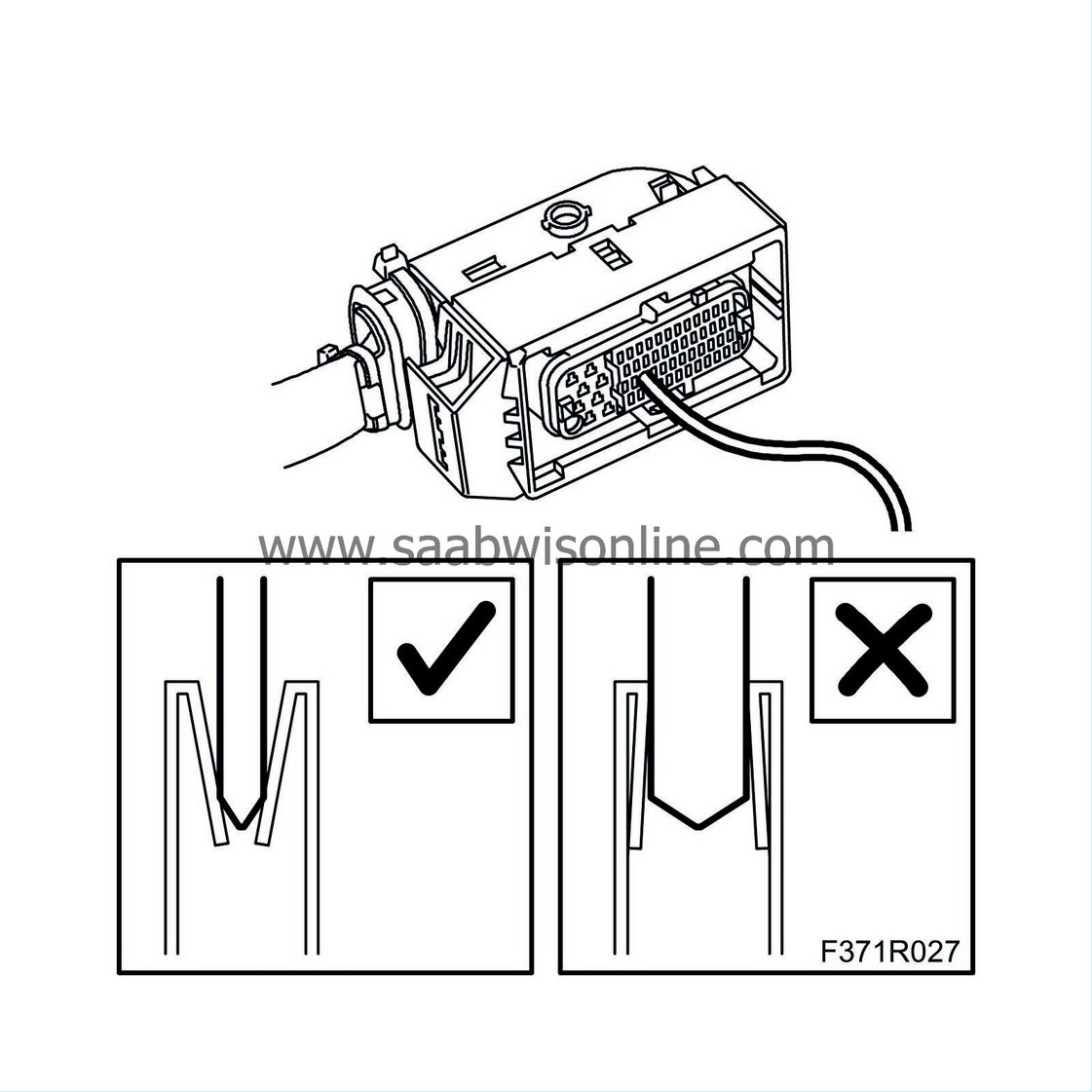

3.

|

A test cable with the right pin size (from kit 86 12 731) must be used to check the connector's clamping force.

|

Note

|

|

A test cable that is too large will damage the connector's sleeves.

|

|

|

|

•

|

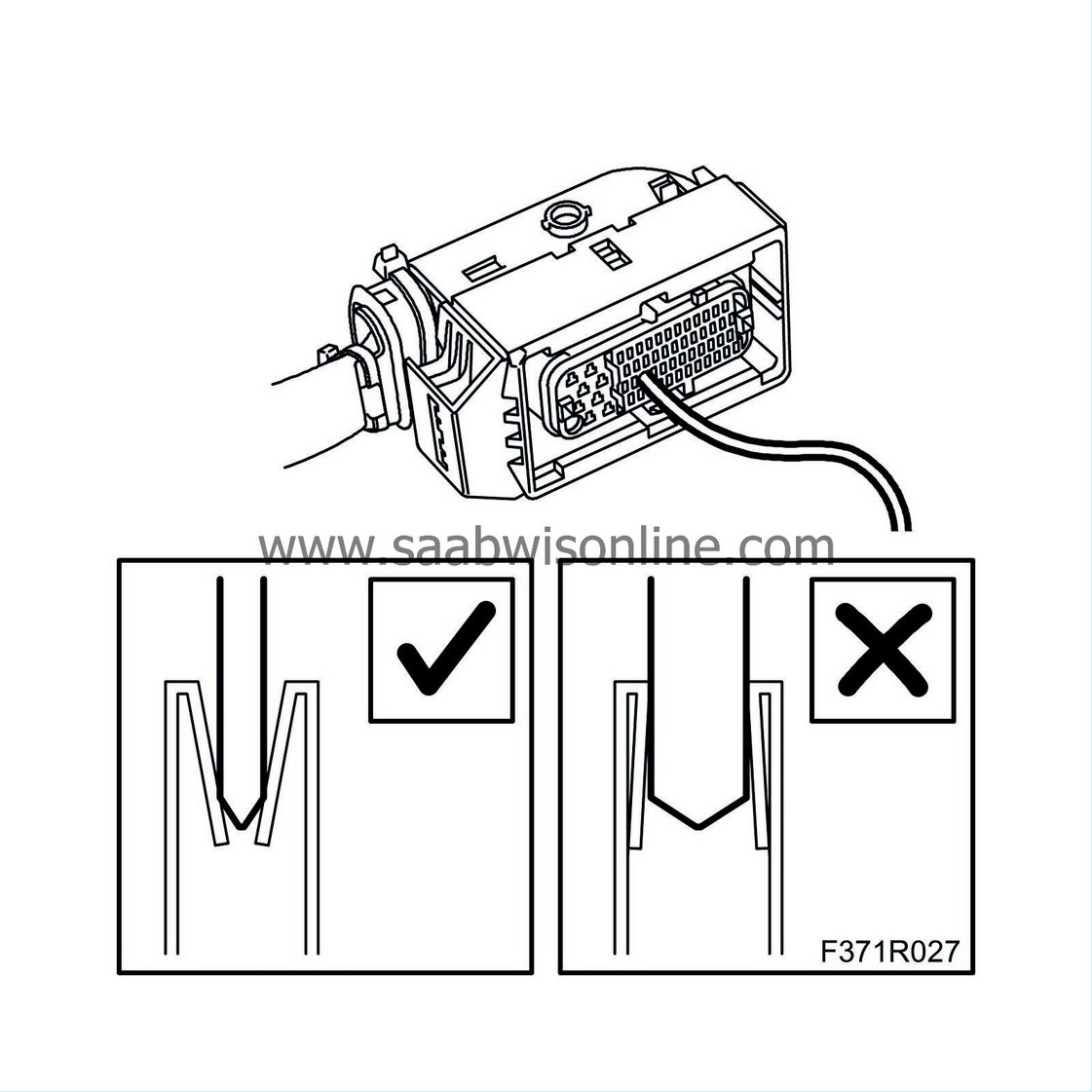

Insert the test cable's pins in the connector's pins to assess the clamping force on the relevant pins. Poor clamping force on the connector's pins can cause connector play.

|

|

|

•

|

Also check that the pins mate at the same height as the other pins in the connector. A too low mating height indicates pushed back pins in the connector, which can cause connector play.

|

|

4.

|

Check the cables or connectors to ensure there is no breakage.

|

|

5.

|

Check the wiring harness, splicing sleeves and earth connections.

|