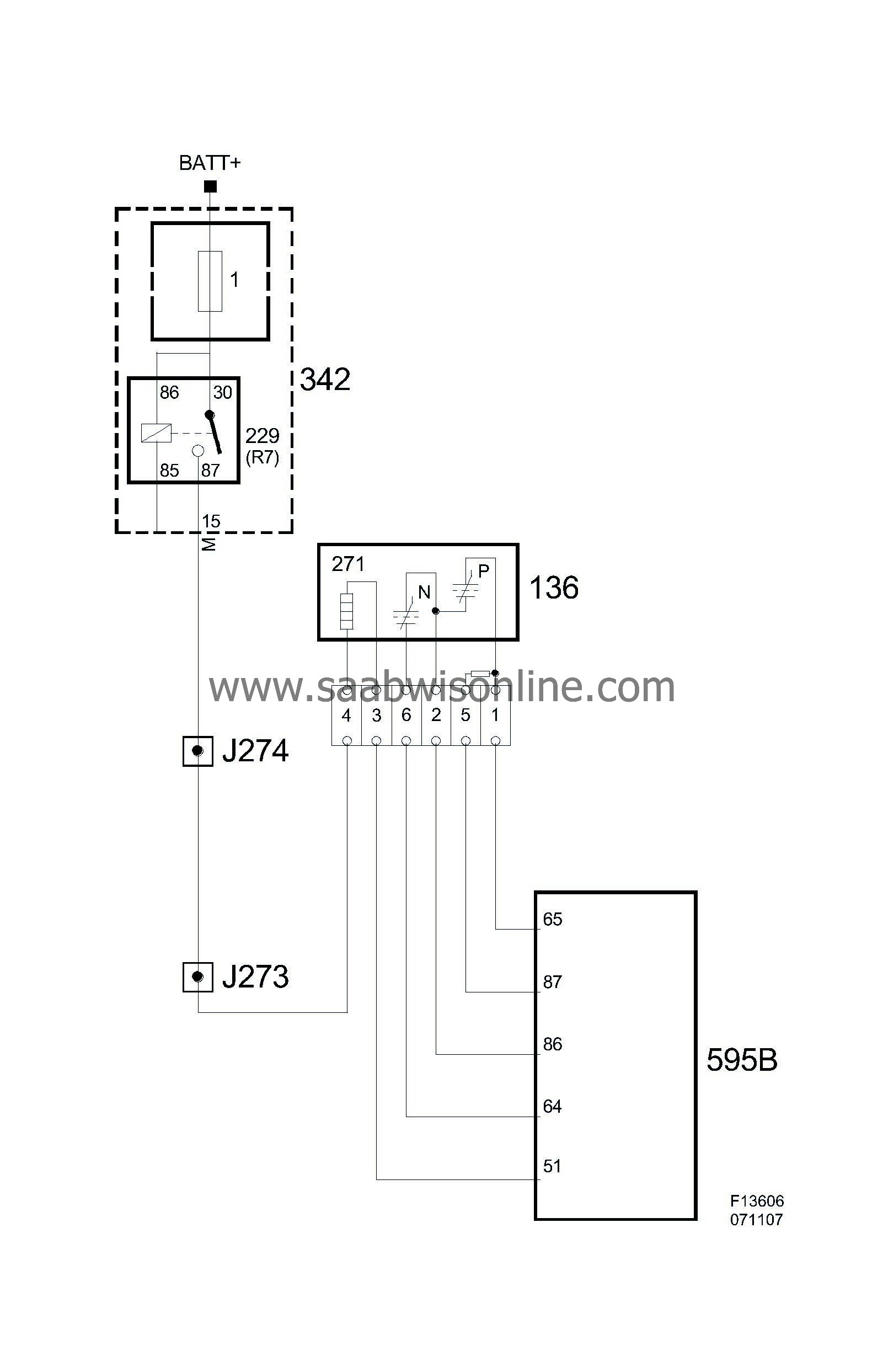

Heated oxygen-sensor (136)

| Heated oxygen-sensor (136) |

| Type |

Broadband lambda sond.

| Connection |

| Pin No. | Signal type | Description |

| 1 | Pump current | From ECM pin 65(B). |

| 2 | Virtual ground 2.5 V | Sensor and Nernst cell are connected to ECM pin 86(B). |

| 3 | Ground preheating | Preheating is grounded from ECM pin 51(B). |

| 4 | Power supply, preheating | Via main relay 229. Connects to UEC pin 15(M). |

| 5 | Sensor, trim resistance value | Connected to ECM pin 87(B). |

| 6 | Output voltage, Nernst cell | To ECM pin 64(B). |

Diagram

| Function |

The broadband oxygen sensor is significantly more complex than a narrow band oxygen sensor which is normally used for petrol engines.

In principle the sensor consists a heated narrow band sensor, a so-called Nernst cell, which is connected to a pump cell. The cells are produced from ZrO2 with porous platinum electrodes. The cells are positioned at a distance of 10-50 micrometres from each other, this gap is connected to the surrounding exhaust gases via a small hole.

The pump cell pumps oxygen from the measured gap to the surroundings if the exhaust gases have a lambda value above lambda=1. When the value lambda=1 is reached the voltage from the Nernst cell is 450 mV, a voltage that the ECM attempts to hold constant by varying the pump current. Consequently, the size of the current through the pump cell is a measure of the oxygen composition of the exhaust gases. A high lambda value in the exhaust gases results in a relatively high positive pump current.

The temperature of the oxygen sensor must be regulated precisely. ECM does so by varying the preheating current in the heating element.

Amongst other things, the sensor is used to ensure the function of the mass air flow sensor and the injectors.