B-pillar, spare part, complete side

|

|

B-pillar, spare part, complete side

|

Depending on the damage, the B-pillar can be replaced with two alternative spare part configurations. In the method described below, one complete side with reinforcement is used. For replacement of the B-pillar with separate spare parts, see.

|

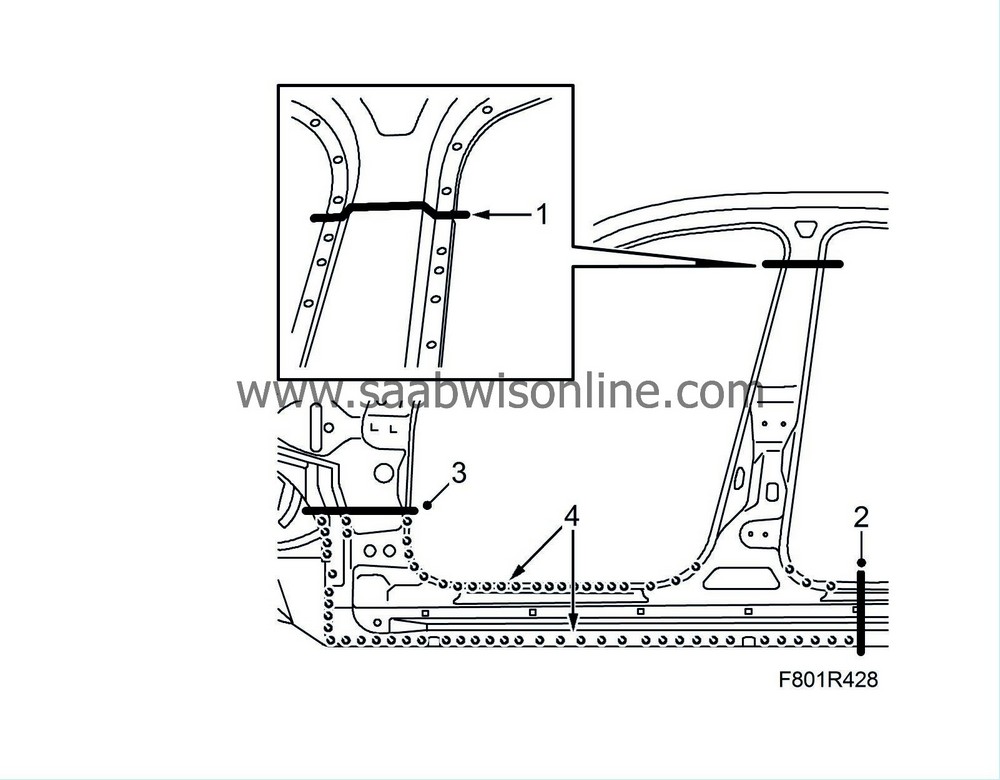

1.

|

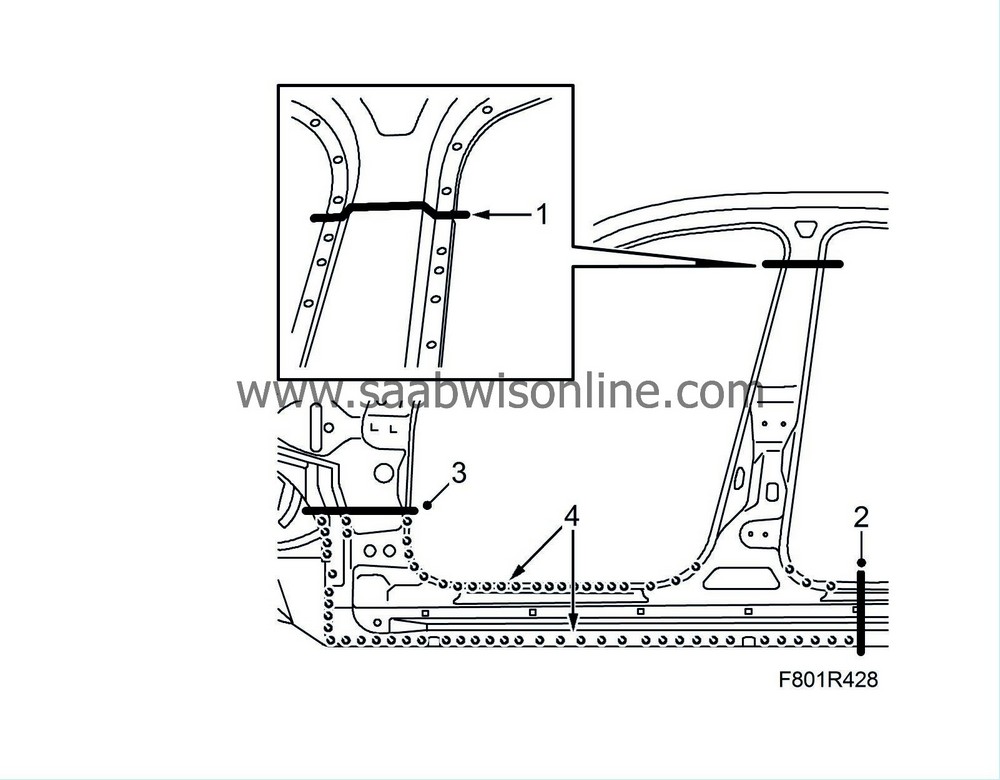

Cut the B-pillar as indicated by the marks. The cut shall be located 60 mm under the B-pillar measurement point. Cut through all the panel layers.

|

|

2.

|

Cut the rear section of the sill as illustrated. Cut only through the outer panel.

|

|

3.

|

Cut the front sill as illustrated. Cut through 2 panels.

|

|

4.

|

Drill out the spot welds.

|

|

5.

|

Cut the B-pillar inner panel from the inside of the car as illustrated.

|

|

6.

|

Tap out the outer sill together with the B-pillar.

|

|

7.

|

Protect the roof from welding and grinding splatter.

|

|

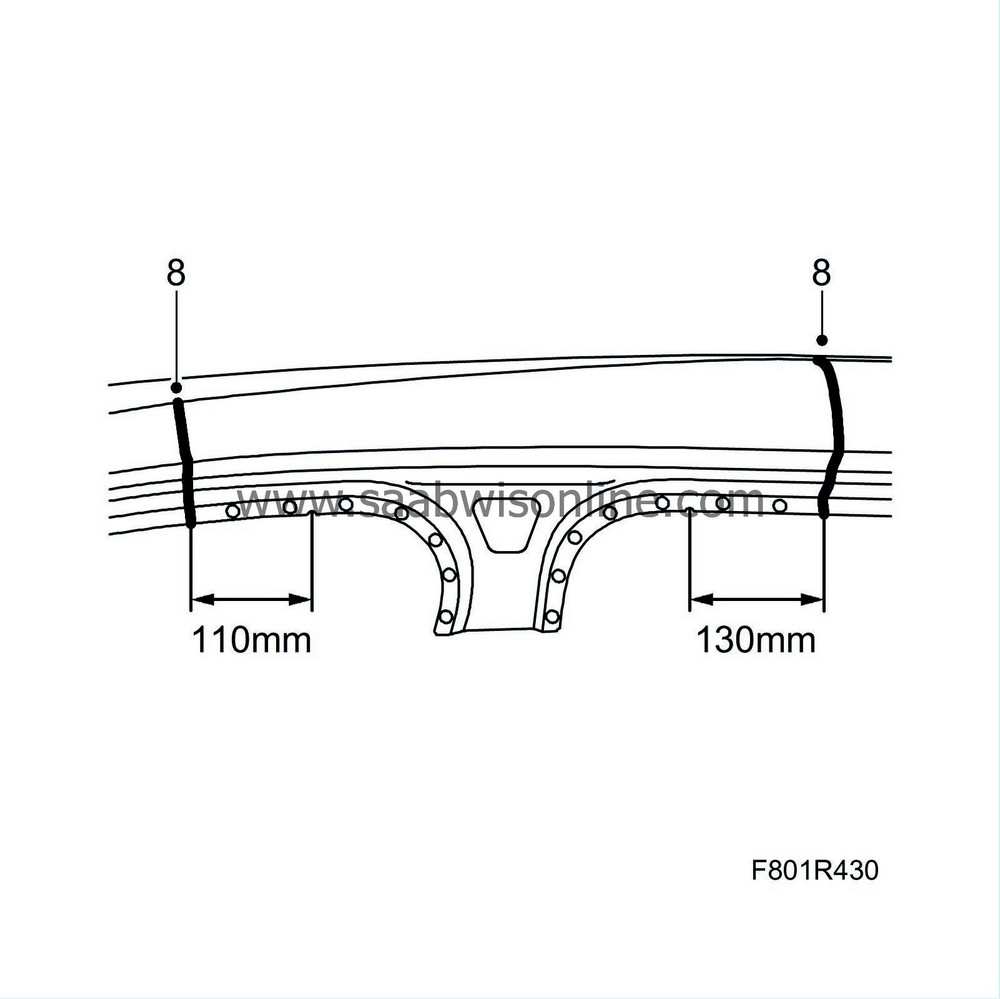

8.

|

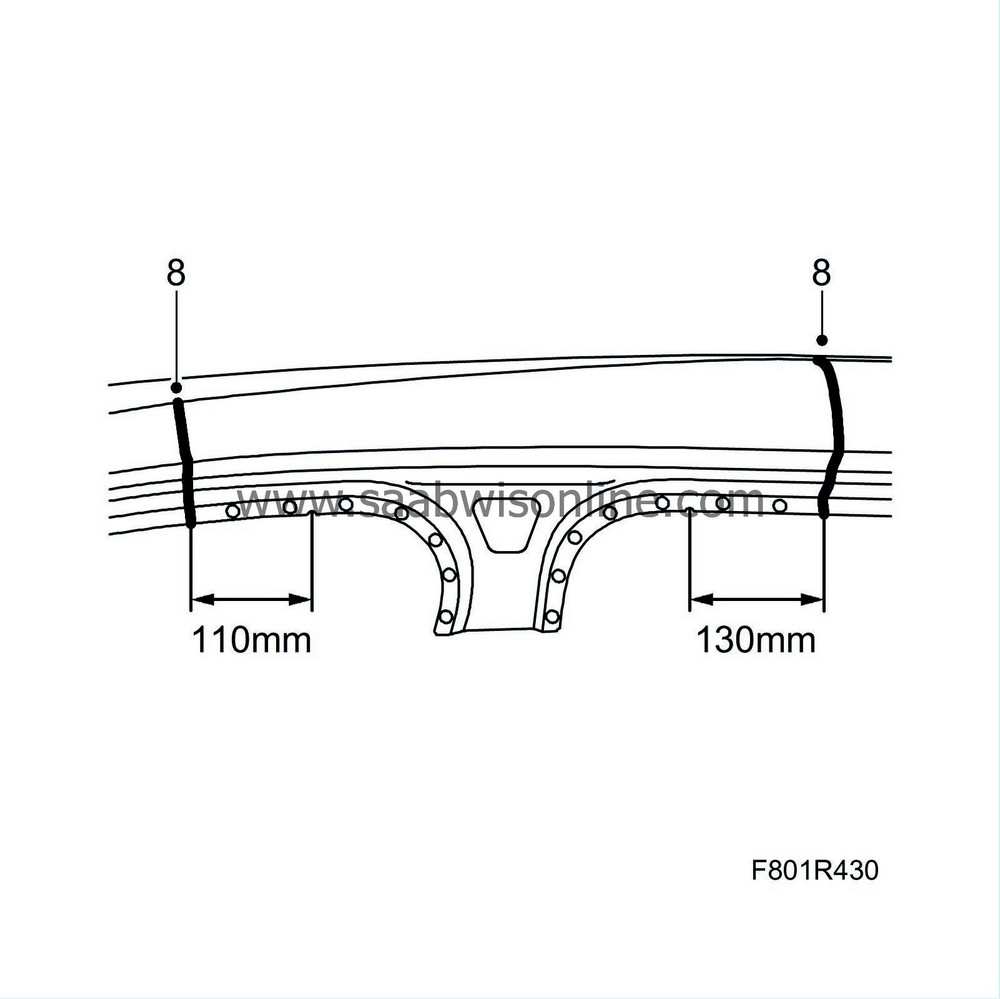

Cut the upper section of the B-pillar's outer panel as illustrated. Measure from the measurement points.

|

|

9.

|

Cut the upper section of the B-pillar's outer panel as illustrated.

|

|

10.

|

Drill out the spot welds. Tap the section away.

|

|

11.

|

Drill out the spot welds at the roof through the roof panel and outer panel.

|

|

12.

|

Carefully tap up the edge of the roof and drill out the spot welds on the remaining section of outer panel. Tap the section of outer panel away.

|

|

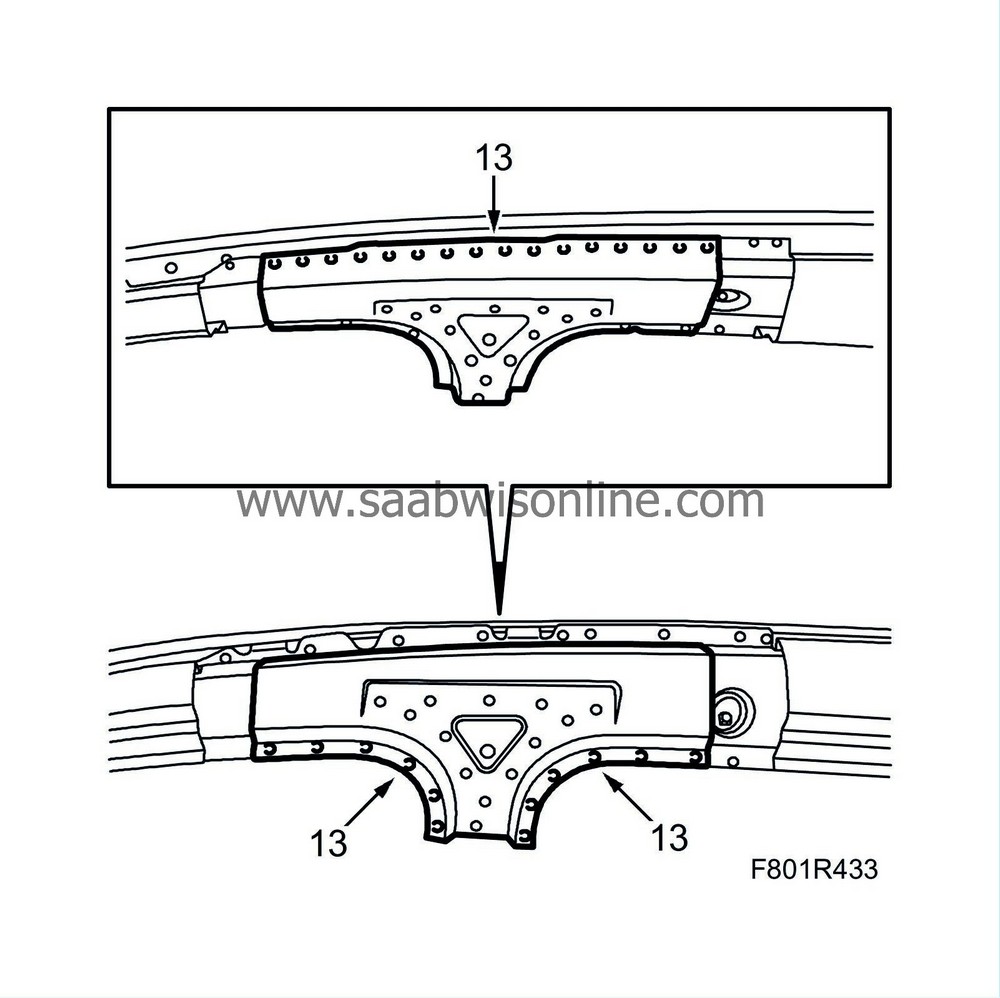

13.

|

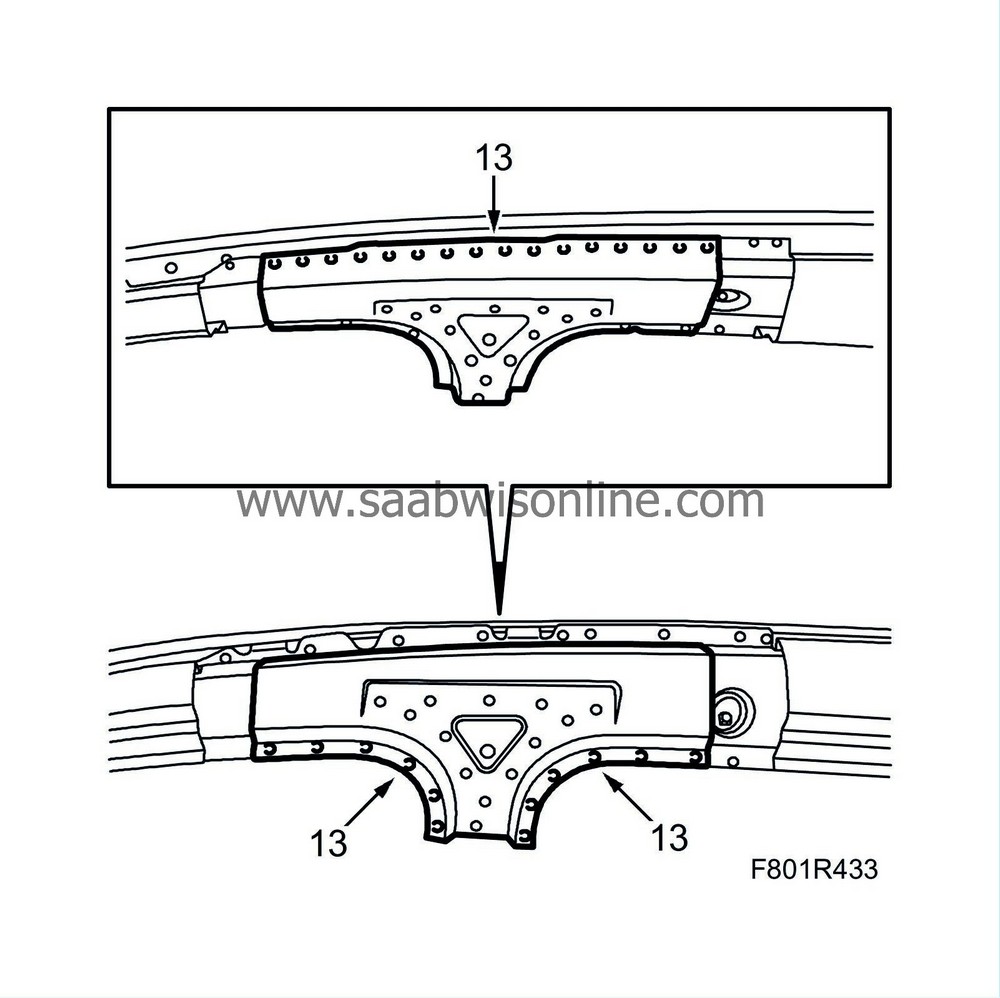

Drill out the spot welds for the B-pillar reinforcement. Carefully tap away the reinforcement.

|

|

14.

|

Mark out the positions on the inside of the B-pillar's upper and lower sections.

|

|

15.

|

Drill out the spot welds on the inside of the B-pillar's upper section. Tap the section away.

|

|

16.

|

Drill out the spot welds on the inside of the B-pillar's lower section. Tap the section away.

|

|

17.

|

Drill holes for plug welding in the spare part, the inside of the B-pillar.

|

|

18.

|

Grind all surfaces that are to be plug welded.

|

|

19.

|

Apply welding primer to all surfaces that are to be plug or spot welded.

|

|

20.

|

Align the inside of the B-pillar using the earlier markings.

|

|

21.

|

Weld in the inside of the B-pillar at the lower edge. Grind in the welds

|

|

22.

|

Weld in the inside of the B-pillar at the upper edge. Grind in the welds.

|

|

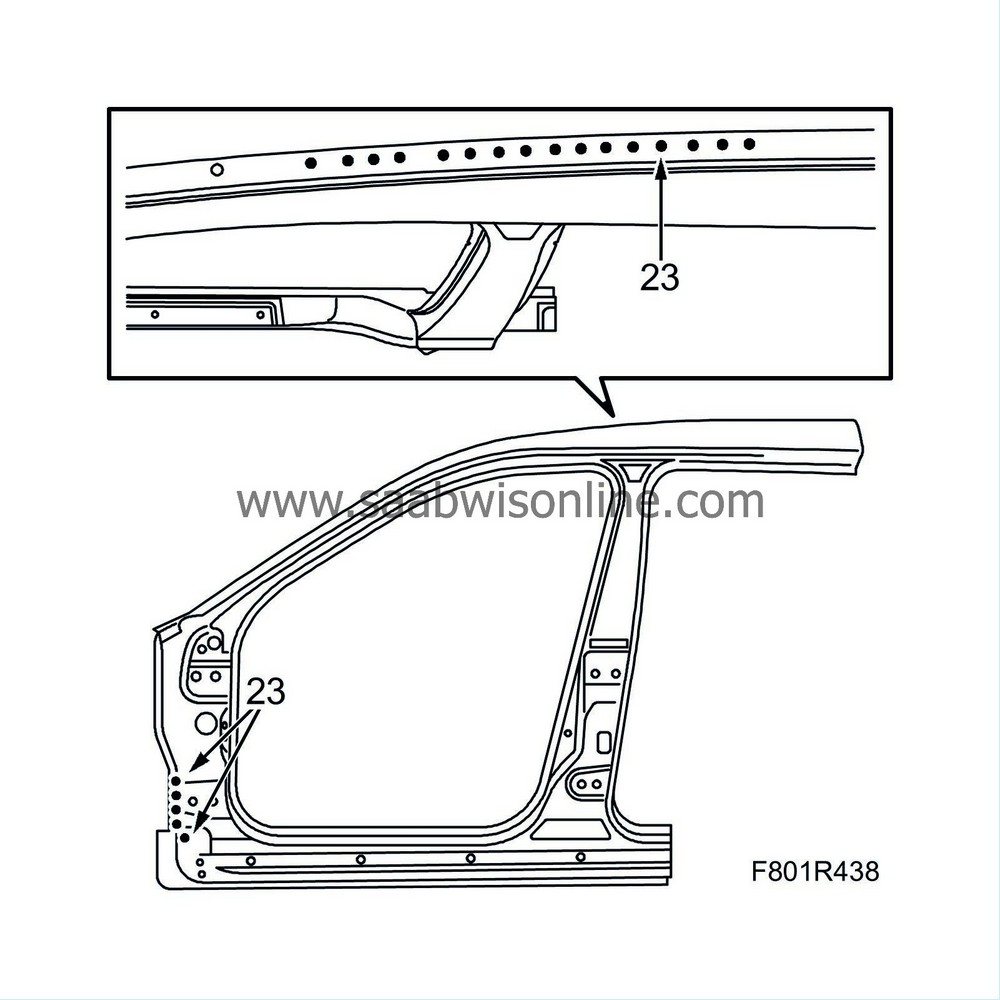

23.

|

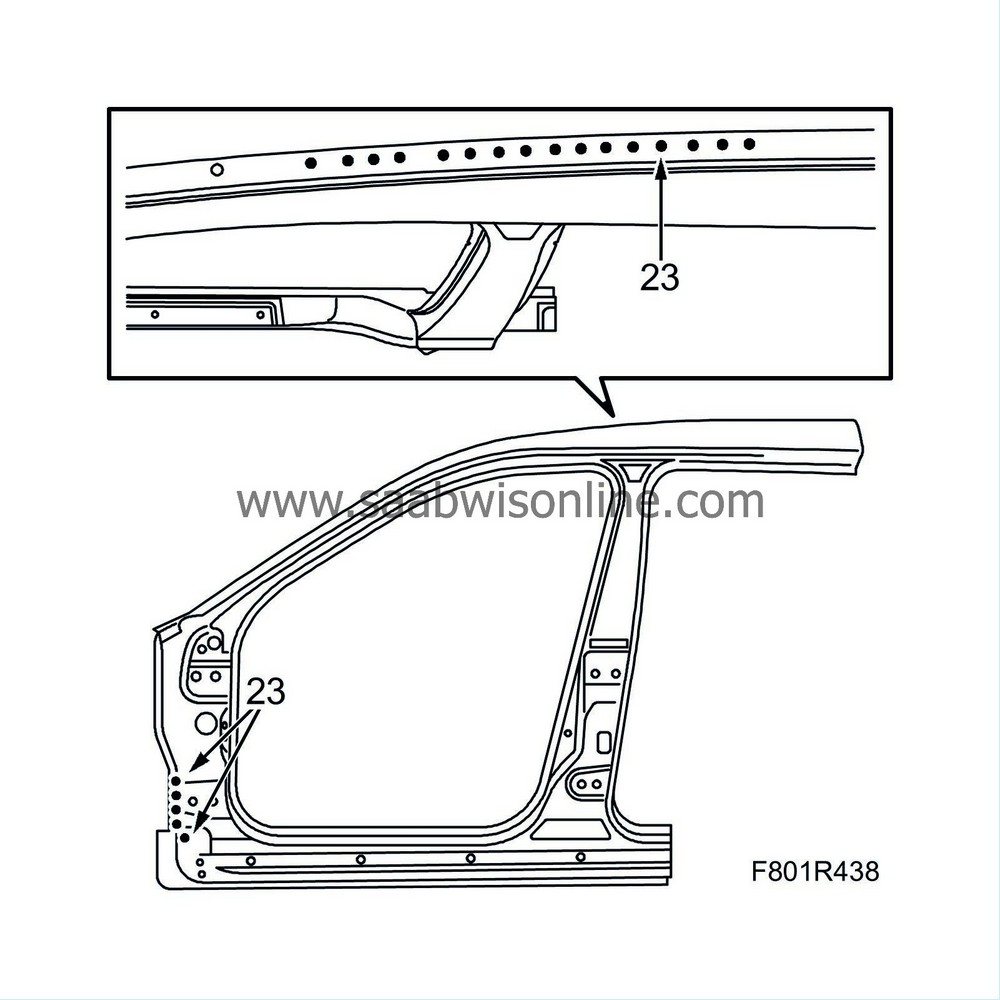

Drill through the outer panel and the reinforcement at the upper edge of the spare part for plug welding.

|

|

24.

|

Prepare the whole side of the spare part. Cut the spare part's upper edge against the roof so that it fits in with the earlier cutting.

|

|

25.

|

Make a mark on the front sill of the replacement panel. Make the mark so that it matches the cut previously made on the car. The cut should be made a few mm above the mark so the length can be adjusted during mounting. The cut should be made through all panels.

|

|

26.

|

Cut the rear sill of the spare part so that it fits the cut made earlier on the rear sill.

|

|

27.

|

Cut the outer front sill of the replacement panel to be able to weld the reinforcement.

|

|

28.

|

Drill out the spot welds and save the loose piece. Drill out the plug welding on the front sill of the spare part.

|

|

29.

|

Grind all surfaces that are to be welded.

|

|

30.

|

Apply welding primer to all surfaces that are to be plug or spot welded.

|

|

31.

|

Align the spare part by inserting it under the roof, rear sill and front reinforcement.

|

|

32.

|

Plug weld, all-weld and seam weld the spare part in at the upper edge against the roof. Grind in the welds.

|

|

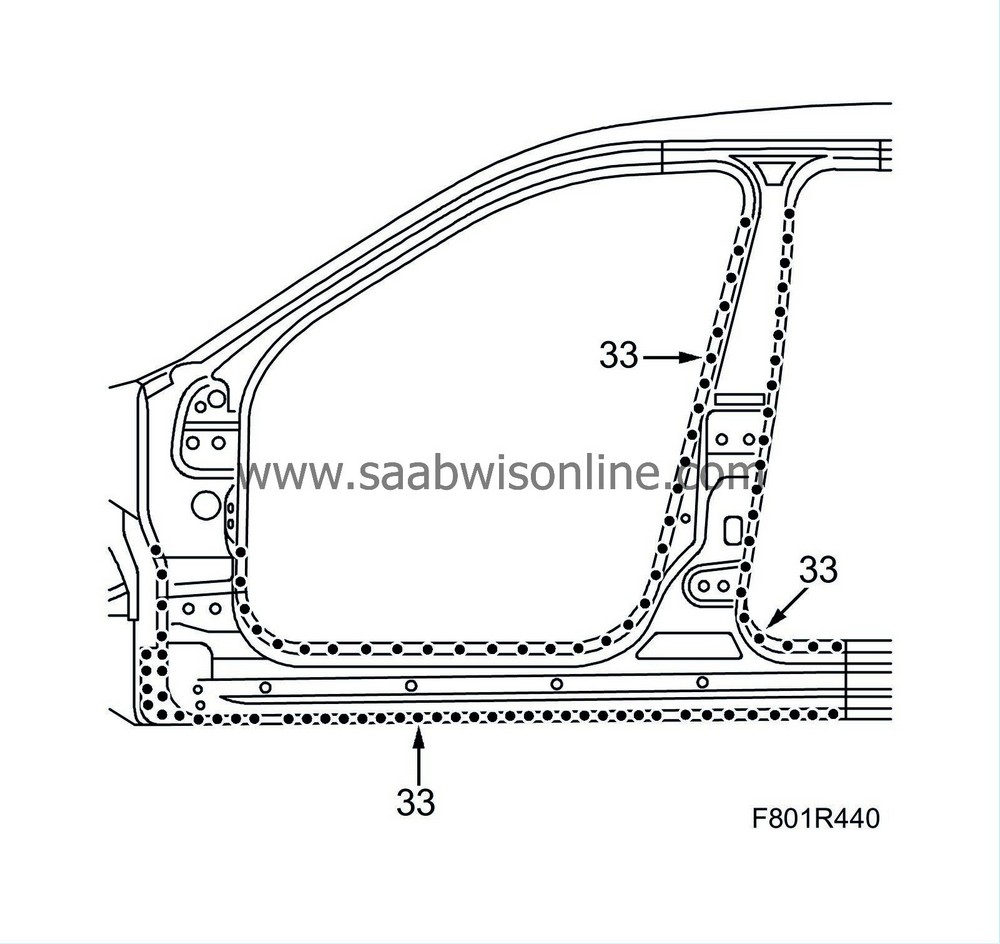

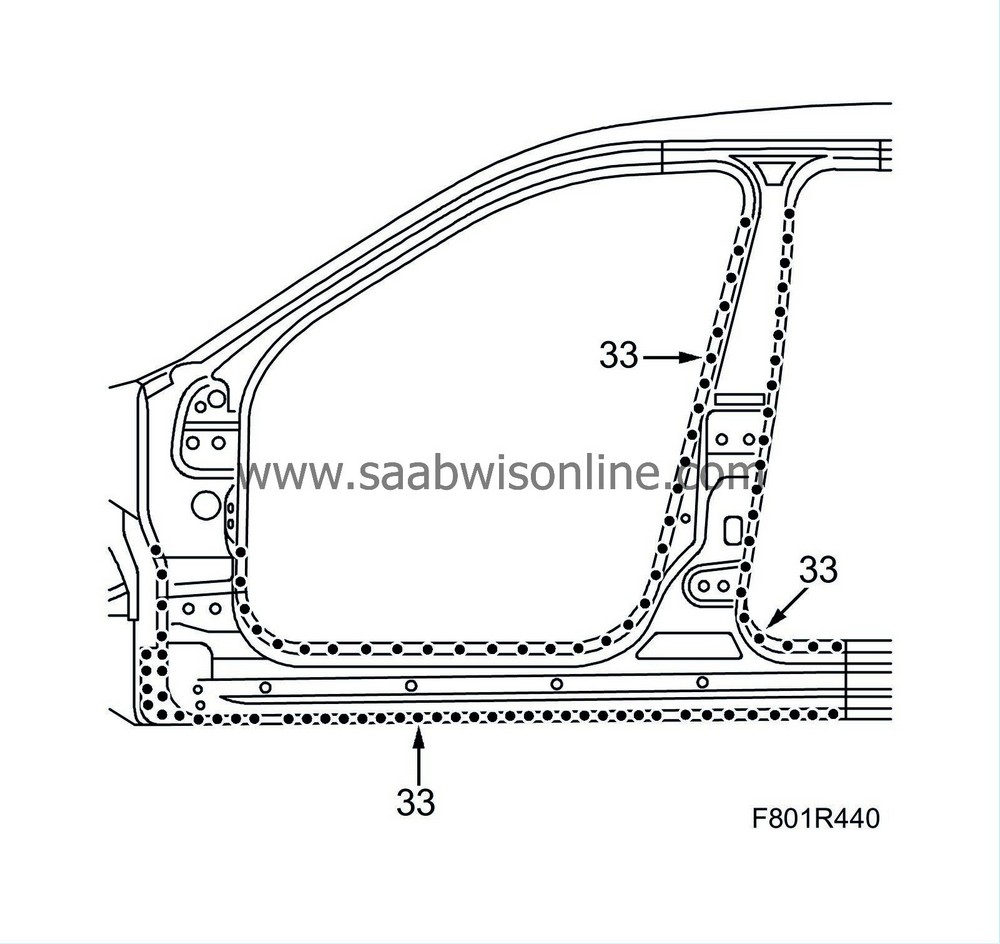

33.

|

Spot-weld the spare part.

|

|

34.

|

Tap down the edge of the roof against the outer panel and the B-pillar reinforcement. Plug weld the drilled-out holes.

|

|

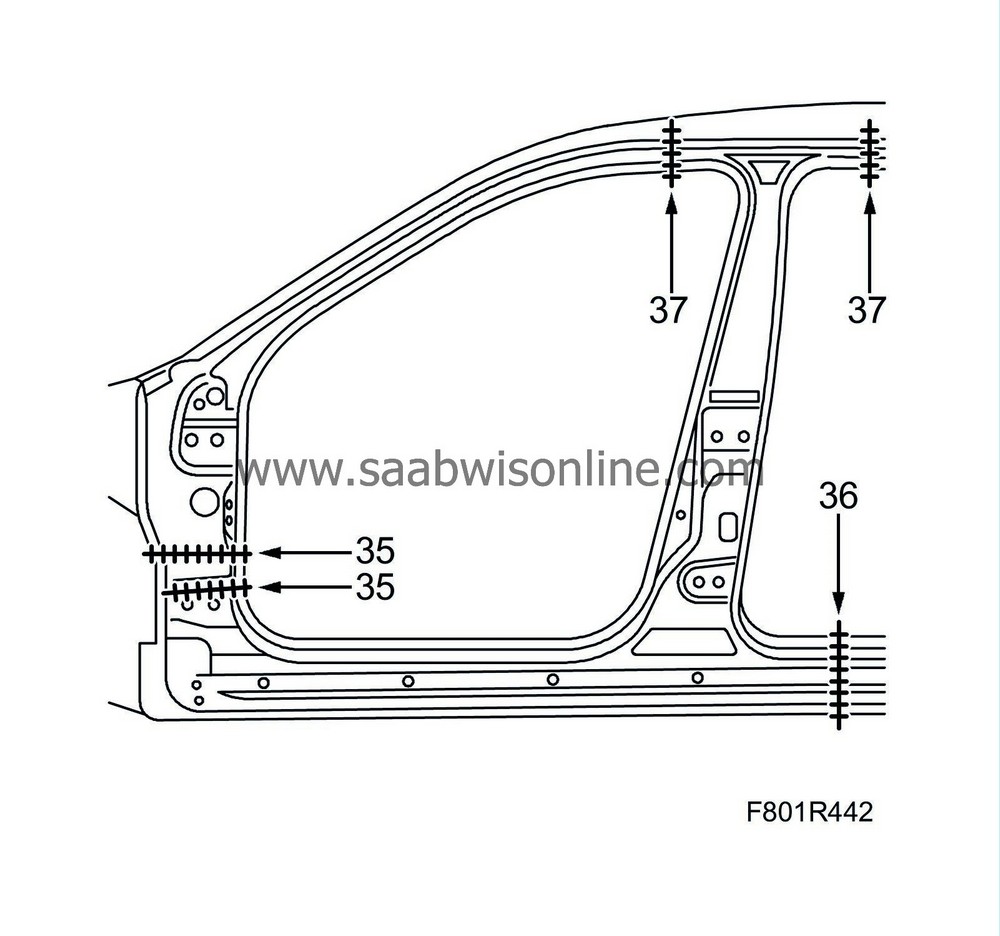

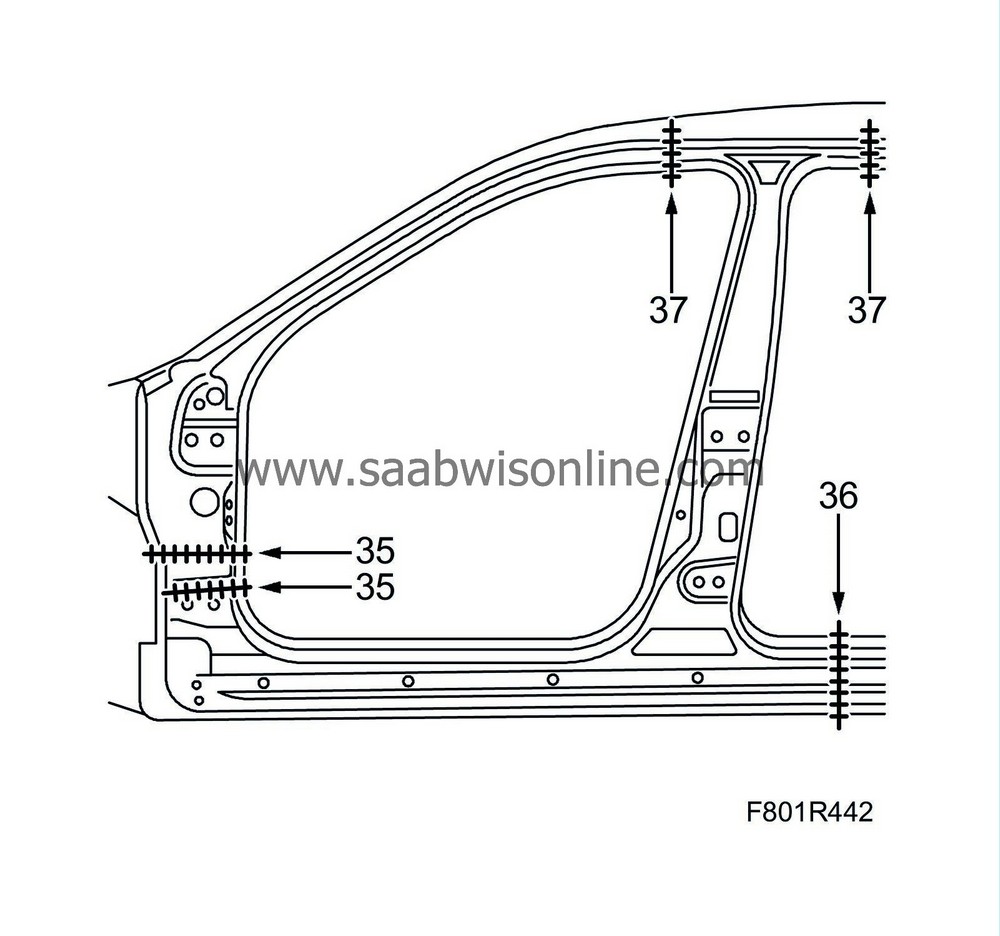

35.

|

All-weld in the front sill reinforcement and the loose piece.

|

|

36.

|

All-weld the rear sill.

|

|

37.

|

All-weld the upper section of the B-pillar.

|

|

39.

|

Wash away surplus welding primer. Welding primer reduces the adhesion of paint, filler and sealant.

|

|

40.

|

Apply primer to all bare metal surfaces.

|

|

41.

|

Seal joints and seams with sealant.

|

|

42.

|

Apply rust protector after painting. Use Terotex HV 400.

|