Seat member, CV

| Seat member, CV |

| 1. |

Position the car in an aligning bench and cross-measure if necessary.

|

|

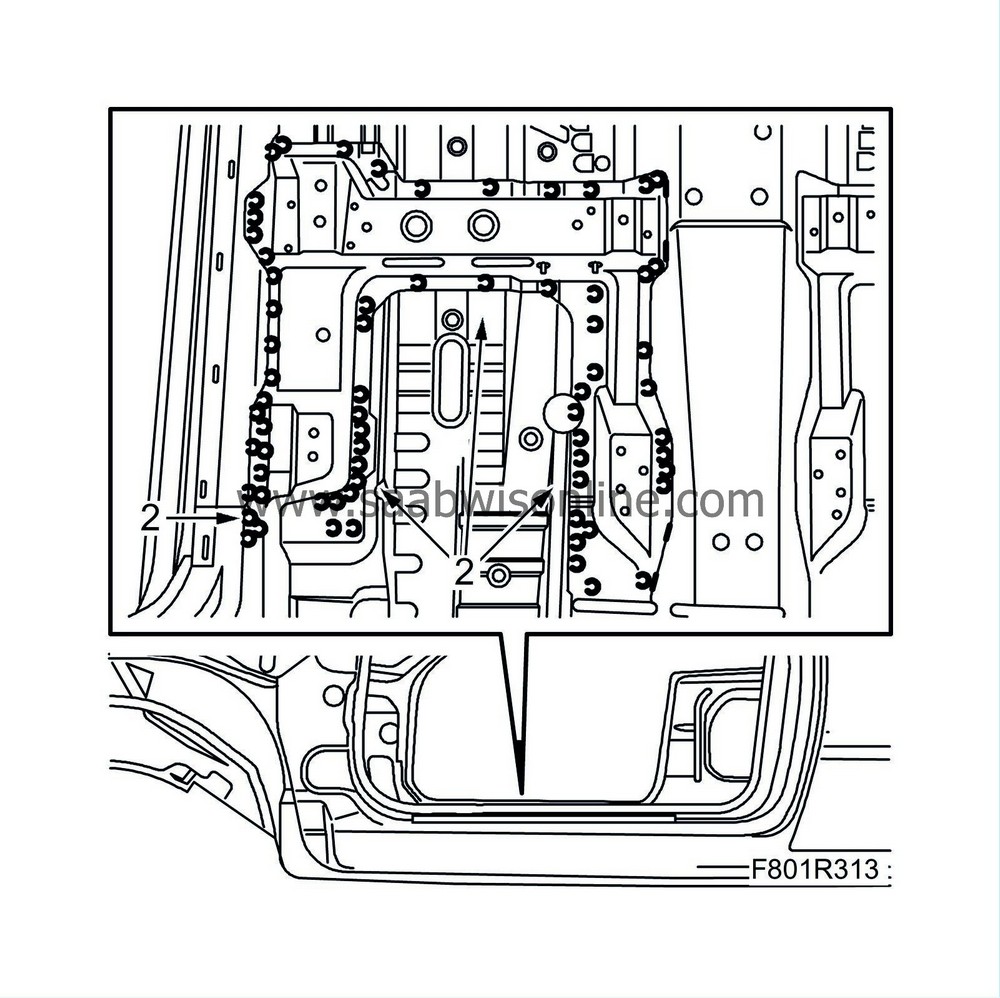

| 2. |

Drill out the spot welds.

|

|

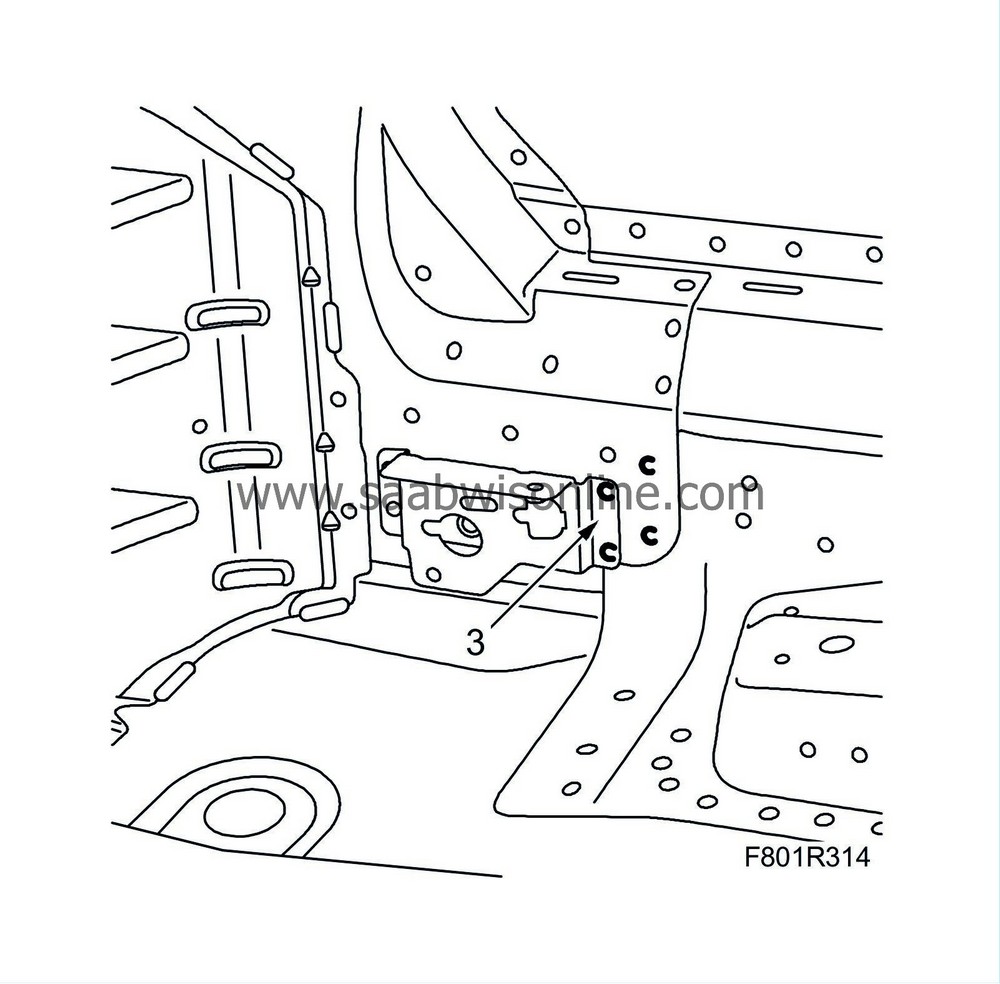

| 3. |

Drill out the spot welds.

|

|

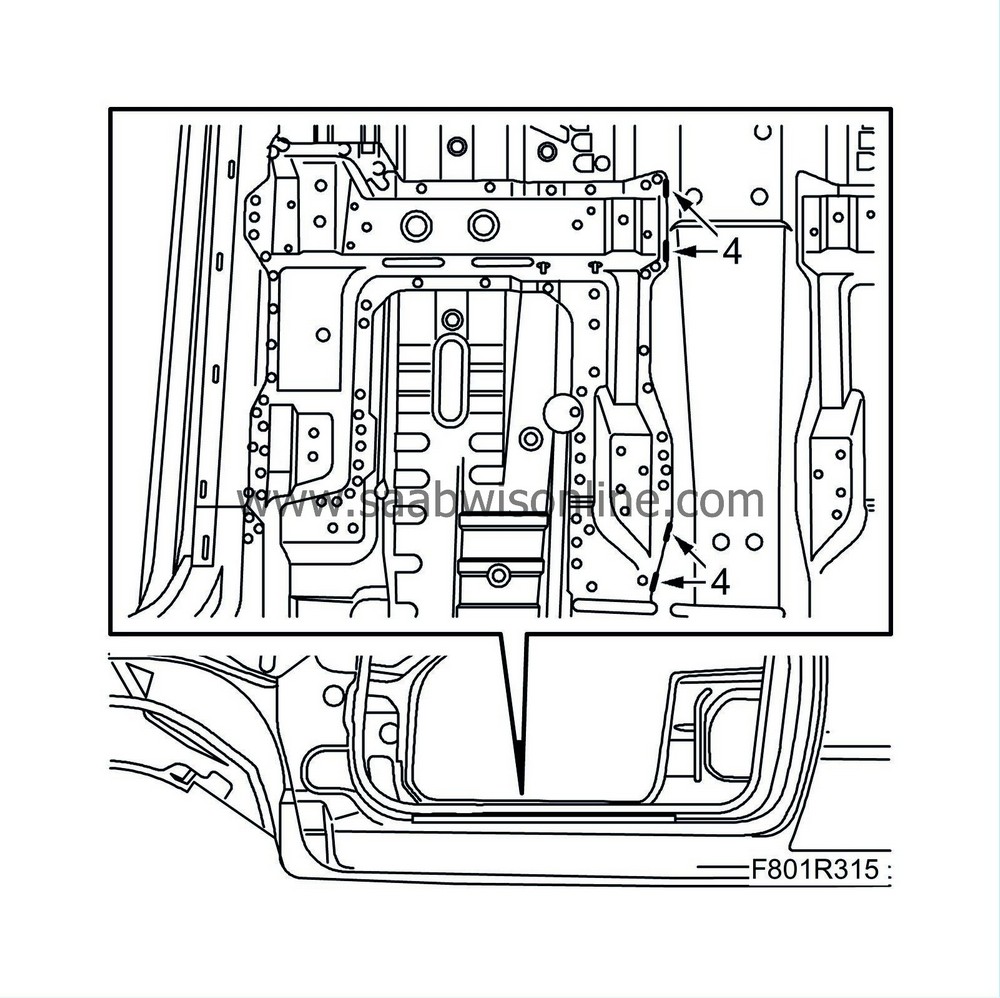

| 4. |

Grind away the seam welds to the seat member.

|

|

| 5. |

Bend up the corners slightly to easier remove the seat member.

|

|

| 6. |

Knock loose the seat member and straighten any deformed metal.

|

|

| 7. |

Grind all surfaces that are to be welded.

|

|

| 8. |

Drill holes for plug-welding in the spare part.

|

|

| 9. |

Apply welding primer to the surfaces to be spot and plug welded. Use Teroson Zink Spray.

|

|

| 10. |

Place the seat member in fitting position and secure with a few welding clamps.

|

|

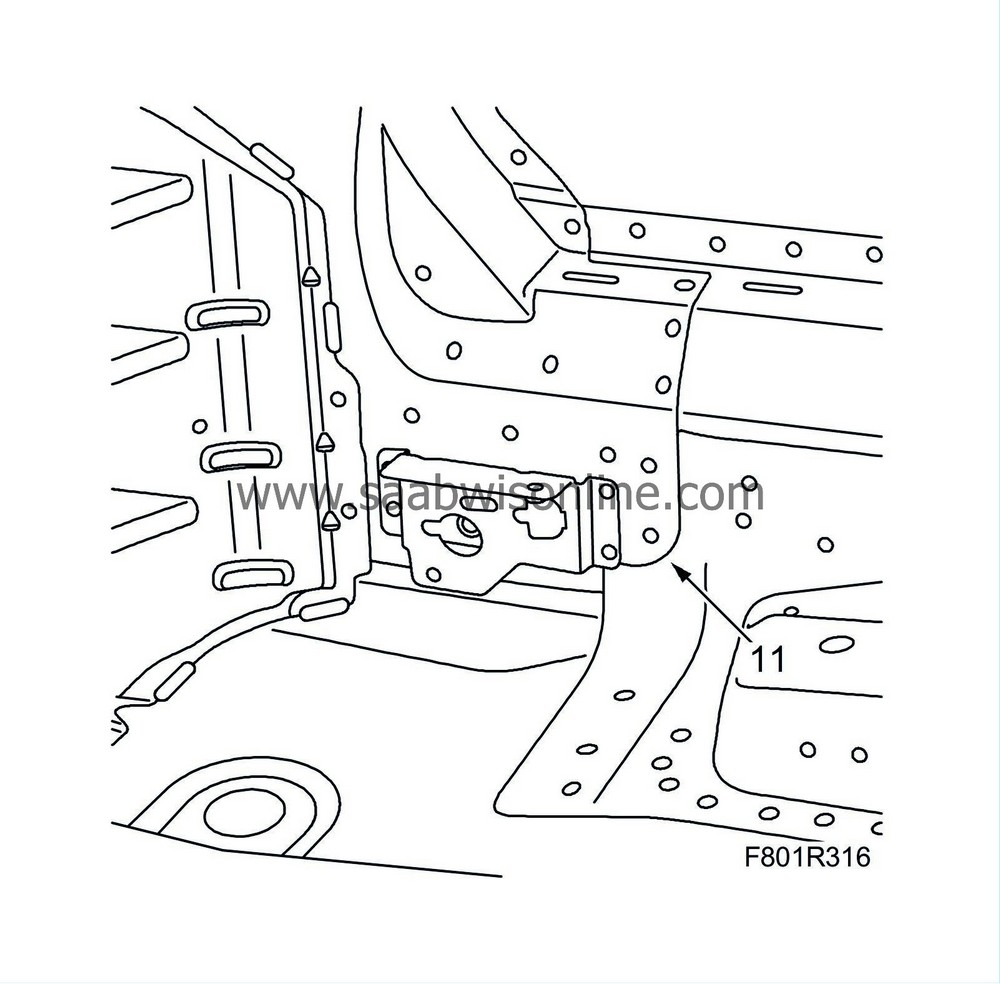

| 11. |

Adjust the corner that is overlapping the seat member.

|

|

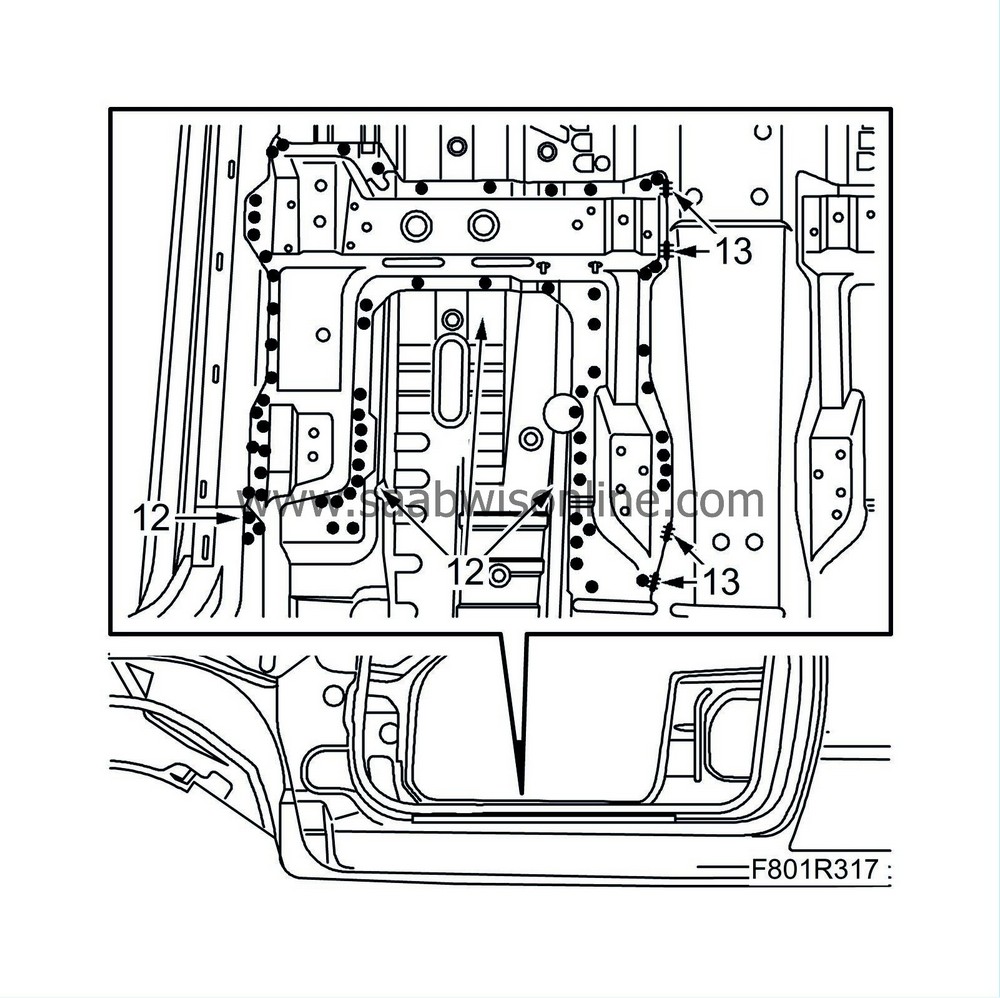

| 12. |

Spot and plug weld the seat member.

|

|

| 13. |

Seam weld the seat member.

|

|

| 14. |

Wash away surplus welding primer. Welding primer reduces the adhesion of paint, filler and sealant.

|

|

| 15. |

Apply primer to all bare metal surfaces. Use Standox 1K.

|

|

| 16. |

Seal joints and seams with sealant. Use 1K-PUR.

|

|

| 17. |

Apply anti-corrosion agent to internal surfaces after painting. Use Terotex HV 400.

|

|