(TA291-1002) Extended trouble shooting Turbo 1.9 DTR Diesel

| TECHNICAL ADVICE - Quick information for your help | |

| Bulletin Nbr: | TA291-1002 |

| Date: ........... | March 2010 |

| Market: | Diesel |

| Extended trouble shooting Turbo 1.9 DTR Diesel |

| VEHICLES CONCERNED |

Saab 9-3 My 08- with 1.9 DTR diesel engines.

| BACKGROUND |

Analysis has shown that 50% of replaced turbo’s from the field are tested with no fault found. In many cases the replacement is caused by other components in the turbo system such as cracked / kinked/ loose hoses or other issues.

Note: There are cases where there is no MIL (Malfunction Indication Lamp) and fault code set but there is still a failure in the system.

Note: Low boost pressure can also create abnormal heavy soot build up.

| CONDITIONS |

All driving conditions.

| SYMPTOM DESCRIPTION |

Low performance, noise or exhaust leakage.

| ACTION |

Check for failure codes with Tech2. If there are codes follow the troubleshooting according to TIS2WEB.

Low performance

Boost pressure performance can be checked with Tech 2 during acceleration from 1500 rpm and up to full throttle by comparing requested manifold absolute pressure and manifold absolute pressure; the difference should not exceed 20-30 KPa.If the difference is larger:

| • |

Check for loose/cracked/kinked hoses around the turbo

|

|

| • |

Check for loose/cracked/kinked hoses around the intercooler and

boost pressure control valve

|

|

Pressure test the inter cooler with hoses from outlet turbo to throttle body with 150 KPa (1,5 bar)

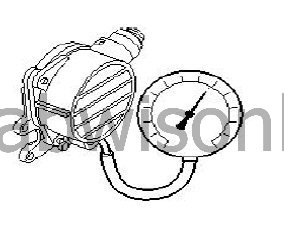

Pressure gauge 83 93 514 and plug kit EN-47656 can be used.

Note: A sticking EGR valve can cause low boost pressure without fault codes.

Connect gauge 8393514 between the boost pressure control valve and wastegate

Start the Engine and check that the waste-gate rod is moving and the under pressure of at least -0.4 bar is developed.

Check the vacuum from the vacuum pump by connecting gauge 8393514 to the vacuum pump according to picture below. Note: The under pressure must be at least -0.4 bar

Note: A cracked intercooler or hose can also create noises that might appear coming from the Turbo.

If min under pressure is not achieved then replace vacuum pump.

If OK:

Connect gauge 83 93 514 to the boost pressure control valve out connector.

Start the engine and let it run on idle.

Activate the boost control valve with Tech 2

Increase to 100%; the value should be 0 bar

To check the waste-gate:

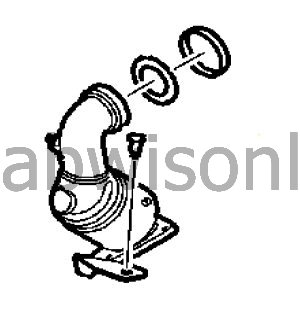

Connect the hand vacuum pump 30 14 883 to the waste-gate and create a vacuum

Check there is no leakage and that the waste-gate rod is moving.

If the remark is noise or exhaust leakage:

Check the front catalytic converter connection to the turbo in terms of leakage. Pressure test the exhaust system and use soapy water to check for leaks.

If soot deposits are on the manifold-turbo or catalytic converter remove the catalytic converter and replace the gasket.

Note: This joint is extremely sensitive and the catalytic converter should be dismounted at the rear end to ensure it is in line with the turbo before tightening the T/A GB 10/003 clamp and ensure a gas tight connection.

If the noise is present after gasket replacement inspect the manifold and the bolts on the cylinder head to ensure the torque.