Reverse gear

| Reverse gear |

| 1. |

Set up the reverse gear in

87 90 487 Sleeve, differential bearing

.

|

|

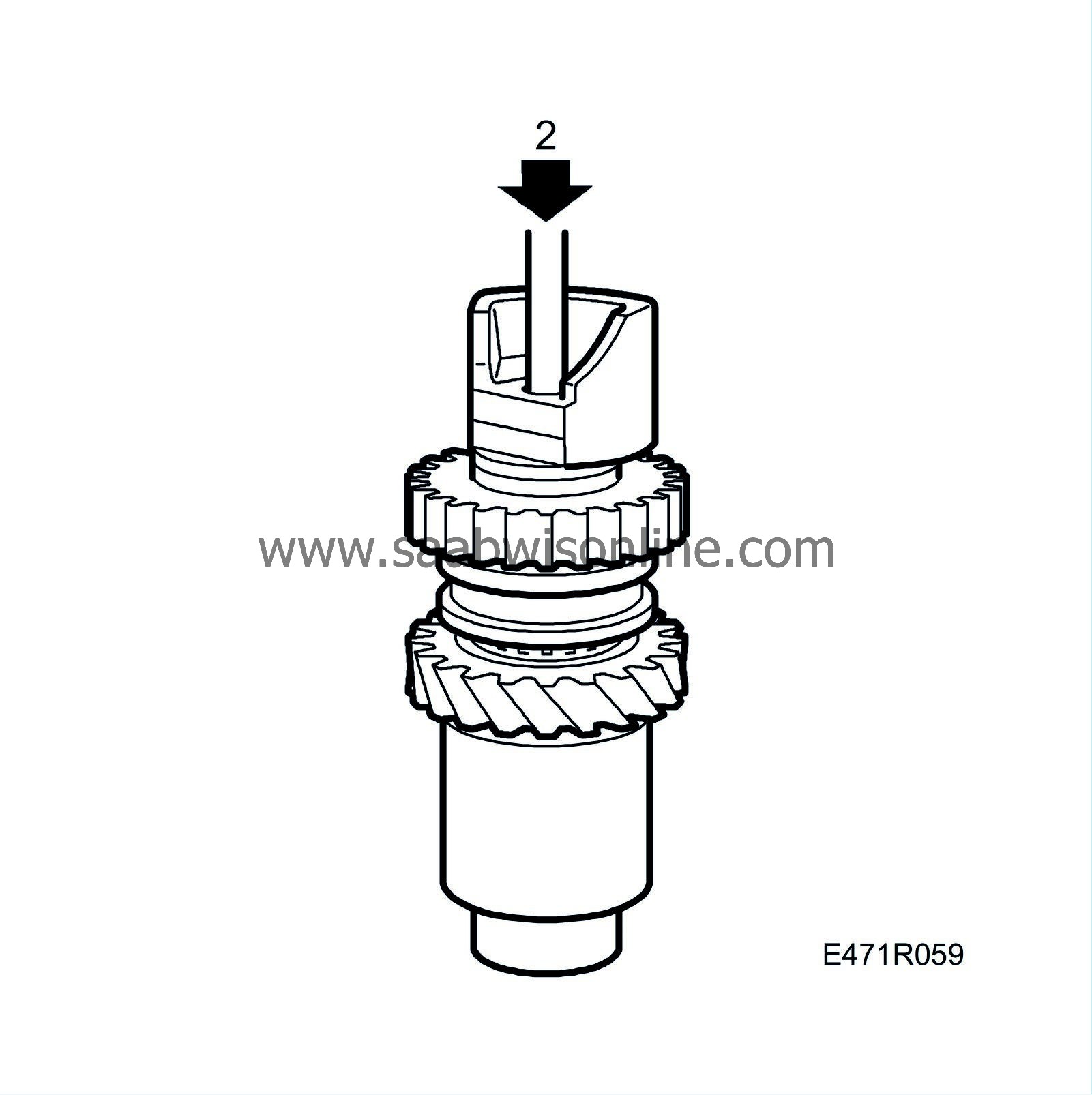

| 2. |

Carefully tap the reverse gear out of its support using a drift.

|

||||||||||

| 3. |

Lift off the bearing support, bearing washer, reverse gear pinion, synchromesh sleeve, baulk ring, wire ring, reverse gear wheel and needle bearing from the reverse gear.

|

|

| 4. |

Check the condition of all parts as regards wear. Replace damaged or defective parts. Measure the wear on the synchromesh by fitting it in place. Measure with a feeler gauge in three places and calculate an average of the readings. If the dimension is less than 0.5 mm the synchromesh must be replaced.

|

|

| To assemble |

Grease all components with synthetic manual gearbox oil before fitting, refer to Summary of lubricants and sealants .

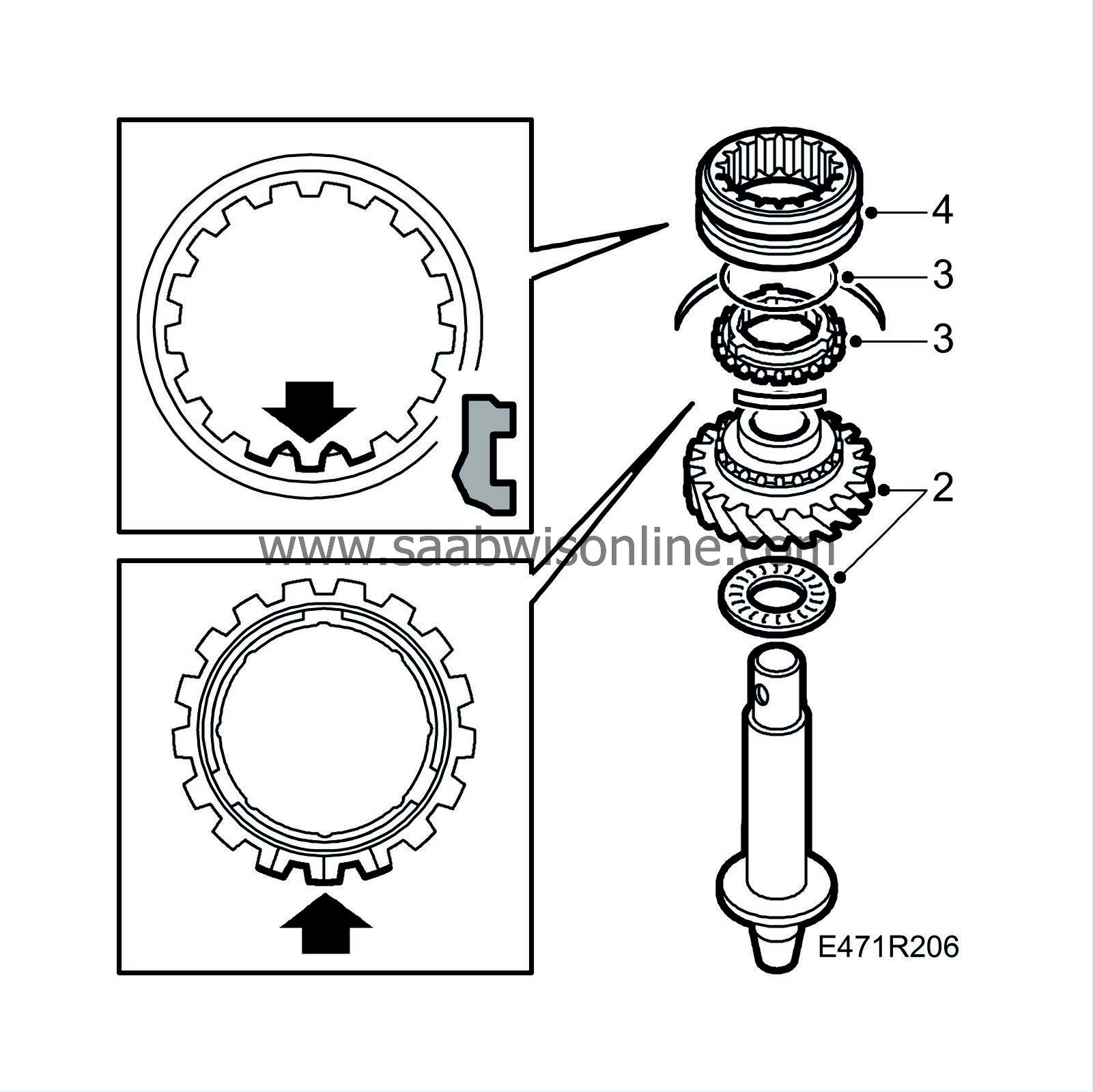

| 1. |

Place the reverse shaft in a 17 mm sleeve so that the lower support washer does not become detached from the shaft.

|

|

| 2. |

Fit the needle bearing and reverse gear wheel to the shaft.

|

|

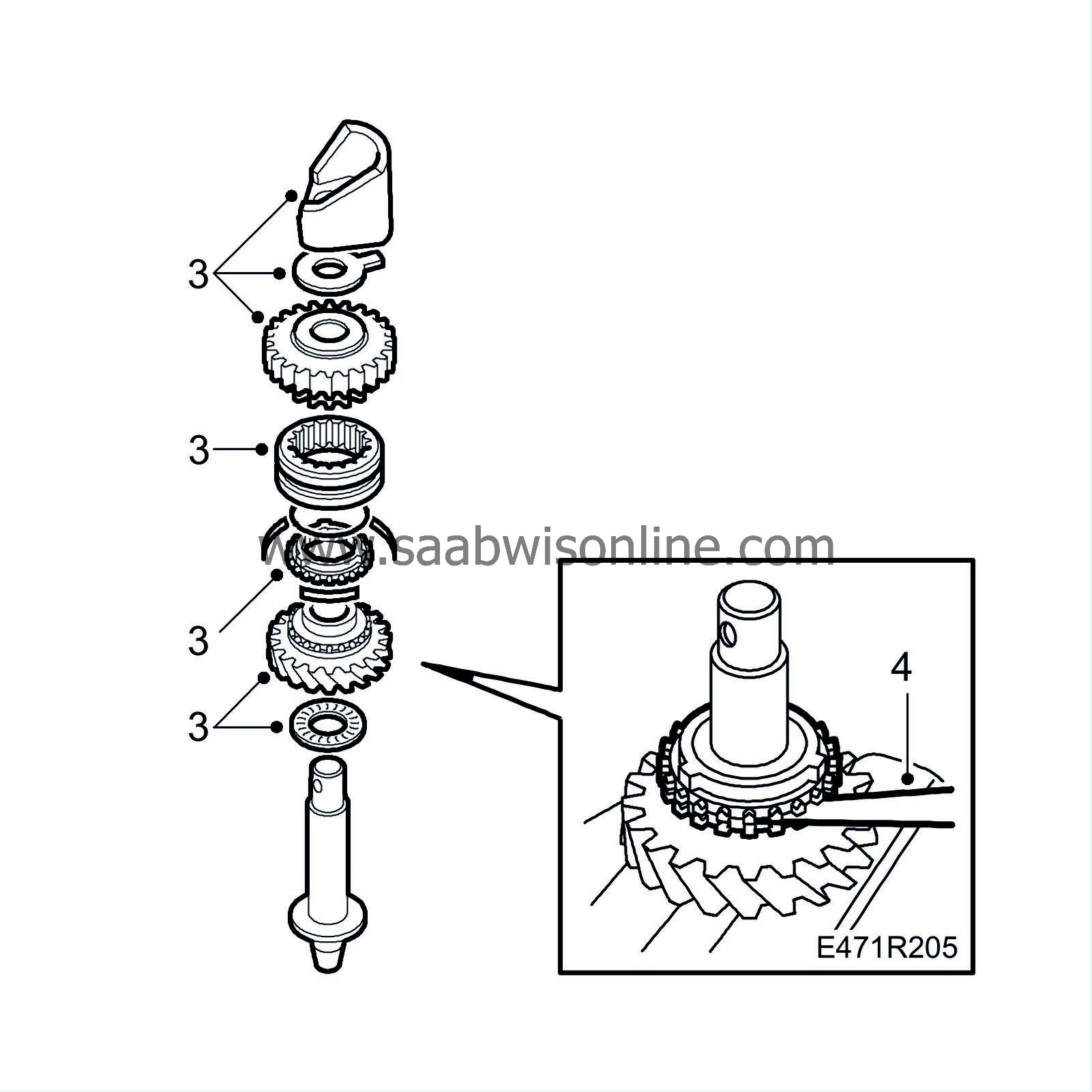

| 3. |

Fit the baulk ring. Check that the wire ring is fitted to the baulk ring.

|

|

| 4. |

Fit the synchromesh sleeve.

|

|

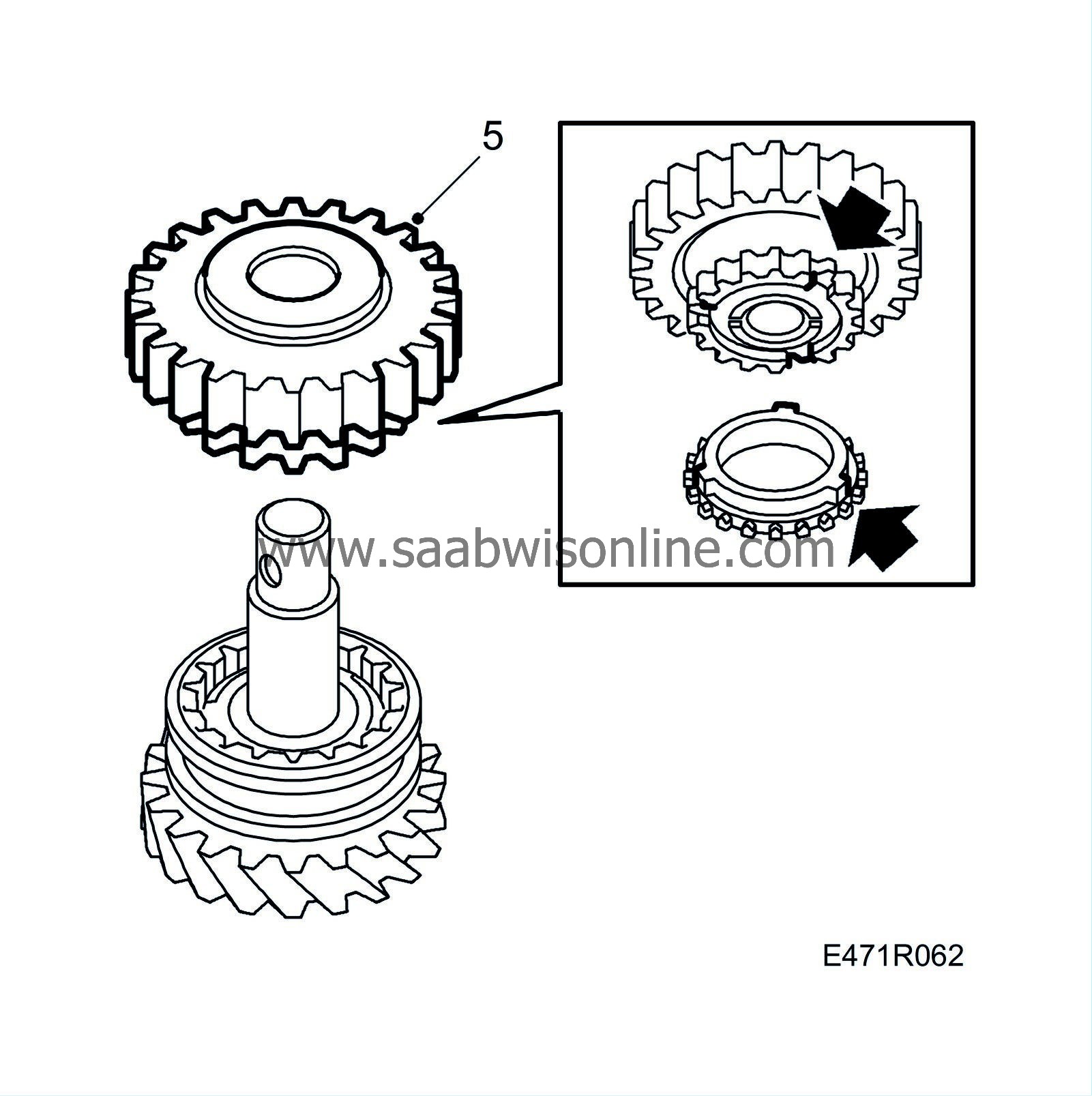

| 5. |

Fit the reverse pinion with integrated synchromesh hub.

|

||||||||||

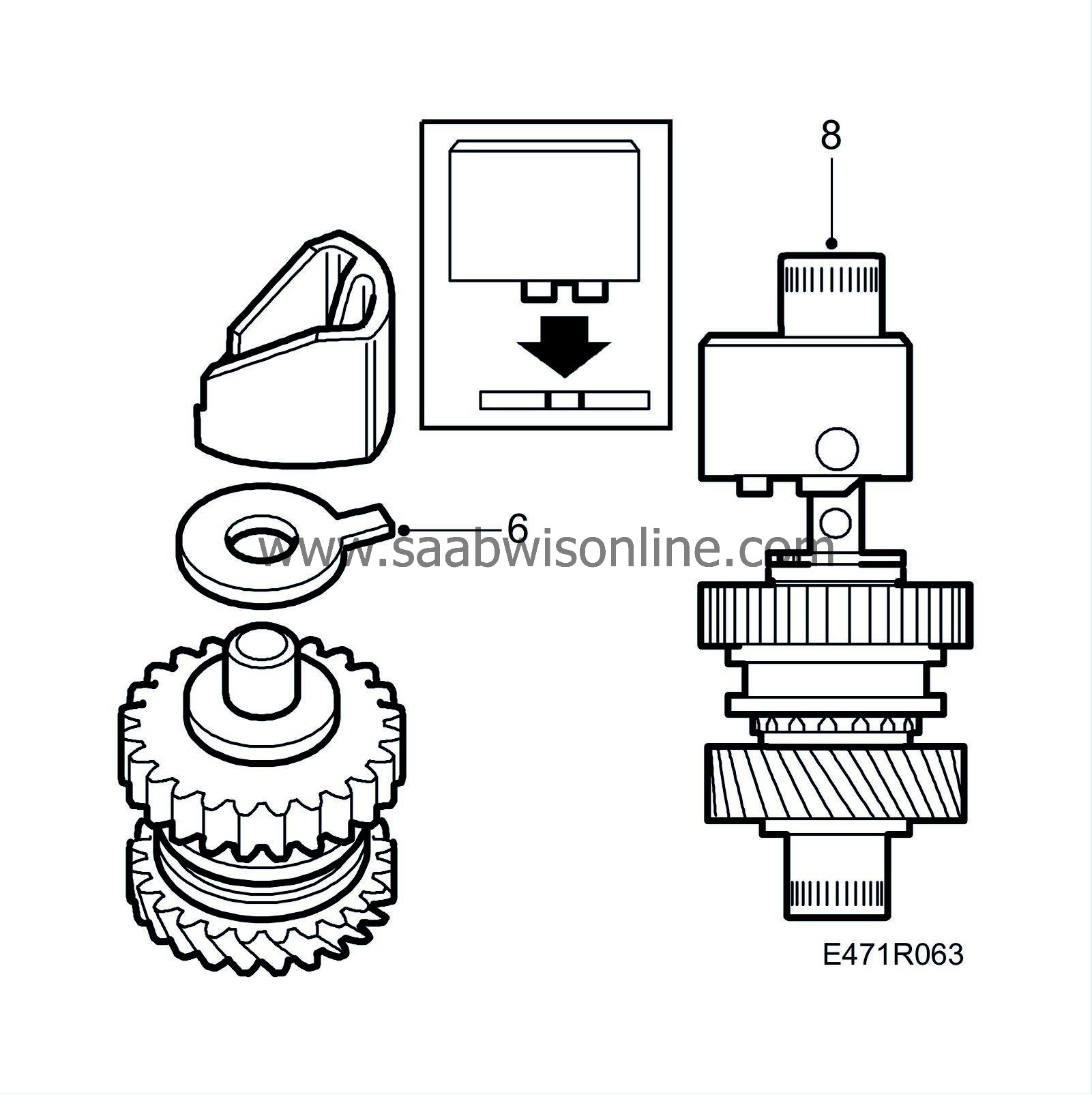

| 6. |

Fit the bearing washer. Check that the washer's tag is between the lugs on the reverse shaft support.

|

|||||||

| 7. |

Sparingly apply

Cylindrical fastening, Loctite 648

in the shaft hole on the rear axle support. Always use a new rear axle support to ensure a press fit.

|

|

| 8. |

Press on the reverse shaft support as illustrated (the holes should be aligned). Use a 17 mm sleeve and press on fully.

|

||||||||||

| 9. |

Secure the reverse shaft by screwing it in the clutch housing.

Tightening torque 24 Nm (18 lbf ft) |

|

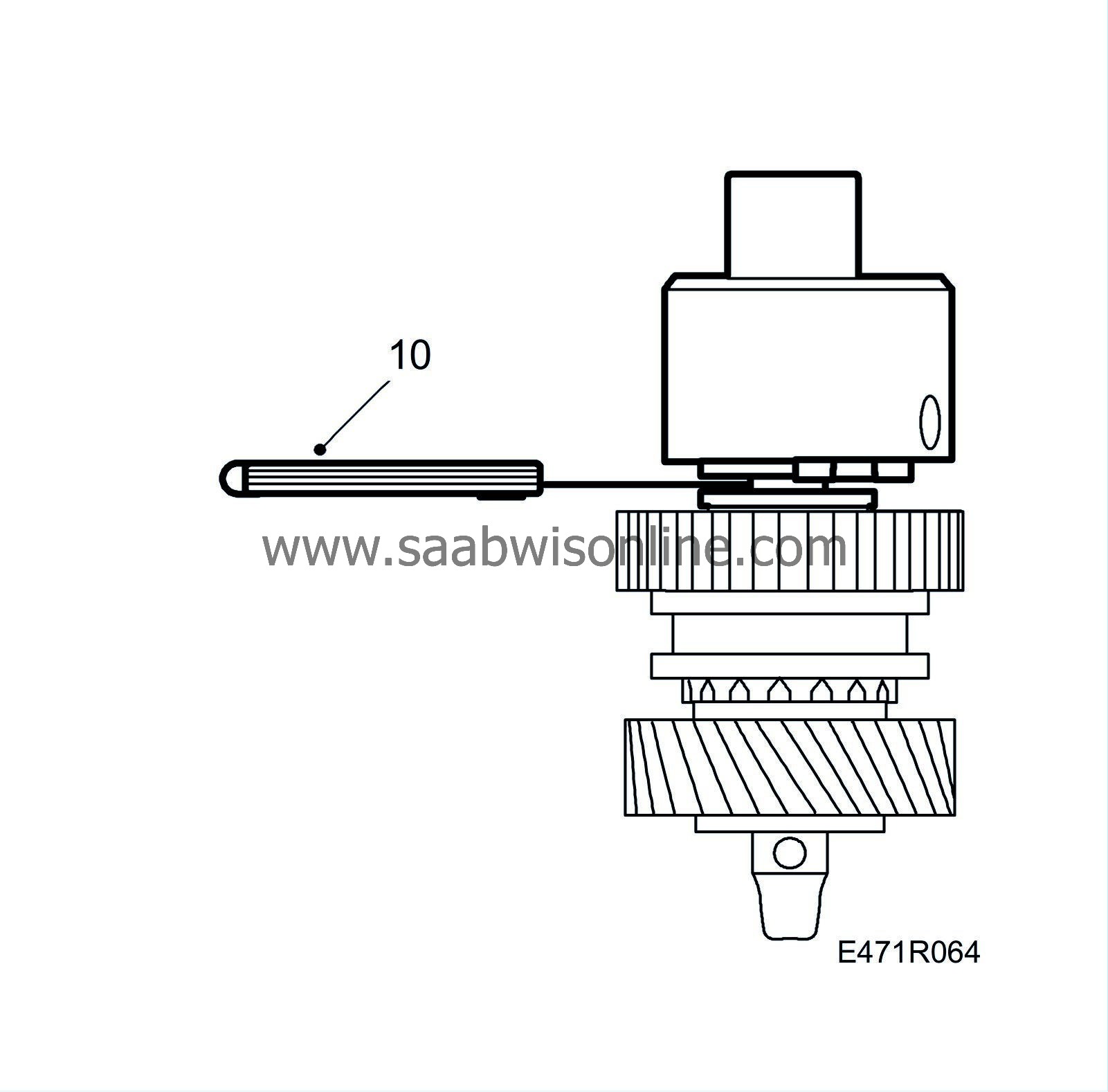

| 11. |

Try shifting the reverse gear by pushing the synchromesh sleeve up and down.

|

|