Anti-roll bar

| Anti-roll bar |

| To remove |

| 1. |

Raise the car.

|

|

| 2. |

Remove the rear wheels.

|

|

| 3. |

Cars with tyre pressure monitoring:

Remove the rear RH wing liner

.

|

|

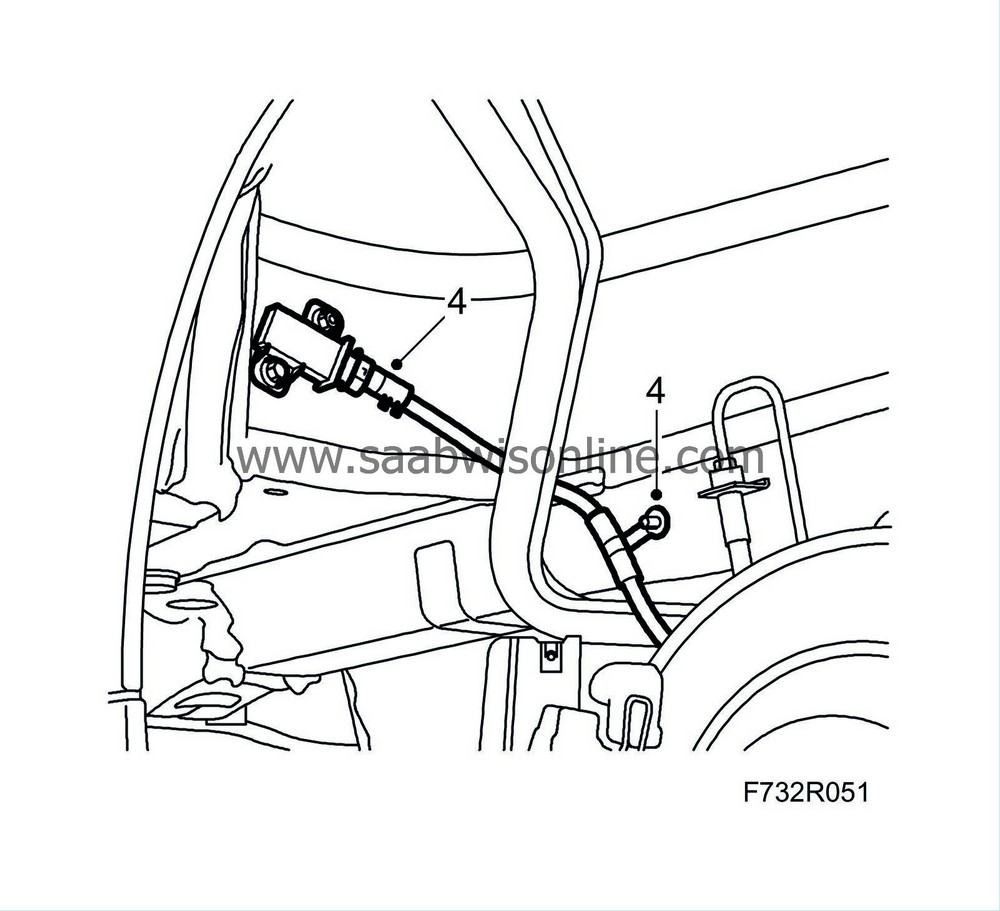

| 4. |

Cars with tyre pressure monitoring:

Unplug the connector of the signal detector, release the wheel housing clips and fold down the wiring harness.

|

|

| 5. |

CV:

Remove the chassis reinforcement from the rear subframe

.

Cut the front pipe between the flexihose and the silencer, 87 mm above the silencer. Use 83 95 667 Pipe cutter/exhaust system . See also Front silencer . Lift down the rear section of the exhaust system. |

|

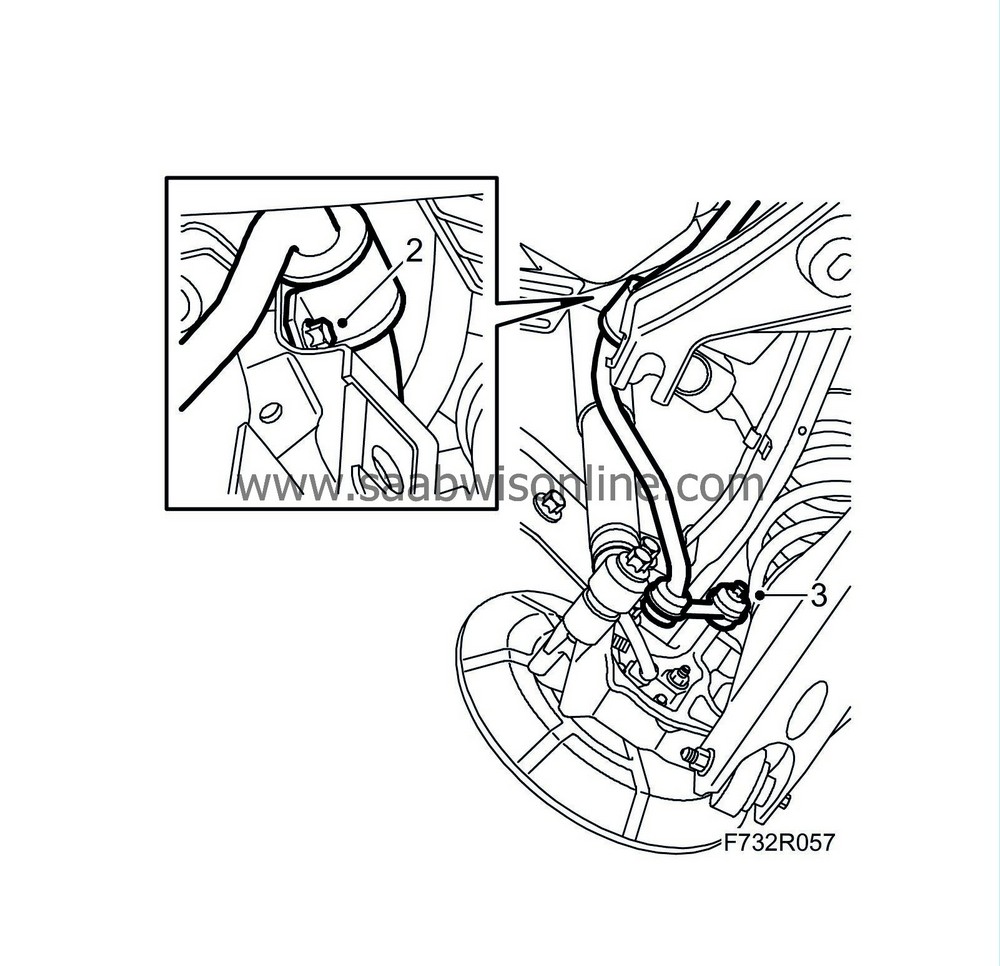

| 6. |

Remove the retaining spring from the brake caliper.

|

|

| 7. |

Remove the protective covers.

Remove the hydraulic body and suspend it with a hook in the brake pipe holder.

Remove the outer brake pad. |

|||||||

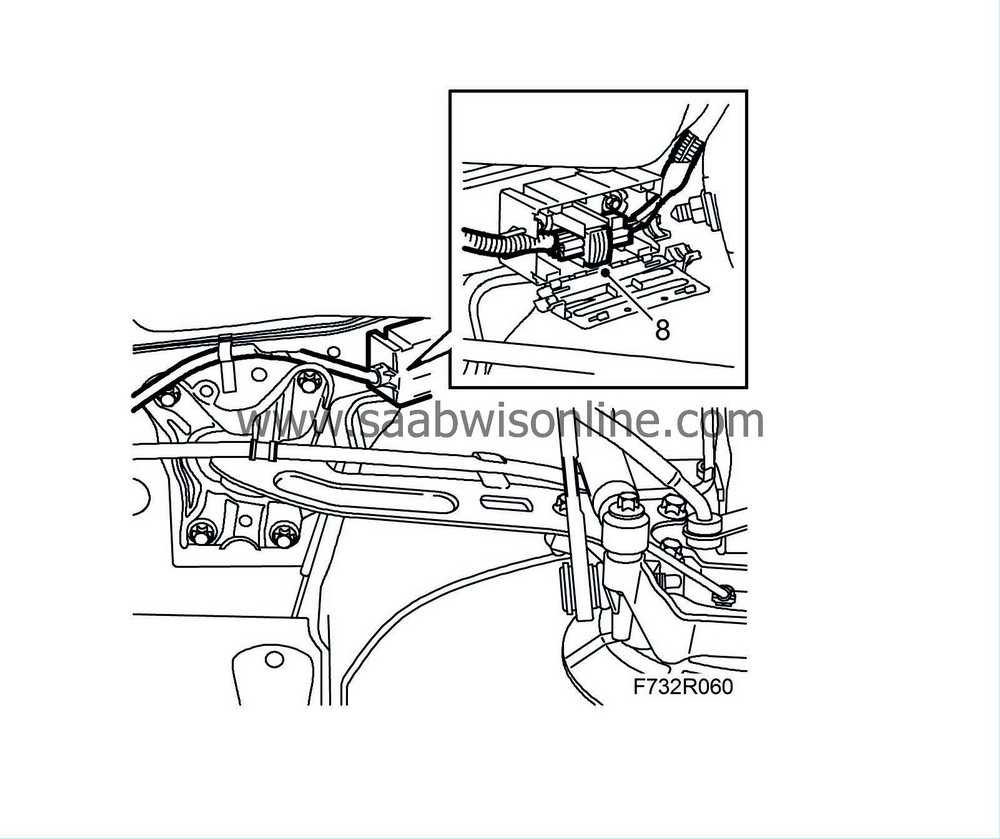

| 8. |

Remove the hydraulic body on the other side according to steps 6-7.

|

|

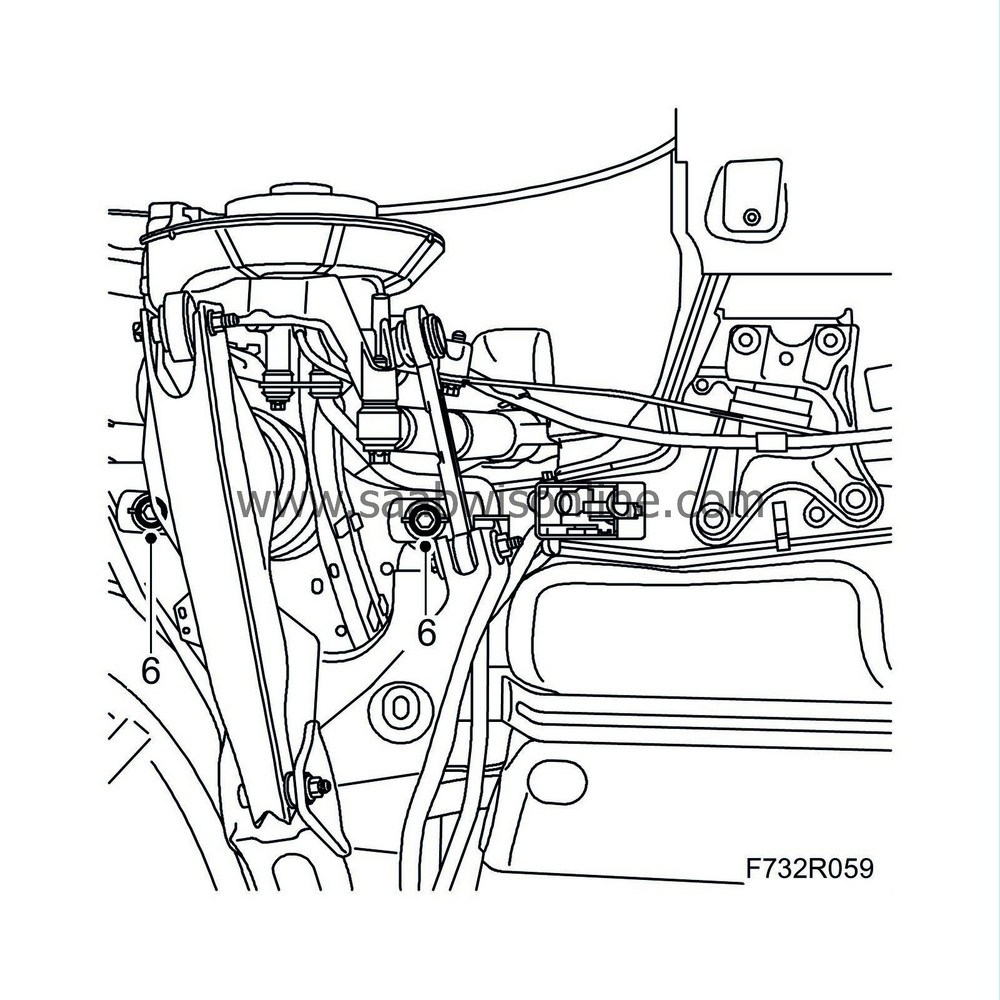

| 9. |

Relieve the weight on the shock absorbers on both sides.

Clean the bolts holding the shock absorbers to the steering swivel member and lubricate the threads. Remove the bolts.

|

|

| 10. |

Open the protective case and unplug the connection for the electrical circuit.

|

|

| 11. |

Place a pillar jack under the centre of the subframe.

|

|

| 12. |

Remove the subframe bolts from the body

|

|

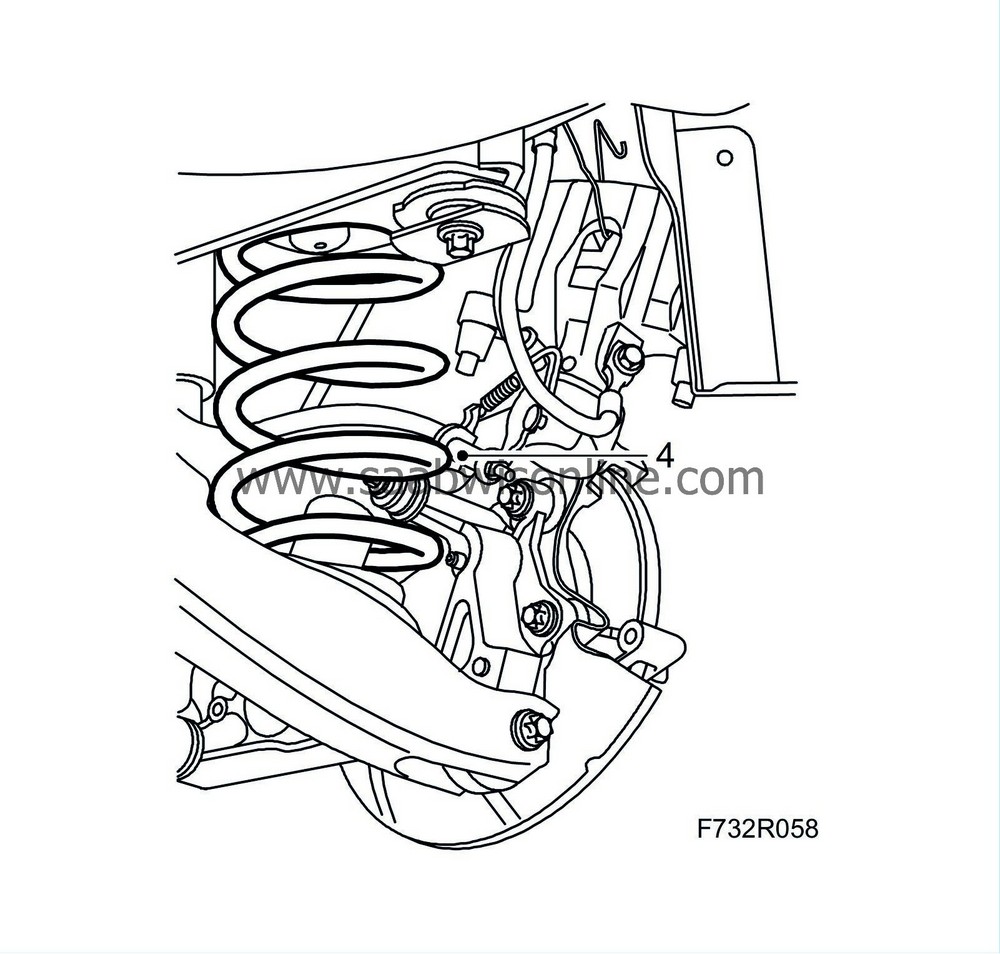

| 13. |

Lower the subframe and lift the springs away.

|

|||||||

| 14. |

Remove the anti-roll bar from the steering swivel members.

|

|

| 15. |

Remove the anti-roll bar mountings from the subframe.

|

|

| 16. |

Lift out the anti-roll bar towards the rear between the subframe and the body.

|

|

| To fit |

| 1. |

Lift the anti-roll bar into place between the subframe and the body.

|

|

| 2. |

Fit the bushes and caps on the subframe.

Fit the anti-roll bar to the subframe. Tightening torque bolt 8 8 (flange diameter 15.2 mm): 18 Nm (13 lbf ft) and use Thread locking adhesive, Loctite 242Tightening torque bolt 10 9 (flange diameter 16.7 mm): 31 Nm (23 lbf ft)

|

|

| 3. |

Fit the anti-roll bar link to the steering swivel member on both sides.

Tightening torque 53 Nm (39 lbf ft) |

|

| 4. |

Fit the spring supports on the springs. Place the springs on the lower suspension arms.

|

|

| 5. |

Raise the subframe with a pillar jack, pushing it forward slightly.

|

|||||||

| 6. |

Fit the subframe to the body.

Tightening torque 75 Nm +135° (55 lbf ft +1350°)

|

|

| 7. |

Remove the jack.

|

|

| 8. |

Connect the wiring harness, plug in the connector and close the protective case.

|

|

| 9. |

Lift the steering swivel members and fit the shock absorbers on both sides.

Tightening torque 150 Nm (110 lbf ft)

|

|||||||

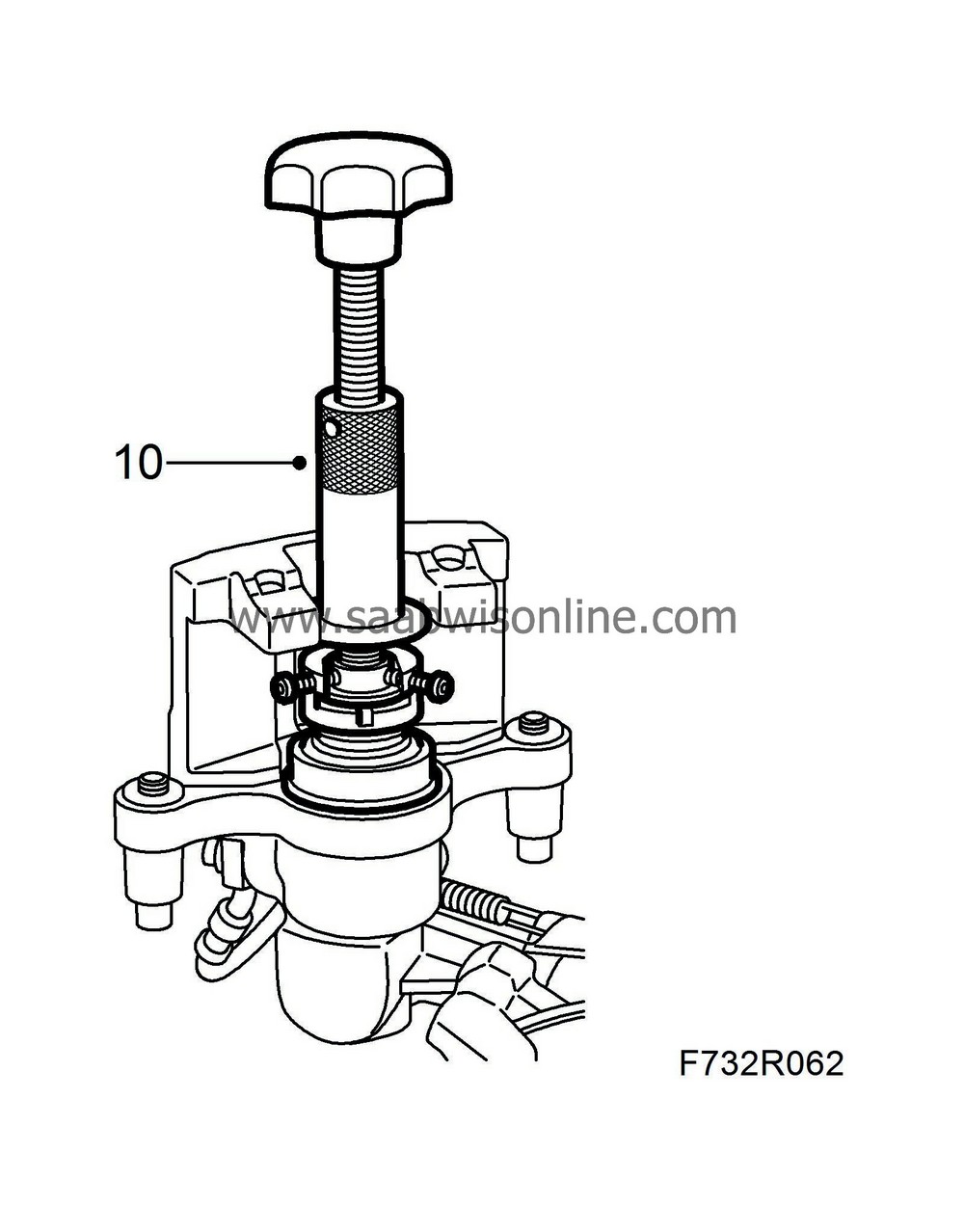

| 10. |

Remove the inner brake pad.

Screw in the brake piston with 89 96 969 Resetting tool and 89 96 977 Adapter .

|

|

| 11. |

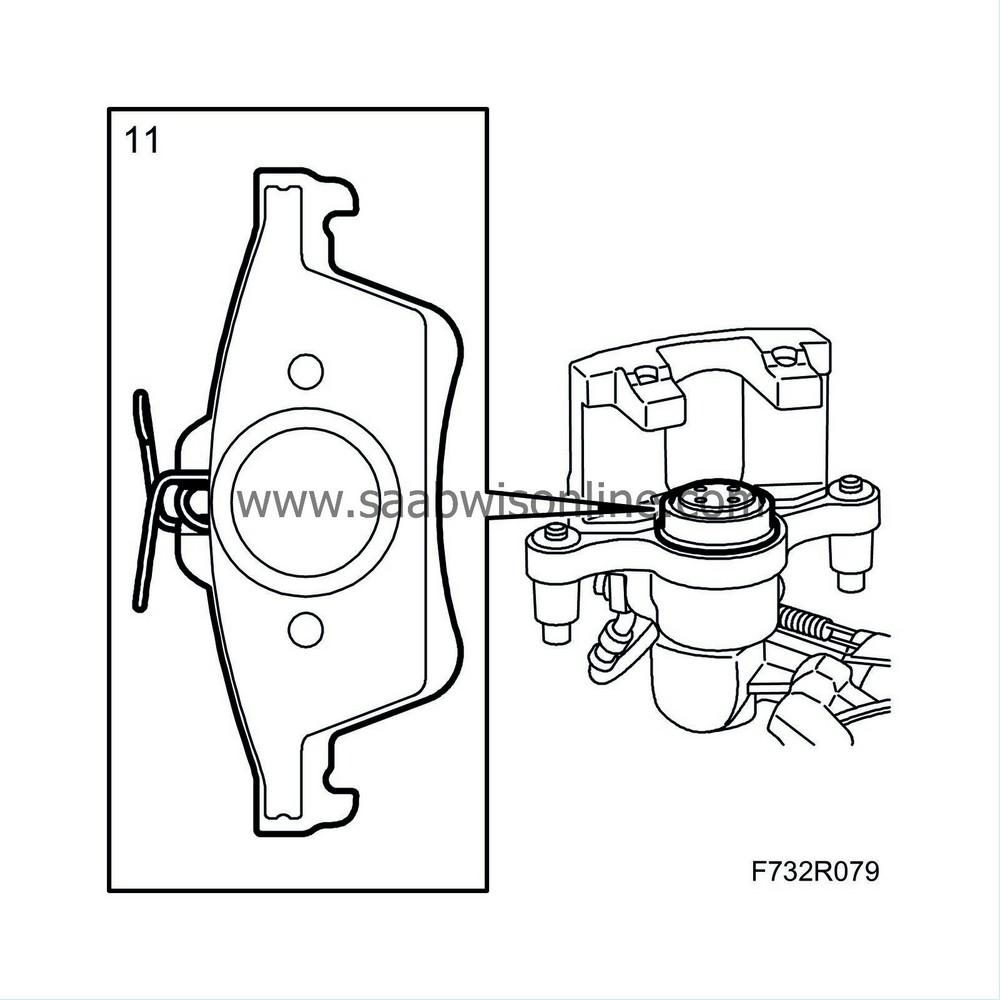

Fit the brake pads.

|

|

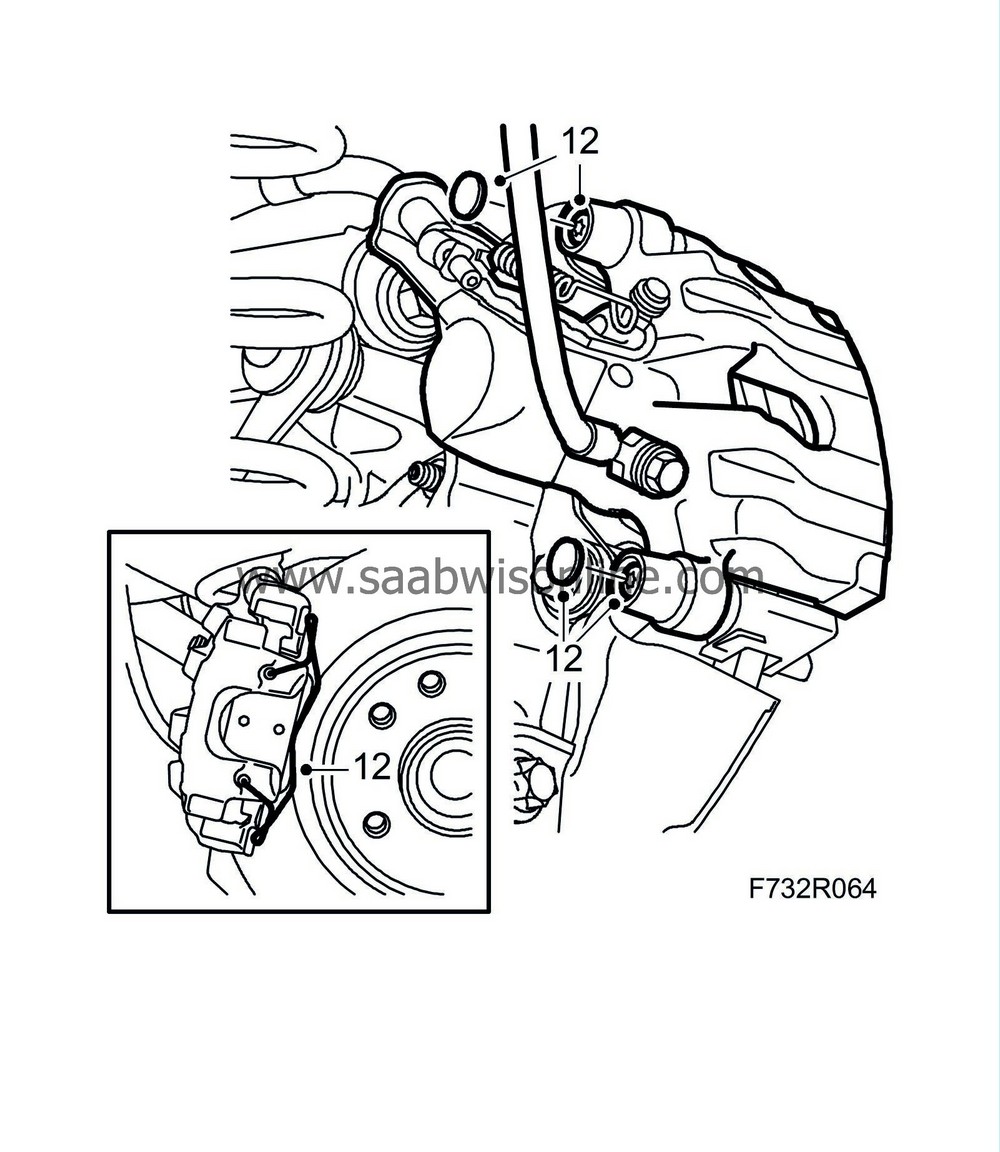

| 12. |

Fit the hydraulic body.

Tightening torque 28 Nm (21 lbf ft) Fit the protective covers. Fit the retaining spring to the hydraulic body.

|

|

| 13. |

Repeat steps 10-12 for the other side.

|

|

| 14. |

Clean the exhaust pipe joints and fittings. Fit the pipes with joint clamps. See EPC and

Fitting, front silencer

.

Tightening torque 40 Nm (30 lbf ft) |

|

| 15. |

CV:

Fit the chassis reinforcement to the rear subframe

.

|

|

| 16. |

Cars with tyre pressure monitoring:

Fit the wiring harness and plug in the connector for the signal detector.

Fit the wing liner

.

|

|

| 17. |

Fit the rear wheels

.

|

|

| 18. |

Lower the car to the floor.

|

|

| 19. |

Depress the brake pedal several times to press out the self adjustment of the brake pistons and the parking brake.

|

|